V510 Propeller Compliance Checklist

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Make Measurement Matter 12 March 2020

94 A-Z OF MEMBERS AND PROFILES 241 MAKE MEASUREMENT MATTER 12 MARCH 2020 The GTMA has teamed up with the successful Engineering Materials Live and FAST LIVE exhibitions, to deliver ‘Make Measurement Matter’ • QUALITY VISITORS • UNIQUE FORMAT • LOW COST Current attendees of the FAST LIVE and Engineering Materials Live events, compliment the Make Measurement Matter content, with visitors involved in production, design engineering, manufacturing, measurement, testing, quality and inspection. ATED WITH CO-LOC ATED WITH CO-LOC ATED WITH CO-LOC H 2020 12 MARC H 2020 0121 392 8994 12 [email protected] www.gtma.co.uk www.gtma.co.uk SUPPLIERSH DIREC 2020T ORY 12 MARC A-Z OF MEMBERS AND PROFILES 95 A-Z of members and members’ profiles INCLUDING: SECTORS AND MARKET SERVED BY INDIVIDUAL COMPANIES Find the right company for the right product and service. For up-to-date information please also see: www.gtma.co.uk 96 A-Z OF MEMBERS AND PROFILES 241 3D LASERTEC LTD Mansfield i-centre T 01623 600 627 Oakham Business Park W www.3dlasertec.co.uk Hamilton Way, Mansfield Nottinghamshire NG18 5BR Managing Director & Sales Contact: Wayne Kilford Sales Contact: Patrick Harrison Our customer base now extends through To see the laser machinery in operation Injection, blow, extrusion and rotational or to satisfy your queries related to laser moulds, pharmaceutical, Aerospace and engraving any special materials or indeed medical industry, gun manufacturers, general discussion relating to your project printing, ceramic plus other general and then call for an appointment. obscure requests. 3D Lasertec Ltd are privately owned and The need for laser engraving on projects established in February 1999. -

Shownews Farnsborough Day 4

D A Y 4 AVIATION WEEK & SPACE TECHNOLOGY / AIR TRANSPORT WORLD / SPEEDNEWS July 14, 2016 Farnborough Airshow Engine War Intensifies P&W’s geared turbofan and CFM LEAP battle to power A320s.PAGE 3 Qatar Cools on A350s Al Baker considers 777-300ERs to fill gap in delivery schedule. PAGE 3 Apache Fires Brimstone MBDA completes live firing trials of the direct-fire missile. PAGE 4 Norsk Titanium Wins Deals Additive manufacturing company to supply major OEMs. PAGE 6 Airbus Halves A380 Production ISTAR Chief Speaks Out Airbus is making a large cut to its A380 output, innovating and investing in the A380,” he RAF’s intelligence head criticizes as the manufacturer continues to struggle with added. In an effort to defer concerns that reduction of Sentinel fleet. PAGE 8 securing additional sales for its largest aircraft. Airbus may abandon the A380, Bregier said, The company said on Tuesday that in 2018 “The A380 is here to stay.” Personal Health for Engines it will reduce production of the aircraft from Airbus currently has orders for 319 A380s. It GE Aviation applies data analyt- the current 2.5 per month to one. has delivered a total of 193, 27 of which were ics on an industrial scale. PAGE 10 “With this prudent, proactive step we delivered in 2015. This year it has handed over are establishing a new target for our indus- 14 aircraft, as of mid-July. trial planning, meeting current commercial The decision to reduce production further Airship, C-130J: Cargo Duo demand, but keeping all our options open will result in a huge challenge to keep the pro- Lockheed markets civil C-130 and to benefit from future A380 markets,” CEO gram profitable on a recurring cost basis. -

Records Fall at Farnborough As Sales Pass $135 Billion

ISSN 1718-7966 JULY 21, 2014 / VOL. 448 WEEKLY AVIATION HEADLINES Read by thousands of aviation professionals and technical decision-makers every week www.avitrader.com WORLD NEWS More Malaysia Airlines grief The Airbus A350 XWB The US stock market fell sharply was a guest on fears of renewed hostilities of honour at after the news that a Malaysian Farnborough Airlines flight was allegedly shot (left) last week down over eastern Ukraine, with as it nears its service all 298 people on board reported entry date dead. US vice president Joe Biden with Qatar said the plane was “blown out of Airways later the sky”, apparently by a surface- this year. to-air missile as the Boeing 777 Airbus jet cruised at 33,000 feet, some 1,000 feet above a closed section of airspace. Ukraine has accused Records fall at Farnborough as sales pass $135 billion pro-Russian “terrorists” of shoot- Airbus, CFM International beat forecasts with new highs at UK show ing the plane down with a Soviet- era SA-11 missile as it flew from The 2014 Farnborough Interna- Farnborough International Airshow: Major orders* tional Airshow closed its doors Amsterdam to Kuala Lumpur. Airframer Customer Order Value¹ last week safe in the knowledge Boeing 777 Qatar Airways 50 777-9X $19bn Record show for CFM Int’l that it had broken records on many fronts - not least on total Boeing 777, 737 Air Lease 6 777-300ER, 20 737 MAX $3.9bn CFM International, the 50/50 orders and commitments for Air- Airbus A320 family SMBC 110 A320neo, 5 A320 ceo $11.8bn joint company between Snec- bus and Boeing aircraft, which ma (Safran) and GE, celebrated Airbus A320 family Air Lease 60 A321neo $7.23bn hit a combined $115.5bn at list record sales worth some $21.4bn Embraer E-Jet Trans States 50 E175 E2 $2.4bn prices for 697 aircraft - over 60% at Farnborough. -

AED Fleet Contact List

AED Fleet Contact List September 2021 Make Model Primary Office Operations - Primary Operations - Secondary Avionics - Primary Avionics - Secondary Maintenance - Primary Maintenance - Secondary Air Tractor All Models MKC Persky, David (FAA) Hawkins, Kenneth (FAA) Marsh, Kenneth (FAA) Rockhill, Thane D (FAA) BadHorse, Jim (FAA) Airbus A300/310 SEA Hutton, Rick (FAA) Dunn, Stephen H (FAA) Gandy, Scott A (FAA) Watkins, Dale M (FAA) Patzke, Roy (FAA) Taylor, Joe (FAA) Airbus A318-321 CEO/NEO SEA Culet, James (FAA) Elovich, John D (FAA) Watkins, Dale M (FAA) Gandy, Scott A (FAA) Hunter, Milton C (FAA) Dodd, Mike B (FAA) Airbus A330/340 SEA Culet, James (FAA) Robinson, David L (FAA) Flores, John A (FAA) Watkins, Dale M (FAA) DiMarco, Joe (FAA) Johnson, Rocky (FAA) Airbus A350 All Series SEA Robinson, David L (FAA) Culet, James (FAA) Watkins, Dale M (FAA) Flores, John A (FAA) Dodd, Mike B (FAA) Johnson, Rocky (FAA) Airbus A380 All Series SEA Robinson, David L (FAA) Culet, James (FAA) Flores, John A (FAA) Watkins, Dale M (FAA) Patzke, Roy (FAA) DiMarco, Joe (FAA) Aircraft Industries All Models, L-410 etc. MKC Persky, David (FAA) McKee, Andrew S (FAA) Marsh, Kenneth (FAA) Pruneda, Jesse (FAA) Airships All Models MKC Thorstensen, Donald (FAA) Hawkins, Kenneth (FAA) Marsh, Kenneth (FAA) McVay, Chris (FAA) Alenia C-27J LGB Nash, Michael A (FAA) Lee, Derald R (FAA) Siegman, James E (FAA) Hayes, Lyle (FAA) McManaman, James M (FAA) Alexandria Aircraft/Eagle Aircraft All Models MKC Lott, Andrew D (FAA) Hawkins, Kenneth (FAA) Marsh, Kenneth (FAA) Pruneda, -

CAA - Airworthiness Approved Organisations

CAA - Airworthiness Approved Organisations Category BCAR Name British Balloon and Airship Club Limited (DAI/8298/74) (GA) Address Cushy DingleWatery LaneLlanishen Reference Number DAI/8298/74 Category BCAR Chepstow Website www.bbac.org Regional Office NP16 6QT Approval Date 26 FEBRUARY 2001 Organisational Data Exposition AW\Exposition\BCAR A8-15 BBAC-TC-134 ISSUE 02 REVISION 00 02 NOVEMBER 2017 Name Lindstrand Technologies Ltd (AD/1935/05) Address Factory 2Maesbury Road Reference Number AD/1935/05 Category BCAR Oswestry Website Shropshire Regional Office SY10 8GA Approval Date Organisational Data Category BCAR A5-1 Name Deltair Aerospace Limited (TRA) (GA) (A5-1) Address 17 Aston Road, Reference Number Category BCAR A5-1 Waterlooville Website http://www.deltair- aerospace.co.uk/contact Hampshire Regional Office PO7 7XG United Kingdom Approval Date Organisational Data 30 July 2021 Page 1 of 82 Name Acro Aeronautical Services (TRA)(GA) (A5-1) Address Rossmore38 Manor Park Avenue Reference Number Category BCAR A5-1 Princes Risborough Website Buckinghamshire Regional Office HP27 9AS Approval Date Organisational Data Name British Gliding Association (TRA) (GA) (A5-1) Address 8 Merus Court,Meridian Business Reference Number Park Category BCAR A5-1 Leicester Website Leicestershire Regional Office LE19 1RJ Approval Date Organisational Data Name Shipping and Airlines (TRA) (GA) (A5-1) Address Hangar 513,Biggin Hill Airport, Reference Number Category BCAR A5-1 Westerham Website Kent Regional Office TN16 3BN Approval Date Organisational Data Name -

The Connection

The Connection ROYAL AIR FORCE HISTORICAL SOCIETY 2 The opinions expressed in this publication are those of the contributors concerned and are not necessarily those held by the Royal Air Force Historical Society. Copyright 2011: Royal Air Force Historical Society First published in the UK in 2011 by the Royal Air Force Historical Society All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording or by any information storage and retrieval system, without permission from the Publisher in writing. ISBN 978-0-,010120-2-1 Printed by 3indrush 4roup 3indrush House Avenue Two Station 5ane 3itney O72. 273 1 ROYAL AIR FORCE HISTORICAL SOCIETY President 8arshal of the Royal Air Force Sir 8ichael Beetham 4CB CBE DFC AFC Vice-President Air 8arshal Sir Frederick Sowrey KCB CBE AFC Committee Chairman Air Vice-8arshal N B Baldwin CB CBE FRAeS Vice-Chairman 4roup Captain J D Heron OBE Secretary 4roup Captain K J Dearman 8embership Secretary Dr Jack Dunham PhD CPsychol A8RAeS Treasurer J Boyes TD CA 8embers Air Commodore 4 R Pitchfork 8BE BA FRAes 3ing Commander C Cummings *J S Cox Esq BA 8A *AV8 P Dye OBE BSc(Eng) CEng AC4I 8RAeS *4roup Captain A J Byford 8A 8A RAF *3ing Commander C Hunter 88DS RAF Editor A Publications 3ing Commander C 4 Jefford 8BE BA 8anager *Ex Officio 2 CONTENTS THE BE4INNIN4 B THE 3HITE FA8I5C by Sir 4eorge 10 3hite BEFORE AND DURIN4 THE FIRST 3OR5D 3AR by Prof 1D Duncan 4reenman THE BRISTO5 F5CIN4 SCHOO5S by Bill 8organ 2, BRISTO5ES -

Aerospace & Defence Brochure

Contact your local Righton Blackburns With a vast stock range in aluminium, stainless steel, carbon and alloy steels, titanium, Aerospace Service Centre copper alloys and nickel alloys, the Righton Blackburns Aerospace and Defence materials offering is unrivalled. 1 BRISTOL The standard aerospace stock range is available in round bar, hollow bar, forged bars, tube Tel: +44 (0)117 948 2600 Email: [email protected] & plate and blanks & rings. Contract driven ferrous & non-ferrous material can be sourced 21 if required. 1 PLYMOUTH 32 Why use Righton Blackburns Aerospace? Tel: +44 (0)1752 844 931 n Customer inventory and stores management 32 Email: [email protected] n Direct feed to line service n State of the art cutting and processing equipment 3 PORTSMOUTH n Import and export services Tel: +44 (0)2392 623 070 n Non-destructive/destructive testing Email: [email protected] n Metal heat treatment to customer requirements n PMI inspection on goods inwards and outwards n Third party chemical and mechanical testing n Pre-machining operations such as bore drilling, skimming of scale 1 and chamfering n Metallurgical and material application suitability support - 3 designers, procurement and machine shops 2 n Kaizen events with customers Specialist Markets For further information on the full range of products we supply into our specialist markets, please contact your local Service Centre to request a copy of the brochures dedicated to those specific markets. Architecture & Automotive & Marine & Shipbuilding Power Generation -

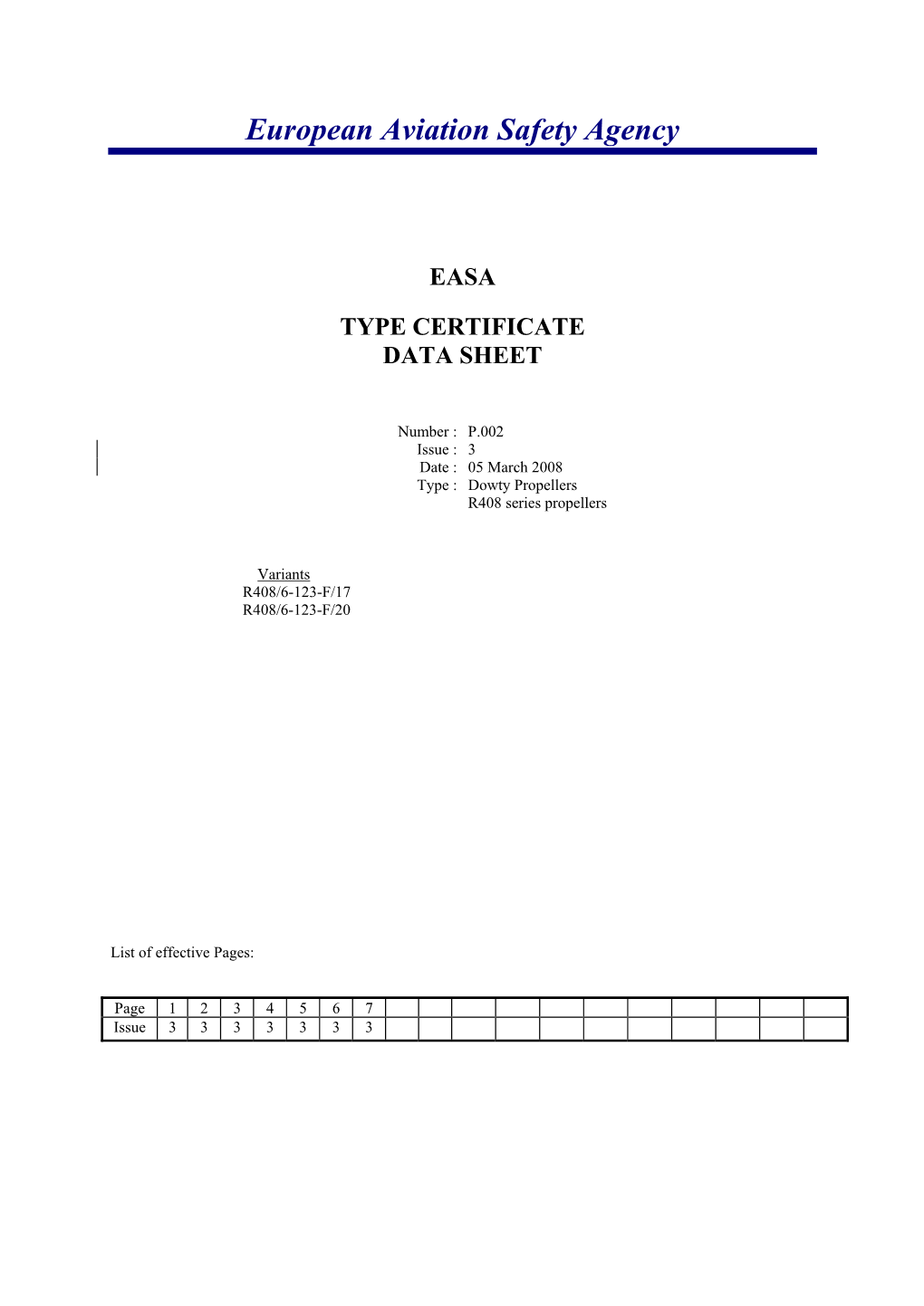

Dowty Propellers

Dowty Propellers Dowty Propellers signs a letter of intent with XAC to provide propeller systems for the MA700 regional aircraft July 15, 2014 - Gloucester, United Kingdom – China’s AVIC Aircraft Xi’An Aircraft Company (XAC) and Dowty Propellers have signed a letter of intent to provide propeller systems for the new MA700 aircraft. AVIC Aircraft Xi’An Aircraft Company Director and General Manager Wang Chengkuan, and Oliver Towers, President of Dowty Propellers, signed the LOI for the MA700 aircraft’s propeller system at the 2014 Farnborough Air Show. Also in attendance were AVIC Aircraft Director and General Manager Chen Fusheng and Brad Mottier and Xiang Weiming, Dowty Propellers’ shareholder representatives. The propeller to be provided by Dowty Propellers builds on more than 75 years of experience in propeller design, manufacture and support, and incorporates new blade aerodynamic designs, along with a highly-reliable and proven propeller system. The propeller will allow the aircraft to deliver optimal levels of endurance and fuel efficiency, while achieving a low-noise environment for the cabin, and competitive life-cycle costs. As an all-new generation of turboprop aircraft, the MA700’s range of 800 km. positions it in the medium capacity sector of regional air transport, with the capability of operating in high altitude, high temperature locations. About AVIC Chinese Aviation Industry Corporation (AVIC) is a large, state-owned enterprise covering aviation equipment, transport, engines, helicopters, airborne equipment and systems for multiple industrial sectors. It has over 200 member units, more than 20 listed corporations and approximately 400,000 employees. In July 2009, AVIC was featured in “Fortune” magazine amongst the world’s top 500 enterprises, thereby becoming the first Chinese aviation manufacturing and military enterprise to do so. -

August 2017 Front Cover the FINAL.Indd

AEROSPACE 2017 August 44 Number 8 Volume Society Royal Aeronautical August 2017 AFRICAN AIRLINES BETTER BRIEFINGS FOR PILOTS ISRAEL’S MISSILE DEFENCE SYSTEM www.aerosociety.com MAGNETIC ATTRACTION? DAVID LEARMOUNT ASKS, WHY ARE WE NOT USING TRUE NORTH? On demand, cost effective dedicated payload delivery to any orbit Skyrocketing innovation. We’re in the midst of a new space race. Around the world, demand for innovative satellite applications is surging, creating an enormous appetite for small payload launch capabilities. Even the most modern small vertical launch systems still demand dedicated, remote and costly fixed infrastructure. Only horizontal launch systems and spaceports can offer the global small payload launch capacity necessary to meet current demand and fuel future growth. follow us Volume 44 Number 8 August 2017 North by North Why does Taxi to LEO please aviation continue Six years after the last 14 to navigate by Space Shuttle mission, Magnetic North 38 the US counts down rather than True to regaining its human North? spacefl ight access. Contents Boeing Defense Correspondence on all aerospace matters is welcome at: The Editor, AEROSPACE, No.4 Hamilton Place, London W1J 7BQ, UK [email protected] Comment Regulars 4 Radome 12 Transmission The latest aviation and Your letters, emails, tweets aeronautical intelligence, and feedback. analysis and comment. 58 The Last Word Smothering the infant king 10 Antenna Keith Hayward looks at Howard Wheeldon the increasing competition considers Boeing’s claims between private and Some 40 years ago, the then civil airliner giants of Boeing, McDonnell of unfair competition from government space Douglas and Lockheed laughed at the idea of a European ‘Airbus’ widebody Bombardier’s CSeries. -

Urban Air Mobility − Focus Unstable Approaches and Data Mining Can the Uk Join the Hypersonics Race?

AEROSPACE March 2020 URBAN AIR MOBILITY − FOCUS UNSTABLE APPROACHES AND DATA MINING CAN THE UK JOIN THE HYPERSONICS RACE? www.aerosociety.com Marc h 2020 V olume 47 Number 3 IN THE BIGGEST CRISIS IN ITS boeing104-YEAR HISTORY − WHAT NEXT FOR THE AEROSPACE GIANT? Royal A eronautical Society blues Unpaid memberships will lapse on 31 March 2020 Membership fees were due on 1 January - Don’t forget to pay your subscription before it expires* As per the Society’s Regulations, unpaid How to renew: memberships will lapse on 31 March 2020 and all memberships will be suspended where a Online: Log in to your account on the Society’s payment for an individual subscription has not website to pay at: been received before this date. This excludes www.aerosociety.com/login members paying their annual subscriptions by Direct Debit in monthly instalments. If you do not have an account, you can register Your membership benefits include: online and pay your subscription straight away. ⚫ Your monthly subscription to AEROSPACE Telephone: Call the Subscriptions Department magazine on: ⚫ Use of your RAeS post nominals, as applicable +44 (0)20 7670 4315 / 4304 ⚫ Access to over 400 global events yearly Cheque: Cheques should be made payable to ⚫ Discounted rates for conferences the Royal Aeronautical Society and sent to the ⚫ Online publications including Society News, Subscriptions Department at No.4 Hamilton blogs and podcasts Place, London W1J 7BQ, UK. ⚫ Involvement with your local Branch BACS Transfer: Pay by Bank Transfer (or by BACS) into the Society’s bank account, quoting ⚫ Networking opportunities your name and membership number. -

As 9110-Iso 9001

Certificate of Approval This is to certify that the Management System of: GE Aviation Systems Australia Pty Ltd 3 Hakea Street, Brisbane Airport, 4007, Australia has been approved by LRQA to the following standards: AS 9110C (technically equivalent to prEN 9110:2016 and SJAC 9110:B) | ISO 9001:2015 Lloyd's Register of Quality Assurance is accredited under the IAQG ICOP scheme Certification Structure – Several Sites Basem Obaid - Area Operations Manager Issued By: Lloyd's Register Quality Assurance Limited This certificate is valid only in association with the certificate schedule bearing the same number on which the locations applicable to this approval are listed. Issue Date: 18 April 2017 Re-Issue Date: 23 March 2018 Expiry Date: 17 April 2020 Certificate Identity Number: 10071286 Approval Number(s): AS 9110 - 0049268 / ISO 9001 - 0049269 The scope of this approval is applicable to: Repair and modification of avionics, electrical, instrumentation and galley equipment, sales distribution and calibration of ground support equipment. Maintenance, Repair and Overhaul of Dowty Propellers, composite blade & bearing assemblies and propeller spinners. Management, Inspection, Packaging and Delivery of BAE Hawk Canopies and Windscreens. Lloyd's Register Group Limited, its affiliates and subsidiaries, including Lloyd's Register Quality Assurance Limited (LRQA), and their respective officers, employees or agents are, individually and collectively, referred to in this clause as 'Lloyd's Register'. Lloyd's Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance on the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant Lloyd's Register entity for the provision of this information or advice and in that case any responsibility or liability is exclusively on the terms and conditions set out in that contract. -

MAA Approved Organizations

UK Military Aviation Authority Approved Organizations Version: 20210920-MAA_Approved_Organizations_Publishing.xlsx This document lists all Approved Organizations that are part of: Air Traffic Management Equipment Approved Organization Scheme, Contrator Flying Approved Organization Scheme, Design Approved Organization Scheme, Maintenance Approved Organization Scheme Name Full Name Locations Scope Cert Latest No Sched Latest No Scheme All Platforms Aquila is the service provider for Marshall which is divided into three areas: Marshall Technical UK.MAA.AAOS.0013 Aquila Air Traffic Management Services Ltd Fareham Services, Marshall Air traffic control service and Temporary Technical Services. 0 5 AAOS No Aircraft Queen Elizabeth Class - Combat Management System - CMS 1 (QEC Variant) / Air Traffic Control. Queen Elizabeth Class - Shared Infrastructure - Version 3. Queen Elizabeth Class / Type 45 - METOC. UK.MAA.AAOS.0018 BAE Systems Surface Ships Limited (BAE Systems Naval Ships Combat Systems) New Malden 0 0 AAOS QE Class Carriers 2D Land Based Radars, including Watchman Air Traffic Control Radar 3D Land Based Radars, including T101 & T102 Air Defence Radars 2D Naval Radars, including RT994 Surveillance Radar 3D Naval Radars, including Sampson Multi-Function Radar, S1850M Long Range Radar, ARTISAN Medium Range Radar Type 997 UK.MAA.AAOS.0003 BAES Maritime Services (Product and Training Services) Cowes Advanced Digital Tracker (ADT) 0 3 AAOS No Aircraft UKASACS Command and Control System (UCCS) at CRC's Boulmer and Scampton. Flight Plan Dissemination