Spalted Wood

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

A Method for Digital Color Analysis of Spalted Wood Using Scion Image Software

Materials 2009, 2, 62-75; doi:10.3390/ma2010062 OPEN ACCESS materials ISSN 1996-1944 www.mdpi.com/journal/materials Article A Method for Digital Color Analysis of Spalted Wood Using Scion Image Software Sara C. Robinson *, Peter E. Laks and Ethan J. Turnquist Michigan Technological University / 1400 Townsend Dr., Houghton, MI 49931, USA; E-Mails: [email protected] (P.L.); [email protected] (E.T.) * Author to whom correspondence should be addressed; E-Mail: [email protected] Received: 9 January 2009; in revised form: 31 January 2009 / Accepted: 13 February 2009 / Published: 16 February 2009 Abstract: Color analysis of spalted wood surfaces requires a non-subjective, repeatable method for determining percent of pigmentation on the wood surface. Previously published methods used human visual perception with a square grid overlay to determine the percent of surface pigmentation. Our new method uses Scion Image©, a graphical software program used for grayscale and color analysis, to separate fungal pigments from the wood background. These human interface processes render the wood block into HSV (hue, saturation, value, within the RGB color space), allowing subtle and drastic color changes to be visualized, selected and analyzed by the software. Analysis with Scion Image© allows for a faster, less subjective, and easily repeatable procedure that is superior to simple human visual perception. Keywords: Spalting; Scion Image; color analysis. 1. Introduction Spalting is a natural coloration process in which fungi with pigmented hyphae colonize wood in a high enough concentration for a visual, macroscopic color change to occur. Zone lines, areas of melanized hyphal tissue or pseudosclerotial plates, and the bleaching effect caused by many white rot fungi are also considered to be spalting [1]. -

Wood Species and Culture Age Affect Zone Line Production of Xylaria Polymorpha

18 The Open Mycology Journal, 2010, 4, 18-21 Open Access Wood Species and Culture Age Affect Zone Line Production of Xylaria polymorpha Sara C. Robinson* and Peter E. Laks Michigan Technological University, 1400 Townsend Drive, Hougton, MI 49931-1295, USA Abstract: Three pure cultures of Xylaria polymorpha were isolated from fruiting bodies at yearly intervals over two years and maintained on 2% malt agar plates at room temperature. Immediately after isolation of the third culture, the cultures were inoculated onto sugar maple (Acer saccharum), aspen (Populus tremuloides), birch (Betula alleghaniensis), and basswood (Tilia americana) 14 mm cubes and incubated for 10 weeks in jars containing vermiculite. More zone lines were produced on aspen and sugar maple than on yellow birch or basswood. Increasing culture age generally caused a decrease in zone line production; however the effect was only statistically significant in sugar maple. The results indicate that aspen is preferable for zone line production with X. polymorpha, as both external and internal zone lines occur on this wood species, and zone line production remains high despite the age of the culture. Keywords: Spalting, Xylaria polymorpha, zone lines. INTRODUCTION As commercial interest in spalted wood increases, it is necessary to understand not just which wood species are Zone lines can be produced by a wide variety of basidio- most quickly decayed by a specific fungus, but to discover mycete fungi and some ascomycete fungi. They often appear which wood species are most quickly spalted, preferably macroscopically as thin, dark lines that delineate patches of without an associated increase in decay. -

Spalt Your Own Lumber Learn How Wood and Fungi Interact to Create Your Own Beautiful Boards by Sara Robinson

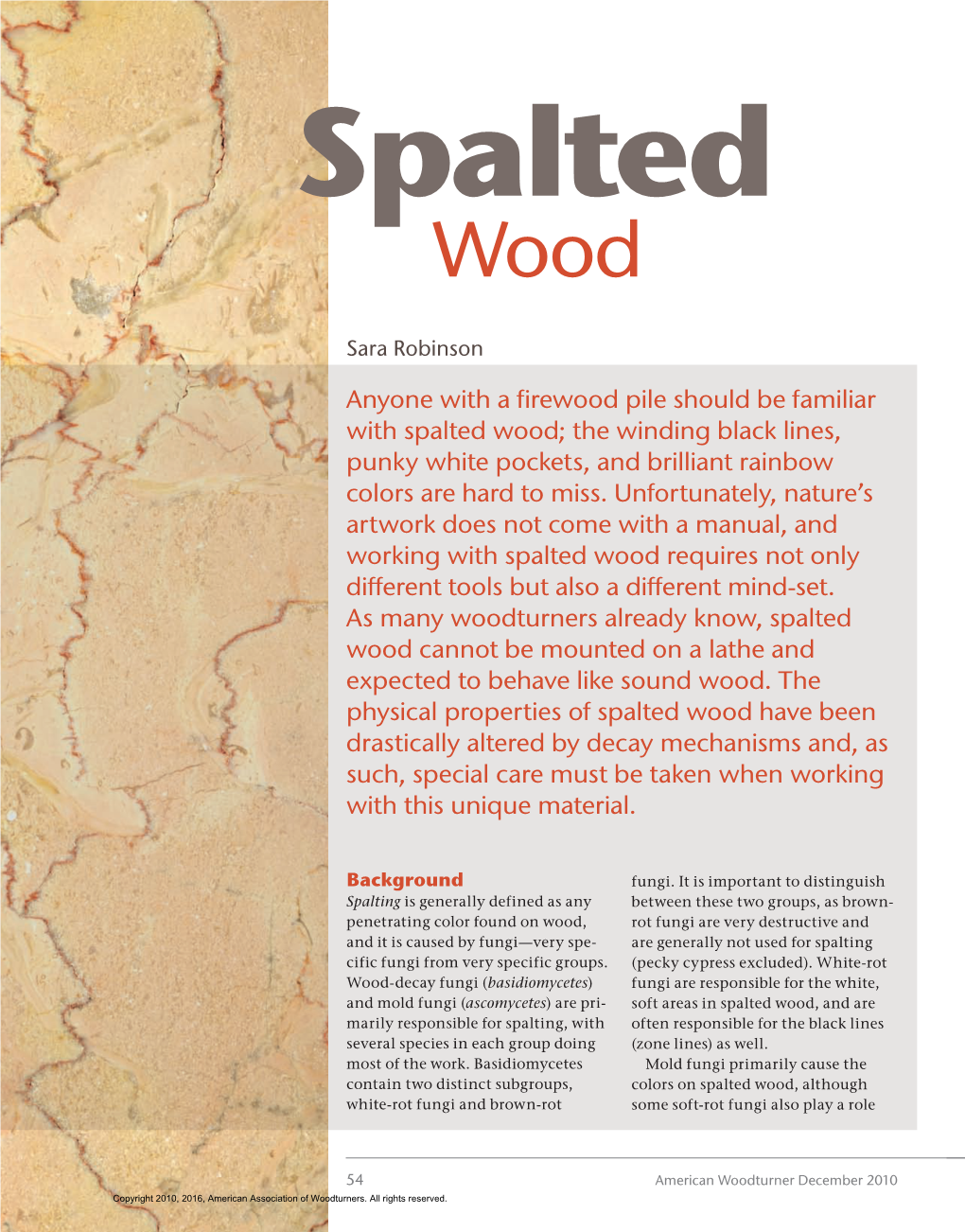

Spalt Your Own Lumber Learn how wood and fungi interact to create your own beautiful boards by Sara Robinson Any product associated with rot and decay is likely to have an image problem. Spalted wood is no exception: Youʼre more likely to find it in your firewood pile than in your local lumberyard. However, a growing number of woodworkers are looking past the decay and discovering the beauties of spalted wood (see health note below). These include colors not normally found in wood, contrasting light and dark colors adjacent to each other, and most notably, brown and black lines running through the wood. Unique to spalted wood, these lines can range from one or two running down a board to something resembling contour lines drawn by a drunken mapmaker. MORE ON SPALTING Read Robinsonʼs new column on spalting in the woodworking life blog Meet the fungi that create spalted wood and learn how it occurs in the wild Learn how to work with spalted wood Find out how to make your own spalted wood Download Robinsonʼs original article, in printer-friendly format, from FWW #191 Best of all, like fingerprints, each board of spalted wood is unique. It is this diversity that has drawn me to study spalting academically and to use it as a wood turner. Iʼll talk about how you can try to re-create this process under controlled conditions at home. DIY spalting Spalting wood is a lot like growing plants. With the right amounts of food, water, and heat, you should end up with good results, but success is by no means guaranteed. -

Spalt Your Own Since the Question of Spalting Comes up Time and Again, I Will Share a Description of What I Use When the Natural

Spalt Your Own A Recipe for Creating Spalted Wood Since the question of spalting comes up time and again, I will share a description of what I use when the natural ingredients aren't available. A "brew" of some kind is required when the conditions for natural spalting do not exist. There are a lot of ways to induce spalting. Like everything else in woodturning, nothing is "tried and true". You will have to experiment. Some wood spalts. Some wood just rots. Others (cherry and walnut) don't do much of anything. This spalting brew has everything necessary for almost anything to grow in any wood that wants to spalt. Use it on maple, birch, beech, sweetgum, oak, alder, holly, pecan and just any hard wood you wish. • 1-qt water • 2-scoops Miracle grow • 2-cans beer, drink one and put th other in the spalting brew. • 1-qt horse manure, doesn't have to be fresh, but the ammonia odor should still be present when it gets wet. • 1-qt dried oak leaves There is nothing sacred about any of the ingredients as long as we have the nitrogen, organics, ammonia, sugar, malt extracts, tannins, and leaf molds - everything necessary for all kinds of things to grow in the wood. The only additional ingredient is heat. You can use packaged steer manure from the garden store and add a half cup of household ammonia. Don't use the sudsing type because it contains detergents which will kill the growth. All leaves contain some amount of tannins, oak leaves contain more than others. -

Preliminary Examination of the Toxicity of Spalting Fungal Pigments: a Comparison Between Extraction Methods

Journal of Fungi Article Preliminary Examination of the Toxicity of Spalting Fungal Pigments: A Comparison between Extraction Methods Badria H. Almurshidi 1, R.C. Van Court 1 , Sarath M. Vega Gutierrez 1 , Stacey Harper 2 , Bryan Harper 2 and Seri C. Robinson 1,* 1 Department of Wood Science, Oregon State University, Corvallis, OR 97333, USA; [email protected] (B.H.A.); [email protected] (R.C.V.C.); [email protected] (S.M.V.G.) 2 Department of Toxicology, Oregon State University, Corvallis, OR 97331, USA; [email protected] (S.H.); [email protected] (B.H.) * Correspondence: [email protected] Abstract: Spalting fungal pigments have shown potential in technologies ranging from green energy generation to natural colorants. However, their unknown toxicity has been a barrier to industrial adoption. In order to gain an understanding of the safety of the pigments, zebrafish embryos were exposed to multiple forms of liquid media and solvent-extracted pigments with concentrations of purified pigment ranging from 0 to 50 mM from Chlorociboria aeruginosa, Chlorociboria aeruginascens, and Scytalidium cuboideum. Purified xylindein from Chlorociboria sp. did not show toxicity at any tested concentration, while the red pigment dramada from S. cuboideum was only associated with significant toxicity above 23.2 uM. However, liquid cultures and pigment extracted into dichloromethane (DCM) showed toxicity, suggesting the co-production of bioactive secondary metabolites. Future research on purification and the bioavailability of the red dramada pigment will be important to identify Citation: Almurshidi, B.H.; Van appropriate use; however, purified forms of the blue-green pigment xylindein are likely safe for use Court, R.C.; Vega Gutierrez, S.M.; across industries. -

Wood Colorization Through Pressure Treating: the Potential of Extracted Colorants from Spalting Fungi As a Replacement for Woodworkers’ Aniline Dyes

Materials 2014, 7, 5427-5437; doi:10.3390/ma7085427 OPEN ACCESS materials ISSN 1996-1944 www.mdpi.com/journal/materials Article Wood Colorization through Pressure Treating: The Potential of Extracted Colorants from Spalting Fungi as a Replacement for Woodworkers’ Aniline Dyes Sara C. Robinson 1,*, Eric Hinsch 1, Genevieve Weber 1, Kristina Leipus 2 and Daniel Cerney 2 1 Department of Wood Science & Engineering, 119 Richardson Hall, Oregon State University, Corvallis, OR 97331, USA; E-Mails: [email protected] (E.H.); [email protected] (G.W.) 2 School of Forest Resources and Environmental Science, Michigan Technological University, 1400 Townsend Dr., Houghton, MI 49931, USA; E-Mails: [email protected] (K.L.); [email protected] (D.C.) * Author to whom correspondence should be addressed; E-Mail: [email protected]; Tel.: +1-541-737-4233. Received: 8 May 2014; in revised form: 18 June 2014 / Accepted: 17 July 2014 / Published: 24 July 2014 Abstract: The extracellular colorants produced by Chlorociboria aeruginosa, Scytalidium cuboideum, and Scytalidium ganodermophthorum, three commonly utilized spalting fungi, were tested against a standard woodworker’s aniline dye to determine if the fungal colorants could be utilized in an effort to find a naturally occurring replacement for the synthetic dye. Fungal colorants were delivered in two methods within a pressure treater—the first through solubilization of extracted colorants in dichloromethane, and the second via liquid culture consisting of water, malt, and the actively growing fungus. Visual external evaluation of the wood test blocks showed complete surface coloration of all wood species with all colorants, with the exception of the green colorant (xylindein) from C. -

Utilizing Pigment-Producing Fungi to Add Commercial Value to American Beech (Fagus Grandifolia)

Appl Microbiol Biotechnol (2012) 93:1041–1048 DOI 10.1007/s00253-011-3576-9 BIOTECHNOLOGICAL PRODUCTS AND PROCESS ENGINEERING Utilizing pigment-producing fungi to add commercial value to American beech (Fagus grandifolia) Sara C. Robinson & Daniela Tudor & Paul A. Cooper Received: 20 April 2011 /Revised: 15 August 2011 /Accepted: 8 September 2011 /Published online: 20 September 2011 # Springer-Verlag 2011 Abstract American beech (Fagus grandifolia) is an abun- Introduction dant, underutilized tree in certain areas of North America, and methods to increase its market value are of consider- Pigments produced by fungi are routinely utilized as colorants able interest. This research utilized pigment-producing for both foodstuffs and materials. Some of the more fungi to induce color in American beech to potentially prominently utilized fungal pigments come from the water- establish its use as a decorative wood. Wood samples were soluble orange/red pigments produced by Monascus spp., inoculated with Trametes versicolor, Xylaria polymorpha, frequently utilized in rice wines in eastern countries (De Inonotus hispidus, and Arthrographis cuboidea to induce Carvalho et al. 2003). Pigments from Monascus purpureus fungal pigmentation. Black pigmentation (T. versicolor, X. Piedallu are used in wool dying (De Santis et al. 2005), and polymorpha, I. hispidus) was sporadic, occurred primarily an anthraquinone pigment isolated from Penicillium oxalicum on the surfaces of the heartwood, but not internally. Pink Currie & Thom is currently being developed for use as a pigmentation (A. cuboidea) occurred throughout all of the ‘natural’ food additive that may have some anticancer effects tested beech samples, but was difficult to see in the (Dufossé et al. -

Toxicity of Fungal Pigments from Chlorociboria Spp. and Scytalidium Spp

AN ABSTRACT OF THE THESIS OF Badria H. Almurshidi for the degree of Master of Science in Wood Science presented on June 4, 2015 Title: Toxicity of Fungal Pigments from Chlorociboria spp. and Scytalidium spp. Abstract Approved: Sara C. Robinson Commercial methodologies for producing fungal pigments are of worldwide interest due to the desire to move away from synthetic dyes. Chlorociboria species and Scytalidium species have been reported to produce sufficient yields of pigments for commercial production and have attracted special attention because of their use in spalted wood applications. However, there are few data about the toxicity of these pigments on humans or the ecosystem. The main objective of this thesis was to examine fungal pigment mixture toxicity and its effects on living organisms using a zebrafish embryo acute toxicity bioassay. Pigment mixtures from wood agar cultures and liquid malt media were screened. There were significant adverse effects from both the DCM-extracted pigment and the liquid malt medium although there was variability in the toxicity endpoints. The results from this study suggest that all dichloromethane (DCM) pigment extracts followed a dose/ response curve and caused higher mortality in higher concentrations after a short time of exposure except the DCM-red pigment extract which follow a non monotonic dose/response curve. The response from both DCM pigment extracts and liquid malt pigment depended on the solubility and bioavailability factors in the water. Overall, the results indicate that the pigments extracted from these fungi are likely toxic to humans. However, as no completely purified compounds were tested, it is possible that other secondary fungal metabolites and wood extractives that were also retrieved during the extraction process might also have played a role in the toxicity. -

Wood Species Affects Laboratory Colonization Rates of Chlorociboria Sp

International Biodeterioration & Biodegradation 64 (2010) 305e308 Contents lists available at ScienceDirect International Biodeterioration & Biodegradation journal homepage: www.elsevier.com/locate/ibiod Wood species affects laboratory colonization rates of Chlorociboria sp. Sara C. Robinson*, Peter E. Laks Michigan Technological University, UJ Noblet Forestry Building, 1400 Townsend Dr., Houghton, MI 49931, USA article info abstract Article history: This research attempted to determine conditions and wood species required to maximize xylindein Received 12 January 2010 production from a Chlorociboria sp. under laboratory conditions for use in induced spalting. A pure culture of Received in revised form a Chlorociboria species was isolated from fruiting bodies and grown on 2% malt extract agar. The colonies 4 March 2010 reached a maximum diameter of 18 mm in four weeks, although the blue-green xylindein pigment continued Accepted 23 March 2010 to diffuse through the culture media for at least eight months. In vermiculite jar tests, this Chlorociboria Available online 22 April 2010 isolate colonized Populus tremuloides more heavily than Acer saccharum or Betula alleghaniensis,anddidnot colonize Tilia americana at all. Pre-inoculation of test blocks with white rot fungi did not significantly affect Keywords: Acer saccharum xylindein production, regardless of wood species. Ó Chlorociboria sp. 2010 Elsevier Ltd. All rights reserved. Populus spp. Spalting Xylindein 1. Introduction as compared to fungi that do not produce diffusible pigments. Hence, the diffusion of xylindein can produce a relatively large Chlorociboria spp. are green stain ascomycete fungi found volume of pigmented substrate without extensive colonization by throughout North America (Dixon, 1975). They produce small, blue- the fungus. Despite the research by Berthet, however, this diffusion green disc-like apothecia on hardwood logs, although the fruiting has not been confirmed by microscopy. -

Colorfastness of Extracted Wood-Staining Fungal Pigments on Fabrics: a New Potential for Textile Dyes

Volume 9, Issue 3, 2015 Colorfastness of Extracted Wood-staining Fungal Pigments on Fabrics: a new potential for textile dyes Eric M. Hinsch Hsiou-Lien Chen Wood Science and Engineering Associate Professor, Oregon State University Design & Human Environment, Oregon State University Genevieve Weber Wood Science and Engineering Sara C. Robinson Oregon State University Assistant Professor, Wood Science & Engineering, Oregon State University ABSTRACT In this study, pigments from three species of pigmenting fungi, Chlorociboria aeruginosa (xylindein, green), Scytalidium cuboideum (draconin red, red), and Scytalidium ganodermophthorum (yellow), were used to dye multi-fabric test strips. Tests for color stability and tests for colorfastness to washing with and without bleach, and to perspiration, were conducted. Color readings were taken using a colorimeter, and color differences were statistically determined based on overall color change as calculated using the CIE L*a*b* color space. The results indicated that all three pigments were stable over time, indicating that these pigments can be used for fabric dyeing, eliminating the need for additional chemicals or heat as is required for traditional fabric dyes. Xylindein and draconin red exhibited good colorfastness to washing, and xylindein good colorfastness to perspiration. These results indicate that xylindein shows good potential as a dye for garment fabrics, and draconin red shows good potential as a dye for second- layer garment fabrics. Keywords: fungi, pigments, textiles, dyeing Introduction demand for more eco-friendly, sustainable, Natural dyes have been used to color and natural coloration (Kumar & Sinha, textiles for hundreds of years. However, 2004; Shahid & Mohammad, 2013). New since the advent of the Industrial Revolution forms of natural dyes are being investigated, and the invention of synthetic dyes, and in the last twelve years there has been a commercial dye houses have switched almost focus on developing methods to use fungal entirely to synthetics. -

Spotlight on Spalted Wood

WoodSense most woodworkers are familiar. Fruiti ng Fungi �indPigmented is zone lined, wood about can bewhich more Rummagingdif�icult to locate, around and a forestvery rare Spotlight on nearto �ind very in adecayed useable logs condition. will Fruiti ng bodies of Turkey probably lead you to the green Tail (Trametes versicolor) stained wood referred to as Spalted Wood Unfortunately, the wood will likelyElf’s Cup be so(Chlorociboria soft and decayed spp.) that The rott en truth behind the decay you can only use it for inlay work, Spalted African tamarind unless you want to impregnate By Dr. Sara C. Robinson it with a thin cyanoacrylate or Technical consultant: Larry Osborn shellac to stabilize it. Most of the Dried fruiti ng bodies of Elf’s Fruiti ng bodies of Dead Man’s walking around the woods and Cup, Chlorociboria ssp. Finger (Xylaria polymorpha) Many woodworkers families from a contaminated signature category are zone lines, hackingother colors into you’lldowned only logs �ind with by misunderstand spalted wood– piece brought into the shop. often black but sometimes red, a hatchet or chainsaw. If you’re that is, wood that displays So what is real, and what is green, pink, yellow, brown. These lucky, you may see bright colors– myth? It turns out that wood scroll across wood and serve pinks or yellows–several inches associated with decay. Some scientists understand spalting as a boundary for one fungus under the bark. These tend to be claimspeci�ic that physical bacteria characteristic cause those quite well, with many having to protect its resources from in more sound wood, and might fantastic winding black lines that spent years researching the another. -

Spalting, Science, and Fungal Extracts – Retooling an Ancient Art for a Green Planet

Spalting, Science, And Fungal Extracts – Retooling An Ancient Art For A Green Planet Sara C. Robinson little to no attention. North America where wood artists Fungus hunters are likely familiar with and crafters are using them as part of ungi come in a vast array of at least one of these pigment-producing a greater “spalting revival.” The word colors, from pale pinks to bright fungi, Chlorociboria aeruginosa or spalting is relatively new, having only blue-greens to dark blacks. its very similar cousin Chlorociboria been in the general English language FAnd yet, when most people think of aeruginascens (both known as “elf’s since the mid 1970s, and generally fungal colors they think of the fruiting cup”). The blue-green cup fungus refers to color in wood that came from body. Some, especially those in the grows on very decayed wood and a fungus (note the emphasis on in, as field of blue stain control, may think leaves behind the stunningly beautiful color found on wood from mold fungi of fungal mycelium and the melanin pigment called xylindein. Wood colored is not considered spalting). Three types bound within the hyphae that creates of spalting are recognized: the white that blue-grey color in wood. And an rot of hardwoods that leaves the wood even smaller group may think of the with a visibly lighter appearance, the extracellular pigments made by “Fungi zone lines (often black or brown, mold fungi such as Penicillium do not always play nicely but other colors exist) that and Trichoderma, whose with each other… The beautiful colors delineate fungal boundaries pigments can penetrate or are made as a response several centimeters into and boundary shapes produced by some of to changes in climatic and various substrates.