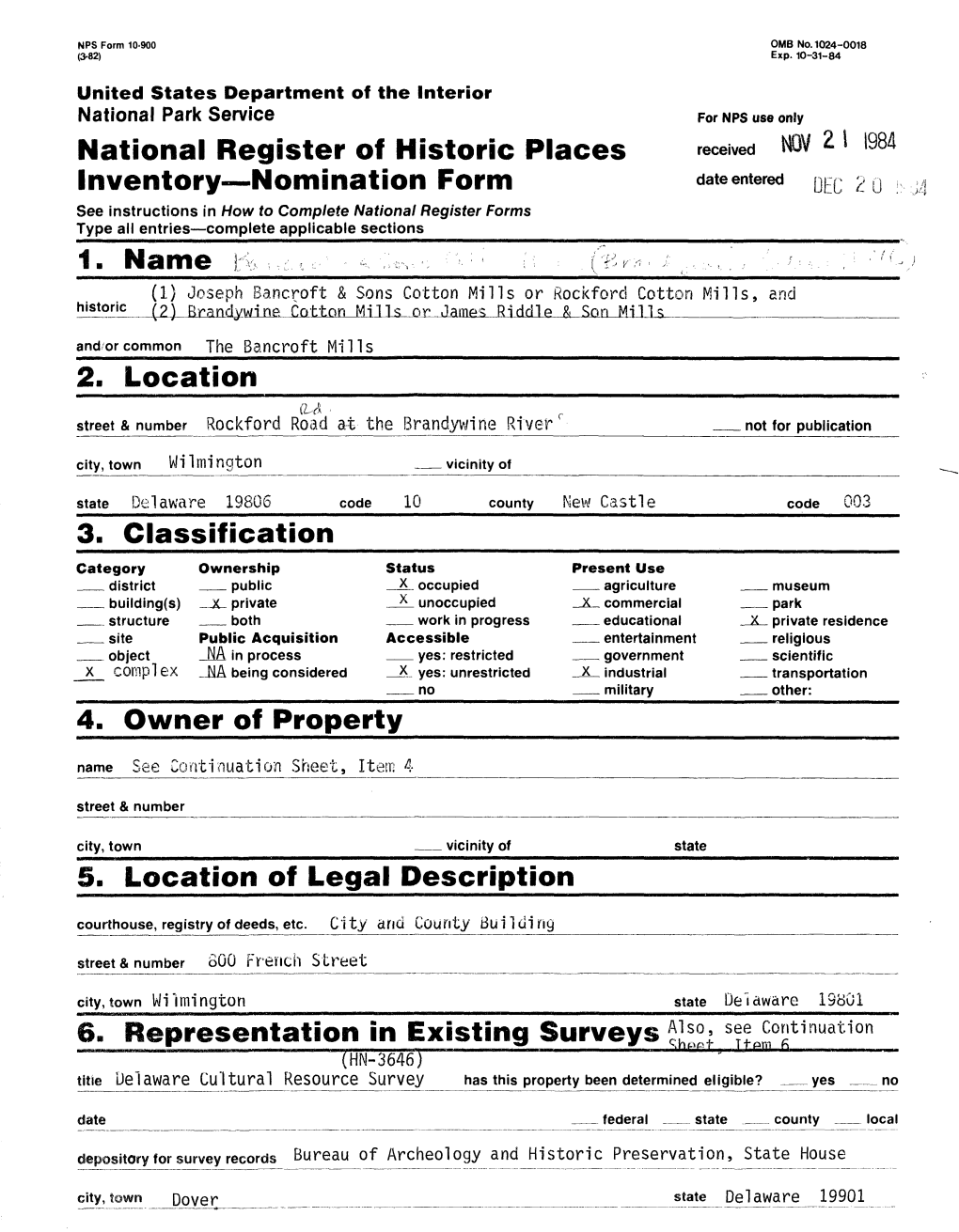

National Register of Historic Places Inventory—Nomination Form 1. Name LV

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Study on Improving the Production Rate by Rapier Looms in Textile Industry Aby Chummar, Soni Kuriakose, George Mathew

ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 2, Issue 7, January 2013 Study on Improving the Production Rate by Rapier Looms in Textile Industry Aby Chummar, Soni Kuriakose, George Mathew the company. It is mainly manufactured by the shuttle looms. Abstract— In India the textile industry is growing very fast. Conventional shuttle looms are mainly used during the Most of the earlier established textile industries are using weaving process in the industry. All these shuttle looms are conventional shuttle looms for the production of the cloth. But the too old. In these present conventional shuttle looms, it is advancement in the technology made the textile industry more competitive. The effective usage of the new methods of the necessary to pass a shuttle weighing around half a kilogram weaving technology, which is more energy efficient, makes the through the warp shed to insert a length of weft yarn which production more economical. It is found out that the usage of the weighs only few grams. The shuttle has to be accelerated conventional looms badly affects the cloth production. This study rapidly at the starting of picking cycle and also to be focuses on identifying the problems associated with the low decelerated, stopped abruptly at the opposite end. This production by the shuttle loom and suggesting suitable methods process creates heavy noise and shock and consumes by which these problems can be reduced. considerable energy. Beat-up is done by slay motion which again weighs a few hundred kilograms. The wear life of the Index Terms—Greige Fabric Picks, Rapier Loom, Shuttle Loom. -

HIGHLAND PARK MANUFACTURING COMPANY MILL NO. 3 This Report

HIGHLAND PARK MANUFACTURING COMPANY MILL NO. 3 This report was written on December 3, 1986 1. Name and location of the property: The property known as the Old Highland Park Manufacturing Company Mill No. 3 is located at 2901 N. Davidson Street, Charlotte, North Carolina. 2. Name, address, and telephone number of the present owner of the property: The owner of the property is: Highland Park Group, Inc. 200 Queens Rd. Suite 200 Charlotte, NC 28204 Telephone: (704) 377-4700 3. Representative photographs of the property: This report contains representative photographs of the property. 4. A map depicting the location of the property: This report contains a map which depicts the location of the property. 2901 N Davidson St Map data ©2018 Google 200 ft 2901 N Davidson St Charlotte, NC 28205 At this location Breathe Refuge 4.0 (4) 5. Current Deed Book Reference to the property: The most recent deed to this property is recorded in Mecklenburg County Deed Book 5223, page 325. The Tax Parcel Number of the property is: 083-078-01. 6. A brief historical sketch of the property: This report contains a brief historical sketch of the property prepared by Dr. William H. Huffman. 7. A brief architectural description of the property: This report contains a brief architectural description of the property prepared by Thomas W. Hanchett. 8. Documentation of why and in what ways the property meets the criteria for designation set forth in N.C.G.S. 160A-399.4: a. Special significance in terms of its history, architecture, and/or cultural importance: The Commission judges that the property known as the Old Highland Park Manufacturing Company Mill No. -

An Analysis of the City of Wilmington

COMMUNITY ENVIRONMENTAL PROFILES – A TOOL FOR MEETING ENVIRONMENTAL JUSTICE GOALS: An Analysis of the City of Wilmington Researchers: Amy Roe Vernese Inniss Marcos Luna Emery Graham Dick Bosire Maragia Scott Smizik Sangeetha Sriram Kamala Dorsner Supervised by: John Byrne, Director Gerard Alleng, Policy Fellow Yda Schreuder, Senior Policy Fellow and Associate Professor of Geography Center for Energy and Environmental Policy College of Human Services, Education and Public Policy University of Delaware for the Science, Engineering &Technology Services Program a program supported by the Delaware General Assembly and the University of Delaware October 2003 Community Environmental Profiles: A Tool for Meeting Environmental Justice Goals – An Analysis of The City of Wilmington Researchers: Amy Roe Vernese Inniss Marcos Luna Emery Graham Dick Bosire Maragia Scott Smizik Sangeetha Sriram Kamala Dorsner Supervised by: John Byrne, Director Gerard Alleng, Policy Fellow Yda Schreuder, Senior Policy Fellow Center for Energy and Environmental Policy College of Human Services, Education and Public Policy University of Delaware for the Science, Engineering & Technology Services Program a program supported by the Delaware General Assembly and the University of Delaware October 2003 Preface It is a pleasure to present you with this report of the 2002 Science, Engineering & Technology (SET) Services Program. The report is designed to provide the Delaware General Assembly and the citizens of this State with an environmental profile that encompasses social, economic and environmental conditions in the City of Wilmington. CEEP received valuable assistance in preparing this report from many individuals in academia, state and local government. We owe our debt to Sally Wasileski, analytical chemist, and Terra Dassau, atmospheric chemist, both PhD. -

Exploiting Yeast Diversity to Produce Renewable Chemicals from Rice Straw and Husk

Exploiting yeast diversity to produce renewable chemicals from rice straw and husk Jia Wu 100030434 A thesis submitted for the degree of Doctor of Philosophy to The University of East Anglia 2018 Quadram Institute Bioscience Norwich Research Park, Norwich, NR4 7UA ©This copy of the thesis has been supplied on condition that anyone who consults it is understood to recognise that its copyright rests with the author and that use of any information derived therefrom must be in accordance with Current UK Copyright Law. In addition, any quotation or extract must include full attribution. Declaration Exploiting yeast diversity to produce renewable chemicals from rice straw and husk I certify that the work contained in this thesis is entirely the result of my own work, except where due reference is made to other authors as part of a joint piece of work. It has not previously been submitted in any form to the University of East Anglia or any other University. Jia Wu Abstract Exploiting organic lignocellulosic wastes via bio-refining processes has been widely accepted as one of the renewable, environmentally friendly solutions to producing platform chemicals and liquid fuels. Pre-treatment serves as an initial step to improve the accessibility of lignocellulosic polysaccharides to enzymes, and fermentation is a core step to obtain a range of products from the sugars. However, inhibitors of enzymatic saccharification and fermentation are unavoidably generated during hydrothermal pre-treatment. Therefore, the aim of this study has been to assess the associations and possibly correlations between severities of pre-treatment, yield of fermentable sugars and formation of inhibitors, and to evaluate the potential of 11 yeast diverse yeast strains for the potential to produce not only ethanol but also some highly- sought-after platform chemicals. -

Toward Eliminating Pre-Consumer Emissions of Microplastics from the Textile Industry

Toward eliminating pre-consumer emissions of microplastics from the textile industry Photo credit: Mark Godfrey Photo credit: Devan King Abstract There is growing global awareness that microfibers are, we know enough to take microplastics are a potentially harmful action now to reduce the flows of these pollutant in oceans, freshwater, soil and air. materials into natural systems like rivers While there are many important sources of and oceans. The elimination of pre- microplastic pollution, we now know the consumer microfiber pollution will require textile lifecycle of manufacturing, use and changes along all stages of the textile disposal is a major emission pathway of supply chain. These changes include: microplastics. Microplastics emitted during a textile’s lifecycle are referred to as 1. Better understanding the relative microfibers or ‘fiber fragments.’ To date, emissions of microfibers at each much of the attention has focused on the manufacturing step (from fiber to yarn shedding, washing and disposal of to fabric to garment). synthetic textiles by consumers. 2. Developing microfiber control technologies and codifying best However, this is only part of the picture practices. and ignores microfiber leakage during the manufacturing and processing of these 3. Scaling these solutions to Tier 1, 2 and 3 materials. We estimate that pre-consumer suppliers via a combination of textile manufacturing releases 0.12 million regulatory and brand or retailer-led metric tons (MT) per year of synthetic action. microfibers into the environment – a similar 4. Continuing to raise industry, order of magnitude to that of the consumer government and consumer awareness use phase (laundering). That would mean of the topic. -

Textile Manufacturing

Textile Manufacturing Industry Overview Not all textile manufacturing industries produce hazardous you suspect that you generate a waste that is not included in this waste. If, however, you use hazardous solvents and materials summary, contact your state hazardous waste management agency containing toxic chemicals, you might be subject to Resource or EPA Regional office for assistance. Conservation and Recovery Act (RCRA) requirements covering the generztion, transportation, and management of hazardous waste. Waste Minimization An effective waste minimization program can reduce the costs, The following textile manufacturing industry segments are liabilities, and regulatory burdens of hazardous waste manage- covered by this summary: ment, while potentially enhancing efficiency, product quality, and community relations. Waste minimization techniques that can Broad woven fabric mills and wool mills, including help you reduce the amount of hazardous waste that you generate dyeing and finishing include: Knitting mills and knit goods finishing Other dyeing and finishing textile mills Production planning and sequencing Floor covering mills, including dyeing and finishing. Process/equipment adjustment or modification - Raw material substitution Loss prevention and housekeeping Hazardous Wastes from Textile Waste segregation and separation Manufacturing Recycling. Most ofthe hazardous waste generated by textile manufacturers results from the use of solvents. Solvents are used in the dry- Training and supervision of employees implementing waste cleaning of synthetic fiber knit fabrics and woven and wool fab- minimization techniques is an important part of your successful rics; in specialty operations such as tricot and lace splitting or program. Call the RCWSuperfund Hotline toll-free at 800424- solvent scouring; in dyeing operations; and in some finishing op- 9346 (or TDD 800-553-7672for the hearing-impaired) for waste erations for impregnation or coating of textile fibers. -

Please Click Here to Download a PDF of the Detailed Listing to Part 3

Portfolio Approx. Earliest No: of Type Cylinder Horse RPM Owner of Other Details Number No: of Date on Engines of Diameter x Power Engine Drawings Drawings Engine Stroke REEL TWENTYNINE Scotland: Ayr 208 12 Sep 1800 1 28” 1/8 x 6’0 30 38 David Dale Cotton Mill. Later acquired by James Finlay & Co. Engine erected at Catrine. Lanark 13 1790 1 S 26” x 6’0 10 John & William Purchased from Folliot Scott & Wilson Co. Forge Mill Engine at Wilson Town, Lanark. 193 14 Sep 1799 1 D 29” x 6’0 32 John Pattison Parchment dated October 1, 1799. John Pattison of Glasgow. Cotton Mill, Glasgow. Payment £797. 106,000lbs. 10 feet high. Purchased by Mr Dunn. 199 7 April 1800 1 D 17” 2/3 x 4’0 10 John Cotton Mill. Brigtown near Bartholomew Glasgow. 202 8 April 1800 1 19” 1/4 x 4’0 12 James Cook & Flax Mill, Glasgow. Co 204 8 May 1800 1 16” x 4’0 8 Robert Brewery, Glasgow. Struthers & Co 209 8 Aug 1800 1 D 28” 1/8 x 6’0 30 Corporation of Flour Mill. Patrick Mills, Bakers Glasgow. 216 3 Feb 1801 1 16” x 4’0 8 50 James Monach Cotton Mill, Glasgow. Originally Matthew Boulton’s Mint Engine. Belonged to Indoe and Galbraith by 1813. 228 9 Aug 1801 1 19” 1/4 x 4’0 12 Tennant Knox Chemical Manufactory, & Co Glasgow. Portfolio Approx. Earliest No: of Type Cylinder Horse RPM Owner of Other Details Number No: of Date on Engines of Diameter x Power Engine Drawings Drawings Engine Stroke Renfrewshire 177 14 Dec 1798 1 D 21” 1/4 x 5’0 16 Underwood Parchment dated January 1, Spinning Co 1799. -

Development of Hemicelluloses Biorefineries for Integration Into Kraft Pulp Mills

UNIVERSITÉ DE MONTRÉAL DEVELOPMENT OF HEMICELLULOSES BIOREFINERIES FOR INTEGRATION INTO KRAFT PULP MILLS OLUMOYE ABIODUN AJAO DÉPARTEMENT DE GÉNIE CHIMIQUE ÉCOLE POLYTECHNIQUE DE MONTRÉAL THÈSE PRÉSENTÉE EN VUE DE L’OBTENTION DU DIPLÔME DE PHILOSOPHIAE DOCTOR (GÉNIE CHIMIQUE) SEPTEMBRE 2014 © Olumoye Abiodun Ajao, 2014. UNIVERSITÉ DE MONTRÉAL ÉCOLE POLYTECHNIQUE DE MONTRÉAL Cette thèse intitulée: DEVELOPMENT OF HEMICELLULOSES BIOREFINERIES FOR INTEGRATION INTO KRAFT PULP MILLS présentée par: AJAO Olumoye Abiodun en vue de l’obtention du diplôme de : Philosophiae Doctor a été dûment acceptée par le jury d’examen constitué de: M. LEGROS Robert, Ph.D., président M. PARIS Jean, Ph.D., membre et directeur de recherche Mme MARINOVA Mariya, Ph.D., membre et codirectrice de recherche M. SAVADOGO Oumarou, D. d’état., membre et codirecteur de recherche M. HENRY Olivier, Ph.D., membre M. VAN HEININGEN Adriaan R. P., Ph.D., membre iii DEDICATION To my family, iv ACKNOWLEDGMENT Looking back at the past 4 years, I am leaving with a strong conviction that joining E2D2BF, a creative, supportive and culturally diverse team, was one of the best decisions I ever made. Special thanks to Prof. Jean Paris, who made this possible in the first place. Thank you for being an inspiration, I am immensely grateful for the opportunity and the conducive environment for independent self-development that you fostered. My gratitude goes to Dr. Mariya Marinova for her advice, encouragement and helping me see my work from a different point of view. Prof. Savadogo, your kind suggestions, support and appreciation of my work means a lot to me. I count myself privileged to have had you all as my team of directors. -

Download Case Study

Visit us at graham.co.uk Murrays’ Mills, Manchester Life Framework Reviving a relic of the past £22m January 2016 July 2017 / Project value / The build commenced / The duration Resurrecting the world’s oldest surviving steam-powered cotton mill, while preserving its historic 19th Century features, the Murrays’ Mills project is a £22 million innovative design-led development of a stunning Grade II* listed building. Housing 124 distinctive one, two and three bedroom apartments, the Phase One scheme, completed within 18 months, retains the historic fabric of the building, including the original stone circular staircase, amidst contemporary new build technology. The brief The focus was on sympathetically revitalising this irreplaceable heritage site and transforming it into an emerging residential area of a thriving, modern Manchester. Delivering cutting edge standards of new build development, the vision was for Murrays’ Mills to help meet the growing demand for high quality accommodation in the city. The challenges “The transformation of Murrays’ Mills is a As a Grade II* listed building, preserving the special character of this significant milestone in Ancoats’ emergence historic relic from the industrial revolution required creativity, skill and as a desirable and vibrant neighbourhood, expert care from our team throughout the design and construction it is a brilliant way to address the demand phases. Careful planning, and robust communication, with the client (Manchester Life), and the relevant local authorities, was critical to the for central accommodation in a way that successful completion of this transformative development. Located preserves and carefully evolves our former on a constrained city centre site within a ‘Conservation Area’, traffic industrial areas.” management and the phasing of works had to be carefully managed throughout the entire 18-month programme. -

Cotton Mills for the Continent

cotton mills_klartext.qxd 30.05.2005 9:11 Uhr Seite 1 Cotton mills for the continent Sidney Stott und der englische Spinnereibau in Münsterland und Twente Sidney Stott en de Engelse spinnerijen in Munsterland en Twente 1 cotton mills_klartext.qxd 30.05.2005 9:11 Uhr Seite 2 Cotton mills for the continent Bildnachweis/Verantwoording Sidney Stott und der englische Spinnereibau in afbeldingen Münsterland und Twente – Sidney Stott en de Engelse spinnerijen in Munsterland en Twente Andreas Oehlke, Rheine: 6, 47, 110, 138 Archiv Manz, Stuttgard: 130, 131, 132l Herausgegeben von/Uitgegeven door Axel Föhl, Rheinisches Amt für Denkmalpflege, Arnold Lassotta, Andreas Oehlke, Siebe Rossel, Brauweiler: 7, 8, 9 Axel Föhl und Manfred Hamm: Industriegeschichte Hermann Josef Stenkamp und Ronald Stenvert des Textils: 119 Westfälisches Industriemuseum, Beltman Architekten en Ingenieurs BV, Enschede: Dortmund 2005 111, 112, 127oben, 128 Fischer: Besteming Semarang: 23u, 25lo Redaktion/Redactie Duncan Gurr and Julian Hunt: The cotton mills of Oldham: 37, 81r Hermann Josef Stenkamp Eduard Westerhoff: 56, 57 Hans-Joachim Isecke, TECCON Ingenieurtechnik, Zugleich Begleitpublikation zur Ausstel- Stuhr: 86 lung/Tevens publicatie bij de tentoonstelling John A. Ledeboer: Spinnerij Oosterveld: 100 des Westfälischen Industriemuseums John Lang: Who was Sir Philip Stott?: 40 Museum Jannink, Enschede: 19, 98 – Textilmuseum Bocholt, Museum voor Industriële Acheologie en Textiel, des Museums Jannink in Enschede Gent: 16oben und des Textilmuseums Rheine Ortschronik (Stadtarchiv) Rüti: 110 Peter Heckhuis, Rheine: 67u, 137 Publikation und Ausstellung ermöglichten/ Privatbesitz: 15, 25u, 26u, 30, 31, 46, 65, 66, 67oben, 83oben, 87oben, 88u, 88r, 90, 92, 125l Publicatie en tentoonstelling werden Rheinisches Industriemuseum, Schauplatz Ratingen: mogelijk gemaakt door 11, 17 Europäische Union Ronald Stenvert: 26r, 39r, 97, 113oben, 113r, 114, 125r, Westfälisches Industriemuseum 126 Kulturforum Rheine Roger N. -

Cotton and the Community: Exploring Changing Concepts of Identity and Community on Lancashire’S Cotton Frontier C.1890-1950

Cotton and the Community: Exploring Changing Concepts of Identity and Community on Lancashire’s Cotton Frontier c.1890-1950 By Jack Southern A thesis submitted in partial fulfillment for the requirements for the degree of a PhD, at the University of Central Lancashire April 2016 1 i University of Central Lancashire STUDENT DECLARATION FORM I declare that whilst being registered as a candidate of the research degree, I have not been a registered candidate or enrolled student for another aware of the University or other academic or professional institution. I declare that no material contained in this thesis has been used for any other submission for an academic award and is solely my own work. Signature of Candidate ________________________________________________ Type of Award: Doctor of Philosophy School: Education and Social Sciences ii ABSTRACT This thesis explores the evolution of identity and community within north east Lancashire during a period when the area gained regional and national prominence through its involvement in the cotton industry. It examines how the overarching shared culture of the area could evolve under altering economic conditions, and how expressions of identity fluctuated through the cotton industry’s peak and decline. In effect, it explores how local populations could shape and be shaped by the cotton industry. By focusing on a compact area with diverse settlements, this thesis contributes to the wider understanding of what it was to live in an area dominated by a single industry. The complex legacy that the cotton industry’s decline has had is explored through a range of settlement types, from large town to small village. -

Wages and Working Hours in the Textiles, Clothing, Leather and Footwear Industries

GDFTCLI/2014 Wages and Working Hours in the Textiles, Clothing, Leather and Footwear Industries Sectoral Sectoral Activities Department Activities International Labour Office (ILO) Department 4, route des Morillons CH-1211 Genève 22 Switzerland GDFTCLI/2014 INTERNATIONAL LABOUR ORGANIZATION Sectoral Activities Department Wages and working hours in the textiles, clothing, leather and footwear industries Issues Paper for discussion at the Global Dialogue Forum on Wages and Working Hours in the Textiles, Clothing, Leather and Footwear Industries (Geneva, 23–25 September 2014) Geneva, 2014 INTERNATIONAL LABOUR OFFICE, GENEVA Copyright © International Labour Organization 2014 First edition 2014 Publications of the International Labour Office enjoy copyright under Protocol 2 of the Universal Copyright Convention. Nevertheless, short excerpts from them may be reproduced without authorization, on condition that the source is indicated. For rights of reproduction or translation, application should be made to ILO Publications (Rights and Permissions), International Labour Office, CH-1211 Geneva 22, Switzerland. The International Labour Office welcomes such applications. Libraries, institutions and other users registered with reproduction rights organizations may make copies in accordance with the licences issued to them for this purpose. Visit www.ifrro.org to find the reproduction rights organization in your country. Wages and working hours in the textiles, clothing, leather and footwear industries: Issues Paper for discussion at the Global Dialogue