Cadmium Telluride

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

VIPV Position Paper Final Version.Pdf

VIPV Position Paper Vehicle-integrated Photovoltaics (VIPV) as a core source for electricity in road transport Lightyear One, 2019 Content 1. Political Context............................................................................................................................... 1 2. Introduction to the VIPV Market ..................................................................................................... 2 2.1 Passenger Cars ............................................................................................................................... 3 2.2 Light- and Heavy-Duty Vehicles ..................................................................................................... 5 3. The Motivation for VIPV .................................................................................................................. 6 3.1 General Benefits of VIPV ............................................................................................................... 6 3.2 VIPV Energy Flow Model ............................................................................................................... 8 3.3 Environmental Benefits in Comparison to the German Grid Mix ................................................. 9 4. Requirements and To-Dos for VIPV ............................................................................................... 11 4.1 Important Selection Criteria for VIPV .......................................................................................... 11 4.2 Technological Requirements -

Thin-Film Cadmium Telluride Photovoltaics: ES&H Issues, Solutions, and Perspectives

February 1998 • NREL/TP-520-24057 Thin-Film Cadmium Telluride Photovoltaics: ES&H Issues, Solutions, and Perspectives Ken Zweibel, NREL Paul Moskowitz, BNL Vasilis Fthenakis, BNL National Renewable Energy Laboratory 1617 Cole Boulevard Golden, Colorado 80401-3393 A national laboratory of the U.S. Department of Energy Managed by Midwest Research Institute for the U.S. Department of Energy under contract No. DE-AC36-99-GO10337 Prepared under Task no. PV804401 February 1998 NOTICE The submitted manuscript has been offered by an employee of the Midwest Research Institute (MRI), a contractor of the US Government under Contract No. DE-AC36-99GO10337. Accordingly, the US Government and MRI retain a nonexclusive royalty-free license to publish or reproduce the published form of this contribution, or allow others to do so, for US Government purposes. This report was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or any agency thereof. -

$1/W Photovoltaic Systems

U.S. Department of Energy Advanced Research Projects Agency‐Energy Energy Efficiency and Renewable Energy $1/W Photovoltaic Systems White Paper to Explore A Grand Challenge for Electricity from Solar DISCLAIMER: The purpose of this paper is to facilitate discussion among participants in the “$1/W Systems: A Grand Challenge for Electricity from Solar” Workshop, to be held on August 10‐11, 2010 in Washington, DC. This paper does not represent, reflect, or endorse an existing, planned, or proposed policy of the U.S. Government, including but not limited to the U.S. Department of Energy. The U.S. Department of Energy does not guarantee the accuracy, relevance, timeliness, or completeness of information herein, and does not endorse any sources used to obtain this information. As such, this paper is not subject to the Information Quality Act and implementing regulations and guidelines. $1/Watt White Paper 1 | Page U.S. Department of Energy Advanced Research Projects Agency‐Energy Energy Efficiency and Renewable Energy I. Introduction A key plank of the Obama Administration’s Energy Policy is to put the country on a path to reduce Green House Gas (GHG) Emissions by 80% by 2050. Solar energy technology has the potential to play a major role in achieving this goal but to date has been limited by high costs. The U.S. Department of Energy (DOE) estimates that a $1/watt installed photovoltaic solar energy system – equivalent to 5‐6 cents/kWh – would make solar without additional subsidies competitive with the wholesale rate of electricity, nearly everywhere in the US. A solar energy system priced at $1/Watt would unlock the potential of the sun to provide low‐cost, clean limitless electricity to the U.S. -

Electroless Deposition of Cdte on Stainless Steel 304 Substrates By

Electroless Deposition of CdTe on Stainless Steel 304 Substrates By James Francis Malika Submitted in Partial Fulfillment of the Requirements for the Degree of Master of Science in the Chemistry Program YOUNGSTOWN STATE UNIVERSITY May 2021 Electroless Deposition of CdTe on Stainless Steel 304 Substrates James Francis Malika I hereby release this thesis to the public. I understand that this thesis will be made available from the Ohio LINK ETD Center and the Maag Library Circulation Desk for public access. I also authorize the University or other individuals to make copies of this thesis as needed for scholarly research. Signature: James Francis Malika, Student Date Approvals: Dr. Clovis A. Linkous, Thesis Advisor Date Dr. Timothy R. Wagner, Committee Member Date Dr. Christopher Arnsten, Committee Member Date Dr. Salvatore A. Sanders, Dean of Graduate Studies Date ABSTRACT The semiconductor cadmium telluride (CdTe) has become the leading material for thin- film photovoltaic applications. Among the many techniques for preparing these thin films, electroless deposition, commonly known as chemical bath deposition, deserves special focus since it has been shown to be a pollution-free, low-temperature and inexpensive method. In this project, CdTe thin films were deposited on stainless steel 304 by the electroless deposition method using cadmium acetate and tellurium oxide dissolved in pH 12.5 NH3(aq). The deposition was based on the gradual release of 2+ 2- cadmium ions (Cd ) and the gradual addition of tellurium as TeO3 and their subsequent reduction in a hot aqueous alkaline chemical bath at 70 oC. This was attained by adding a complexing agent such as ammonia and a chemical reducing agent. -

Solar Electrolyzer Coupling Via Load-Matching

SOLAR ELECTROLYZER COUPLING VIA LOAD-MATCHING AND DOPING IN CADMIUM TELLURIDE SOLAR CELLS TO OVERCOME VOLTAGE LIMITATIONS by Gowri Manasa Sriramagiri A thesis submitted to the Faculty of the University of Delaware in partial fulfillment of the requirements for the degree of Doctor of Philosophy in Electrical and Computer Engineering Winter 2019 © 2018 Gowri M. Sriramagiri All Rights Reserved SOLAR ELECTROLYZER COUPLING VIA LOAD-MATCHING AND DOPING IN CADMIUM TELLURIDE SOLAR CELLS TO OVERCOME VOLTAGE LIMITATIONS by Gowri Manasa Sriramagiri Approved: __________________________________________________________ Kenneth E. Barner, Ph.D. Chair of the Department of Electrical and Computer Engineering Approved: __________________________________________________________ Levi T. Thompson, Ph.D. Dean of the College of Engineering Approved: __________________________________________________________ Douglas J. Doren, Ph.D. Interim Vice Provost for Graduate & Professional Education I certify that I have read this dissertation and that in my opinion it meets the academic and professional standard required by the University as a dissertation for the degree of Doctor of Philosophy. Approved: __________________________________________________________ Steven S. Hegedus, Ph.D. Professor in charge of dissertation I certify that I have read this dissertation and that in my opinion it meets the academic and professional standard required by the University as a dissertation for the degree of Doctor of Philosophy. Approved: __________________________________________________________ -

Preparation and Characterisation of Certain Ii Vi I Iii Vi2 Semiconductor Thin films and Transparent Conducting Oxides

Malaya Journal of Matematik, Vol. S, No. 2, 3911-3915, 2020 https://doi.org/10.26637/MJM0S20/1008 Preparation and characterisation of certain ii vi i iii vi2 semiconductor thin films and transparent conducting oxides R. Rani1 and R. Velavan 2 Abstract Today certainly one of our main demanding situations to the arena scientific community is to find a maintainable deliver of electrical power. At gift, most of our energy come from fossil (i.E. Coal, liquefied petroleum, oil, herbal fuel) and nuclear sources. Not simplest are these assets of power non-renewable and in dwindling amounts, they also can be polluting to the surroundings. Burning of fossil fuels releases almost 7 billion lots of CO2 in line with yr, ensuing in environmental troubles inclusive of the greenhouse impact and worldwide warming. Burning of unrefined coal also consequences in acid rain, which is at once accountable for massive location wooded area and natural world destruction as well as soil pollutants. A collection of incidents at several nuclear electricity vegetation, combined with the shortage of an extended-time period waste disposal strategy, has resulted within the termination of nuclear power programmes inside the USA and most European nations. Keywords CO2m Electricity Vegetation, Acid Rain. 1,2Department of Physics, Bharath Institute of Higher Education and Research, Selaiyur, Chennai-600073, Tamil Nadu, India. Article History: Received 01 October 2020; Accepted 10 December 2020 c 2020 MJM. Contents 2. The need to develop clean renewable energy resources to decrease the generation of greenhouse gases (CO2 1 Introduction......................................3911 and CH4) 2 Principle of solar cells...........................3912 3. -

13.4.2 Cadmium Telluride Solar Cells

13. Thin-Film Solar Cells 205 Kesterites Figure 13.1 shows the abundance in the Earth’s crust for several elements. As we can see, indium is a very rare element. However, it is a crucial element of CIGS solar cells. Because of its scarcity, In might be the limiting step in the upscaling of the CIGS PV technology to future terawatt scales. In addition, the current thin-film display industry depends on In as well, as ITO is integrated in many display screens. As a consequence, other chalcogenic semiconductors are investigated that do not con- tain rare elements. A interesting class of materials are the kesterites which are quarternary or pentary semiconductors consisting of four or five elements, respectively. While the name giving mineral kesterite [Cu2(ZnFe)SnS4], where zinc and iron atoms can substitute each other, is not used as a semiconductor, kesterite without iron (Cu 2ZnSnS4) is used. It also is known as copper zinc tin sulphide (CZTS) and is a I 2-II-IV-VI4 semiconductor. Other kester- ites are for example copper zinc tin selenide (Cu2ZnSnSe4, CZTSe), or ones using a mixture of sulphur and selenium, Cu 2ZnSn(SSe)4 (CZTSS). In difference to CIGS, CZTS is based on non-toxic and abundantly available elements. The current record efficiency is 12%. It is achieved with an CZTSS solar cells on lab-scale by IBM [ 47 ]. 13.4.2 Cadmium telluride solar cells In this section we will discuss the cadmium telluride (CdTe) technology, which currently is the thin-film technology with the lowest demonstrated cost per Wp. -

Cadmium Telluride to the National Toxicology Program

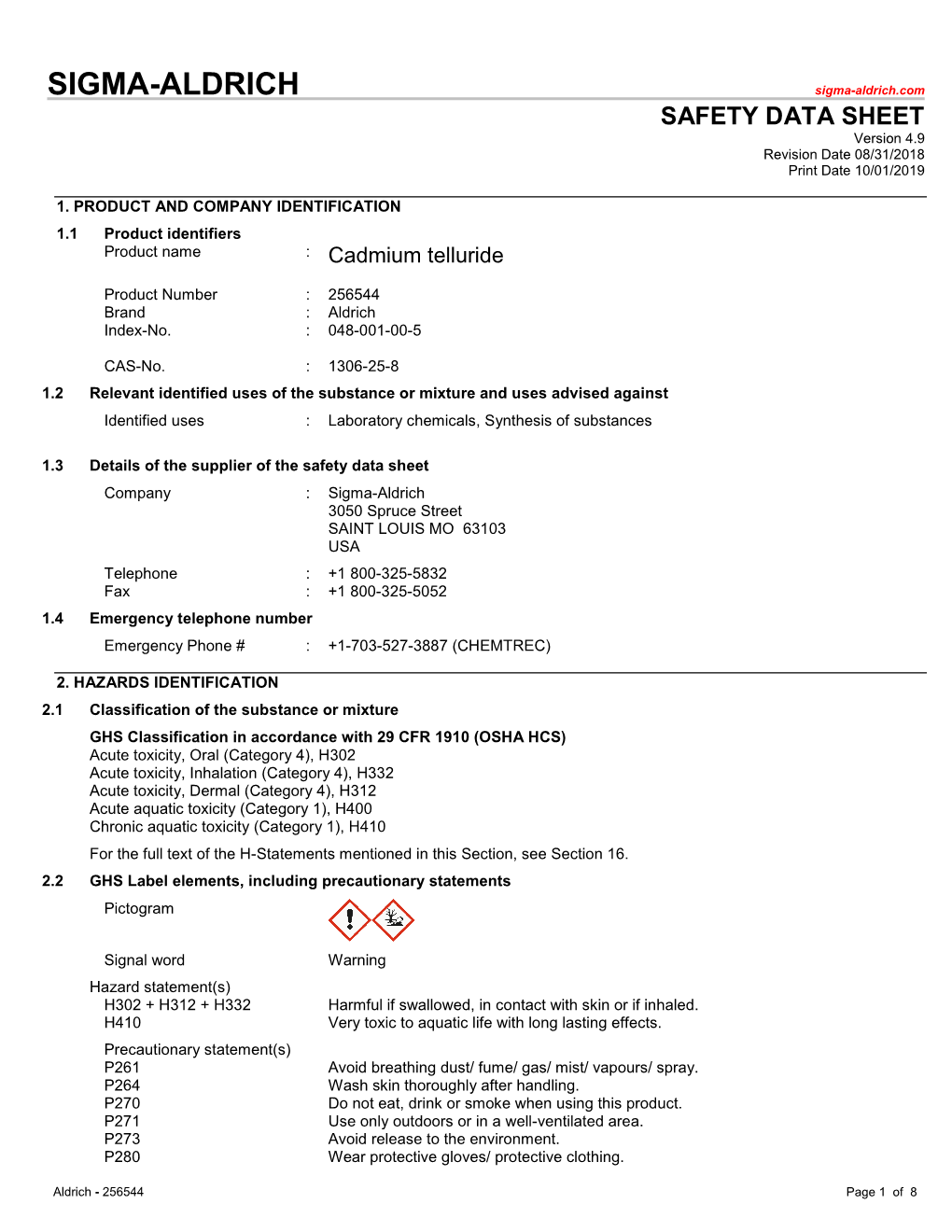

NOMINATION OF CADMIUM TELLURIDE TO THE NATIONAL TOXICOLOGY PROGRAM Introduction Brookhaven National Laboratory (BNL) and the U.S. Department of Energy (DOE) are nominating Cadmium Telluride (CdTe) for inclusion in the National Toxicology Program (NTP). This nomination is strongly supported by the National Renewable Energy Laboratory (NREL) and First Solar Inc. The material has the potential for widespread applications in photovoltaic energy generation that will involve extensive human interfaces. Hence, we consider that a definitive toxicological study of the effects of long-term exposure to CdTe is a necessity. I. Chemical Identification a. CAS name: Cadmium Telluride (CdTe) b. Common name: Cadmium Telluride (CdTe) c. CASRN: 1306-25-8 d. Chemical Class: Cadmium compounds e. Physical properties i. Physical description: Cadmium telluride is a black, dense, cubic crystalline compound that does not occur naturally. ii. Formula: CdTe; MW=240 iii. Melting and boiling points: The melting point of CdTe is 1041°C, and evaporation starts at 1050°C. Sublimation occurs at lower temperatures, but its vapor pressure at 800ºC is only 2.5 torr (0.003 atm). iv. Solubility: CdTe is insoluble in water; v. Stability & Reactivity: CdTe may decompose on exposure to atmospheric moisture and can react with H2O and O2 at elevated temperatures vi. Comparisons of CdTe with the parent compounds Cd and Te: CdTe is more stable than its parent compounds Cd and Te and most other Cd compounds, as indicated by its melting point and solubility (Table 1). Table 1. Physical -

The Effects of Chlorine and Selenium in Cadmium Telluride Solar

The Effects of Chlorine and Selenium in Cadmium Telluride Solar Cells By Thomas Fiducia Abstract Solar photovoltaics (PV) holds great promise to change the way that electricity is produced and used globally. As it stands, electricity is generated mainly by large coal and gas-fired power stations, which are expensive to build and rely on a fuel supply that becomes more expensive over time. By contrast, the costs of solar PV are falling rapidly, and solar is already producing electricity at lower levelised costs than coal and gas power stations. Moreover, it can do so with a very low environmental impact, and since it is a ‘distributed’ power source that does not require a fuel supply, also improves access to electricity and the overall security of supply. However, if these benefits are to be realised, deployment of solar PV needs to continue to scale significantly. Solar PV currently supplies only ~3% of worldwide electricity demand, and demand for electricity is set to nearly double by 2050 as a result of the electrification of heating and transport and rising living standards. In order to continue its rapid growth and help to meet a significant portion of future electricity demand, solar module efficiencies need to continue to rise and production costs need to decrease further. Fast-deposited thin-film PV technologies like cadmium telluride (CdTe) offer a promising route to achieve the necessary price decreases and industry scale-up because they are intrinsically less expensive to produce than the incumbent silicon PV modules, which require careful crystal growth and individual processing of each wafer, cell and module. -

Innovative Solar Technology from the Netherlands Visit Us the PV at B4G/B 1S2EC

September 2011 SEC Hamburg PV Innovative solar technology from the Netherlands Visit us at the PV SEC B4G/B12 Launchingof evaporation cabinet • • • • • • • • • • • • Innovative solar technology from the Netherlands Dutch companies, knowledge institutes the new technical opportunities have led to and government authorities are market opportunities and sales. The Dutch working flat out on new technologies solar industry – present in great numbers and countless innovations in the field during the PV SEC – will demonstrate during of solar power. They are deeds and this event that they are able to transform answers appropriate for the global opportunities into business. push for power transition. They are deeds that will not just shape the There is a lot of positive news to report on future of the Netherlands, but the regarding knowledge, abilities and sales. Like future of the entire world. the funding of Solliance and the installation of the Solliance Industry Board, which you A future in which the Netherlands will can read all about in this magazine. hopefully lead with innovations. In which dependency on fossil fuels will decrease. There is also a part for the Dutch A future in which the Netherlands will government to play in the marketing of globally play a role of crucial importance. new technologies through the creation The potential is there. The Netherlands of an industry-friendly home market does not just have a knowledge institute and the stimulation of innovation. The in the Energieonderzoek Centrum Dutch government increasingly supports Nederland that enjoys global status, test and demonstration projects within it also has companies like OTB Solar, the field of solar power. -

Transient Response of Cadmium Telluride Modules to Light Exposure Preprint C

Transient Response of Cadmium Telluride Modules to Light Exposure Preprint C. Deline, J. del Cueto, and D. S. Albin National Renewable Energy Laboratory C. Petersen, L. Tyler, and G. TamizhMani Arizona State University Presented at the 37th IEEE Photovoltaic Specialists Conference (PVSC 37) Seattle, Washington June 19-24, 2011 NREL is a national laboratory of the U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy, operated by the Alliance for Sustainable Energy, LLC. Conference Paper NREL/CP-5200-50744 July 2011 Contract No. DE-AC36-08GO28308 NOTICE The submitted manuscript has been offered by an employee of the Alliance for Sustainable Energy, LLC (Alliance), a contractor of the US Government under Contract No. DE-AC36-08GO28308. Accordingly, the US Government and Alliance retain a nonexclusive royalty-free license to publish or reproduce the published form of this contribution, or allow others to do so, for US Government purposes. This report was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or any agency thereof. -

Cdte-Based Thin Film Solar Cells: Past, Present and Future

energies Review CdTe-Based Thin Film Solar Cells: Past, Present and Future Alessandro Romeo * and Elisa Artegiani Laboratory for Photovoltaics and Solid-State Physics (LAPS), Department of Computer Science, University of Verona, Ca’ Vignal 1, Strada Le Grazie 15, 37134 Verona, Italy; [email protected] * Correspondence: [email protected]; Tel.: +39-045-8027-936 Abstract: CdTe is a very robust and chemically stable material and for this reason its related solar cell thin film photovoltaic technology is now the only thin film technology in the first 10 top producers in the world. CdTe has an optimum band gap for the Schockley-Queisser limit and could deliver very high efficiencies as single junction device of more than 32%, with an open circuit voltage of 1 V and a short circuit current density exceeding 30 mA/cm2. CdTe solar cells were introduced at the beginning of the 70s and they have been studied and implemented particularly in the last 30 years. The strong improvement in efficiency in the last 5 years was obtained by a new redesign of the CdTe solar cell device reaching a single solar cell efficiency of 22.1% and a module efficiency of 19%. In this paper we describe the fabrication process following the history of the solar cell as it was developed in the early years up to the latest development and changes. Moreover the paper also presents future possible alternative absorbers and discusses the only apparently controversial environmental impacts of this fantastic technology. Keywords: solar cells; thin films; CdTe 1. Introduction Citation: Romeo, A.; Artegiani, E.