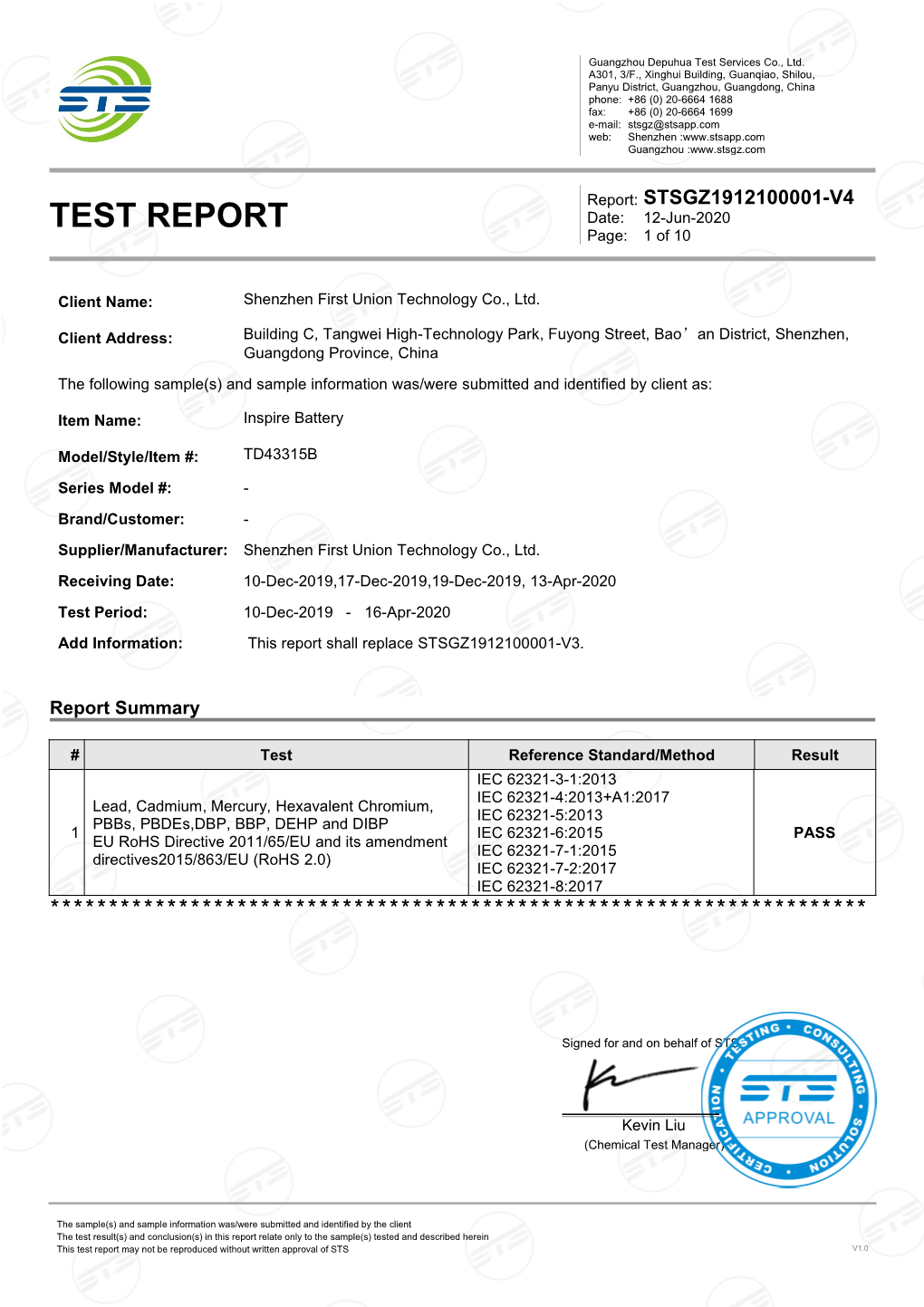

TEST REPORT Page: 1 of 10

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

BP Neural Network Based Prediction of Potential Mikania Micrantha

se t Re arc s h: re O o p Qiu et al., Forest Res 2018, 7:1 F e f n o A DOI: 10.4172/2168-9776.100021 l 6 c a c n e r s u s o J Forest Research: Open Access ISSN: 2168-9776 Research Article Open Access BP Neural Network Based Prediction of Potential Mikania micrantha Distribution in Guangzhou City Qiu L1,2, Zhang D1,2, Huang H3, Xiong Q4 and Zhang G4* 1School of Geosciences and Info-Physics, Central South University, Hunan, Changsha, China 2Key Laboratory of Metallogenic Prediction of Nonferrous Metals and Geological Environment Monitor (Central South University), Ministry of Education, Changsha, China 3Shengli College of China University of Petroleum, Shandong, Dongying, China 4Central South University of Forestry and Technology, Hunan, Changsha, China *Corresponding author: Zhang G, Central South University of Forestry and Technology, Hunan, Changsha, China, Tel: 9364682275; E-mail: [email protected] Received date: January 16, 2018; Accepted date: February 09, 2018; Published date: February 12, 2018 Copyright: © 2018 Qiu L, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Abstract To predict the distribution of Mikania micrantha, one of the most harmful invasive plants in Guangzhou City, the author selected relevant environmental factors and established a feasible simple model based on BP neural network to use its strong nonlinear ability in this -

BIS Places Destabilizing Military Modernization Administration

Federal Register / Vol. 86, No. 67 / Friday, April 9, 2021 / Rules and Regulations 18437 (i) Burma. Office of Chief of Military Background described below under the standard set Security Affairs (OCMSA) and the forth in § 744.11(b) of the EAR. The Entity List (supplement no. 4 to Directorate of Signal. The ERC determined that the seven part 744 of the Export Administration (ii) Cuba. Directorate of Military subject entities are engaging in or Regulations (EAR)) identifies entities for Intelligence (DIM) and Directorate of enabling activities contrary to U.S. which there is reasonable cause to Military Counterintelligence (CIM). national security and foreign policy believe, based on specific and (iii) China, People’s Republic of. interests, as follows: articulable facts, that the entities have Intelligence Bureau of the Joint Staff The ‘‘National Supercomputing been involved, are involved, or pose a Department. Center Jinan,’’ ‘‘National significant risk of being or becoming (iv) Iran. Islamic Revolutionary Guard Supercomputing Center Shenzhen,’’ involved in activities contrary to the ‘‘National Supercomputing Center Corps Intelligence Organization (IRGC– national security or foreign policy IO) and Artesh Directorate for Wuxi,’’ ‘‘National Supercomputer interests of the United States. The EAR Center Zhengzhou,’’ ‘‘Shanghai High- Intelligence (J2). (15 CFR parts 730–774) impose (v) Korea, North. Reconnaissance Performance Integrated Circuit Design additional license requirements on, and Center,’’ ‘‘Sunway Microelectronics,’’ General Bureau (RGB). limit the availability of most license (vi) Russia. Main Intelligence and ‘‘Tianjin Phytium Information exceptions for, exports, reexports, and Technology’’ are being added to the Directorate (GRU). transfers (in-country) to listed entities. (vii) Syria. Military Intelligence Entity List on the basis of their The license review policy for each listed procurement of U.S.-origin items for Service. -

Assessment of Spatial Accessibility to Residential Care Facilities in 2020 in Guangzhou by Small-Scale Residential Community Data

sustainability Article Assessment of Spatial Accessibility to Residential Care Facilities in 2020 in Guangzhou by Small-Scale Residential Community Data Danni Wang 1,2, Changjian Qiao 3, Sijie Liu 4, Chongyang Wang 2,5,* , Ji Yang 2,5, Yong Li 2,5 and Peng Huang 6 1 Department of Resources and the Urban Planning, Xin Hua College of Sun Yat-Sen University, Guangzhou 510520, China; [email protected] 2 Southern Marine Science and Engineering Guangdong Laboratory (Guangzhou), Guangzhou 511458, China; [email protected] (J.Y.); [email protected] (Y.L.) 3 College of Resources and Environment, Academician Workstation for Urban-Rural Spatial Data Mining, Henan University of Economics and Law, Zhengzhou 450046, China; [email protected] 4 Land and Resources Technology Center of Guangdong Province, Guangzhou 510075, China; [email protected] 5 Key Lab of Guangdong for Utilization of Remote Sensing and Geographical Information System, Guangdong Open Laboratory of Geospatial Information Technology and Application, Guangzhou Institute of Geography, Guangzhou 510070, China 6 Shenzhen Municipal Planning and Natural Resources Bureau-Bao’an Management Bureau, Shenzhen 518101, China; [email protected] * Correspondence: [email protected]; Tel.: +86-188-0208-0904 Received: 27 February 2020; Accepted: 12 April 2020; Published: 15 April 2020 Abstract: Population aging has increasingly challenged socio-economic development worldwide, highlighting the significance of relevant research such as accessibility to residential care facilities (RCFs). However, a number of previous studies are carried out only on street (town)-to-district scales, which could cause errors of the accessibility to RCFs for a family. In order to improve the resolution to individual families, we measure and compare the accessibilities to RCFs based on 3494 residential communities and 169 streets of Guangzhou in 2020 through the two-step floating catchment area (2SFCA) method. -

Test Report Guangzhou Quality Supervision and Testing Institute

Test Report Test Report No.: 轻委2020-05-0955 Applicant: Hunan Kangweining Medical Device- s Co., Ltd Sample Name: Disposable medical mask(non-ste- rile) Type and Specification: Flat Ear hanging 17.5cm×9.5cm Completion Date: 2020-06-02 Guangzhou Quality Supervision and Testing Institute (GQT) Important Statement 1. Guangzhou Quality Supervision and Testing Institute (GQT) is the products quality super- vision and testing organization that is set up by the Government and in charge by Guangzhou Administration for Market Regulation. GQT is a social public welfare institution that pro- viding technical support for the government to strengthen the market supervision and ad- ministration, and also accepting commissioned inspection. 2. GQT and the National Quality Supervision and Testing center (center) and the Products Quality Supervision and Testing Station (station) guarantee that the inspection is scien- tific, impartial and accurate and are responsible for the testing result and also keep con- fidentiality of the samples and technical information provided by the applicants. 3. Any report without the signatures of the tester, checker and approver, or altered, or without the special chapter for Inspection and Testing of the Institute (center/station), or without the special testing seal , will be taken as invalid. The test shall not be par- tial copied, picked up and tampered without the authorization of GQT (Center/ Station). 4. The entrusted testing is only valid to the provided samples.The applicant shall not use the inspection results without authorization of GQT (Center/ Station) for undue publicity. 5. The sample and relevant information provided by the applicant, GQT (Center/Station)is not responsible for its authenticity and integrity. -

Shop Direct Factory List Dec 18

Factory Factory Address Country Sector FTE No. workers % Male % Female ESSENTIAL CLOTHING LTD Akulichala, Sakashhor, Maddha Para, Kaliakor, Gazipur, Bangladesh BANGLADESH Garments 669 55% 45% NANTONG AIKE GARMENTS COMPANY LTD Group 14, Huanchi Village, Jiangan Town, Rugao City, Jaingsu Province, China CHINA Garments 159 22% 78% DEEKAY KNITWEARS LTD SF No. 229, Karaipudhur, Arulpuram, Palladam Road, Tirupur, 641605, Tamil Nadu, India INDIA Garments 129 57% 43% HD4U No. 8, Yijiang Road, Lianhang Economic Development Zone, Haining CHINA Home Textiles 98 45% 55% AIRSPRUNG BEDS LTD Canal Road, Canal Road Industrial Estate, Trowbridge, Wiltshire, BA14 8RQ, United Kingdom UK Furniture 398 83% 17% ASIAN LEATHERS LIMITED Asian House, E. M. Bypass, Kasba, Kolkata, 700017, India INDIA Accessories 978 77% 23% AMAN KNITTINGS LIMITED Nazimnagar, Hemayetpur, Savar, Dhaka, Bangladesh BANGLADESH Garments 1708 60% 30% V K FASHION LTD formerly STYLEWISE LTD Unit 5, 99 Bridge Road, Leicester, LE5 3LD, United Kingdom UK Garments 51 43% 57% AMAN GRAPHIC & DESIGN LTD. Najim Nagar, Hemayetpur, Savar, Dhaka, Bangladesh BANGLADESH Garments 3260 40% 60% WENZHOU SUNRISE INDUSTRIAL CO., LTD. Floor 2, 1 Building Qiangqiang Group, Shanghui Industrial Zone, Louqiao Street, Ouhai, Wenzhou, Zhejiang Province, China CHINA Accessories 716 58% 42% AMAZING EXPORTS CORPORATION - UNIT I Sf No. 105, Valayankadu, P. Vadugapal Ayam Post, Dharapuram Road, Palladam, 541664, India INDIA Garments 490 53% 47% ANDRA JEWELS LTD 7 Clive Avenue, Hastings, East Sussex, TN35 5LD, United Kingdom UK Accessories 68 CAVENDISH UPHOLSTERY LIMITED Mayfield Mill, Briercliffe Road, Chorley Lancashire PR6 0DA, United Kingdom UK Furniture 33 66% 34% FUZHOU BEST ART & CRAFTS CO., LTD No. 3 Building, Lifu Plastic, Nanshanyang Industrial Zone, Baisha Town, Minhou, Fuzhou, China CHINA Homewares 44 41% 59% HUAHONG HOLDING GROUP No. -

7020-02 INTERNATIONAL TRADE COMMISSION Certain Led Lighting Devices and Components Thereof Investigation No. 337-TA-1107 Institu

This document is scheduled to be published in the Federal Register on 04/10/2018 and available online at https://federalregister.gov/d/2018-07306, and on FDsys.gov 7020-02 INTERNATIONAL TRADE COMMISSION Certain Led Lighting Devices and Components Thereof Investigation No. 337-TA-1107 Institution of Investigation AGENCY: U.S. International Trade Commission ACTION: Notice SUMMARY: Notice is hereby given that a complaint was filed with the U.S. International Trade Commission on March 6, 2018, under section 337 of the Tariff Act of 1930, as amended, on behalf of Fraen Corporation of Reading, Massachusetts. The complaint was supplemented on March 20, 2018. The complaint alleges violations of section 337 based upon the importation into the United States, the sale for importation, and the sale within the United States after importation of certain LED lighting devices and components thereof by reason of infringement of certain claims of U.S. Patent Nos. 9,411,083 (“the ‘083 patent”) and 9,772,499 (“the ‘499 patent”). The complaint further alleges that an industry in the United States exists as required by the applicable Federal Statute. The complainant requests that the Commission institute an investigation and, after the investigation, issue a general exclusion order, or in the alternative a limited exclusion order, and cease and desist orders. ADDRESSES: The complaint, except for any confidential information contained therein, is available for inspection during official business hours (8:45 a.m. to 5:15 p.m.) in the Office of the Secretary, U.S. International Trade Commission, 500 E Street, S.W., Room 112, Washington, D.C. -

CHINA VANKE CO., LTD.* 萬科企業股份有限公司 (A Joint Stock Company Incorporated in the People’S Republic of China with Limited Liability) (Stock Code: 2202)

Hong Kong Exchanges and Clearing Limited and The Stock Exchange of Hong Kong Limited take no responsibility for the contents of this announcement, make no representation as to its accuracy or completeness and expressly disclaim any liability whatsoever for any loss howsoever arising from or in reliance upon the whole or any part of the contents of this announcement. CHINA VANKE CO., LTD.* 萬科企業股份有限公司 (A joint stock company incorporated in the People’s Republic of China with limited liability) (Stock Code: 2202) 2019 ANNUAL RESULTS ANNOUNCEMENT The board of directors (the “Board”) of China Vanke Co., Ltd.* (the “Company”) is pleased to announce the audited results of the Company and its subsidiaries for the year ended 31 December 2019. This announcement, containing the full text of the 2019 Annual Report of the Company, complies with the relevant requirements of the Rules Governing the Listing of Securities on The Stock Exchange of Hong Kong Limited in relation to information to accompany preliminary announcement of annual results. Printed version of the Company’s 2019 Annual Report will be delivered to the H-Share Holders of the Company and available for viewing on the websites of The Stock Exchange of Hong Kong Limited (www.hkexnews.hk) and of the Company (www.vanke.com) in April 2020. Both the Chinese and English versions of this results announcement are available on the websites of the Company (www.vanke.com) and The Stock Exchange of Hong Kong Limited (www.hkexnews.hk). In the event of any discrepancies in interpretations between the English version and Chinese version, the Chinese version shall prevail, except for the financial report prepared in accordance with International Financial Reporting Standards, of which the English version shall prevail. -

The Stock Exchange of Hong Kong Limited Takes No Responsibility For

Hong Kong Exchanges and Clearing Limited and The Stock Exchange of Hong Kong Limited take no responsibility for the contents of this announcement, make no representation as to its accuracy or completeness and expressly disclaim any liability whatsoever for any loss howsoever arising from or in reliance upon the whole or any part of the contents of this announcement. (Stock Code: 603) ANNOUNCEMENT This announcement is made by the Company pursuant to Rule 13.09(2) of the Listing Rules and the Inside Information Provisions under Part XIVA of the SFO. The Board is pleased to announce that on 25 November 2014, CCNG entered into the JV Contract with Panyu Transportation Construction, pursuant to which CCNG and Panyu Transportation Construction agreed to cooperate in the Natural Gas Filling Stations Project, and invest in the establishment of the JV to build and operate natural gas filling stations and sell natural gas, etc. in Panyu District and Nansha District of Guangzhou, Guangdong Province, China. Through the Natural Gas Filling Stations Project, the Group will further develop its domestic gas market, strengthen and expand its market share of domestic gas business. This announcement is made by China Oil And Gas Group Limited (the “Company”, together with its subsidiaries, the “Group”) pursuant to Rule 13.09(2) of the Rules Governing the Listing of Securities on The Stock Exchange of Hong Kong Limited (the “Listing Rules”) and the Inside Information Provisions under Part XIVA of the Securities and Futures Ordinance (Chapter 571 of the Laws of Hong Kong) (the “SFO”). JV CONTRACT The board (the “Board”) of directors (the “Directors”) of the Company is pleased to announce that on 25 November 2014, the Company through its subsidiary, 中油中泰燃氣投資集團有限公司 (China City Natural Gas Co. -

Yuexiu Property Acquires 51% Equity Interests in Two Metro Property Projects

[For Immediate Release] Yuexiu Property Acquires 51% Equity Interests in Two Metro Property Projects (10 September 2019 – Hong Kong) Yuexiu Property Company Limited (“Yuexiu Property” or “the Company”) (HKEx Stock Code: 00123) announces that it has exercised options pursuant to two option deeds to separately acquire 51% equity interests in two companies that each own a property development project atop a metro station, one in Huangpu District and another one in Panyu District, from its parent company Guangzhou Yue Xiu Holdings Limited (“Guangzhou Yuexiu”) at a consideration of RMB4,881 million and RMB4,030 million respectively. One of the property development projects is located in Luogang, the downtown area of Huangpu District, and is adjacent to Xiangxue Station on Line 6 of the Guangzhou Metro. A multi-purpose complex that consists of residential buildings and facilities for education with total gross floor area (“GFA”) of approximately 0.94 million sq.m. will be built at the project. The other property development project is located in Panyu District. It is atop Chen Tougang Station, which is at the middle of Line 22 of the Guangzhou Metro. The project is also adjacent to Guangzhou South Railway Station. Residential buildings with total GFA of approximately 0.88 million sq.m. will be built there. Line 22 is expected to be put into full operation in 2022. Upon completion of the acquisitions, the total GFA of the Company’s metro property projects will increase to 3.2 million sq.m., which will account for 15% of the total landbank of the Company and 36.3% of the landbank of the Company in tier-one cities respectively as of 30 June 2019. -

June 11, 2021 Zhuhai Gaoge Medical Technology Co., Ltd. Olivia Meng

June 11, 2021 Zhuhai Gaoge Medical Technology Co., Ltd. ℅ Olivia Meng Regulatory Affairs Manager Guangzhou Osmunda Medical Device Technical Service Co., Ltd. 8-9th Floor, R&D Building, No. 26 Qinglan Street, Panyu District Guangzhou, Guangdong 510006 China Re: K203732 Trade/Device Name: Surgical Face Mask Regulation Number: 21 CFR 878.4040 Regulation Name: Surgical apparel Regulatory Class: Class II Product Code: FXX Dated: April 25, 2021 Received: April 30, 2021 Dear Olivia Meng: We have reviewed your Section 510(k) premarket notification of intent to market the device referenced above and have determined the device is substantially equivalent (for the indications for use stated in the enclosure) to legally marketed predicate devices marketed in interstate commerce prior to May 28, 1976, the enactment date of the Medical Device Amendments, or to devices that have been reclassified in accordance with the provisions of the Federal Food, Drug, and Cosmetic Act (Act) that do not require approval of a premarket approval application (PMA). You may, therefore, market the device, subject to the general controls provisions of the Act. Although this letter refers to your product as a device, please be aware that some cleared products may instead be combination products. The 510(k) Premarket Notification Database located at https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfpmn/pmn.cfm identifies combination product submissions. The general controls provisions of the Act include requirements for annual registration, listing of devices, good manufacturing practice, labeling, and prohibitions against misbranding and adulteration. Please note: CDRH does not evaluate information related to contract liability warranties. We remind you, however, that device labeling must be truthful and not misleading. -

Safety Data Sheets (Sdss)

Safety Data Sheets (SDSs) Safety Data Sheets (SDSs) DONGGUAN SANQIXIN ELECTRONICS CO.,Ltd.(DongGuan) Client Co;Ltd 3rd Floor, Honglong Building C, Pankeng Road 1-1, Wulian village,Fenggang Town , Dongguan City(WEST VILLAGE SECTION),SHAWAN TOWN , PANYU DISTRICT, GUANGZHOU Add. of Client CITY, CHINA Cylindrical Lithium-ion Cell Description Model /Type 18650 DONGGUAN SANQIXIN ELECTRONICS CO.,Ltd.(DongGuan) Manufacturer Co;Ltd 3rd Floor, Honglong Building C, Pankeng Road 1-1, Wulian village,Fenggang Town , Dongguan City(WEST VILLAGE Add. of SECTION),SHAWAN TOWN , PANYU DISTRICT, GUANGZHOU Manufacturer CITY, CHINA Nominal Voltage 3.7V, 1200mAh, 4.44Wh Date of Receipt 2019-08-05 Laboratory Shenzhen ZRLK Testing Technology Co., Ltd. 6F, Fuxinfa Industrial Park, Liuxiandong, Xili Street, Nanshan District, Address Shenzhen, China Approved Maggie.Gao Signatory Inspected by Ailis.Ma Censored by Lahm Peng Report No.: ZKS190800048 Page 1 of 11 TRF No. SDS-1A Safety Data Sheets (SDSs) 1. IDENTIFICATION OF THE SUBSTANCE/PREPARATION AND OF THE COMPANY/UNDERTAKING Product Identifier Product name: Cylindrical Lithium-ion Cell Model: 18650 Other means of identification Synonyms:none Recommended use of the chemical and restrictions on use Recommended Use:Used in portabl electronic equipments; Uses advidsed against: a) Do not dismantle, open or shred secondary cells or batteries. b) Keep batteries out of the reach of children Battery usage by children should be supervised. Especially keep small batteries out of reach of small children. c) Seek medical advice immediately if a cell or a battery has been swallowed. d) Do not expose cells or batteries to heat or fire. Avoid storage in direct sunlight. -

Factory Name Address City Zip Code Province Country # of Workers Category Jiangsu Asset Underwear Co., Ltd

Factory name Address City Zip code Province Country # of workers Category Jiangsu Asset Underwear Co., Ltd. No. 6, Wang One Road, Economic Development Zone, Lianshui County Huaian 223001 Jiangsu China <1000 apparel Shen Zhen BP Co., Ltd. 1-5 Floor, B12, Hengfeng Industrial Zone, Hezhou, Xixiang Bao'an Area Shenzhen 518100 Guangdong China <1000 apparel Zhong Shan Kin Tak Garment Factory Ltd. Wan An Industrial District, Ji Dong 1, Xiaolan Town Zhongshan 528400 Guangdong China <1000 apparel Zhongshan Vigor Garment Co., Ltd. Chang Ling Lu, Lan Bian Village, NanLangZhen Zhongshan 528400 Guangdong China <1000 apparel Intimate Fashion Co., Ltd. 140 Moo.5, Phutthamonthon 5 Road, Omnoi Kratumban 74130 Samut Sakhon Thailand <1000 apparel Elite Fame Garment Factory Shang Nan, Yuanzhou Town, Bolou Huizhou City Huizhou City 528400 Guangdong China <1000 apparel DongGuan XuYang Textile Co.,Ltd NO.127,yongmao road ,renzhou village,santian town Dongguan 523999 Guangdong China <1000 fabric Maoming City Jinquan Rubber & Plastics Products Co.,Ltd No.57 Qiongsha Road,ShaYuan Town Dianbai District, Maoming 525028 Guangdong China <1000 elastic Hongda High-Tech Holding Co., Ltd No. 118 Jian She Road Xucun Town Haining 311409 Zhejiang China <1000 fabric Fuzhou Meijiahua Knitting & Textile Co., Ltd Room 1416, Building 16th, Haixibaiyue Town 2nd 18 Duyuan Road Fuzhou 350019 Fujian China <1000 fabric Deqing Taihe Industries Co., Ltd Gantang High & New Technology Development Zone Decheng Town Deqing 526600 Guangdong China <1000 fabric Dongguan City Humen Town Xinghui