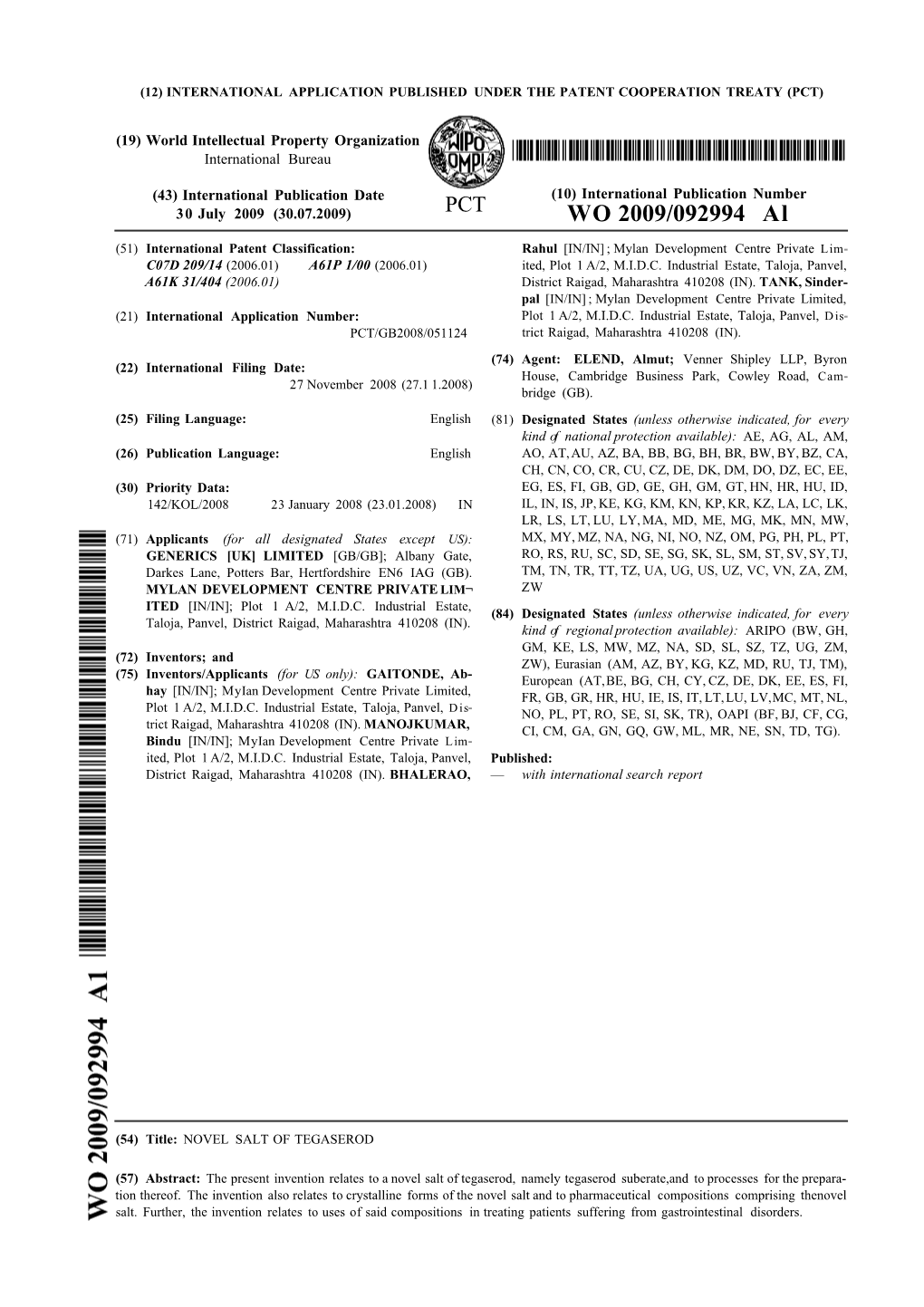

WO 2009/092994 Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

THE HARD TRUTH ABOUT PROKINETIC MEDICATION USE in PETS Introduction Pathophysiology/Etiology to That Observed in Dogs

VETTALK Volume 15, Number 04 American College of Veterinary Pharmacists THE HARD TRUTH ABOUT PROKINETIC MEDICATION USE IN PETS Introduction Pathophysiology/Etiology to that observed in dogs. It can be The moving topic of this Vet Talk As with most diseases in the veteri- due to a trichobezoar, dehydration, newsletter will be prokinetic medica- nary world, the etiology and patho- obesity, old age, diabetes, immobility, tions. The availability of information physiology of constipation are varied pain from trauma to the low back, on the many prokinetic agents is var- depending on the species being dis- bladder infection, or an anal sac infec- ied at best so an overall consensus of cussed, where in their gastrointestinal tion. In cases that are more chronic, prokinetic medications will be as- tract the problem is occurring, and underlying disease such as colitis or sessed in this article, hopefully giving any accompanying comorbid condi- Irritable Bowel Syndrome (IBS) may better insight to practitioners about tions. be the culprit. On the other hand, the which agents to use in their patients. cause may be idiopathic which is Canines: In man’s best friend, consti- frustrating for both veterinarian and Prevalence pation has many origins. A dog’s patient since this form is most diffi- Chronic constipation and gastroin- digestive tract itself is complex but cult to treat. testinal stasis are highly debilitating ultimately the mass movements and conditions that not only affect human haustral contractions from the large Equines: Despite their large size, patients but our four legged patients intestine (colon), propel feces into the horses have incredibly delicate diges- as well! Though this condition is rectum stimulating the internal anal tive systems. -

The Pharmacology of Prokinetic Agents and Their Role in the Treatment of Gastrointestinal Disorders

The Pharmacology of ProkineticAgents IJGE Issue 4 Vol 1 2003 Review Article The Pharmacology of Prokinetic Agents and Their Role in the Treatment of Gastrointestinal Disorders George Y. Wu, M.D, Ph.D. INTRODUCTION Metoclopramide Normal peristalsis of the gut requires complex, coordinated neural and motor activity. Pharmacologic Category : Gastrointestinal Abnormalities can occur at a number of different Agent. Prokinetic levels, and can be caused by numerous etiologies. This review summarizes current as well as new Symptomatic treatment of diabetic gastric agents that show promise in the treatment of stasis gastrointestinal motility disorders. For these Gastroesophageal reflux e conditions, the most common medications used in s Facilitation of intubation of the small the US are erythromycin, metoclopramide, and U intestine neostigmine (in acute intestinal pseudo- Prevention and/or treatment of nausea and obstruction). A new prokinetic agent, tegaserod, vomiting associated with chemotherapy, has been recently approved, while other serotonin radiation therapy, or post-surgery (1) agonist agents (prucalopride, YM-31636, SK-951, n ML 10302) are currently undergoing clinical o Blocks dopamine receptors in chemoreceptor i t studies. Other prokinetics, such as domperidone, c trigger zone of the CNS (2) A are not yet approved in the US, although are used in f Enhances the response to acetylcholine of o other countries. tissue in the upper GI tract, causing enhanced m s i n motility and accelerated gastric emptying a DELAYED GASTRIC EMPTYING OR h without stimulating gastric, biliary, or c G A S T R O E S O P H A G E A L R E F L U X e pancreatic secretions. -

Tegaserod in the Treatment of Constipation-Predominant Functional Gastrointestinal Disorders

DRUG PROFILE Tegaserod in the treatment of constipation-predominant functional gastrointestinal disorders Anurag Agrawal & Irritable bowel syndrome is a common condition for which, until recently, treatment Peter Whorwell† options have been limited. Tegaserod has selective serotonin subtype 4 receptor agonist †Author for correspondence activity and acts by increasing gastrointestinal motility, secretion and possibly reducing ERC Building, First Floor, Wythenshawe Hospital, visceral sensitivity. It has been developed to treat patients with irritable bowel syndrome Southmoor Road, who suffer from abdominal pain, constipation and bloating. Studies so far suggest that it is Manchester, M23 9LT, an effective treatment for these symptoms with an excellent safety profile. Its role in other UK Tel.: +44 161 291 5813 functional gastrointestinal disorders, such as functional dyspepsia, is still being assessed. Fax: +44 161 291 4184 This review describes the structure, pharmacokinetic and pharmacodynamic properties of tegaserod and its effect on gastrointestinal physiology, as well as its clinical utility. Irritable bowel syndrome (IBS) is the most com- drugs such as antidiarrheals, laxatives, antispas- mon condition dealt with by gastroenterolo- modics and antidepressants. Behavioral therapy gists, accounting for up to 30% of their practice is sometimes tried in patients who do not and 10% of primary care case loads [1]. It is respond to conventional treatment. characterized by abdominal pain or discomfort In addition to its costs to the patient, IBS also often related to a change in bowel habit and fre- has a significant direct and indirect economic quently exacerbated by eating. Investigation burden. The direct cost in terms of healthcare reveals no structural abnormality, although a utilization has been estimated to be between variety of gastrointestinal (GI) physiological US$1.7–10 billion/year in the USA alone. -

Zelnorm®) for Safety Reasons

NATIONAL PBM BULLETIN April 3, 2007 DEPARTMENT OF VETERANS AFFAIRS VETERANS HEALTH ADMINISTRATION PHARMACY BENEFITS MANAGEMENT STRATEGIC HEALTHCARE GROUP, MEDICAL ADVISORY PANEL, AND CENTER FOR MEDICATION SAFETY (VA MEDSAFE) Discontinued Marketing of Tegaserod (Zelnorm®) for Safety Reasons I. ISSUE – On March 30, 2007, Novartis suspended US marketing and sales of tegaserod in compliance with the Food and Drug Administration’s (FDA) request which was based on a retrospective analysis of pooled clinical trial data showing increased risk of serious cardiovascular adverse events associated with use of tegaserod compared to placebo. II. BACKGROUND – Novartis reported results of an analysis involving 29 short-term randomized, controlled clinical trials of tegaserod which included over 18,000 patients in the clinical trial database. Serious cardiovascular events (angina, MI, and stroke) occurred in 13 of 11,614 (0.11%) tegaserod-treated patients compared to 1 of 7,031 (0.01%) placebo-treated patients (p=0.024). All patients affected had pre-existing cardiovascular disease. III. DISCUSSION – Tegaserod was approved in July 2002 for the short-term treatment of constipation-predominant irritable bowel syndrome (IBS) in women. Subsequently, the drug was approved in August 2004 for the treatment of chronic constipation in men and women under age 65. In January 2006, VA PBM provided criteria for nonformulary use of tegaserod based on available evidence reviewed in the PBM Drug Monograph for tegaserod. A preliminary utilization evaluation was conducted by VAMedSAFE to look at variations in prescribing patterns. Although not an approved indication, patients with gastroesophageal reflux disease (GERD) appeared to be the largest users of tegaserod. -

Zelnorm Page: 1 of 5

Federal Employee Program® 1310 G Street, N.W. Washington, D.C. 20005 202.942.1000 Fax 202.942.1125 5.50.25 Section: Prescription Drugs Effective Date: April 1, 2020 Subsection: Gastrointestinal Agents Original Policy Date: April 26, 2019 Subject: Zelnorm Page: 1 of 5 Last Review Date: March 13, 2020 Zelnorm Description Zelnorm (tegaserod) Background Zelnorm is an agonist of serotonin type-4 (5-HT4) receptors that stimulates the peristaltic reflex and intestinal secretion, inhibits visceral sensitivity, enhances basal motor activity, and normalizes impaired motility throughout the gastrointestinal tract (1). Regulatory Status FDA-approved indication: Zelnorm is a serotonin-4 (5-HT4) receptor agonist indicated for treatment of adult women less than 65 years of age with irritable bowel syndrome with constipation (IBS-C) (1). Limitations of Use: The safety and effectiveness of Zelnorm in men with IBS-C have not been established (1). Zelnorm is contraindicated in patients with: (1) 1. A history of myocardial infarction (MI), stroke, transient ischemic attack (TIA), or angina. 2. A history of ischemic colitis or other forms of intestinal ischemia. 3. Severe renal impairment (eGFR < 15 mL/min/1.73 m2) or end-stage renal disease. 4. Moderate and severe hepatic impairment (Child-Pugh B or C). 5. A history of bowel obstruction, symptomatic gallbladder disease, suspected sphincter of Oddi Dysfunction, or abdominal adhesions. 5.50.25 Section: Prescription Drugs Effective Date: April 1, 2020 Subsection: Gastrointestinal Agents Original Policy Date: April 26, 2019 Subject: Zelnorm Page: 2 of 5 The safety and effectiveness of Zelnorm in pediatric patients less than 18 years of age have not been established (1). -

Rifaximin (XIFAXAN)

Rifaximin (XIFAXAN) for Irritable Bowel Syndrome with Diarrhea National Drug Monograph March 2016 VA Pharmacy Benefits Management Services, Medical Advisory Panel, and VISN Pharmacist Executives The purpose of VA PBM Services drug monographs is to provide a focused drug review for making formulary decisions. Updates will be made when new clinical data warrant additional formulary discussion. Documents will be placed in the Archive section when the information is deemed to be no longer current. FDA Approval Information Description/Mechanism of Minimally absorbed, broad-spectrum antibacterial that inhibits bacterial RNA Action synthesis. The specific mechanism of action of rifaximin in irritable bowel syndrome (IBS) has not been determined. The most likely mechanism of rifaximin is reduction in overall bacterial load, particularly in the large bowel1; however, rifaximin also seems to modulate gut microenvironment and produce cytoprotective effects.2 Indication(s) Under Review in Treatment of IBS with diarrhea (IBS-D) in adults this Document Dosage Form(s) Under 550 mg tablet Review REMS REMS No REMS Postmarketing Requirements Pregnancy Rating No data available on pregnant women to inform any drug associated risks. Executive Summary Efficacy Rifaximin had a small, statistically significant beneficial effect relative to placebo in global IBS symptom response using pooled data: 40.7% vs. 31.7%, with a difference of 9.0 percentage points, p < 0.001; NNT = 11. Rifaximin had a small, statistically significant beneficial effect relative to placebo in terms of the response rate for adequate relief of bloating (the key secondary efficacy measure): 40.2% vs. 30.3%, difference of 9.9 percentage points, p < 0.001; NNT = 10 (pooled results). -

Emerging Drug List — Tegaserod Hydrogen Maleate

Emerging Drug List CANADIAN COORDINATING OFFICE FOR HEALTH TEGASEROD HYDROGEN MALEATE TECHNOLOGY ASSESSMENT NO. 32 MAY 2002 Generic (Trade Name): Tegaserod hydrogen maleate (Zelnorm™) Manufacturer: Novartis Pharmaceuticals Indication: For the symptomatic treatment of irritable bowel syndrome with constipation (IBS-C) in female patients whose main symptoms are constipation and abdominal pain and/or discomfort. The maximum duration of treatment should be no longer than 12 weeks and the treatment should be discontinued if there has been no response after four weeks. Current Regulatory Zelnorm™ was approved by Health Canada's Therapeutic Products Directorate on Status: March 12, 2002. Launch in Canada is impending1. Description: Tegaserod is a partial agonist of 5-HT4 receptors, a new chemical class of proki- netic medications. This subclass of receptors is found throughout the gastroin- testinal tract, and it is postulated that when activated, they minimize the percep- tion of discomfort, pain and constipation associated with IBS. Tegaserod exhibits a low absolute bioavailablity after oral dosing (11%), and the time to achieve a peak concentration ranges from one to 1.3 hours.2 It is highly protein bound (98% to α1-acid glycoprotein) and its terminal half-life is 11± 5 hours. Diarrhea, abdominal pain, headache, flatulence and fatigue are the most frequently report- ed adverse events. Compared to placebo, no differences in QTc interval prolon- gations have been reported in clinical trials, although syncope (an effect seen with cisapride) has been observed at a greater frequency in tegaserod users. The recommended dosage of Zelnorm™ is 6 mg twice daily, administered prior to a meal with water. -

Zelnorm Fda Ac Backgrounder Errata

ZELNORM FDA AC BACKGROUNDER ERRATA Items from the FDA Briefing Document issued for the Advisory Committee meeting held October 17, 2018. The text for correction is identified by a strikethrough, with correction following in double underline, unless otherwise specified. 1. The following paragraph appears on page 26: From a mechanistic perspective, the potential for tegaserod to cause CV ischemia is not well understood. Available 5-HT receptor affinity and functional response data for tegaserod indicate that the drug binds to 5-HT4 receptors with high affinity as an agonist, and binds with moderate to high affinities for 5-HT1 receptor subtypes, as an agonist. Tegaserod also has antagonistic activity at 5-HT2 receptor subtypes. This paragraph is revised to the following: From a mechanistic perspective, the potential for tegaserod to cause CV ischemia is not well understood. Available 5-HT receptor affinity and functional response data for tegaserod indicate that the drug binds to 5-HT4 receptors with high affinity as an agonist, and binds with moderate to high affinities for 5-HT1 and 5-HT2 receptor subtypes, as an agonist. Tegaserod also has antagonistic activity at the 5-HT1 and 5-HT2 receptor subtypes that mediate vasoconstriction [24]. Based on the Cmax of tegaserod (10 nM) at the recommended dose, it is likely that tegaserod binding to 5-HT receptors in humans will be mostly limited to the 5-HT4 and 5-HT2B subtypes (see Table 15 below). 2. The following paragraph appears on page 26: Intravenous administration of 1 mg/kg in rats (1.6 times the recommended oral human dose (6 mg/dose) based on mg/m2) produced reductions in systolic and diastolic blood pressure, with no effects observed at 0.1 mg/kg or lower. -

Albert Hofmann's Pioneering Work on Ergot Alkaloids and Its Impact On

BIRTHDAY 83 CHIMIA 2006, 60, No. 1/2 Chimia 60 (2006) 83–87 © Schweizerische Chemische Gesellschaft ISSN 0009–4293 Albert Hofmann’s Pioneering Work on Ergot Alkaloids and Its Impact on the Search of Novel Drugs at Sandoz, a Predecessor Company of Novartis Dedicated to Dr. Albert Hofmann on the occasion of his 100th birthday Rudolf K.A. Giger* and Günter Engela Abstract: The scientific research on ergot alkaloids is fundamentally related to the work of Dr. Albert Hofmann, who was able to produce, from 1935 onwards, a number of novel and valuable drugs, some of which are still in use today. The complex chemical structures of ergot peptide alkaloids and their pluripotent pharmacological activity were a great challenge for Dr. Hofmann and his associates who sought to unravel the secrets of the ergot peptide alkaloids; a source of inspiration for the design of novel, selective and valuable medicines. Keywords: Aminocyclole · Bromocriptine Parlodel® · Dihydroergotamine Dihydergot® · Dihydro ergot peptide alkaloids · Ergobasin/ergometrin · Ergocornine · Ergocristine · α- and β-Ergocryptine · Ergolene · Ergoline · Ergoloid mesylate Hydergine® · Ergotamine Gynergen® · Ergotoxine · Lisuride · Lysergic acid diethylamide LSD · Methylergometrine Methergine® · Methysergide Deseril® · Paspalic acid · Pindolol Visken® · Psilocybin · Serotonin · Tegaserod Zelmac®/Zelnorm® · Tropisetron Navoban® Fig. 1. Albert Hofmann in 1943, 1979 and 2001 (Photos in 2001 taken by J. Zadrobilek and P. Schmetz) Dr. Albert Hofmann (Fig. 1), born on From the ‘Ergot Poison’ to *Correspondence: Dr. R.K.A. Giger January 11, 1906, started his extremely Ergotamine Novartis Pharma AG NIBR Global Discovery Chemistry successful career in 1929 at Sandoz Phar- Lead Synthesis & Chemogenetics ma in the chemical department directed The scientific research on ergot alka- WSJ-507.5.51 by Prof. -

I NDA/BLA Multi-Disciplinary Review and Evaluation

NDA 021200 S015 Zelnorm (tegaserod) NDA/BLA Multi-Disciplinary Review and Evaluation Application Type sNDA Application Number(s) 021200, s015 Priority or Standard Standard Submit Date(s) 2/26/2018 Received Date(s) 2/26/2018 PDUFA Goal Date 12/26/2018 Division/Office DGIEP/ODE III Review Completion Date 3/22/2019 Established/Proper Name Tegaserod Maleate (Proposed) Trade Name Zelnorm Pharmacologic Class Serotonin (5-HT4) receptor agonist Applicant Sloan Pharma S.a.r.l, Bertrange, Cham Branch Authorized US Agent: US WorldMed, LLC Dosage form Oral tablets Applicant proposed Dosing 6 mg twice daily Regimen Applicant Proposed Treatment of women less than 65 years with irritable bowel Indication(s)/Population(s) syndrome with constipation (IBS-C). (Proposed contraindications: history of myocardial infarction, stroke, transient ischemic attack, or angina, and more than one cardiovascular risk factor: hypertension, tobacco use, diabetes, hypercholesterolemia, age ≥55 years, and obesity). Recommendation on Approval Regulatory Action Recommended Treatment of adult women less than 65 years of age with irritable Indication(s)/Population(s) bowel syndrome with constipation (if applicable) (Contraindication: history of myocardial infarction, stroke, transient ischemic attack, or angina). Recommended Dosing 6 mg twice daily Regimen i Reference ID: 4407897 NDA 021200 S015 Zelnorm (tegaserod) Table of Contents Reviewers of Multi-Disciplinary Review and Evaluation .............................................. 1 Glossary ........................................................................................................................ -

Therapeutic Class Overview Irritable Bowel Syndrome and Constipation Agents

Therapeutic Class Overview Irritable Bowel Syndrome and Constipation Agents INTRODUCTION Irritable bowel syndrome (IBS) is a gastrointestinal disorder that most commonly manifests as chronic abdominal pain and altered bowel habits in the absence of any organic disorder (Wald 2017). IBS may consist of diarrhea-predominant (IBS-D), constipation-predominant (IBS-C), IBS with a mixed symptomatology (IBS-M), or unclassified IBS (IBS-U). Switching between the subtypes of IBS is also possible (Ford et al 2018). IBS is a functional disorder of the gastrointestinal tract characterized by symptoms of abdominal pain, discomfort and bloating, and abnormal bowel habits with bouts of diarrhea and/or constipation. The exact pathogenesis of the disorder is unknown; however, it is believed that altered gastrointestinal tract motility, visceral hypersensitivity, autonomic dysfunction, and psychological factors indicate disturbances within the enteric nervous system, which controls the gastrointestinal system (Andresen et al 2008, Ford et al 2009, Quigley et al 2012, World Gastroenterology Organization [WGO] 2015). Prevalence estimates of IBS range from 10 to 12%, and it typically occurs in young adulthood (Ford et al 2018). IBS-D is more common in men, and IBS-C is more common in women (WGO 2015). Symptoms of IBS often interfere with daily life and social functioning (WGO 2015). The general goals of therapy in IBS are to alleviate the patient’s symptoms and to target any specific exacerbating factors (eg, medications, dietary changes), concerns about serious illness, stressors, or potential psychiatric comorbidities that may exist (Wald 2017). Non-pharmacological interventions to combat IBS symptoms include dietary modifications such as exclusion of gas- producing foods (eg, beans, prunes, Brussel sprouts, bagels, etc.), and consumption of probiotics, as well as psychosocial therapies (eg, hypnosis, biofeedback, etc.) (Ford et al 2018). -

A Brief Summary for 5-HT Receptors

ndrom Sy es tic & e G n e e n G e f T o Watry and Lu, J Genet Syndr Gene Ther 2013, 4:2 Journal of Genetic Syndromes h l e a r n a r p DOI: 10.4172/2157-7412.1000129 u y o J & Gene Therapy ISSN: 2157-7412 Short Commentary Open Access A Brief Summary for 5-HT Receptors Watry S and Lu J* Department of Neuroscience and Department of Neurology, School of Medicine and Public Health, Waisman Center, University of Wisconsin, Madison, WI 53705, USA As a group of G protein-coupled receptors (GPCRs) and ligand- (Anpirtoline) [42]; CGS 12066B [43]; SB 216641 [44]; RU 24969 [45]; gated ion channels (LGICs), the serotonin (5-HT) receptors are CP 93129 [46]. found in the central and peripheral nervous systems. After activated Application value: Depression [47]; Anxiety [48]; Aggression by the neurotransmitter serotonin, their natural ligand, 5-HT [49]; Migraine [50]; Drug Addicton [51]; increased locomotor activity receptors mediate both excitatory and inhibitory neurotransmission [52]; brain reward mechanisms (agonist); Alcoholism [53]; Sleep [54]; by modulating the release of many neurotransmitters, including hypothermia [55]. glutamate, GABA, dopamine, epinephrine/norepinephrine, and acetylcholine, as well as many hormones, including oxytocin, prolactin, Receptor: 5-HT 1D [56] vasopressin, cortisol, corticotropin, and substance P, among others. 5-HT receptors influence various biological and neurological processes Structure: GPCR [56]. such as aggression, anxiety, appetite, cognition, learning, memory, Localization: Raphe nuclei; Cortex, Caudate, Globus Pallidus mood, nausea, sleep, and thermoregulation. Accordingly, 5-HT [57]; Basal Ganglia, Substantia Nigra, Hippocampal Formation, receptors are the target of a variety of pharmaceutical drugs, including Raphe Nuclei [58]; Caudate Nucleus, Lateral Geniculate Nuclei, Spinal many antidepressants, antipsychotics, anorectics, antiemetics, Trigominal Nucleus [32]; Globus Pallidus [59].