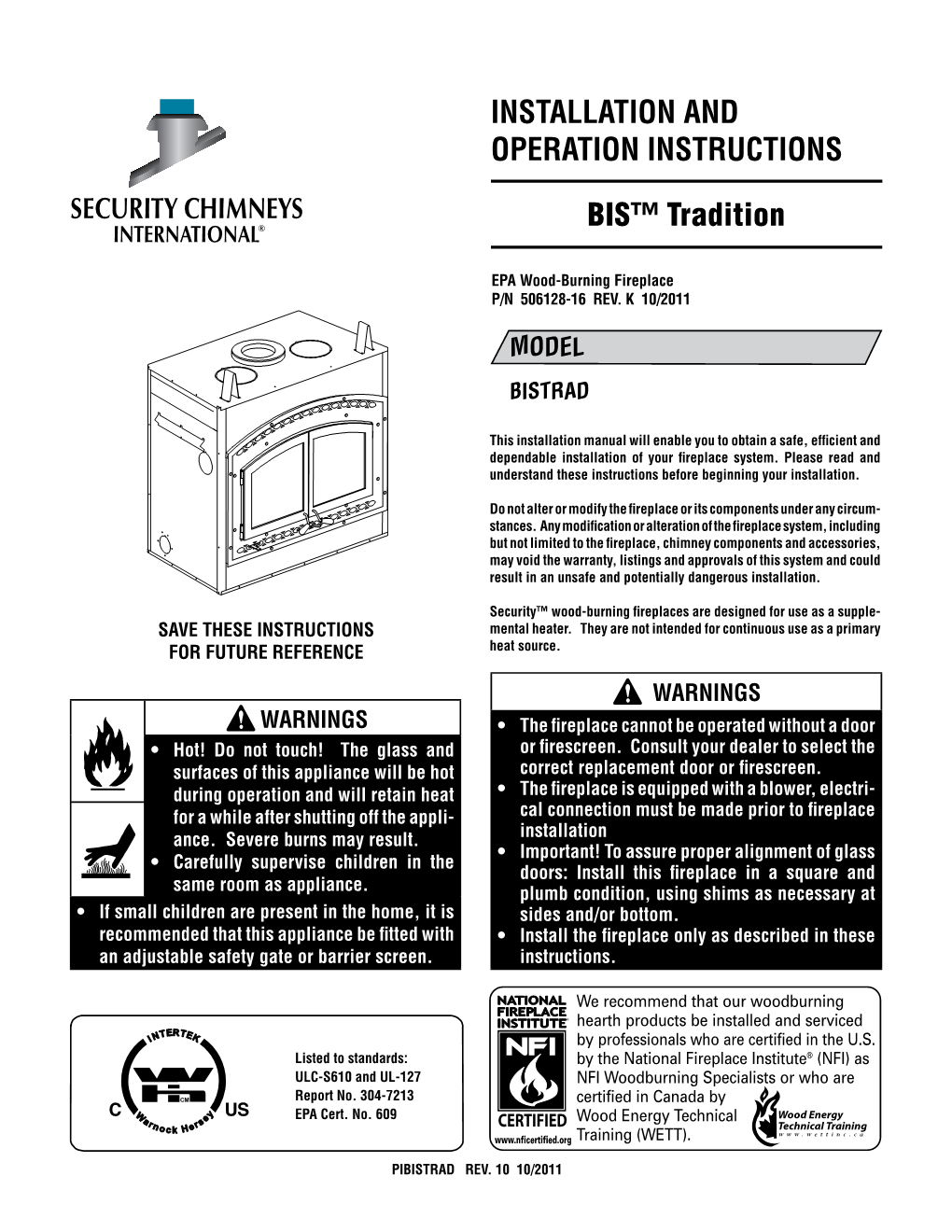

BIS™ Tradition INSTALLATION and OPERATION INSTRUCTIONS

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Solar Updraft Tower : Das Aufwindkraftwerk Motivation and Concept - Text

The Solar Updraft Tower : Das Aufwindkraftwerk Motivation and Concept - Text Joerg Schlaich and Rudolf Bergermann The most significant problems of our time, poverty in the Third World and the climate change are interlinked through energy supply and can be solved, if we only want to! The industrialized countries pollute the worldwide climate with their fossil-fuelled power generation. The poor are poor because they cannot afford sufficient energy supply and the population keeps growing. (Fig. 1) If the billions of people who must do without sufficient energy supply would have to cover their energy needs with coal, oil and gas, the climate could not be saved and the environment would be destroyed. Hence, poverty and climate problems can only be solved with global concepts, mutually and equally beneficial to the poor and to the industrialized countries. The poor countries on the „southern hemisphere“, especially the African, have one advantage over the rich countries in the „northern hemisphere“: Sun + Desert, i.e. intensive solar radiation on agriculturally futile land. (Fig. 2) If these poor countries had large scale affordable solar power plants, - affordable because they were built mainly with their own resources and skills -, and which they did not need to import at exorbitant cost, they would profit twice: by their inexhaustible, affordable power supply and by innumerable new jobs. “The Taliban aren’t fighting for religion but for money. If they had jobs, they would stop fighting!” Sham Sher Khan from TIME, April 20, 2009 As electric energy can be transported over very large distances with surprisingly little loss they could export their solar electricity to the industrialized countries. -

A Huff and a Puff, and It Blew the Chimney Down

A HUFF, AND A PUFF, AND… IT BLEW THE CHIMNEY DOWN Kerry S. Lee, P.E., MBA, M.ASCE 1 Gary S. Dunlap, AIA 2 Daniel M. Killian, P.E., B.S. 3 1 Director of Engineering, Nelson Architectural Engineers, Inc., 2740 Dallas Parkway, Suite 220, Plano, Texas 75093; email: [email protected]; phone: 469-429-9000 2 Assistant Director of Architecture, Nelson Architectural Engineers, Inc., 2740 Dallas Parkway, Suite 220, Plano, Texas 75093; email: [email protected]; phone: 469-429-9000 3 Project Director, Nelson Architectural Engineers, Inc., 2740 Dallas Parkway, Suite 220, Plano, Texas 75093; email: [email protected]; phone: 469-429-9000 Abstract This paper will present case studies and assessment of collapses of tall, free standing residential masonry chimneys resulting from windstorms in North Texas. The case studies will outline the assessment of the causes of the collapses and a discussion of design and/or construction defects. A review of limited and highly lacking documentation on design, construction and code requirements governing the architectural and structural “design” and construction of residential chimneys will be conducted. The paper will provide a discussion of the lack of design standards and poor construction practices used for residential load-bearing masonry chimneys. This paper will illustrate how the lack of design, construction, and code requirements results in chimneys lacking sufficient capacity to resist below design wind loads leading to unsafe conditions. It is only a matter of time before the collapse of one of these elevated masonry chimney “missiles” results in severe injury or death of an inhabitant. Introduction The majority of residential structures being built throughout the country today rely on construction requirements outlined within the International Residential Code (IRC). -

Renaissance Linear 50 Sp Owner's Manual

RENAISSANCE LINEAR 50 SP OWNER’S MANUAL Keep these instructions for future use. RL50SP-OWAN - 2020-02 2 Dear Customer, The Renaissance LINEAR 50 SP is a member of the Renaissance Fireplaces family of ultra-high-end fireplaces. The LINEAR 50 SP is unique in its design. The 50" wide opening provides an enormous linear space to watch the fire. It combines technology with elegance, allowing you to enjoy an open fire in a modern fashion. We have designed your new fireplace to be easy to install, operate and maintain. It is in your best interest to become familiar with it. Congratulations on your choice of the LINEAR 50 SP. We at Renaissance Fireplaces are confident that you have purchased a fireplace that burns beautifully, without compromise. Sincerely, Renaissance FireplacesTM Team August 2017 TABLE OF CONTENTS GETTING STARTED: WHAT TO KNOW AND DO BEFORE THE FIRST FIRING 4 IMPORTANT SAFETY AND OPERATION PRECAUTIONS 4 Do's and Don'ts 4 Avoiding Excessive Temperatures 5 FEATURES 6 Unique Decorative Fireplace 6 Options 6 PROPER FUEL 7 What to Burn at All Times 7 We strongly recommend that our What to Burn Occasionally and Carefully 7 products be installed and serviced What Never to Burn 8 by professionals who are certified FIRST FIRES 8 by the National Fireplace Institute OPERATING THE FIREPLACE 8 in the U.S. or by Wood Energy BEFORE FIREBUILDING 8 Technology Transfer Inc. in Glass Door Operation 8 Canada. Outside Air Control 9 Chimney Damper 9 BUILDING THE FIRE 10 CONTROLLING THE FIRE 10 REFUELING 10 MAINTENANCE 11 ROUTINE TASKS 11 Disposal of Ashes 11 General Cleaning 11 Paint 11 Glass Cleaning 11 GASKETS 12 ADJUSTING THE DOOR LATCH 13 CHIMNEY CLEANING 13 REPLACEMENT PARTS 13 LISTING LABEL 14 WARRANTY 15 GETTING STARTED: WHAT TO KNOW AND DO BEFORE THE FIRST FIRING 3 GETTING STARTED: WHAT TO KNOW AND DO BEFORE THE FIRST FIRING 4 GETTING STARTED: WHAT TO KNOW AND DO BEFORE THE FIRST FIRING IMPORTANT SAFETY AND OPERATION PRECAUTIONS DO'S AND DON'TS If this fireplace is not properly installed, a house fire could result. -

Wind- Chimney

WIND-CHIMNEY Integrating the Principles of a Wind-Catcher and a Solar-Chimney to Provide Natural Ventilation A Thesis presented to the Faculty of California Polytechnic State University, San Luis Obispo In Partial Fulfillment of the Requirements for the Degree Master of Science in Architecture by Fereshteh Tavakolinia December 2011 WIND-CHIMNEY Integrating the Principles of a Wind-Catcher and a Solar-Chimney to Provide Natural Ventilation © 2011 Fereshteh Tavakolinia ALL RIGHTS RESERVED ii COMMITTEE MEMBERSHIP TITLE: WIND-CHIMNEY Integrating the Principles of a Wind-Catcher and a Solar-Chimney to Provide Natural Ventilation AUTHOR: Fereshteh Tavakolinia DATE SUBMITTED: December 2011 COMMITTEE CHAIR: James A. Doerfler, Associate Department Head COMMITTEE MEMBER: Jacob Feldman, Professor iii WIND-CHIMNEY Integrating the principles of a wind-catcher and a solar chimney to provide natural ventilation Fereshteh Tavakolinia Abstract This paper suggests using a wind-catcher integrated with a solar-chimney in a single story building so that the resident might benefit from natural ventilation, a passive cooling system, and heating strategies; it would also help to decrease energy use, CO2 emissions, and pollution. This system is able to remove undesirable interior heat pollution from a building and provide thermal comfort for the occupant. The present study introduces the use of a solar-chimney with an underground air channel combined with a wind-catcher, all as part of one device. Both the wind-catcher and solar chimney concepts used for improving a room’s natural ventilation are individually and analytically studied. This paper shows that the solar-chimney can be completely used to control and improve the underground cooling system during the day without any electricity. -

The Impact of Air Well Geometry in a Malaysian Single Storey Terraced House

sustainability Article The Impact of Air Well Geometry in a Malaysian Single Storey Terraced House Pau Chung Leng 1, Mohd Hamdan Ahmad 1,*, Dilshan Remaz Ossen 2, Gabriel H.T. Ling 1,* , Samsiah Abdullah 1, Eeydzah Aminudin 3, Wai Loan Liew 4 and Weng Howe Chan 5 1 Faculty of Built Environment and Surveying, Universiti Teknologi Malaysia, Johor 81300, Malaysia; [email protected] (P.C.L.); [email protected] (S.A.) 2 Department of Architecture Engineering, Kingdom University, Riffa 40434, Bahrain; [email protected] 3 School of Civil Engineering, Faculty of Engineering, Universiti Teknologi Malaysia, Johor 81300, Malaysia; [email protected] 4 School of Professional and Continuing Education, Faculty of Engineering, Universiti Teknologi Malaysia, Johor 81300, Malaysia; [email protected] 5 School of Computing, Faculty of Engineering, Universiti Teknologi Malaysia, Johor 81300, Malaysia; [email protected] * Correspondence: [email protected] (M.H.A.); [email protected] (G.H.T.L.); Tel.: +60-19-731-5756 (M.H.A.); +60-14-619-9363 (G.H.T.L.) Received: 3 September 2019; Accepted: 24 September 2019; Published: 16 October 2019 Abstract: In Malaysia, terraced housing hardly provides thermal comfort to the occupants. More often than not, mechanical cooling, which is an energy consuming component, contributes to outdoor heat dissipation that leads to an urban heat island effect. Alternatively, encouraging natural ventilation can eliminate heat from the indoor environment. Unfortunately, with static outdoor air conditioning and lack of windows in terraced houses, the conventional ventilation technique does not work well, even for houses with an air well. Hence, this research investigated ways to maximize natural ventilation in terraced housing by exploring the air well configurations. -

Don't Let Dollars Disappear up Your Chimney!

ENERGY SAVINGTIPS DON’T LET DOLLARS DISAPPEAR UP YOUR CHIMNEY! You wouldn’t leave a window wide open in cold weather. Having a fireplace with an open flue damper is the same as having a window open. That sends precious winter heat and money right up the chimney! Here’s how you can heat your home, and not the neighborhood! KEEP THE FIREPLACE DAMPER CLOSED WHEN THE FIREPLACE IS NOT BEING USED The damper is a flap inside the chimney or flue. It has an open and a closed position. When a fire is burning, the damper should be in the open position to allow smoke to escape up the fireplace flue and out the chimney. When you’re not using the fireplace, the damper should be closed. If you can’t see the handle or chain that opens and closes the damper, use a flashlight and look up inside the chimney flue. The handle could be a lever that moves side to side or back and forth. If a chain operates the damper, you may have to pull both sides to determine which one closes or opens the damper. KEEP YOUR HEAT IN YOUR HOME! Even the most energy efficient homes can fall victim to fireplace air leaks. Your fireplace may be reserved for a handful of special occasions or especially cold nights. When it’s not in use, though, your home loses heat – and costs you money – without you knowing it. Using the heat from your fireplace on a cold winter night may be cozy, but that fire is a very inefficient way to warm up the room. -

Recommended Practices for Masonry Fireplace and Chimney Construction

BALANCING THE VENTILATION TIPS OF SAFE FIREPLACE REFERENCES In order for a fireplace, which utilizes OPERATIONS Published by the New York State Concrete Masonry Association natural draft to function properly, New York State Fire Prevention A fireplace fire, properly laid and fed and Building Code a supply of makeup air must be is easy to tend to and trouble free. Here available to replace the air exhausted is a good method for building a fire. National Fire Protection up the chimney. In older homes there Be sure the damper is open before Association, Quincy, MA is often enough leakage around doors lighting the fire! and windows to provide this air. In International Code Council Use a small amount of paper and newer, tighter homes another source International Building Code of air may need to be provided. Before a moderate number of kindling wood lighting the fire, use incense or a candle pieces to lay down the base. Place International Residential Code to determine if there is an updraft or a three small split logs directly on top. Country Club Hills, Illinois Space the logs to allow air to flow down draft in the chimney. If there is USA - Clay Flue Lining Institute no updraft try cracking open a window freely. National Concrete Masonry or door to provide a source of air to the Use wadded paper wand to light the RECOMMENDED PRACTICES FOR MASONRY room. If any problem persists you may fire. Hold the burning wand at damper Association, Herndon, VA FIREPLACE AND CHIMNEY CONSTRUCTION need to locate other sources of air level to start the draft, then lower it to Brick Industry Association of entering or being exhausted from the the paper/kindling stack. -

Method of Manufacturing Densified Firelog from Unwanted and Diseased Wood, and Method of Doing Business Regarding Same

Europäisches Patentamt *EP001595663A2* (19) European Patent Office Office européen des brevets (11) EP 1 595 663 A2 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: (51) Int Cl.7: B27N 3/28, B27N 1/00 16.11.2005 Bulletin 2005/46 (21) Application number: 05291045.2 (22) Date of filing: 13.05.2005 (84) Designated Contracting States: (72) Inventors: AT BE BG CH CY CZ DE DK EE ES FI FR GB GR • Young, Jennifer J. HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR Los Gatos California 95033 (US) Designated Extension States: • Weissman, Gregg D. AL BA HR LV MK YU Watsonville California 95076 (US) (30) Priority: 14.05.2004 US 571108 P (74) Representative: Burbaud, Eric Cabinet Plasseraud (71) Applicant: Summit Views Llc 65/67 rue de la Victoire 95030 Los Gatos, California (US) 75440 Paris Cedex 09 (FR) (54) Method of manufacturing densified firelog from unwanted and diseased wood, and method of doing business regarding same (57) A method of manufacturing firelogs from un- into a firelog. The sale of the firelog can then be used wanted or diseased forest wood. The method includes to pay for further gathering of the unwanted wood. More- the steps of gathering such unwanted wood products over, the machines used to grind and dry the material from a forest and on-site grinding and drying those wood can be powered by burning the unwanted firewood as products into ground material prior to extruding same well. EP 1 595 663 A2 Printed by Jouve, 75001 PARIS (FR) 1 EP 1 595 663 A2 2 Description [0007] We were also aware of the possibilities of the synergy between the need of public sector entities to Cross-Reference to Related Application perform fuel reduction, and the need for raw materials for firelog production. -

Fireplaces & Chimneys

Fireplaces & Chimneys Fireplaces, Accessories & Venting Solutions ® We Make Fire Better. Custom Luxury Fireplaces Extracted from Iceland’s Mt. Hekla volcano, Isokern brand products have been made from the cleanest, purest pumice for over 80 years. Our masonry components cradle the raw power of fire in the safest, most energy-efficient material on earth. Totally customizable, Isokern allows architects and their clients to pursue their most inspired designs, while connecting with the natural beauty of fire. A Name Built on reliability for years. Since 1989, we have proudly provided exceptional products combined with unmatched customer service from our 8 solution centers and dedicated network of over 400 dealers. >> ICELAND Contents. Did You The Standard ..............................................1 know? Specifications........................................................page 2 Our pumice ships directly from The Magnum ....................................................3 the Mount Hekla Volcano in Iceland to our state-of-the-art Specifications.........................................................page 5 automated manufacturing The Magnum+ ..................................................7 facility in Chesapeake, Virginia. Specifications.........................................................page 9 The Maximus ............................................11 “ Specifications.......................................................page 12 The Bvetto ................................................13 Specifications.......................................................page -

The Chimney-Graft Technique for Preserving Supra-Aortic Branches: a Review

Perspective The chimney-graft technique for preserving supra-aortic branches: a review Konstantinos G. Moulakakis1,2, Spyridon N. Mylonas1,2,3, Ilias Dalainas1, George S. Sfyroeras1, Fotis Markatis1, Thomas Kotsis3, John Kakisis1, Christos D. Liapis1 1Department of Vascular Surgery, Athens University Medical School, Attikon University Hospital, Athens, Greece; 2The Systematic Review Unit, The Collaborative Research (CORE) Group, Sydney, Australia; 3Vascular Unit, 2nd Clinic of Surgery, Aretaieion Hospital, Medical School, University of Athens, Athens, Greece Corresponding to: Konstantinos G. Moulakakis, MD, Ph.D, MSc, FEBVS. Athens University Medical School, Attikon University Hospital, Athens, Greece, Rimini 1 Str, Haidari, Athens, 12462 Greece. Email: [email protected]. Evolution in the endovascular era has influenced the management of aortic arch pathologies. “Chimney” or “snorkel” graft technique has been used as an alternative in high risk patients unfit for open repair. We reviewed the published literature on the chimney graft technique for preservation of the supra-aortic branches in order to provide an extensive insight of its feasibility and efficacy and investigate its outcomes. 18 reports were identified, with a total of 124 patients and 136 chimney. Primary technical success was achieved in 123/124 patients (99.2%). The perioperative mortality rate was 4.8% and the stroke rate was 4%, while events of spinal cord ischemia were rare. The overall endoleak rate was 18.5%; 13 patients (10.5%) developed a type I endoleak and 10 (8%) patients a type II endoleak. During a median follow-up period of 11.4 months (range, 0.87-20.1 months) all implanted chimney grafts remained patent. -

Installation and Operation Manual

INSTALLATION AND OPERATION INSTRUCTIONS Astria® Wood burning Residential and Outdoor Fireplace with Catalyst MODELS PFS ® CAT36P2 CAT36P3 P126767-01 C US P/N 126767-01 Rev. B 10/2015 REPORT NO. 10-078 SAVE THIS BOOK This book is valuable. In addition to instructing you on how to install and maintain your appliance, it also contains information that will enable you to obtain replacement parts or accessory items when needed. Keep it with your other important papers. INSTALLER: Leave this manual with the appliance. Installateur : Laissez cette notice avec l’appareil. CONSUMER: Retain this manual for future reference. Consommateur : Conservez cette notice pour consultation ultérieure. This wood burning fireplace complies with UL127 Ce foyer au bois est conforme aux UL 127 CAN/ULC- CAN/ULC-S610-M87 standard as a FACTORY S610-M87 norme comme une USINE CONSTRUITE BUILT FIREPLACE. CHEMINÉE. This fireplace is approved for use as a wood burning fireplace or for use with a vented gas log approved to ANSI Z21.60 or Z21.84 standards or for use with a vent-free gas log heater approved to ANSI Z21.11.2 standard. An IHP hood must be installed when using a vent-free log heater (see Accessories, page 20). FOR CANADA: The authority having jurisdiction POUR LE CANADA: L’autorité compétente (comme le (such as the municipal building department, fire service municipal du bâtiment, les pompiers, etc.) doit department, etc.) should be contacted before être contacté avant l’installation afin de déterminer la installation to determine the need to obtain a permit. nécessité d’obtenir un permis. -

Heartwood Free Download

HEARTWOOD FREE DOWNLOAD James Lee Burke | 400 pages | 01 Aug 2000 | Random House Publishing Group | 9780440224013 | English | New York, NY, United States Holding small treasures since 1978. Hardwood lignin is primarily derived from sinapyl alcohol and coniferyl alcohol. Heartwood is often visually distinct from the living sapwood, and can be distinguished in a cross-section where the boundary will Heartwood to follow the growth rings. Scroll What we offer Diversified portfolios for all of life's journeys. For a small forest, see Heartwood. See also: Janka hardness test. Dictionary Entries near heartwood heartweed heart- whole heartwise heartwood heartworm heart-wrenching hearty See More Nearby Heartwood. Madison, WI. Springer-Verlag, Berlin. This process is known as secondary growth ; it is the result of cell division in the vascular cambiuma lateral meristem, and subsequent Heartwood of Heartwood new cells. When each of us started out on our path a seed was sown in Heartwood hearts. Journal of Horticultural Research. External Websites. As a tree reaches maturity its crown becomes more open and the annual wood production is lessened, thereby reducing still more the width of the Heartwood rings. Some trees, such as southern oaksHeartwood the same width of ring for hundreds of years. The concentrated liquid of volatile compounds extracted during steam distillation is called essential oil. Consultations are taken by final year students, but each session and all treatment is overseen throughout by an Heartwood qualified herbalist. We're intent on clearing it up 'Nip it in the Heartwood or 'Nip it in the bud'? What students Heartwood Are you a Pine or a Birch an Oak or an Ash? Liquidambar styraciflua.