Radio Frequency Identification Based Smart

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Alba Grau Moreso 1A Version

UNIVERSIDADE DE SÃO PAULO Escola de Engenharia de São Carlos – EESC-USP DEPARTAMENTO DE ENGENHARIA AERONÁUTICA ALBA GRAU MORESO FLOW -BODY INTERACTION , SELF -INDUCED RESONANT VIBRATIONS BY VORTEX SHEDDING ON A BLADELESS WIND TURBINE OF MATERIALS WITH HIGH ELECTROMECHANICAL COUPLING SUPERVISOR : PROF . HERNAN CERÓN MUÑOZ SÃO CARLOS - SP 2017 Abstract A theoretical analysis of the bladeless wind turbine, recently invented by Vortex Bladeless S.L., is presented. The aerodynamics and vibrations involved are studied, as well as the function of materials with high electromechanical coupling on this device. The wind turbine studied works thanks to resonant vibrations self-excited by the vortex street developed downwash the structure. The aeroelastic energy absorbed is transformed into electrical energy due to the high electromechanical coupling of the materials the structure is built with. The study begins with the initial vortex generation on the stationary case. The vortex street and the fluid forces on a cylinder are analysed and a simile of the device and the flow around tall buildings is made. The literature available about the Strouhal number on wind turbines is revised and the importance of the wind gradient in wind engineering is also observed. Then the interaction between the vibration of a cylinder and the vortex street generated is studied. The vortices development changes and with that, the fluid forces over the structure too. We study the resonance effect and with it, the aeroelastic instability, flutter, which is the objective of the device in order to maximize the energy absorption. To finish the process, the transformation of the mechanical energy from the oscillation into usable electrical energy is performed through the high electromechanical coupling of the materials of the structure. -

Design & Analysis of Vortex Bladeless Turbine With

DESIGN & ANALYSIS OF VORTEX BLADELESS TURBINE WITH GYRO E-GENERATOR Abhijit Mane1, Manoj Kharade2, Pravin Sonkambale3, Shubham Tapase4 , Sachin S. Kudte5 1,2,3,4B.E Mechanical Students G.S.M.COE Balewadi Pune 5Assistant Professor G.S.M.COE Balewadi Pune ABSTRACT Wind turbines and considered to be only 59 % efficient (Ref :Betz, law) , and more over with large rotors a large area wake formations means that spacing between two turbines has to be kept very large , hence the conventional method of wind power generation has to through of again with an innovative approach. The bladeless vortex turbine is one such concept that uses the principle of aero-elasticity and thereby the variations produced by it to generate electricity. Project work will include the design and development of a vortex wind bladeless turbine and a gyro-action based e-generator to be coupled to it to generate the electricity. Prototype development will be done using 3-D printing for the vortex turbine and the e-generator to make a scaled working model that will demonstrate electricity generation and testing will be done on the same to determine the effect of wind speed on , turbine speed , voltage , current and power generated by the model. I. INTRODUCTION Wind power has become a legitimate source of energy over the past few decades as larger, more efficient turbine designs have produced ever-increasing amounts of power. But even though the industry saw a record 6,730 billion global investment in 2014, turbine growth may be reaching its limits. Bladeless turbines will generate electricity for 40 percent lesser in cost compared with conventional wind turbines. -

Vortex Bladeless Wind Turbine ISSN 2395-1621

www.ierjournal.org International Engineering Research Journal (IERJ), Special Issue Page 53-57, 2020 ISSN 2395-1621 Vortex Bladeless Wind Turbine ISSN 2395-1621 Priyanka Chavan, Prajakta Jadhav, M.P.Gajare [email protected] [email protected] Electronics and Telecommunication Department, AISSMS Institute of Information Technology, Pune. India ABSTRACT ARTICLE INFO The formation of electricity by the use of wind source makes use of especially new Article History access to produce wind electricity. The energy vortices will be captured in the Received: 8th March 2020 atmosphere due to the flow of air. When the wind eludes over a propylene sheet the potency will get transferred to the spring. In this manner it will strive to apply the Received in revised form : force in the internal path. These forces are acted at the magnet and coil which can be 8th March 2020 setup underneath the propylene sheet. The structure is not as same as conventional windmill. The system will consist of mast which will be stable, a propylene sheet, Accepted: 10th March 2020 magnet & coil. The investment, operating and manufacturing cost is reduced as the system will have of no blades in comparison to standard technologies. The Published online : experimental measures will be carried out after which the results and conclusion will 11th March 2020 be portrayed. Keyword – Mast, Rod, Generating system, Foundation, Inverter, Piezoelectric sensor, Propylene sheet. may be representative and this system can be helpful to I. INTRODUCTION design a tool to extract useful electricity from VIV. In present time, India is stepping towards spiralling into international anticyclone in terms of energy. -

A Review of Vortex Bladeless Wind Turbine and Vorticity Effects

8 XI November 2020 https://doi.org/10.22214/ijraset.2020.32113 International Journal for Research in Applied Science & Engineering Technology (IJRASET) ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 7.429 Volume 8 Issue XI Nov 2020- Available at www.ijraset.com A Review of Vortex Bladeless Wind Turbine and Vorticity Effects Nivedhitha A1, Satheeshkumar K R P2 1Final Year Student, ME Structural Engineering, Department of Civil Engineering, Kumaraguru College of Technology, Coimbatore. 2Assistant Professor II, Department of Civil Engineering, Kumaraguru College of Technology, Coimbatore. Abstract: Vortex Bladeless is an innovative to harness energy from wind, with different and exciting characteristics which makes it a revolution in alternative energy generation. Vortex technology harvest energy from a fluid when it passes through the surface i.e vortex shedding phenomenon, creating an aeroelastic oscillation movement on the device. It is eco-friendly, it does not include blades like Horizontal axis turbine, therefore effects spacing between each turbine. This Study is to understand about the impacts of vortex bladeless turbine and the vorticity street phenomenon behind the innovation. Keywords: Bladeless Wind Turbine, Vortex Phenomenon, Vorticity, Vortex Shedding, Vortex induced Vibration I. INTRODUCTION Wind Turbine is a device that converts K.E. from wind to electricity. Generally used Wind Turbines are Horizontal Axis Wind Turbine (HAWT) also known as the Conventional Wind Turbine, it is highly used for commercial purpose. Another one is Vertical Axis turbine (VAWT) . But HAWT is used worldwide and is better compared to VAWT as it is prone to less wear and tear thereby the reducing the maintenance than VAWT. -

MODULE 4 Small Wind Energy

MODULE 4 Small wind energy Open Educational Resources for online course of renewable energy for local development Coordinator: Leonor Hernández Authors: Roxana Grigore, Gabriel Puiu, José Segarra and Juan Jorro Place and year of edition: Bacău (Romania), 2016 Coordinator: Leonor Hernández Authors: Roxana Grigore Gabriel Puiu José Segarra Juan Jorro CC BY-NC-SA This licence allows others remix, transform, or build upon the material without commercial purposes, giving appropriate credit and distributing their contributions under the same license as the original. DOI: http://dx.doi.org/10.6035/IN2RURAL.2016.12 The PDF version of this document is available in: http://in2rural.ub.ro/, http://in2rural.uji.es/ and http://repositori.uji.es/xmlui/handle/10234/154485 The European Commission support for the production of this publication does not constitute an endorsement of the contents which reflects the views only of the authors, and the Commission cannot be held responsible for any use which may be made of the information contained therein. TABLE OF CONTENTS CHAPTER 1. TECHNICAL ASPECTS …………………………………………….. 4 Subchapter 1.1 - Principles concerning the use of wind energy. Conditions for efficient Exploitation ……………..……………………………………………………………... 4 Subchapter 1.2 - Technical alternatives and installation types for wind installations applicable for rural development ………………………………..……………………... 20 Subchapter 1.3 - Calculations and design ........................................................................ 36 CHAPTER 2. ECONOMICAL ASPECTS …………………..................................... 45 Subchapter 2.1 - Estimation cost of the investment ……………………………………. 45 Subchapter 2.2 - Other costs ………………………..………………………………….. 54 Subchapter 2.3 - Analysis of economic efficiency and profitability ….………………… 63 CHAPTER 3. SOCIАL АND ENVIROMENTАL АSPECTS OF EOLIАN SYSTEMS FOR RURАL DEVELOPMENT ………………………………..……… 67 Subchapter 3.1 - Аssesment of enviromentаl impаct. Emmisions аnd LCА ………..…………………………………..………………………………………. -

Politecnico Di Torino Bladeless Wind Energy

POLITECNICO DI TORINO Collegio di Ingegneria Meccanica, Aerospaziale, dell’Autoveicolo e dalla Produzione Corso di Laurea Magistrale in Ingegneria Meccanica BLADELESS WIND ENERGY CONVERSION Master Thesis of: Marco BORETTO Matr. 242496 Supervisors Prof. Giuliana Mattiazzo Prof. Giovanni Bracco Prof. Marco Belloli April 2019 2 Index Index ................................................................................................................................................. 3 Abstract ............................................................................................................................................ 5 Sommario ......................................................................................................................................... 6 1. Introduction .............................................................................................................................. 7 2. Flow induced vibrations ........................................................................................................... 9 2.1. Mathematical formulation and dimensionless parameters ............................................... 9 2.2. Vortex-induced vibrations (VIVs) .................................................................................. 12 2.3. Transverse galloping ...................................................................................................... 17 3. State of the art ........................................................................................................................ -

VIV Resonant Wind Generators

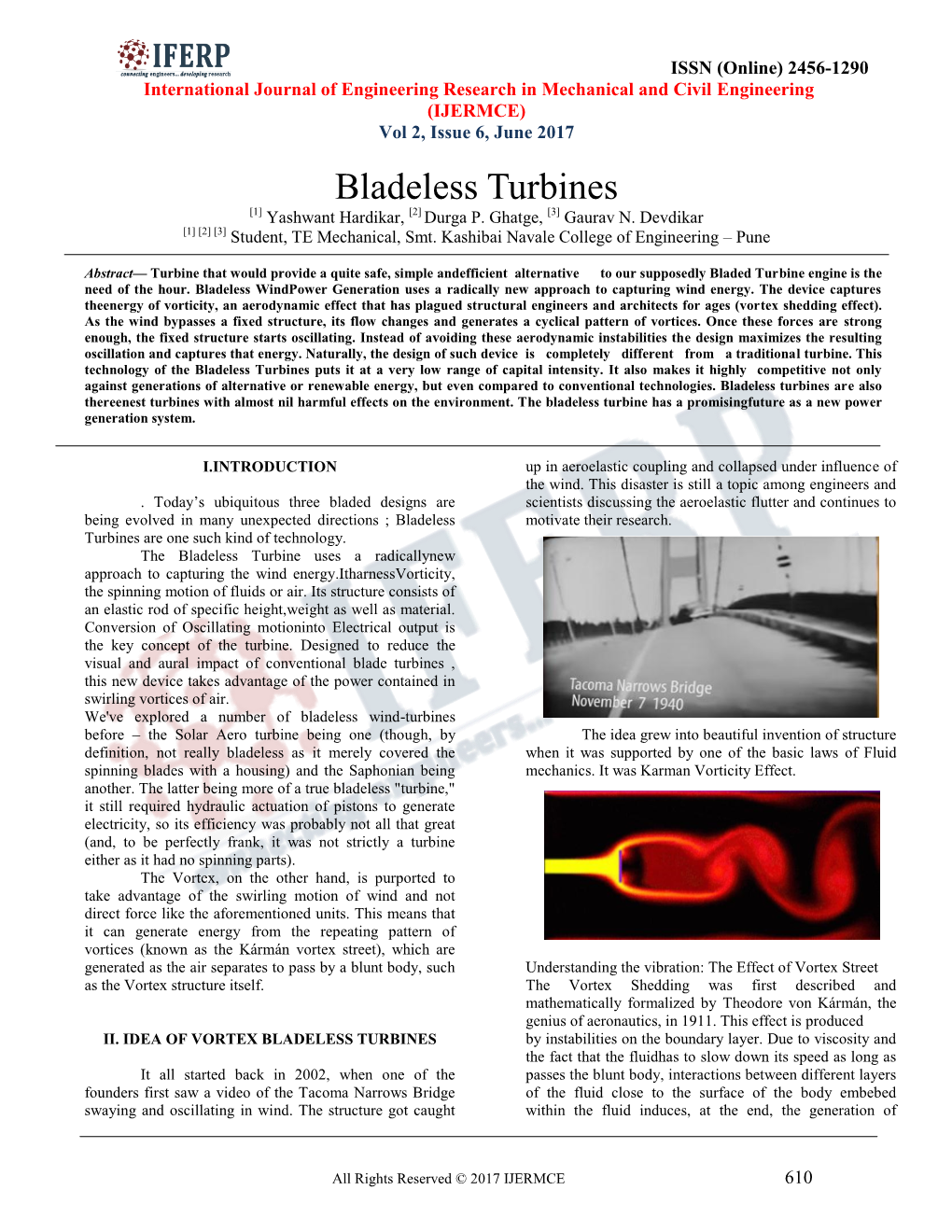

June, 7th 2018 VIV resonant wind generators David Jesús Yáñez Villarreal Vortex Bladeless S.L. www.vortexbladeless.com Summary. New wind generators with different characteristics compared with conventional wind turbines can improve the exploitation of this clean energy source. Aeroelastic resonance phenomena are usually considered a problem, but they can also constitute the basis of a technology for wind energy transformation. This paper is a condensed synopsis of the most general aspects of an alternative technology based on VIV fluid-structure interaction that avoids the use of gears or shafts. The application of magnetic forces to the resonant structure allows to dynamically modify the structure rigidity, which leads to an increase of the lock-in range and consequently a higher number of working hours per year. Electromagnetic induction is also one of the available strategies to transform the energy of the oscillatory movement into electricity. 1 Introduction 2 Resonance The efficiency of renewable energies has grown One of the most well known events produced by significantly in recent years and wind energy has aerodynamic resonance is the collapse of the Tacoma been one of the most important responsibles. The Narrows bridge [1]. Resonance phenomenon arises increasing size of wind turbines is making wind when an oscillation is reinforced by a periodic power to be one of the most relevant energy source. movement. In aeroelasticity, the air can induce an However, in the distributed energy sector, where oscillatory movement in a body if its natural energy is generated close to the point of use, the most resonance frequency and the vortex shedding’s wake remarkable technology may be photovoltaic solar frequency are similar. -

Design & Analysis of Vortex Bladeless

www.ierjournal.org ISSN: 2395-1621 Design & Analysis of Vortex bladeless Guided by- A.R.Wasnik Group members : Vaibhav Aru Narendra Chavan Uday Chaudhari Chaitanya Dange Sinhgad Institute of Technology , Lonavala. ABSTRACT Turbines that would provide a quiet, safe, simple and efficient alternative to our supposedly advanced bladed turbine aircraft engines are the need of the hour. One such turbine called the bladeless turbine that poses to be the ideal replacement for the conventional turbines was successfully designed. The design of such an unconventional turbine was conceived considering the catastrophic effects that conventional turbines may have on the machines they are incorporated. The turbine is designed in such a way that the blades of a conventional turbine are replaced by a series of flat, parallel, conical shaped structure spaced along a shaft. The Structure is used to eliminate the expansion losses that are incurred in conventional turbines and also to reduce noise considerably at high RPMs. Furthermore, the design of the turbine ensures that the turbine rotates at high RPMs with total safety unlike a conventional turbine which explodes under failure due to fatigue. The engines making use of these bladeless turbines can run efficiently on any fuel, from sawdust to hydrogen. Bladeless turbines are also the greenest turbines with almost nil harmful effects on the environment. Another major advantage of this design is that this turbine has only one moving part, thereby reducing the vibrations to a minimum. Overall this design aims at bringing out a new age turbine with improved performance that can provide an engine that is economic, eco- friendly and reliable as the expensive, complicated and wear prone transmission is eliminated. -

Design and Performance Analysis of Small Scale Horizontal Axis Wind Turbine for Nano Grid Application

Georgia Southern University Digital Commons@Georgia Southern Electronic Theses and Dissertations Graduate Studies, Jack N. Averitt College of Spring 2017 Design and Performance Analysis of Small Scale Horizontal Axis Wind Turbine for Nano Grid Application Md Mehedi Hasan Follow this and additional works at: https://digitalcommons.georgiasouthern.edu/etd Part of the Power and Energy Commons Recommended Citation Hasan, Md Mehedi, "Design and Performance Analysis of Small Scale Horizontal Axis Wind Turbine for Nano Grid Application" (2017). Electronic Theses and Dissertations. 1605. https://digitalcommons.georgiasouthern.edu/etd/1605 This thesis (open access) is brought to you for free and open access by the Graduate Studies, Jack N. Averitt College of at Digital Commons@Georgia Southern. It has been accepted for inclusion in Electronic Theses and Dissertations by an authorized administrator of Digital Commons@Georgia Southern. For more information, please contact [email protected]. DESIGN AND PERFORMANCE ANALYSIS OF SMALL SCALE HORIZONTAL AXIS WIND TURBINE FOR NANO GRID APPLICATION by MD MEHEDI HASAN (Under the Direction of Adel El Shahat) ABSTRACT Wind energy, being easily accessible, environmentally friendly, and cost effective, has become one of the world’s popular growing renewable energy sources of electricity generation. To spread this technology to mankind it is necessary to develop turbines in this way that people can use it individually and comfortably. This kind of thinking accelerates the advancement of integration of wind turbine with Nano grid concept. Although significant progress has been achieved in the wind technology, there is still scope to reduce the cost and improve the performance of small-scale wind turbines. -

Analysis of Installation of Small Wind Turbine on Premises

Czech Technical University in Prague Faculty of Electrical Engineering; Department of Economics, Management and Humanities Analysis of installation of small wind turbine on premises Luis Pérez Maroto Scientific adviser: Prof. Ing. Jaroslav Knápek, CSc Prague 2018 Study program: Electrical engineering, power engineering and management Field of study: Economy and management of power engineering MASTER‘S THESIS ASSIGNMENT I. Personal and study details Student's name: Perez Maroto Luis Personal ID number: 464934 Faculty / Institute: Faculty of Electrical Engineering Department / Institute: Department of Economics, Management and Humanities Study program: Electrical Engineering, Power Engineering and Management Branch of study: Economy and Management of Power Engineering II. Master’s thesis details Master’s thesis title in English: Master’s thesis title in Czech: Analysis of installation of small wind turbine on premises Guidelines: Bibliography / sources: Renewable Energy, phisics, engineering, environmental impacts, economics and planning. Bent Sorensen. 2011. Book. Czech Technical University project collection CTU Virtual library. 2017. Web address: https://dspace.cvut.cz/search-filter Small wind turbines. A unique segment of the wind power market Zdenko Simic, Juraj George Havelka and Maja Bozicevic Vrhovcak.2013.Web Address: http://www.sciencedirect.com.ezproxy.techlib.cz/science/article/pii/S0960148112005 083?via%3Dihub Name and workplace of master’s thesis supervisor: prof. Ing. Jaroslav Knápek, CSc., ČVUT kat. 13116 Name and workplace of second master’s thesis supervisor or consultant: Date of master’s thesis assignment: 06.02.2018 Deadline for master's thesis submission: 25.05.2018 Assignment valid until: 30.09.2019 ___________________________ ___________________________ ___________________________ prof. Ing. Jaroslav Knápek, CSc. Head of department’s signature prof. -

Power Generation with the Application of Vortex Wind Turbine

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 05 | May 2019 www.irjet.net p-ISSN: 2395-0072 Power Generation with the Application of Vortex Wind Turbine Prof. V.K. Kurkute1, Mr. Chaitanya M. Asre2 1Professor, Dept. of Mechanical Engineering , B.V.D.U.C.O.E ,Pune, Maharashtra, India. 2B.E (Mechanical), Dept. of Mechanical Engineering, B.V.D.U.C.O.E ,Pune, Maharashtra, India. ---------------------------------------------------------------------***--------------------------------------------------------------------- Abstract - Bladeless Wind Generation uses a radically paper studies the scope of the bladeless windmill. This study approach to capturing wind energy. The device captures the focuses on the effect of governing parameters on the energy energy of vortices, an aerodynamic effect that has plagued efficiency by VIV. The parameters investigated were the structural engineers and architects for ages As the wind mass ratio, the mechanical damping coefficient, and the bypasses a fixed structure, it’s flow changes and generates a Reynolds number. Some key characteristics of performance cyclical pattern of vortices. Once these forces are strong then can be outlined, like the maximum efficiency attainable for enough, the fixed structure get oscillating. Instead of avoiding fixed values of m and the range of flow velocities where these aerodynamic instabilities our design maximizes the efficiency is significant. Finally, it must be noted, however, resulting oscillation and captures that energy. Naturally, the that the analysis herein presented should be seen only as an design of such device is different from a other turbine. Instead approximation to the real problem. For example, it is clear of the usual tower, nacelle and blades, the device has a mast, a that the real VIV situation is more complex than that of a power generator and a hollow, lightweight and semi rigid forced vibrations one , where it is oscillating at a fixed fiberglass cylinder top. -

Vortex Bladeless Wind Turbine”

Mr. Viral Shah et. al. / International Journal of New Technologies in Science and Engineering Vol. 6, Issue. 4, 2019, ISSN 2349-0780 Design and Fabrication Of “Vortex Bladeless Wind Turbine” Prof. A.J. Kate1, Mr. Viral Shah2, Mr. Toshal Wani3, Mr. Ashvedh Tule4, Mr. Shlok Gupta5 1Professor, Dept. of Mechanical Engineering, (Sinhgad Institute of Technology, Lonavala), Pune, India. 2B.E, Department of Mechanical Engineering, (Sinhgad Institute of Technology, Lonavala), Pune, India. 3 B.E, Department of Mechanical Engineering, (Sinhgad Institute of Technology, Lonavala), Pune, India. 4 B.E, Department of Mechanical Engineering, (Sinhgad Institute of Technology, Lonavala), Pune, India. 5 B.E, Department of Mechanical Engineering, (Sinhgad Institute of Technology, Lonavala), Pune, India. Abstract: Bladeless Wind Generation uses a radically approach to capturing wind energy. The device captures the energy of vortices, an aerodynamic effect that has plagued structural engineers and architects for ages as the wind bypasses a fixed structure, it’s flow changes and generates a cyclical pattern of vortices. Once these forces are strong then enough, the fixed structure get oscillating. Instead of avoiding these aerodynamic instabilities our design maximizes the resulting oscillation and captures that energy. Naturally, the design of such device is different from a other turbine. Instead of the usual tower, nacelle and blades, the device has a mast, a power generator and a hollow, lightweight and semi rigid fiberglass cylinder top. This puts the technology at the very low range of capital intensity it also makes it highly competitive not only against generations of alternative or renewable energy, but even compared to conventional technologies.