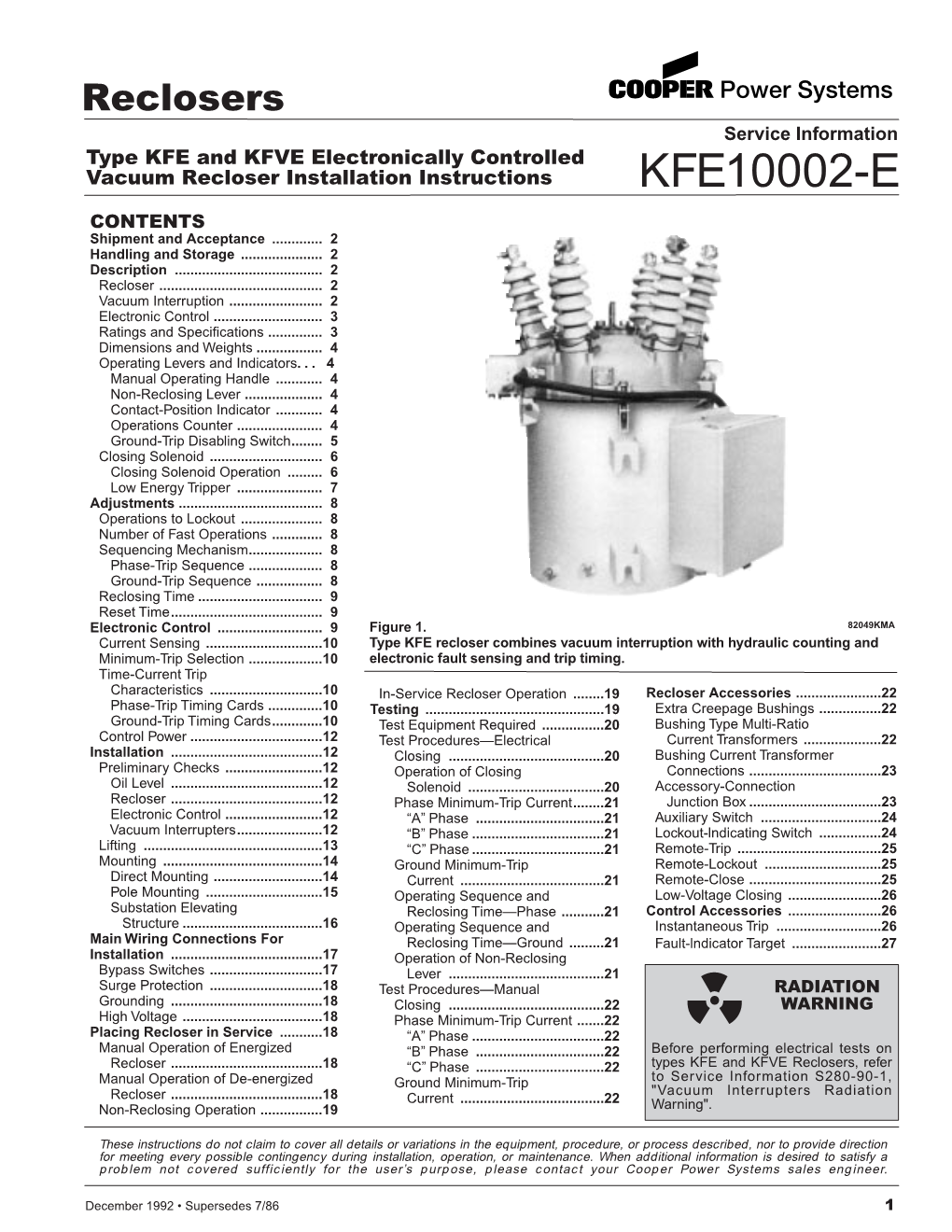

KFE and KFVE Recloser Instructions

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Vacuum Recloser 3AD HG 11.42 · Edition 2018 Medium-Voltage Equipment

Catalog Siemens Vacuum Recloser 3AD HG 11.42 · Edition 2018 Medium-Voltage Equipment siemens.com/recloser R-HG11-339.tif 2 Siemens Vacuum Recloser 3AD · Siemens HG 11.42 · 2018 Contents Contents Page Siemens Vacuum Description 5 Recloser 3AD General 6 Switch unit 7 1 Controller 7SR224 9 Medium-Voltage Equipment Controller 7SC80 14 Catalog HG 11.42 · 2018 Special functions and applications 19 Standards, ambient conditions, altitude correction factor and number of operating cycles 20 Invalid: Catalog HG 11.42 · 2016 Product range overview 21 Scope of delivery 22 siemens.com/recloser Product Selection 25 Ordering data and configuration example 26 Selection of primary ratings 27 2 Selection of controller 30 Selection of additional equipment 34 Selection of accessories and spare parts 35 Additional components for increased performance 37 3EK7 specifications according to IEC 38 3EK8 specifications according to IEEE 39 3EK7 / 3EK8 surge arresters 40 Technical Data 41 Electrical data, dimensions and weights: Voltage level 12 kV 42 3 Voltage level 15.5 kV 42 Voltage level 24 kV 43 Voltage level 27 kV 44 Voltage level 38 kV 45 Dimension drawings 46 Annex 51 Inquiry form 52 Configuration instructions 53 4 Configuration aid Foldout page The products and systems described in this catalog are manufactured and sold according to a certified management system (acc. to ISO 9001, ISO 14001 and BS OHSAS 18001). Siemens Vacuum Recloser 3AD · Siemens HG 11.42 · 2018 3 R-HG11-300.tif 4 Siemens Vacuum Recloser 3AD · Siemens HG 11.42 · 2018 Description Contents -

AUTO RECLOSER | SECTIONALIZER Switchgear for Smart Grids REV 3.0

AUTO RECLOSER | SECTIONALIZER Switchgear for Smart Grids REV 3.0 Content S. No. Heading Page 1 Introduction 4 2 Smart Grid & Power Distribution 5 3 Auto Reclosing and Sectionalizing 6-7 4 Design and Technology 8-11 Overview Pole Assembly Arc Interruption Control Panel Magnetic Actuator HT Circuit Breaker 5 Quality and Safety 12 6 Protection 13-14 7 Restraint and supervision 15 8 Measurement 16 9 Communication 17 10 SCADA for standalone operation 18 11 SCADA for standalone operation 19 12 Accessories 20 13 Technical Specification 21 14 Dimension (Circuit Breaker) 22 15 Dimension (Control Panel) 23 16 Ordering Information 24 16 Installation 25 Introduction NIKUM aims to provide customers with the latest technology combined with outstanding performance, affordable pricing, and excellent service aimed at unparalleled customer satisfaction. Our products are all high quality and the natural option for you. This is why they are all extensively type tested in independent laboratories as per IEC/ANSI standards. This is especially true when it comes to our feeder automation services and products, where years of information and modular manufacturing techniques enable our outdoor vacuum reclosers to fulfil any need and schedule. Since 1991, NIKUM has been manufacturing MV switchgear. With over two decades of experience in this field NIKUM, our team has extensive knowledge and skills in this field. All the technology available today has been indigenously developed by NIKUM in our in-house R&D facility. The hard working engineers in our R&D department who continuously work out for better results and performance of the equipments, have experience as well as the qualifications for the work. -

Smart Recloser

Smart Recloser A Major Qualifying Project Report Submitted to the Faculty of the WORCESTER POLYTECHNIC INSTITUTE In partial fulfillment of the requirements for the Degree of Bachelor of Science in Electrical and Computer Engineering Submitted by: Salvador Antoniou __________________ Thomas Cucinotta __________________ James Silvia __________________ Date: April 28, 2011 Approved by: __________________________ Professor Alexander E. Emanuel - Advisor ABSTRACT The goal of this project was to develop an intelligent recloser system that is able to differentiate between a temporary and a persistent fault, and then take proper action. The intended use of this system is to increase reliability and energy quality. The system was realized by using a non-invasive method to monitor the soundness of the line. Through signal processing, this information is converted into logic that a microprocessor can use to control the recloser. I ACKNOWLEDGEMENTS First and foremost, we would like to express our gratitude to Professor Alexander E. Emanuel for this eternal patience, guidance, and support throughout the project. We would also like to thank Professors Stephen Bitar and James O’Rourke for their troubleshooting assistance. Next, we would like to thank Tom Angelotti and Patrick Morrison of the ECE Shop for providing us with the equipment needed to complete this project. Last but not least, we would like to thank the ECE department at WPI for providing us with valuable knowledge throughout the course of our undergraduate studies. II TABLE OF CONTENTS Abstract -

Product Guide 2019 OVERHEAD DISTRIBUTION SWITCHGEAR & RECLOSERS

Product Guide 2019 OVERHEAD DISTRIBUTION SWITCHGEAR & RECLOSERS Our selection of distribution reclosers and overhead switchgear meet 15.5kV to 38kV system rating requirements (800A continuous current, 12.kA rms symmetrical interrupting) for direct pole, padmount and substation applications. Their flexible designs include options for manual and remote operation, as well as integration with distribution automation and automatic transfer control solutions. Our reclosers and overhead switches are electronically controlled vacuum fault interrupter switchgear, making them more reliable for voltage switching and protection. The Viper®-S, Viper®-ST and Viper®-SP come with a dead tank design that reduces interruptions from wildlife interferences and provides added safety for the operators with the modules being at ground potential. Viper-ST Independent Pole Operation Recloser Our Viper-ST dielectric independent pole-operated recloser offers reliable, maintenance-free performance for overcurrent protection, with flexibility to isolate single or two faulted phases on three phase circuits, improving reliability further in the process. Viper-ST Viper-S Three Phase Recloser Our Viper-S mechanically ganged three phase recloser combines electronically controlled vacuum fault interrupters with the maintenance benefits of a solid dielectric insulated device. Viper-S Viper-SP Single Phase Recloser Our Viper-SP single phase recloser paired with the SEL- 351RS Kestrel offers a variety of configurations and site- ready solutions with the maintenance-free benefits of a solid dielectric insulated device. Viper-SP Diamondback Loadbreak Switch The Diamondback switch is a solid dielectric, three-phase load break switch for overhead applications and combines the time-proven reliability of vacuum bottles with the maintenance-free benefits of a solid dielectric insulated device. -

4. Converter Transformer Protection

1 NATIONAL TRANSMISSION AND DESPATCH COMPANY LIMITED Protection Perspective of HVDC Technology By: Muhammad Shafiq General Manager (Tech)/CE(SP )NTDCL Index 1. Introduction HVDC Transmission Applications Bi-polar and Multi-Terminal HVDC Transmission system How HVDC works? 2. Protection zones for HVDC Long- Distance Transmission Scheme 2.1 Protection of AC portion AC Bus bar protection AC line protection AC filter protection Converter transformer protection Index Cont’d. 2.2 Protection of DC portion Converter protection DC Bus-bar protection DC Filter protection Electrode line protection DC line/cable protection Harmonic protection 3. Hybrid Optical DC Measuring HVDC Transmission Applications Bulk electricity transmission over long distance with few losses Interconnection of AC grids (Back-to-Back) HVDC Transmission Applications Submarine or underground cable Offshore wind farm generation Multi-terminal connection Bi-Polar HVDC Transmission system Two poles - two conductors in transmission line, one positive with respect to earth & other negative The mid point of Bi-poles in each terminal is earthed via an electrode line and earth electrode. In normal condition power flows through lines & negligible current flows through earth electrode. (in order of less than 10 Amps.) Multi – terminal HVDC Transmission system Three or more terminal connected in parallel, some feed power and some receive power from HVDC Bus. Provides Inter connection between the three or more AC network. HOW HVDC WORKS ? POWER FLOW EQUATIONS FOR DC TRANSMISSION: Vdr (Vdr-Vdi) POWER(P) = R Where Vdr is DC voltage at rectifier end Vdi is DC voltage at inverter end R is the resistance of line Protection Zones for HVDC Long- Distance Transmission Scheme Protection of AC Portion 1. -

Siemens Vacuum Recloser 3AD Catalog EN

Siemens Vacuum Recloser 3AD Medium-Voltage Equipment Totally Integrated Power – Vacuum Recloser 3AD Catalog Edition HG 11.42 2016 siemens.com/recloser Siemens Vacuum Recloser 3AD R-HG11-172.tif 2 Siemens HG 11.42 · 2016 Siemens Vacuum Recloser 3AD Contents Contents Page Siemens Vacuum Description 5 Recloser 3AD General 6 Switch unit 7 1 Controller 7SR224 9 Medium-Voltage Equipment Controller 7SC80 14 Catalog HG 11.42 · 2016 Special functions and applications 19 Standards, ambient conditions, altitude correction factor and number of operating cycles 20 Invalid: Catalog HG 11.42 · 2011 Catalog HG 11.42 · 2015 (PDF version) Product range overview and scope of delivery 21 siemens.com/recloser Product Selection 23 Ordering data and configuration example 24 Selection of primary ratings 25 2 Selection of controller 27 Selection of additional equipment 31 Additional components for increased performance 33 Technical Data 35 Electrical data, dimensions and weights: Voltage level 12 kV 36 3 Voltage level 15.5 kV 36 Voltage level 24 kV 37 Voltage level 27 kV 38 Voltage level 38 kV 39 Dimension drawings 40 Annex 45 Inquiry form 46 Configuration instructions 47 4 Configuration aid Foldout page The products and systems described in this catalog are manufactured and sold according to a certified management system (acc. to ISO 9001, ISO 14001 and BS OHSAS 18001). Siemens HG 11.42 · 2016 3 Siemens Vacuum Recloser 3AD R-HG11-300.tif 4 Siemens HG 11.42 · 2016 Siemens Vacuum Recloser 3AD Description Contents Contents Page Description 5 General 6 1 Switch -

KFVE and KFVME (27 Kv) Bus Bar Kit KRK710-1 Installation Instructions

Reclosers Cooper Power Systems Type KFVE and KFVME (27kV) Service Information Bus Bar Kit KRK710-1 Installation Instructions KFE10010-E Figure 1. 961047KM Type KFVE and KFVME (27kV) bus bar kit KRK710-1. Contents Safety Information ....................................................... 2 Installation .................................................................... 4 Safety Instructions ..................................................... 2 Disassembly Procedures........................................... 4 Hazard Statement Definitions.................................... 2 Capscrew Replacement............................................. 6 Product Information..................................................... 3 Reassembly Procedures............................................ 6 Introduction................................................................ 3 Testing........................................................................... 9 Description................................................................. 3 June 1996 • New Issue 1 Printed in USA Type KFVE and KFVME Bus Bar Kit Installation Instructions ! ! SAFETY SAFETY FOR LIFE SAFETY FOR LIFE FOR LIFE Kyle Distribution Switchgear products meet or exceed all applicable industry standards relating to product safety. We actively promote safe practices in the use and maintenance of our products through our service literature, instructional training programs, and the continuous efforts of all Kyle employees involved in product design, manufacture, marketing, and service. We -

GE Power/Vac 7 Vacuum Distribution Recloser

GE Power Switching & Controls GE Power/Vac 7 Vacuum Distribution Recloser Power/Vac7 Type PVDR 15.5 kV and 27.0 kV Three Phase Vacuum Circuit Recloser GE Power Switching & Controls Introduces Power/Vac Vacuum Distribution Recloser An addition to the proven vacuum distribution product line. The GE Distribution Recloser is a • Reliable Arc Interruption Power/Vac (in-air), Type PVDR, four Arc interruption typically occurs at shot recloser for use in applications the first current zero after contact on distribution systems. separation. The high dielectric strength of the vacuum gap results The Vacuum (in-air) Distribution in an extremely short clearing time. recloser is available as a standard From a normal CLOSED position, offering utilizing the GE-Multilin F650- the recloser can complete fault Recloser Controller. This controller interruption in five cycles. package utilizes the Multi-function F650 relay, 10-pole test switch, 24 vdc battery • Long Service Life with charger (when station DC is not Power/Vac interrupters experience available), and a 120VAC GF-protected no significant contact erosion during receptacle. (Other relay configurations normal duty. They are designed and are available.) tested to meet or exceed performance requirements of applicable ANSI, The Type PVDR Recloser is rated 15.5 IEEE and NEMA standards. kV and 27.0 kV. They are high speed vacuum (in-air) reclosers designed to meet increased demands for uninter- • Low Maintenance rupted power on distribution circuits The Power/Vac interrupter element requiring single or multi-shot reclosing. is designed for 10,000 no-load and The PVDR is capable of interrupting at 5,000 full load operations prior to either 10,000, 12,000 or 16,000 amperes maintenance. -

Outdoor Circuit Breaker GVR Recloser Hawker Siddeley Switchgear

Outdoor circuit breaker GVR Recloser Hawker Siddeley Switchgear rated voltage 15, 27 and 38 kV rated current 630 A Outdoor circuit breakers GVR Recloser GVR switchgear brings the reliability of modern materials and technology to overhead distribution networks The reliability of a system is achieved through: a new, patented, single coil magnetic actuator mechanism which allows the GVR to operate independently of the HV supply and to be tested in an ordinary workshop; environmentally friendly vacuum interruption produces no by-products; the lightweight aluminium tank makes the GVR easier to transport and install; the EPDM rubber bushings are resistant to damage from vandalism or mishandling; by extensive use of insulated mouldings, in particular the bushings, the total number of parts has been reduced by a factor of x 20 and the number of moving parts by x 50. Environmental design The award-winning GVR gas-filled vacuum recloser combines the high reliability of vacuum interruption with the controlled environment and high dielectric strength of SF6, in a compact, maintenance-free unit. Since SF6 is only used as insulation, there is no health hazard from toxic by- products of arcing. Electrical life is well in excess of ANSI and IEC requirements. The magnetic actuator provides consistent performance and a dramatic reduction in the number of moving parts. Materials and finishes have been carefully chosen for reliability – from EPDM bushings, tested for tracking and erosion to IEC 1109, in salt fog and other environments, to the neodymium iron boron permanent magnets used in the mechanism. Application The GVR can be pole mounted or substation mounted and can operate as a stand-alone recloser without the need for an additional auxiliary supply, or it can be integrated into the most advanced distribution automation schemes. -

System Impacts from Interconnection of Distributed Resources: DE-AC36-08-GO28308 Current Status and Identification of Needs for Further Development 5B

Technical Report System Impacts from NREL/TP-550-44727 Interconnection of Distributed January 2009 Resources: Current Status and Identification of Needs for Further Development T.S. Basso Technical Report System Impacts from NREL/TP-550-44727 Interconnection of Distributed January 2009 Resources: Current Status and Identification of Needs for Further Development T.S. Basso Prepared under Task No. DP08.1001 National Renewable Energy Laboratory 1617 Cole Boulevard, Golden, Colorado 80401-3393 303-275-3000 • www.nrel.gov NREL is a national laboratory of the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy Operated by the Alliance for Sustainable Energy, LLC Contract No. DE-AC36-08-GO28308 NOTICE This report was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or any agency thereof. Available electronically at http://www.osti.gov/bridge Available for a processing fee to U.S. Department of Energy and its contractors, in paper, from: U.S. -

Recloser Testing Brochure

Testing and Diagnostics of Reclosers and Sectionalizers Recloser and sectionalizer technology has changed Contents Many utilities in the distribution segment deploy reclosers and sectionalizers to improve the distribution system’s reliability. Both are usually mounted on power poles to save Introduction page site preparation costs. Recloser and Sectionalizer 2 technology has changed Reclosers The need for comprehensive 4 ... reduce customer outage minutes for permanent and Recloser testing especially temporary self-clearing faults, for example if a Maintenance and commissioning falling branch of a tree hits the line. For this purpose, they detect the fault current in the event of a fault. Reclosers Quick and easy testing of typical 6 are a more cost-efficient option than adding breakers or Recloser control functions substations when applicable. Complex testing of Recloser controls, 8 IntelliRupter controls and protection Sectionalizers relays ... are typically installed downstream of a recloser. They Distribution automation scheme 10 detect and count the successive fault current interrup- testing with Reclosers and tions of the recloser and, if the fault persists, isolate the protection relays particular section after a preset number of counts. Because Testing instrument transformers and 12 they are not rated to interrupt fault current they are less breakers expensive compared to a recloser. Our support – your trust A strong and safe connection 14 ARCO 400 An easy solution to test the recloser control 2 Recloser and sectionalizer technology has changed A recloser includes all the elements of a protection system: Each of these elements needs to be tested for proper functionality to ensure that electrical energy is delivered with a minimum of inter- ruption time. -

Optimal Recloser Setting, Considering Reliability and Power Quality in Distribution Networks Rashid Niaz Azari, Mohammad Amin Chitsazan, Iman Niazazari

Optimal Recloser Setting, Considering Reliability and Power Quality in Distribution Networks Rashid Niaz Azari, Mohammad Amin Chitsazan, Iman Niazazari To cite this version: Rashid Niaz Azari, Mohammad Amin Chitsazan, Iman Niazazari. Optimal Recloser Setting, Consid- ering Reliability and Power Quality in Distribution Networks. American Journal of Electrical Power and Energy Systems, 2017, 6 (1), pp.1-6. 10.11648/j.epes.20170601.11. hal-01552223 HAL Id: hal-01552223 https://hal.archives-ouvertes.fr/hal-01552223 Submitted on 1 Jul 2017 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. American Journal of Electrical Power and Energy Systems 2017; 6(2): 1-6 http://www.sciencepublishinggroup.com/j/epes doi: 10.11648/j.epes.20170601.11 ISSN: 2326-912X (Print); ISSN: 2326-9200 (Online) Research/Technical Note Optimal Recloser Setting, Considering Reliability and Power Quality in Distribution Networks Rashid Niaz Azari1, *, Mohammad Amin Chitsazan2, Iman Niazazari2 1Department of Electrical Engineering, Azad University, Sari, Iran 2Department of Electrical Engineering, University of Nevada, Reno, USA Email address: [email protected] (R. N. Azari), [email protected] (M. A. Chitsazan), [email protected] (I. Niazazari) *Corresponding author To cite this article: Rashid Niaz Azari, Mohammad Amin Chitsazan, Iman Niazazari.