Pdi2 As a Simple and Efficient Catalyst for the Hydroamination Of

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

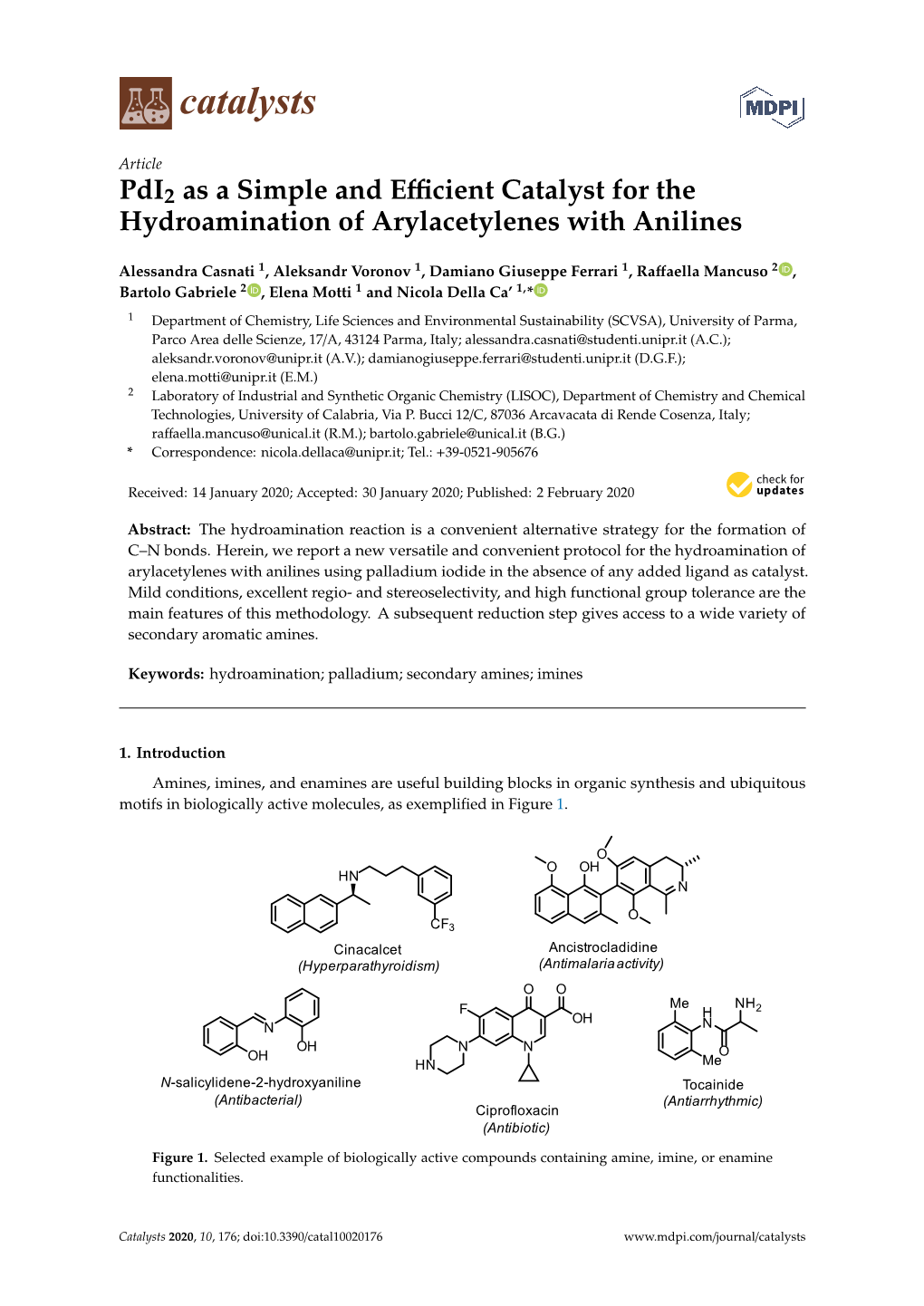

-

83230251.Pdf

View metadata, citation and similar papers at core.ac.uk brought to you by CORE This is an open access article published under an ACS AuthorChoice License, which permits copying and redistribution of the article or any adaptations for non-commercial purposes. provided by DSpace@MIT Article pubs.acs.org/JACS Mechanistic Studies Lead to Dramatically Improved Reaction Conditions for the Cu-Catalyzed Asymmetric Hydroamination of Olefins Jeffrey S. Bandar,† Michael T. Pirnot,† and Stephen L. Buchwald* Department of Chemistry, Massachusetts Institute of Technology, Cambridge, Massachusetts 02139, United States *S Supporting Information ABSTRACT: Enantioselective copper(I) hydride (CuH)- catalyzed hydroamination has undergone significant develop- ment over the past several years. To gain a general understanding of the factors governing these reactions, kinetic and spectroscopic studies were performed on the CuH- catalyzed hydroamination of styrene. Reaction profile analysis, rate order assessment, and Hammett studies indicate that the turnover-limiting step is regeneration of the CuH catalyst by reaction with a silane, with a phosphine-ligated copper(I) benzoate as the catalyst resting state. Spectroscopic, electrospray ionization mass spectrometry, and nonlinear effect studies are consistent with a monomeric active catalyst. With this insight, targeted reagent optimization led to the development of an optimized protocol with an operationally simple setup (ligated copper(II) precatalyst, open to air) and short reaction times (<30 min). This improved protocol is amenable to a diverse range of alkene and alkyne substrate classes. ■ INTRODUCTION Scheme 1. Proposed Catalytic Cycle for CuH-Catalyzed Due to their importance and ubiquity, significant efforts have Hydroamination of Styrene been made toward the construction of enantioenriched amines.1 Hydroamination, the formal addition of a nitrogen and hydrogen atom across a carbon−carbon π-bond, represents a particularly attractive and direct method for appending amino groups onto a molecule. -

Catalytic Organic Transformations Mediated by Actinide Complexes

Inorganics 2015, 3, 392-428; doi:10.3390/inorganics3040392 OPEN ACCESS inorganics ISSN 2304-6740 www.mdpi.com/journal/inorganics Review Catalytic Organic Transformations Mediated by Actinide Complexes Isabell S. R. Karmel, Rami J. Batrice and Moris S. Eisen * Schulich Faculty of Chemistry, Technion—Israel Institute of Technology, Technion City, Haifa 32000, Israel; E-Mails: [email protected] (I.S.R.K.); [email protected] (R.J.B.) * Author to whom correspondence should be addressed; E-Mail: [email protected]; Tel./Fax: +972-4-829-2680. Academic Editors: Stephen Mansell and Steve Liddle Received: 16 September 2015 / Accepted: 9 October 2015 / Published: 30 October 2015 Abstract: This review article presents the development of organoactinides and actinide coordination complexes as catalysts for homogeneous organic transformations. This chapter introduces the basic principles of actinide catalysis and deals with the historic development of actinide complexes in catalytic processes. The application of organoactinides in homogeneous catalysis is exemplified in the hydroelementation reactions, such as the hydroamination, hydrosilylation, hydroalkoxylation and hydrothiolation of alkynes. Additionally, the use of actinide coordination complexes for the catalytic polymerization of α-olefins and the ring opening polymerization of cyclic esters is presented. The last part of this review article highlights novel catalytic transformations mediated by actinide compounds and gives an outlook to the further potential of this field. Keywords: organoactinides; actinide coordination complexes; homogeneous catalysis; hydroelementations; polymerization of olefins; ROP; activation of heterocumulenes 1. Introduction The beginning of modern organoactinide chemistry is often attributed to the synthesis of 8 uranocene, [(η -C8H8)2U] in 1968, as the analogous compound to ferrocene and other transition metal metallocenes [1,2]. -

Enantioselective, Stereodivergent Hydroazidation and Hydroamination of Allenes Catalyzed by Acyclic Diaminocarbene (ADC) Gold(I) Complexes Dimitri A

Angewandte Communications Chemie International Edition:DOI:10.1002/anie.201601550 Gold Catalysis German Edition:DOI:10.1002/ange.201601550 Enantioselective, Stereodivergent Hydroazidation and Hydroamination of Allenes Catalyzed by Acyclic Diaminocarbene (ADC) Gold(I) Complexes Dimitri A. Khrakovsky+,Chuanzhou Tao+,Miles W. Johnson, RichardT.Thornbury, Sophia L. Shevick, and F. Dean Toste* Abstract: The gold-catalyzed enantioselective hydroazidation and hydroamination reactions of allenes are presented herein. ADC gold(I) catalysts derived from BINAM were critical for achieving high levels of enantioselectivity in both transforma- tions.The sense of enantioinduction is reversed for the two different nucleophiles,allowing access to both enantiomers of the corresponding allylic amines using the same catalyst enantiomer. Allylic amines are an important functional motif in synthetic organic chemistry and they have been utilized in the synthesis of numerous biologically active compounds.[1] Closely related Scheme 1. Enantioselective conjugateazidations and hydroazidations. allylic azides are valuable precursors for allylic amines,aswell as for amino acids[2] and amine-containing natural products.[3] Allylic azides have typically been prepared via substitution reactions from the corresponding allylic halides,(homo)- Table 1: Assessment of chiral gold(I) catalysts. allylic alcohols,and their derivatives.[4] More recently,Pd- catalyzed C Hactivation,[5] and Au-catalyzed hydroazidation À of allenes[6] have been employed. While reports of the synthesis -

Copper Hydride Catalyzed Hydroamination of Alkenes and Alkynes

Copper Hydride Catalyzed Hydroamination of Alkenes and Alkynes The MIT Faculty has made this article openly available. Please share how this access benefits you. Your story matters. Citation Pirnot, Michael T., Yi-Ming Wang, and Stephen L. Buchwald. “Copper Hydride Catalyzed Hydroamination of Alkenes and Alkynes.” Angewandte Chemie International Edition 55.1 (2016): 48–57. As Published http://dx.doi.org/10.1002/anie.201507594 Publisher Wiley Blackwell Version Author's final manuscript Citable link http://hdl.handle.net/1721.1/110464 Terms of Use Creative Commons Attribution-Noncommercial-Share Alike Detailed Terms http://creativecommons.org/licenses/by-nc-sa/4.0/ HHS Public Access Author manuscript Author Manuscript Author ManuscriptAngew Chem Author Manuscript Int Ed Engl Author Manuscript . Author manuscript; available in PMC 2016 March 08. Published in final edited form as: Angew Chem Int Ed Engl. 2016 January 4; 55(1): 48–57. doi:10.1002/anie.201507594. Copper Hydride-Catalyzed Hydroamination of Alkenes and Alkynes Dr. Michael T. Pirnot†, Dr. Yi-Ming Wang†, and Prof. Dr. Stephen L. Buchwald Department of Chemistry, Massachusetts Institute of Technology 77 Massachusetts Avenue, Cambridge, MA 02139 (USA) Stephen L. Buchwald: [email protected] Abstract Over the past few years, CuH-catalyzed hydroamination has been discovered and developed as a robust and conceptually novel approach for the synthesis of enantioenriched secondary and tertiary amines. The success in this area of research was made possible through the large body of precedent in copper(I) hydride catalysis and the well-explored use of hydroxylamine esters as electrophilic amine sources in related copper-catalyzed processes. -

Platinum-Based Catalysts for the Hydroamination of Olefins with Sulfonamides and Weakly Basic Anilines Dmitry Karshtedt,†,‡ Alexis T

Published on Web 08/20/2005 Platinum-Based Catalysts for the Hydroamination of Olefins with Sulfonamides and Weakly Basic Anilines Dmitry Karshtedt,†,‡ Alexis T. Bell,*,‡,§ and T. Don Tilley*,†,‡ Contribution from the Departments of Chemistry and Chemical Engineering, UniVersity of California, Berkeley, Berkeley, California 94720, and Chemical Sciences DiVision, Lawrence Berkeley National Laboratory, 1 Cyclotron Road, Berkeley, California 94720 Received May 2, 2005; E-mail: [email protected] Abstract: Electrophilic Pt(II) complexes catalyze efficient hydroaminations of olefins by sulfonamides and weakly basic anilines. Catalysts include the structurally characterized complex (COD)Pt(OTf)2 (1) and the known dimer [PtCl2(C2H4)]2, activated by AgBF4. Experiments with substituted anilines establish an empirical pKa cutoff (conjugate acid pKa < 1) for the participation of nitrogen-containing substrates in this catalysis. Arylsulfonamides (conjugate acid pKa ≈ -6) with various para substituents hydroaminate olefins such as cyclohexene in yields greater than 95% at 90 °C. Hydroamination of propylene by p-toluenesulfonamide proceeds with Markovnikov selectivity, suggesting a mechanism that involves olefin activation at Pt. With norbornene and p-toluenesulfonamide as the substrates and 1 as the catalyst, intermediate [(COD)Pt- 19 195 (norbornene)2][OTf]2 (3) was identified and characterized by F and Pt NMR spectroscopies and mass spectrometry. Kinetic studies provide the empirical rate law, rate ) kobs[Pt][sulfonamide], and are consistent -

Hydroamination Feb 2011

Catalytic Asymmetric Hydroaminations (And Hydroalkoxylations, But Mostly Hydroaminations) Anna Allen MacMillan Group Meeting February 16, 2011 Hydroamination (and Hydroalkoxylation): An Outline Brief Introduction to Hydroaminations Rare Earth Metal-Catalyzed Asymmetric Hydroaminations Intramolecular reactions Intermolecular reactions Group 4 Metal-Catalyzed Asymmetric Hydroaminations Cationic metal catalysts Neutral metal catalysts Late Transition Metal-Catalyzed Asymmetric Hydroaminations Iridium-catalyzed reactions Palladium-catalyzed reactions Gold-catalyzed reactions Rhodium-catalyzed reactions Base-Catalyzed Asymmetric Hydroaminations Brønsted Acid-Catalyzed Asymmetric Hydroaminations Muller, T. E.; Hultzsch, K. C.; Yus, M.; Foubelo, F.; Tada, M. Chem. Rev. 2008, 108, 3795. Aillaud, I.; Collin, J.; Hannedouche, J.; Schulz, E. Dalton Trans. 2007, 5105. Hultzsch, K. C. Adv. Synth. Catal. 2005, 347, 367. Hydroamination Reactions ! Amines are a valuable and commercially important class of compounds used for bulk chemicals specialty chemicals and pharmaceuticals synthesis of amines: OH NH2 O NH2 R R R R R R R R Br NH2 NO2 NH2 R R R R R R R R ! Most classical methods require refined starting materials and generate unwanted byproducts hydroamination reaction: NR2 R R2N H R R R H direct addition of an amine across a carbon-carbon multiple bond ! Hydroaminations are 100% atom economical and use simple and inexpensive starting materials Hydroamination Reactions hydroamination reaction: direct addition of an amine across a carbon-carbon multiple bond NR2 NR2 R R2N H R R R R2N H R R R R H H alkylamine vinylamine H H H H N N R R R NH2 R NH2 Why are hydroamination reactions not used more? Challenges: thermodynamically feasible (slightly exothermal) but entropically negative high reaction barrier repulsion between the nitrogen lone pair and the olefin/alkyne !-system regioselectivity (markovnikov vs. -

Sharanappa Nembenna

Sharanappa Nembenna ____________________________________________________________ β−Diketiminate Ligand Supported Group 2 Metal Hydroxide, Halide, Oxygen Bridged Heterobimetallic and Heterotrimetallic Complexes: Synthesis and X-ray Structural Studies Göttingen 2007 β−Diketiminate Ligand Supported Group 2 Metal Hydroxide, Halide, Oxygen Bridged Heterobimetallic and Heterotrimetallic Complexes: Synthesis and X-ray Structural Studies Dissertation zur Erlangung des Doktorgrades der Mathematisch-Naturwissenschaftlichen Fakultäten der Georg-August-Universität zu Göttingen Vorgelegt von Sharanappa Nembenna Aus Kallur (INDIA) Göttingen 2007 D 7 Referent: Prof. Dr. Dr. h. c. mult. Herbert W. Roesky Korreferent: Prof. Dr. Dietmar Stalke Tag der mündlichen Prüfung: 30.10.2007 Dedicated to my mother Channabasamma and My eldest brother late Mallikarjungouda Acknowledgement The work described in this doctoral thesis has been carried out under the guidance and supervision of Prof. Dr. Dr. h. c. mult. Herbert W. Roesky at the Institut für Anorganische Chemie der Georg-August-Universität in Göttingen between April 2004 and September 2007. My grateful thanks to Prof. Dr. Dr. h. c. mult. Herbert W. Roesky for his constant advice, guidance, motivation, suggestions, and discussions throughout this work. I would like to thank him for his personal attention and the freedom I enjoyed during my stay in Göttingen. I would like to thank Prof. G. M. Sheldrick, Prof. D. Stalke, Prof. J. Magull, Dr. M. Noltemeyer, Mr. H. Ott, Ms. A. Hofmeister, Mr. A. Pal, and Mr. H.-G. Schmidt for their kind help in X-ray crystallographic studies. I thank Dr. R. B. Oswald for the theoretical studies. And also I thank Dr. P.-J. Wilbrandt, Mr. M. Hahn, Ms. U. -

John F. Hartwig Henry Rapoport Professor of Chemistry

John F. Hartwig Henry Rapoport Professor of Chemistry Department of Chemistry, University of California Berkeley 718 Latimer Hall MC# 1460, Berkeley, CA 94720-1460 Email: [email protected] http://www.cchem.berkeley.edu/jfhgrp/ Personal Born August 7, 1964 in Elmhurst, IL Employment 2011-present University of California, Berkeley Henry Rapoport Professor of Chemistry. 2011-present Lawrence Berkeley National Laboratory, Berkeley Senior Faculty Scientist. 2006-2011 University of Illinois Urbana-Champaign Kenneth L. Reinhart Jr. Professor of Chemistry. 2004-2006 Yale University, New Haven, CT Irénée DuPont Professor of Chemistry. 1998-2004 Yale University, New Haven, CT Professor of Chemistry. 1996-1998 Yale University, New Haven, CT Associate Professor of Chemistry. 1992-1996 Yale University, New Haven, CT Assistant Professor of Chemistry. Appointment commenced July 1, 1992. 1990-1992 Massachusetts Institute of Technology, Cambridge, MA American Cancer Society Postdoctoral Associate. 1986-1989 University of California, Berkeley, CA Graduate Student Instructor. Taught organic chemistry to undergraduate students and inorganic chemistry to graduate students. 1985 Monsanto Japan Ltd., Kawachi, Japan Worked among an all-Japanese staff for three months on an agricultural and surface science research project. 1984 General Electric Research and Development, Schenectady, NY Synthesis of novel monomers, ionomers and polymer blends. Education 1990-1992 Massachusetts Institute of Technology, Cambridge, MA Postdoctoral Advisor: Prof. Stephen J. Lippard Studied the Pt-DNA adducts formed by an orally active platinum antitumor drug and the ability of these adducts to block DNA replication and bind cellular proteins. Designed, synthesized, and analyzed a platinum antitumor drug possessing a fluorescent ligand for in vivo monitoring. 1986-1990 University of California, Berkeley, CA Ph.D., Chemistry. -

Catalytic Intermolecular Hydroamination of Vinyl Ethers Hydroaminationnirmal of Vinyl Ethers K

LETTER 3135 Catalytic Intermolecular Hydroamination of Vinyl Ethers HydroaminationNirmal of Vinyl Ethers K. Pahadi,* Jon A. Tunge* Department of Chemistry, University of Kansas, 1251 Wescoe Hall Drive, Lawrence, KS 66045-7582, USA Fax +1(785)8645396; E-mail: [email protected] Received 30 July 2009 the concentration of vinyl ether to 1.6 M (4 equiv) slightly Abstract: This manuscript details the development of a palladium- catalyzed hydroamination of vinyl ethers. It is proposed that palla- lowers the yield (entry 5), while using just 2 equivalents dium catalyzes the hydroamination via Brønsted base catalysis, considerably lowered the yield of aminol (entry 6) and in- where palladium is protonated by the relatively acidic sulfonamide creased the time necessary for reaction completion. More- to generate a palladium hydride as well as the active anionic sul- over, substantial quantities of enamine 4a were formed. fonamide nucleophile. Thus, this process is distinct from known Further lowering the concentration of 2 to 0.5 M dramati- palladium-catalyzed hydroaminations of styrene derivatives that cally decreased the yield of 3, and only a trace amount of utilize less acidic amines. enamine 4 was observed. Dioxane, MeCN, DCE, and Key words: hydroamination, vinyl ether, palladium, sulfonamide THF were also tested as potential solvents; only dioxane provided any product. However, when 1,4-dioxane was used as solvent, a 1:1 mixture of 3a and 4a was obtained Transition-metal-catalyzed intermolecular hydroamina- Table 1 a tion of alkenes has attracted a great attention in recent Conditions for Hydroamination years.1 Much research in this line has centered on the in- PG OBu tramolecular hydroamination of simple alkyl-substituted N 2,3 Ph a-olefins. -

John F. Hartwig*

Career in Review: John F. Hartwig* Presentation in Guangbin’s Lab Apr 4th, 2013 Changxia Yuan *Patial work of Prof. Hartwig M1 John F. Hartwig Biography Timeline Selected People from Hartwig’s Group in Academic: Selected Honor and Awards: Seth Herzon (Yale) Jianrong Zhou (Nayang 2013 Herbert C. Brown Award for Research in Synthetic Methods Toshimichi Ohmura (Kyoto U.) Techological. U.) 2012 Member, National Academy of Sciences Yasuhiro Yamashita (Tokyo U.) Qilong Shen (Shanghai I. of OC) 2008 Mukaiyama Award from the Society of Synthetic Organic Jun Takaya (Tokyo Inst. of T.) Jing Zhao (Nanjing U.) Chemistry, Japan Makoto Yamashita (Kyoto U.) ~95% employed!! 2007 Tetrahedron Young Investigator Award in Organic Synthesis 2004 Thieme‐IUPAC Prize in Synthetic Organic Chemistry 1998 A.C. Cope Scholar Award Journal Activities: Editor for Organometallics and CHEMCATCHEM Publications: 295 Journals, 11 chapters of books, 1 textbook, 10 patents . Career: 幻灯片 2 M1 Honors Honors are awarded at graduation by the departments of concentration. Departments determine honors on the basis of the grades received by the student in departmental studies in the sophomore, junior, and senior years (including junior independent work, the senior thesis, and, for students in the A.B. program, the senior departmental examination). Each department chooses the weight to be assigned to the various components in the honors calculation. The degree may be awarded with honors, high honors, or highest honors. Moffat, 3/24/2013 Pd‐Catalyzed Arylation of Carbonyl Compound . Well-established mechanism: O 0 LnPd Scope of the Ar ArX R arylation oxidative R'' R' addition General Arylation mechanism Ar Ar PdL O C‐bound Pd n Ar O PdLn vs. -

Copper-Catalyzed Hydroamination of Alkenes and Alkynes

COPPER-CATALYZED HYDROAMINATION OF ALKENES AND ALKYNES Reported by Alfredo Garcia September 29th, 2015 INTRODUCTION Amines are found in a variety of biologically active natural products and medicines.1 Synthesis of amines by direct addition alkenes and alkynes is an attractive area of research in view of the availability and ease of preparation of these starting materials.2 Metal-catalyzed hydroamination reactions have been developed using, but not limited to, lanthanides, alkali and alkaline earth metals, and early and late transition metals. However, many of these catalysts are limited in substrate scope, are air and moisture sensitive, and are relatively expensive.2 The search for efficient, selective, and environmentally benign hydroamination catalysts with broader substrate scope (particularly for unactivated substrates) are in high demand. Recent advances in copper-catalyzed hydroamination provide general and practical systems for the hydroamination of alkenes and alkynes. These catalysts display a broad substrate scope and high levels of regio- and enantioselectivity.3 COPPER-CATALYZED HYDROAMINATION Alkenes 1 9-BBN The first copper-catalyzed hydroamination developed R 1 R2N R 4 ICyCuCl was limited to the addition of aryl amines to activated olefins. R2N-OBz Scheme 1. Anti-Markovnikov hydroamination of Later advances include an anti-Markovnikov hydroamination terminal, unactivated alkenes II of unactivated, terminal alkenes via a Cu (OAc)2 R3 R2 N 5 ligand [Si]-H hydroboration/electrophilic amination strategy (Scheme 1). R1 Ar H L*CuI H R1 This work inspired the development of a novel method for Ar I highly enantioselective, copper-catalyzed hydroamination of [Si]-H styrenes to branched tertiary amines.6,7 The hydroamination R3 R2 N OBz (Figure 1) commences with insertion of the styrene, ligand L*CuI L*CuIII R1 R1 Ar Ar bound copper hydride I (formed from silane reduction of H H III II Cu(OAc)2), producing alkyl copper species II. -

An Electronic Nest to Modulate the Catalytic Activity in Hydroamination

OPEN The Non-innocent Phenalenyl Unit: An SUBJECT AREAS: Electronic Nest to Modulate the Catalytic CATALYSIS HOMOGENEOUS CATALYSIS Activity in Hydroamination Reaction CHEMISTRY Arup Mukherjee, Tamal K. Sen, Pradip Kr Ghorai & Swadhin K. Mandal ORGANOMETALLIC CHEMISTRY Department of Chemical Sciences, Indian Institute of Science Education and Research-Kolkata, Mohanpur-741252, India. Received 4 April 2013 The phenalenyl unit has played intriguing role in different fields of research spanning from chemistry, Accepted material chemistry to device physics acting as key electronic reservoir which has not only led to the best 9 September 2013 organic single component conductor but also created the spin memory device of next generation. Now we show the non-innocent behaviour of phenalenyl unit in modulating the catalytic behaviour in a Published homogeneous organic transformation. The present study establishes that the cationic state of phenalenyl 2 October 2013 unit can act as an organic Lewis acceptor unit to influence the catalytic outcome of intermolecular hydroamination reaction of carbodiimides. For the present study, we utilized organoaluminum complexes of phenalenyl ligands in which the phenalenyl unit maintains the closed shell electronic state. The DFT calculation reveals that the energy of LUMO of the catalyst is mainly controlled by phenalenyl ligands which Correspondence and in turn determines the outcome of the catalysis. requests for materials should be addressed to 1 S.K.M. (swadhin. on-innocent ligands (NILs) have long attracted attention because of their unusual redox properties and [email protected]. their apparent, often deceptive, ability to stabilize metals in unusual oxidation states. The NILs have been employed not only for spectroscopic studies2,3 but also in different chemical transformations4,5.