Electromagnetic Wave Absorption in K Band and V Band with Carbon Microcoils

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

And H-Band Spectra of Globular Clusters in The

A&A 543, A75 (2012) Astronomy DOI: 10.1051/0004-6361/201218847 & c ESO 2012 ! Astrophysics Integrated J-andH-band spectra of globular clusters in the LMC: implications for stellar population models and galaxy age dating!,!!,!!! M. Lyubenova1,H.Kuntschner2,M.Rejkuba2,D.R.Silva3,M.Kissler-Patig2,andL.E.Tacconi-Garman2 1 Max Planck Institute for Astronomy, Königstuhl 17, 69117 Heidelberg, Germany e-mail: [email protected] 2 European Southern Observatory, Karl-Schwarzschild-Str. 2, 85748 Garching bei München, Germany 3 National Optical Astronomy Observatory, 950 North Cherry Ave., Tucson, AZ, 85719 USA Received 19 January 2012 / Accepted 1 May 2012 ABSTRACT Context. The rest-frame near-IR spectra of intermediate age (1–2 Gyr) stellar populations aredominatedbycarbonbasedabsorption features offering a wealth of information. Yet, spectral libraries that include the near-IR wavelength range do not sample a sufficiently broad range of ages and metallicities to allowforaccuratecalibrationofstellar population models and thus the interpretation of the observations. Aims. In this paper we investigate the integrated J-andH-band spectra of six intermediate age and old globular clusters in the Large Magellanic Cloud (LMC). Methods. The observations for six clusters were obtained with the SINFONI integral field spectrograph at the ESO VLT Yepun tele- scope, covering the J (1.09–1.41 µm) and H-band (1.43–1.86 µm) spectral range. The spectral resolution is 6.7 Å in J and 6.6 Å in H-band (FWHM). The observations were made in natural seeing, covering the central 24"" 24"" of each cluster and in addition sam- pling the brightest eight red giant branch and asymptotic giant branch (AGB) star candidates× within the clusters’ tidal radii. -

The UKIRT Infrared Deep Sky Survey ZY JHK Photometric System: Passbands and Synthetic Colours

Mon. Not. R. Astron. Soc. 367, 454–468 (2006) doi:10.1111/j.1365-2966.2005.09969.x The UKIRT Infrared Deep Sky Survey ZY JHK photometric system: passbands and synthetic colours P. C. Hewett,1⋆ S. J. Warren,2 S. K. Leggett3 and S. T. Hodgkin1 1Institute of Astronomy, Madingley Road, Cambridge CB3 0HA 2Blackett Laboratory, Imperial College of Science, Technology and Medicine, Prince Consort Road, London SW7 2AZ 3United Kingdom Infrared Telescope, Joint Astronomy Centre, 660 North A‘ohoku Place, Hilo, HI 96720, USA Accepted 2005 December 7. Received 2005 November 28; in original form 2005 September 16 ABSTRACT The United Kingdom Infrared Telescope (UKIRT) Infrared Deep Sky Survey is a set of five surveys of complementary combinations of area, depth and Galactic latitude, which began in 2005 May. The surveys use the UKIRT Wide Field Camera (WFCAM), which has a solid angle of 0.21 deg2. Here, we introduce and characterize the ZY JHK photometric system of the camera, which covers the wavelength range 0.83–2.37 µm. We synthesize response functions for the five passbands, and compute colours in the WFCAM, Sloan Digital Sky Survey (SDSS) and two-Micron All Sky Survey (2MASS) bands, for brown dwarfs, stars, galaxies and quasars of different types. We provide a recipe for others to compute colours from their own spectra. Calculations are presented in the Vega system, and the computed offsets to the AB system are provided, as well as colour equations between WFCAM filters and the SDSS and 2MASS passbands. We highlight the opportunities presented by the new Y filter at 0.97–1.07 µm for surveys for hypothetical Y dwarfs (brown dwarfs cooler than T), and for quasars of very high redshift, z > 6.4. -

Are the Hosts of Gamma-Ray Bursts Sub-Luminous and Blue Galaxies ? ?, ??

(y) View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by CERN Document Server Are the hosts of Gamma-Ray Bursts sub-luminous and blue galaxies ? ?; ?? E. Le Floc’h1, P.-A. Duc1;2,I.F.Mirabel1;3, D.B. Sanders4;5,G.Bosch6, R.J. Diaz7, C.J. Donzelli8, I. Rodrigues1, T.J.-L. Courvoisier9;10,J.Greiner5, S. Mereghetti11, J. Melnick12,J.Maza13,and D. Minniti14 1 CEA/DSM/DAPNIA Service d’Astrophysique, F-91191 Gif-sur-Yvette, France 2 CNRS URA 2052, France 3 Instituto de Astronom´ıa y F´ısica del Espacio, cc 67, suc 28. 1428 Buenos Aires, Argentina 4 Institute for Astronomy, University of Hawaii, 2680 Woodlawn Drive, Honolulu, HI 96822, United States 5 Max-Planck-Institut f¨ur Extraterrestrische Physik, D-85740, Garching, Germany 6 Facultad de Cs. Astronomicas y Geof´ısica, Paseo del Bosque s/n, La Plata, Argentina 7 Observatorio Astron´omico de C´ordoba & SeCyT, UNC, Laprida 854, Cordoba [5000], Argentina 8 IATE, Observatorio Astron´omico & CONICET, Laprida 854, Cordoba [5000], Argentina 9 INTEGRAL Science Data Center, Ch. d’Ecogia 16, CH-1290 Versoix, Switzerland 10 Geneva Observatory, Ch. des Maillettes 11, 1290 Sauverny, Switzerland 11 Istituto di Astrofisica Spaziale e Fisica Cosmica, Sezione di Milano “G. Occhialini”, via Bassini 15, I-20133 Milan, Italy 12 European Southern Observatory, Alonso de Cordova 3107, Santiago, Chile 13 Departamento de Astronom´ıa, Universidad de Chile, Casilla 36-D, Santiago, Chile 14 Department of Astronomy, Pontifica Universidad Cat´olica, Av. Vicu˜na Mackenna 4860, Santiago, Chile Received December 6, 2002 / Accepted December 23, 2002 Abstract. -

A Revision of the X-Ray Properties of MWC 297

A&A 447, 1041–1048 (2006) Astronomy DOI: 10.1051/0004-6361:20053630 & c ESO 2006 Astrophysics Chandra X-ray observations of the stellar group near the Herbig Be star MWC 297 A revision of the X-ray properties of MWC 297 F. Damiani, G. Micela, and S. Sciortino INAF - Osservatorio Astronomico di Palermo G.S.Vaiana, Piazza del Parlamento 1, 90134 Palermo, Italy e-mail: [email protected] Received 14 June 2005 / Accepted 11 October 2005 ABSTRACT We present a Chandra ACIS-I X-ray observation of the region near the Herbig early-Be star MWC 297, where we detect a tight group of point X-ray sources. These are probably physically associated to MWC 297, because of their obvious clustering with respect to the more scattered field-source population. These data are compared to earlier ASCA data with much poorer spatial resolution, from which the detection of strong quiescent and flaring emission from MWC 297 itself was claimed. We argue that this star, contributing only 5% to the total X-ray emission of the group, was probably not the dominant contributor to the observed ASCA emission, while the X-ray brightest star in the group is a much better candidate. This is also supported by the spectral analysis of the Chandra data, with reference to the ASCA spectra. We conclude that none of the X-ray data available for MWC 297 justify the earlier claim of strong magnetic activity in this star. The X-ray emission of MWC 297 during the Chandra observation is even weaker than that found in other Herbig stars with the same spectral type, even accounting for its large line-of-sight absorption. -

LONG RANGE Radar/Laser Detector User's Manual R1

R1 LONG RANGE Radar/Laser Detector User’s Manual © 2019 Uniden America Corporation Issue 5, January 2019 Irving, Texas Printed in Korea CUSTOMER CARE At Uniden®, we care about you! If you need assistance, please do NOT return this product to your place of purchase. Save your receipt/proof of purchase for warranty. Quickly find answers to your questions by: 1. Reading your owner’s manual. 2. Visiting our customer support website at www.uniden.com. Images in this manual may differ slightly from your actual product. DISCLAIMER: Radar detectors are illegal in some states. Some states prohibit mounting any object on your windshield. Check applicable law in your state and any state in which you use the product to verify that using and mounting a radar detector is legal. Uniden radar detectors are not manufactured and/or sold with the intent to be used for illegal purposes. Drive safely and exercise caution while using this product. Do not change settings of the product while driving. Uniden expects consumer’s use of these products to be in compliance with all local, state, and federal law. Uniden expressly disclaims any liability arising out of or related to your use of this product. CONTENTS CUSTOMER CARE .......................................................................................................... 2 FEATURES....................................................................................................5 WHAT’S IN THE BOX ...................................................................................6 PARTS OF THE R1 ........................................................................................6 -

X-Ray Properties of Young Stars and Stellar Clusters 313

Feigelson et al.: X-Ray Properties of Young Stars and Stellar Clusters 313 X-Ray Properties of Young Stars and Stellar Clusters Eric Feigelson and Leisa Townsley Pennsylvania State University Manuel Güdel Paul Scherrer Institute Keivan Stassun Vanderbilt University Although the environments of star and planet formation are thermodynamically cold, sub- stantial X-ray emission from 10–100 MK plasmas is present. In low-mass pre-main-sequence stars, X-rays are produced by violent magnetic reconnection flares. In high-mass O stars, they are produced by wind shocks on both stellar and parsec scales. The recent Chandra Orion Ultra- deep Project, XMM-Newton Extended Survey of Taurus, and Chandra studies of more distant high-mass star-forming regions reveal a wealth of X-ray phenomenology and astrophysics. X- ray flares mostly resemble solar-like magnetic activity from multipolar surface fields, although extreme flares may arise in field lines extending to the protoplanetary disk. Accretion plays a secondary role. Fluorescent iron line emission and absorption in inclined disks demonstrate that X-rays can efficiently illuminate disk material. The consequent ionization of disk gas and irradiation of disk solids addresses a variety of important astrophysical issues of disk dynam- ics, planet formation, and meteoritics. New observations of massive star-forming environments such as M 17, the Carina Nebula, and 30 Doradus show remarkably complex X-ray morpholo- gies including the low-mass stellar population, diffuse X-ray flows from blister HII regions, and inhomogeneous superbubbles. X-ray astronomy is thus providing qualitatively new insights into star and planet formation. 1. INTRODUCTION ment of the stellar surface by electron beams. -

LONG RANGE Radar/Laser Detector User's Manual R9

R9 LONG RANGE Radar/Laser Detector User’s Manual © 2020 Uniden America Corporation Issue 1, February 2020 Irving, Texas Printed in Korea CUSTOMER CARE At Uniden®, we care about you! If you need assistance, please do NOT return this product to your place of purchase Save your receipt/proof of purchase for warranty. Quickly find answers to your questions by: • Reading this User’s Manual. • Visiting our customer support website at www.uniden.com. Images in this manual may differ slightly from your actual product. DISCLAIMER: Radar detectors are illegal in some states. Some states prohibit mounting any object on your windshield. Check applicable law in your state and any state in which you use the product to verify that using and mounting a radar detector is legal. Uniden radar detectors are not manufactured and/or sold with the intent to be used for illegal purposes. Drive safely and exercise caution while using this product. Do not change settings of the product while driving. Uniden expects consumer’s use of these products to be in compliance with all local, state, and federal law. Uniden expressly disclaims any liability arising out of or related to your use of this product. CONTENTS CUSTOMER CARE .......................................................................................................... 2 R9 EXTREME OVERVIEW ............................................................................5 FEATURES ........................................................................................................................ 5 WHAT’S -

MAX 360 with Alert-Signaling Arrows

360Ω Radar / Laser Detection MAX 360 with Alert-signaling Arrows 360Ω ALERTS Designed in the USA ESCORT Inc. 5440 West Chester Road West Chester OH 45069 800.433.3487 EscortRadar.com ©2015 ESCORT Inc. ESCORT®, ESCORT Max 360®, ESCORT Live!™, DEFENDER®, TrueLock™, SpeedAlert®, SmartMute®, MuteDisplay®, 360° Directional Dual Antenna GPS-Powered Lightning SpecDisplay™, AutoSensitivity™, ExpertMeter™ are trademarks of ESCORT Inc. Manufactured in Canada. Features, specifications and prices Alert Arrows Front / Rear Detection Alert Accuracy Fast Response subject to change without notice FCC NOTE: Modifications not expressly approved by the manufacturer could void the user’s FCC granted authority to operate the equipment. FCC ID: QKLM6. Contains FCC ID: QKLBT1. This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received including interference that may cause undesired operation. For Android Made for iPhone 5, iPhone 5c, iPhone 5s, iPhone 6, iPhone 6s and iPhone 6 Plus. iPhone is a trademark of Apple Inc., registered in the U.S. and other countries. “Made for iPhone” means that an electronic accessory has been designed to connect specifically to iPhone and has been certified by the developer to meet Apple performance standards. Apple is not responsible for the operation of this device or its compliance with safety and regulatory standards. Please note that the use of this accessory with iPhone may affect wireless performance. Android is a registered trademark of Google Inc. The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc., and any use of such marks by ESCORT is under license. -

Luminosity and Surface Brightness Distribution of K-Band Galaxies from the UKIDSS Large Area Survey

Mon. Not. R. Astron. Soc. 000,1{17 (2009) Printed 22 October 2018 (MN LATEX style file v2.2) Luminosity and surface brightness distribution of K-band galaxies from the UKIDSS Large Area Survey Anthony J. Smith1?, Jon Loveday1 and Nicholas J. G. Cross2 1Astronomy Centre, University of Sussex, Falmer, Brighton BN1 9QH 2Scottish Universities Physics Alliance, Institute for Astronomy, University of Edinburgh, Royal Observatory, Edinburgh EH9 3HJ Accepted 2009 April 27. Received 2009 April 21; in original form 2008 June 2 ABSTRACT We present luminosity and surface-brightness distributions of 40 111 galaxies with K-band photometry from the United Kingdom Infrared Telescope (UKIRT) Infrared Deep Sky Survey (UKIDSS) Large Area Survey (LAS), Data Release 3 and optical photometry from Data Release 5 of the Sloan Digital Sky Survey (SDSS). Various features and limitations of the new UKIDSS data are examined, such as a problem affecting Petrosian magnitudes of extended sources. Selection limits in K- and r-band magnitude, K-band surface brightness and K-band radius are included explicitly in the 1=Vmax estimate of the space density and luminosity function. The bivariate brightness distribution in K-band absolute magnitude and surface brightness is presented and found to display a clear luminosity{surface brightness correlation that flattens at high luminosity and broadens at low luminosity, consistent with similar analyses at optical wavelengths. Best fitting Schechter function parameters for the K-band luminosity function are found to be M ∗ − 5 log h = −23:19 ± 0:04, α = −0:81 ± 0:04 and φ∗ = (0:0166 ± 0:0008)h3 Mpc−3, although the Schechter function provides a poor fit to the data at high and low luminosity, while the luminosity density in the K band is 8 −3 found to be j = (6:305 ± 0:067) × 10 L h Mpc . -

XMMU J174716.1–281048 and SAX J1806.5–2215

Mon. Not. R. Astron. Soc. 000, 1{?? (2016) Printed 22 November 2018 (MN LATEX style file v2.2) A search for near-infrared counterparts of two faint neutron star X-ray transients : XMMU J174716.1{281048 and SAX J1806.5{2215 Ramanpreet Kaur1?, Rudy Wijnands2, Atish Kamble3, Edward M. Cackett4, Ralf Kutulla5, David Kaplan5, Nathalie Degenaar2;6 1 Physics Department, Suffolk University, 41 temple street, Boston, Massachusetts, 02114, USA 2 Anton Pannekoek Institute for Astronomy, University of Amsterdam, Science Park 904, 1098 XH, Amsterdam, The Netherlands 3 Harvard-Smithsonian Center for Astrophysics, 60 Garden Street, Cambridge, MA 02138 4 Department of Physics and Astronomy, Wayne State University, Detroit, MI 48201, USA 5 Physics Department, University of Wisconsin-Milwaukee, Milwaukee, WI 53211, USA 6 Institute of Astronomy, University of Cambridge, Madingley Road, Cambridge CB3 OHA, UK 22 November 2018 ABSTRACT We present our near-infrared (NIR) imaging observations of two neutron star low mass X-ray binaries XMMU J174716.1{281048 and SAX J1806.5{2215 obtained using the PANIC instrument on the 6.5-meter Magellan telescope and the WHIRC instrument on the 3.5-meter WIYN telescope respectively. Both sources are members of the class of faint to very-faint X-ray binaries and undergo very long X-ray outburst, hence classified as `quasi persistent X-ray binaries'. While XMMU J174716.1{281048 was active for almost 12 years between 2003 and 2015, SAX J1806.5{2215 has been active for more than 5 years now since 2011. From our observations, we identify two NIR stars consistent with the Chandra X-ray error circle of XMMU J174716.1{281048. -

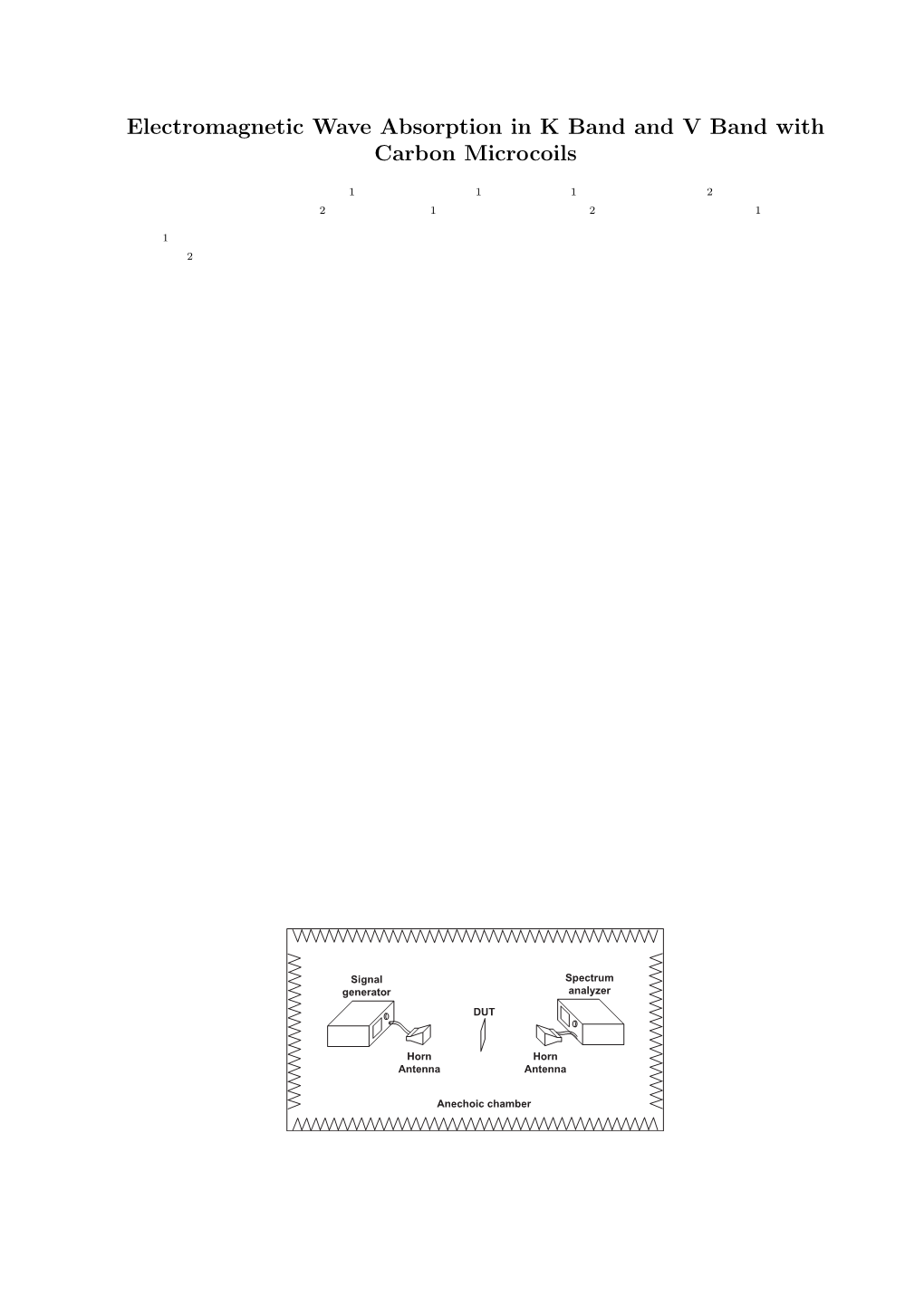

K- and W-Band Free-Space Characterization of Highly Conductive Radar Absorbing Materials

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication. Citation information: DOI 10.1109/TIM.2020.3041821, IEEE Transactions on Instrumentation and Measurement 1 K- and W-band Free-Space Characterization of Highly Conductive Radar Absorbing Materials Nagma Vohra, Student Member, IEEE and Magda El-Shenawee, Senior Member, IEEE lead to a reduced signal to noise ratio or ghost targets [6]. Abstract— This work presents a characterization technique of Furthermore, the coupling between transmit and receive highly conductive material in the K- and W-band. The antennas, and reflections from the adjacent metal structures of transmission line theory model is modified to adapt for the phase the vehicle can cause electromagnetic interference (EMI) in the challenges observed in the measured S-parameters at high automotive radar system. frequency. The S-parameters measurements are obtained using the non-destructive focused beam free-space system connected Engineering and characterization of high-frequency radar with the network analyzer and the millimeter-wave frequency absorbing materials (RAMs) have been investigated in the extenders. The system provides measurements in a frequency literature for years [7], [8]. Additionally, the shielding from the range from 5.8 GHz to 110 GHz, and it includes focused beam horn EM waves depends on the critical properties of the engineered lens antennas to minimize sample edge reflection. The TRL composite materials [9-11]. Therefore, the electromagnetic calibration and the time-gated feature of the network analyzer are characterization of the RAM material versus frequency is of used. -

Multi-Frequency Monitoring of Three Gamma-Ray Quasars

Multi-Frequency Monitoring of Three Gamma-Ray Quasars † Svetlana Jorstad∗ , Alan Marscher∗, Ian McHardy∗∗, Kristopher Makrides∗, Daniel ‡ ‡ § † Salem∗, Thomas Balonek , Jeyhan Kartaltepe , Margo Aller , Valerij Larionov , † ¶ ¶ Natalia Efimova , Claudia Raiteri , Massimo Villata , Omar Kurtanidze", Martin Gaskell†† and Marc Türler‡‡ ∗Inst. for Astrophysical Research, Boston Univ., 725 Commonwealth Ave., Boston, MA 02215 †Sobolev Astronomical Inst., St. Petersburg State Univ., Universitetskij pr. 28, St. Petersburg, 198504 Russia ∗∗Dept. of Physics, Univ. of Southampton, Southampton SO17 1BJ, UK ‡Dept. of Physics and Astronomy, Colgate Univ., 13 Oak Dr., Hamilton, NY 13346 §Astronomy Dept., Univ. of Michigan, 830 Dennison, 501 East University St., Ann Arbor, Michigan 48109 ¶Osservatorio Astronomico di Torino, Via Osservatorio, 20, 10025 Pino Torinese, Italy "Abastumani Obs., 383762, Abastumani, Georgia ††Dept. of Physics and Astronomy, Univ. of Nebrasks, Lincoln, NE 68588 ‡‡Geneva Obs., ch. des Maillettes 51, CH-1290 Sauverny, Switzerland Abstract. We have performed two campaigns of intensive monitoring of the blazars 3C 273, 3C 279, and PKS 1510 089 in the X-ray, optical, near-IR, and radio regions in March and April 2002. The quasar 3C 279 reveals significant interday− variability at all wavelengths. The quasar 3C 273 shows smooth variations in the X-ray and near-IR regions on time scales of 2-3 days. For both quasars the results indicate close connection between X-ray and near-IR emission with a delay of X-rays from 0 to 3 days. The quasar PKS 1510-089 was in a low emission state at all frequencies during the campaigns. INTRODUCTION OBSERVATIONS Blazars form the most energetic subclass of active galac- The X-ray observations of the quasars are part of a long- tic nuclei (AGN) characterized by violent variabilty term monitoring program of blazars performed with the on time scales from hours to years across the electro- Rossi X-ray Timing Explorer (RXTE) starting in Cycle magnetic spectrum [9, 14, 13].