United States Patent Office Patented Jan

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Carbonylation of Protected Or Non-Protected 2-Bromobenzaldehyde Catalyzed by Cobalt Carbonyl

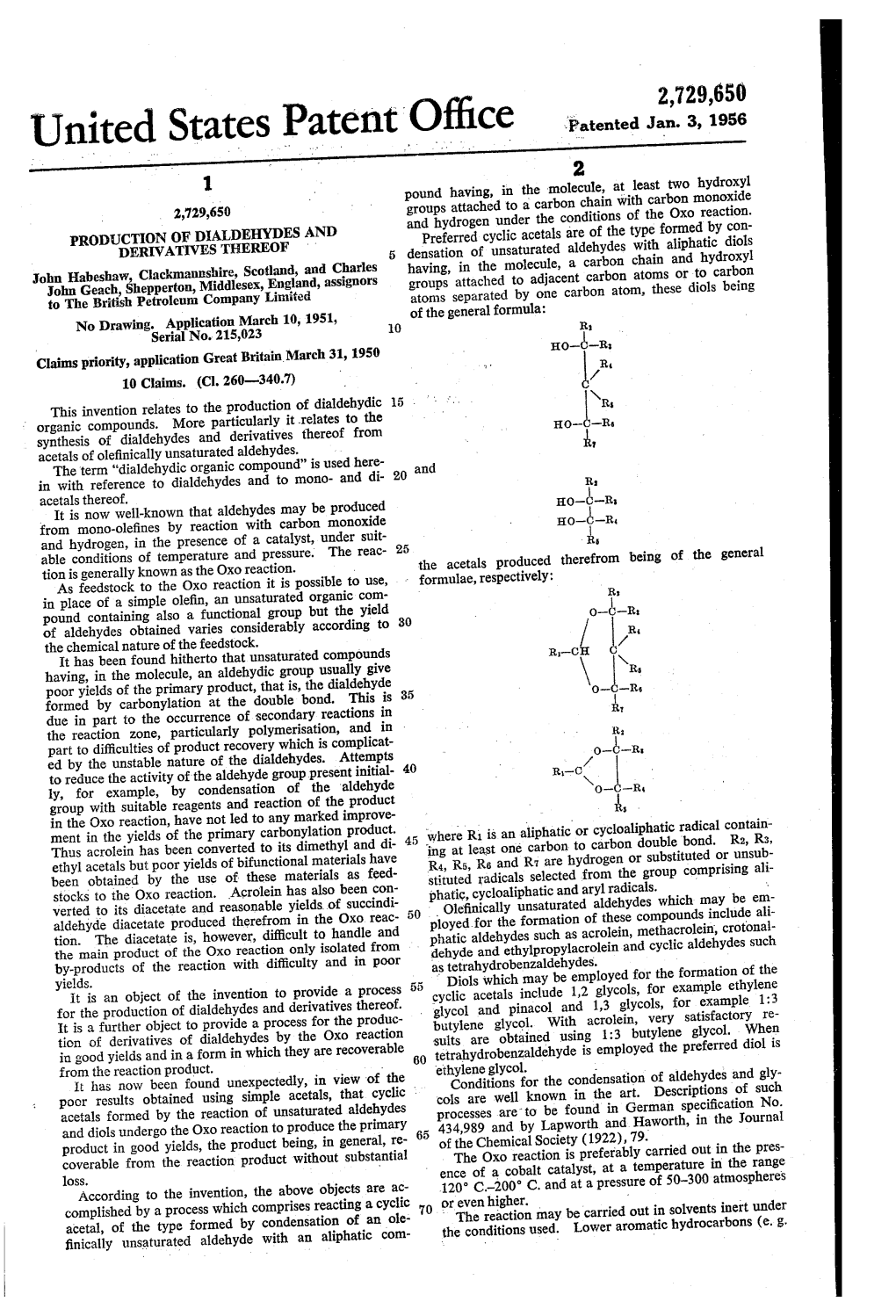

772 Bull. Korean Chem. Soc. 1994, Vol. 15, No. 9 Sang Chui Shim et al. Carbonylation of Protected or Non-protected 2-Bromobenzaldehyde Catalyzed by Cobalt Carbonyl Sang Chui S버 m*, Dong Yub Lee, Heung Jin Choi, Chil Hoon Doh1, and Keun Tai Huh* ^Department of Industrial Chemistry, Kyungpook National University, Taegu 701-702, Korea ^Department of Materials Science and Engineering Kyungsung University, Pusan 608-736, Korea Korea Electrotechnology Research Institute, Changwon, Korea Received May 11, 1994 The cobalt catalyzed carbonylation of bromobenzene having protected aldehyde group gives the corresponding ester in good yields, but 2-bromobenzaldehyde gives 3-alkoxyphthalide in the noticeable yield instead of alkyl 2-formylben- zoates. Introduction Table 1. Carbonylation of 2-Bromobenzenes Having Protected Aldehyde Groups to 2-Substituted Alkyl Benzoates Catalyzed by The metal-catalyzed carbonyl가 ion of aryl halides has ver Cobalt CarbonyF satile utility in the preparative organic chemistry1. Of many Run Reactant catalysts2 used in the carbonylation of aryl halides cobalt Alcohol Product Yield (%y carbonyl species have been conducted under mild conditions, 1 1 CH3CH2OH 2b 88 room temperature and one atmospheric pressure of carbon 2 1 CH3CH2OH 2b 75 。 monoxide. More recently, using dicobalt octacarbonyl at room 3 1 CH3CH2OH 2b 38d temperature under one atmospheric pressure of carbon mo 4 1 CH3OH 2a 80 noxide many applications were reported on the carbonylation 5 1 CH3CH2CH2OH 2c 85 of benzal halides,3-5 and halo (halomethyl)benzenes6-8. 6 (CH3)2CHOH 21 However, studies2,9-11 on the carbonylation of aryl halides 1 2d 7 CH3CH2CH2CH2OH having other reactive functional groups are rare. -

Direct Carboniiatiom of Aromatic Nttriles Using

DIRECT CARBONIIATIOM OF AROMATIC NTTRILES USING DICOBALT OCTACARBONIL by JOSEPH EDMUND GERVAX B..Sc Honours, University of Montreal, Loyola College, l?6l A THESIS SUBMITTED IN PARTIAL FUIFIIMENT OF THE REQUIREMENTS FOR THE DEGREE OF MASTER OF SCIENCE in the Department of Chemistry We accept this; thesis as conforming to the required standard THE UNIVERSITY OF BRITISH COLUMBIA June, 1963 In presenting this thesis in partial fulfilment of the requirements for an advanced degree at the University of British Columbia, I agree that the Library shall make it freely available for reference and study. I further agree that per• mission for extensive copying of this thesis for scholarly purposes may be granted by the Head of my Department or by his representatives. It is understood that copying, or publi• cation of this thesis for financial gain shall not be allowed without my written permission. Department of CHEMISTRY The University of British Columbia,. Vancouver 8, Canada. Date June 2°» W ABSTRACT A new method of synthesizing N-substituted phthalimidines is described. When benzonitrile was reacted with carbon monoxide containing about 0.0k volume percent of hydrogen and in the presence of dicobalt octacarbonyl and pyridine in benzene solution at 235° and 3U00 p.s.i. pressure the following compounds were produced: MTbenzyphthalimidine (8$), N-phenylphthalimidine (3»7%), and benzamide (3*9%)- When lj.0 p.s.i. hydrogen was added under the same reaction conditions, the yield of N-benzylphthalimidine increased (16%)., When benzonitrile was subjected to the same reaction conditions using 2U0 p.s.d* hydrogen and no pyridine, N-benzylphthalimidine (1%%) and sym-dibenzylurea (8$) were produced. -

Chemical Intercalation of Zerovalent Metals Into 2D Layered Bi2se3 Nanoribbons † † ‡ † † † § Kristie J

Article pubs.acs.org/JACS Chemical Intercalation of Zerovalent Metals into 2D Layered Bi2Se3 Nanoribbons † † ‡ † † † § Kristie J. Koski, Colin D. Wessells, Bryan W. Reed, Judy J. Cha, Desheng Kong, and Yi Cui*, , † Department of Materials Science and Engineering, Stanford University, Stanford, California 94305, United States ‡ Physical and Life Sciences Directorate, Lawrence Livermore National Laboratory, 7000 East Avenue, Livermore, California 94550, United States § SLAC National Accelerator Laboratory, Stanford Institute for Materials and Energy Sciences, 2575 Sand Hill Road, Menlo Park, California 94025, United States *S Supporting Information ABSTRACT: We have developed a chemical method to intercalate a variety of zerovalent metal atoms into two-dimen- sional (2D) layered Bi2Se3 chalcogenide nanoribbons. We use a chemical reaction, such as a disproportionation redox reaction, to generate dilute zerovalent metal atoms in a refluxing solution, which intercalate into the layered Bi2Se3 structure. The zerovalent nature of the intercalant allows superstoichiometric intercalation of metal atoms such as Ag, Au, Co, Cu, Fe, In, Ni, and Sn. We foresee the impact of this methodology in establishing novel fundamental physical behaviors and in possible energy applications. 1. INTRODUCTION Ni, and Sn. Some interesting effects that could arise with − 7−10 intercalation are superconductivity, such as in Cu Bi2Se3, Intercalation is the insertion of a guest species into a host 6 lattice. Intercalation into layered materials is essential to battery enhanced conductivity, or possibly opening a surface state gap electrodes, electrochromics, detergents, and solid lubricants and in topological insulator Bi2Se3. This method of zerovalent metal is important in exotic fundamental two-dimensional (2D) intercalation may also be extended to other layered materials. -

Bond Distances and Bond Orders in Binuclear Metal Complexes of the First Row Transition Metals Titanium Through Zinc

Metal-Metal (MM) Bond Distances and Bond Orders in Binuclear Metal Complexes of the First Row Transition Metals Titanium Through Zinc Richard H. Duncan Lyngdoh*,a, Henry F. Schaefer III*,b and R. Bruce King*,b a Department of Chemistry, North-Eastern Hill University, Shillong 793022, India B Centre for Computational Quantum Chemistry, University of Georgia, Athens GA 30602 ABSTRACT: This survey of metal-metal (MM) bond distances in binuclear complexes of the first row 3d-block elements reviews experimental and computational research on a wide range of such systems. The metals surveyed are titanium, vanadium, chromium, manganese, iron, cobalt, nickel, copper, and zinc, representing the only comprehensive presentation of such results to date. Factors impacting MM bond lengths that are discussed here include (a) n+ the formal MM bond order, (b) size of the metal ion present in the bimetallic core (M2) , (c) the metal oxidation state, (d) effects of ligand basicity, coordination mode and number, and (e) steric effects of bulky ligands. Correlations between experimental and computational findings are examined wherever possible, often yielding good agreement for MM bond lengths. The formal bond order provides a key basis for assessing experimental and computationally derived MM bond lengths. The effects of change in the metal upon MM bond length ranges in binuclear complexes suggest trends for single, double, triple, and quadruple MM bonds which are related to the available information on metal atomic radii. It emerges that while specific factors for a limited range of complexes are found to have their expected impact in many cases, the assessment of the net effect of these factors is challenging. -

Metal Carbonyls

MODULE 1: METAL CARBONYLS Key words: Carbon monoxide; transition metal complexes; ligand substitution reactions; mononuclear carbonyls; dinuclear carbonyls; polynuclear carbonyls; catalytic activity; Monsanto process; Collman’s reagent; effective atomic number; 18-electron rule V. D. Bhatt / Selected topics in coordination chemistry / 2 MODULE 1: METAL CARBONYLS LECTURE #1 1. INTRODUCTION: Justus von Liebig attempted initial experiments on reaction of carbon monoxide with metals in 1834. However, it was demonstrated later that the compound he claimed to be potassium carbonyl was not a metal carbonyl at all. After the synthesis of [PtCl2(CO)2] and [PtCl2(CO)]2 reported by Schutzenberger (1868) followed by [Ni(CO)4] reported by Mond et al (1890), Hieber prepared numerous compounds containing metal and carbon monoxide. Compounds having at least one bond between carbon and metal are known as organometallic compounds. Metal carbonyls are the transition metal complexes of carbon monoxide containing metal-carbon bond. Lone pair of electrons are available on both carbon and oxygen atoms of carbon monoxide ligand. However, as the carbon atoms donate electrons to the metal, these complexes are named as carbonyls. A variety of such complexes such as mono nuclear, poly nuclear, homoleptic and mixed ligand are known. These compounds are widely studied due to industrial importance, catalytic properties and structural interest. V. D. Bhatt / Selected topics in coordination chemistry / 3 Carbon monoxide is one of the most important π- acceptor ligand. Because of its π- acidity, carbon monoxide can stabilize zero formal oxidation state of metals in carbonyl complexes. 2. SYNTHESIS OF METAL CARBONYLS Following are some of the general methods of preparation of metal carbonyls. -

The Action of Carbon Monoxide and Hydrogen on Deoxybenzoin Oxime and on 2-Acetonaphthone Oxime

THE ACTION OF CARBON MONOXIDE AND HYDROGEN ON DEOXYBENZOIN OXIME AND ON 2-ACETONAPHTHONE OXIME by Arthur Ronald Hubsoher A THESIS SUBMITTED IN PARTIAL FULFILMENT OF THE REQUIREMENTS POR THE DEGREE OP MASTER OF SCIENCE in the Department of Chemistry We accept this thesis as conforming to the required standard THE UNIVERSITY OF BRITISH COLUMBIA May, 1959 ABSTRACT When deoxybenzoin oxime was reacted with carbon monoxide and hydrogen in the presence of dicobalt ootacarbonyl at elevated temperatures and pressures 5-benzylphthalimidine and 3-phenyl-3,4- dihydroisocarbostyryl were produced. When 2-acetonaphthone oxime was reacted under similar conditions 2-(^-naphthyl)-4-methyl- benzo[h] quinoline, 2-methylbenzoff]phthalimidine and 1- (^-naphthyl)ethylurea were produced. Verification of the structure of 2-(^-naphthyl)-4-methylbenzo[h]- quinoline was attained in part through the hydro• chloride salt, the methiodide salt, the picrate derivative and the 2-(^-naphthyl)-4-formylbenzofh]- quinoline derivative. 2-(^-K.aphthyl )-4-methyl- benzofh] quinoline was also synthesized by reacting 2- acetonaphthone oxime with 2-acetonaphthone at elevated temperatures. The infrared spectra of the above compounds are described. In presenting this thesis in partial fulfilment of the requirements for an advanced degree at the University of British Columbia, I agree that the Library shall make it freely available for reference and study. I further agree that permission for extensive copying of this thesis for scholarly purposes may be granted by the Head of my Department or by his representatives. It is understood that copying or publication of this thesis for financial gain shall not be allowed without my written permission. -

Technical Notes: 1

Strem Chemicals, Inc. www.strem.com Catalog # 27-0400 Cobalt carbonyl (Dicobalt octacarbonyl) (Stabilized with 1-5% hexane) Catalysis Applications Technical Notes: 1. Reagent for the Pauson-Khand conversion of an olefin, an alkyne and carbon monoxide into a cyclopentenone. 2. Precatalyst in combination with triphenylphosphite for the cataytic Pauson-Khand reaction. 3. Catalyzes the rearrangement of 1-alkynylcyclopropanols to cyclopentenones. 4. Catalyzes the conversion of aziridines to -lactams. 5. Catalyzes the conversion of diallylanilines and aryliminies to quinolones. 6. Reagent for the selective cleavage of benzyl ethers. 7. Domino Nicholas and Pauson-Khand process induced by nitroarene reduction. Tech. Note (1) Ref. (1,2) Tech. Note (2) Refs. (3,4,5) Tech. Note (3) Ref. (6,7) Tech. Note (4) Ref. (8) Tech. Note (5) Ref. (9) \ Tech. Note (6) Ref. (10) Tech. Note (7) Ref. (11) References: 1. Comprehensive Organic Synthesis, 1991, Vol. 5, Ch. 9.1, 1037. 2. Encyclopedia of Reagents for Organic Synthesis, 1995, Vol. 6, 3785. 3. J. Am. Chem. Soc., 1994, 116, 3159. 4. J. Am. Chem. Soc., 1996, 118, 2285. 5. Tetrahedron Lett., 1998, 39, 7637. 6. Tetrahedron: Asymmetry, 2000, 11, 797. 7. J. Am. Chem. Soc., 1998, 120, 3903. 8. J. Am. Chem. Soc., 1996, 118, 111. 9. J. Org. Chem., 2003, 68, 3563. 10. Org. Lett., 2010, 12, 536. 11. Tetrahedron Lett., 2015, 56, 4674. CVD/ALD Applications Thermal Behavior: Vapor pressure of 1 Torr at 35 °C [2] Melting point: 51 °C [2] Decomposition temperature 60-70 °C [6] Technical Notes: 1. Volatile carbonyl precursor for various CVD processes for cobalt metal, oxide and silicide films. -

Alkyne-Cobalt-Clusters

COBALT -CLUSTER MEDIATED PROPARGYL CATION AND RADICAI.J REARRANGEMENTS ALKYNE-COBALT-CLUSTERS: SYNTHESES, STRUCTURES AND REARRANGEMENTS OF METAL··STABILIZED PROPARGYL CATIONS AND RADICALS By JOHN H. KALDIS, B.Sc. A Thesis Submitted to the School of Graduate Studies In Partial Fulfillment ofthe Requirements for the Degree Doctor of Philosophy McMaster University © Copyright by John H. Kaldis, August 2003 DOCTOR OF PHILOSOPHY (2003) McMaster University (Chemistry) Hamilton, Ontario TITLE: Alkyne-Cobalt-Clusters: Syntheses, Structures and Rearrangements of Metal-Stabilized Propargyl Cations and Radicals AUTHOR: John H. Kaldis, B.Sc. (University of Western Ontario) SUPERVISOR: Dr. Michael J. McGlinchey NUMBER OF PAGES: XV, 192 11 Abstract Cobalt-clusters are versatile reagents in organometallic chemistry. Their ability to protect an alkyne allows one to selectively manipulate a ligand without undergoing a competitive reaction from the alkyne. Cobalt-clusters geometrically modify linear alkynes to 136-145° degrees, thereby allowing for some non-traditional alkynyl chemistry to occur. In particular, the focus of this dissertation lies upon the chemistry of cobalt-complexed propargyl alkynols, the ability of cobalt to stabilize neighbouring cations generated from these alcohols, and the chemistry that can be accomplished by altering the steric and electronic effects. We have chosen to study the possibility of inducing migration of various substituents from one terminus of the cobalt-complexed alkyne to the alcoholic site ofthe propargyl group via protonation ofthe desired complex. While examining various silanes, and altering the propargyl alcohol itself, we have considered both steric and electronic effects, thereby determining the idealized conditions for such transfers to occur. Furthermore, in our attempts to successfully apply these migrations to several systems, we have acquired a diverse synthetic knowledge of propargyl cobalt-clusters and their intricate reactivity. -

United States Patent Office Patented Jan

3,231,621 United States Patent Office Patented Jan. 25, 1966 2 oxide, hydrogen, and a carbon compound containing 3,231,621 REACTION RATES IN CATALYTIC olefinic linkage with a hydroformylation catalyst com HYDROFORMYLATION prising a complex between a metal, preferably cobalt, Lynn H. Slaugh, Pleasant Hill, Calif., assignor to Shell carbon monoxide, and a nitrogen-containing ligand com Oil Company, New York, N.Y., a corporation of prising a substituted pyridine, to be described hereinafter, Delaware under conditions sufficient to produce aldehydes and alco No Drawing. Filed June 26, 1961, Ser. No. 119,313 hols containing one more carbon atom than present in the 7 Claims. (C. 260-604) olefinic reactant. - As used herein, the term "complex' indicates a co The present invention relates to the preparation of ordination compound which is a combination of a metal oxygenated organic compounds, particularly aldehydes 10 atom with one or more electronically-rich molecules or and alcohols, by the reaction of carbon monoxide and atoms capable of independent existence. hydrogen with olefinic organic compounds in the presence The metal is held in complex combination with the of an improved hydroformylation catalyst. More spe particular nitrogen-containing ligand found most desir cifically, the present invention relates to hydroformyla able for the particular process wherein it is to be used. tion using certain metal complex catalysts having as 5 The ratio of the molar amount of ligand in the complex sociated therewith certain ligands to be described in detail is determined by the coordination number of the par hereinafter. ticular transition metal involved. By “ligand” is meant Hydroformylation is well known in the art and com a molecule having an element with a pair of electrons prises converting an olefin by reaction with carbon mon capable of bonding with a metal atom whereby a complex oxide and hydrogen to a corresponding aldehyde or alco 20 is formed. -

Efficient Synthesis of New Fluorinated Building Blocks by Means of Hydroformylation

Fluorine Chemistry CHIMIA 2014, 68, Nr. 6 371 doi:10.2533/chimia.2014.371 Chimia 68 (2014) 371–377 © Schweizerische Chemische Gesellschaft Efficient Synthesis of New Fluorinated Building Blocks by means of Hydroformylation Lidia Fanfonia, Lisa Diaba, Tomas Smejkal*b, and Bernhard Breit*a Abstract: Hydroformylation of fluorinated alkenes is an efficient method for the preparation of fluorinated functionalized building blocks for the synthesis of biologically active target structures. In this article we summarize known hydroformylation reactions of fluorinated olefins and we add new results from our research groups. Particular attention is paid to the remarkable influence of organofluorine substituents on catalyst activity, regio- and stereoselectivity of the hydroformylation reaction. Keywords: Aldehydes · Alkenes · Hydroformylation · Organofluorides · Rhodium 1. Introduction Fluorine is a key element commonly used in modern pharma and agrochemical products. As a result of the unique elec- tronic and steric properties, fluorinated substituents can beneficially influence the physico-chemical properties, improve bio- logical activity and modulate metabolism Scheme 1. Efficient synthesis of the herbicide Prosulfurone. of active ingredients.[1] Therefore, new technologies which allow the selective and Hydroformylation is a relatively un- 2. Substrates Fluorinated at the cost-efficient synthesis of various fluori- derutilized reaction regarding the use of Double Bond nated intermediates are highly desirable. fluorinated olefins so far. This is surpris- During the last few years, particularly the ing considering the fact that it could poten- 2.1 Vinyl Fluoride toolbox of transition metal-catalyzed reac- tially provide synthetically highly versatile The hydroformylation of vinyl fluoride tions for late stage introduction of a single intermediates – fluorinated aldehydes. -

Cobalt and Palladium Reagents in Organic Synthesis: the Beginning

ACCOUNT 2855 Cobalt and Palladium Reagents in Organic Synthesis: The Beginning Richard F. Heck* For temporary correspondence, c/o Victor Snieckus, Queen’s University, Kingston, ON, K7L 3N6, Canada Fax +1(613)5336089; E-mail: [email protected] A Retrospective heptanal and 30% 2-methylhexanal in high yields. The Abstract: A personal account of the discovery and initial develop- ment of organocobalt and organopalladium chemistry. R. F. Heck, catalyst for the reaction was generally added as cobalt Professor Emeritus, University of Delaware, Newark DE, USA. oxide, carbonate, acetate or similar compounds. It was known that the cobalt compounds were converted into the well-known dicobalt octacarbonyl under the reaction con- In 1956, after completing my graduate training and post- ditions. Studies carried out by Professor Walter Hieber of doctoral work in physical organic chemistry, I entered the the Technische Hochschule in Munich at about this time employment of the Hercules Powder Co. (now Hercules, also suggested that the very unstable (at room temperature Inc.) at their research center in Wilmington, Delaware. I and atmospheric pressure) cobalt hydrocarbonyl, joined a group of chemists working on the development of HCo(CO)4, would be present in the catalytic reaction as a commercial process for producing polyethylene and well.4 polypropylene employing the recently discovered A brief report appeared in the literature in 1953 by a re- Ziegler–Natta catalysts. This work required me to learn search group under Irving Wender2 at the U.S. Govern- the literature on transition-metal chemistry and to do ment Bureau of Mines Labs in Pittsburgh, which laboratory work with air-sensitive and unstable organo- suggested that cobalt hydrocarbonyl was the actual cata- metallic compounds. -

Homogeneous Catalysis Using Inorganic Complexes Deane

HOMOGENEOUS CATALYSIS USING INORGANIC COMPLEXES A Thesis submitted by DEANE EVANS for the Degree of Doctor of Philosphy of the University of London Royal College of Science December 1968 South Kensington, 5.11.7. To Janet Abreviations. Me methyl Et ethyl Ph phenyl All temperatures are in CentiErade. COFTLYTS. Chapter Title Page, Abstract Introduction 7 1. Chlorocarbonylbis(triarlylphosphine)- rhodium(I) complexes 27. 2. Hydroformylation using Rhodium 29. 3. Hydroformylation using other metals 82. Experimental 88. References 100. Acknowledgments I wish to thank Professor G. Wilkinson, F.R.S. for his encouragement and advice during the supervision of this work. I should like to thank all my colleagues especially Dr. J. A. Osborn, Dr. J. F. Young and Dr. L. Pratt for their unfailing advice. I should also like to thank my wife for typing this manuscript for the price of a new dress. Finally, I am indebted to Albright and Wilson Ltd. without whose generous financial aid this work would have been impossible. Especially Dr. H. Coates for his encourage- ment and help during the past decade, and Dr. P. A. T. Hoye for his unfailing patience during my early years in chemistry. ABSTRACT. A simple and quick method of preparing trans-chlorocarbonyl- bis(triarylphosphine)rhodium(I) complexes and trans-chloro- carbonylb4.s(triphenylarsine)rhodium(I)from rhodium trichloride trihydrate is described. The hydroformylation of olefins using compounds of general formulae RhX(C0)(1-Th3)2 (X = Cl, Br Qr I; R = alkyl, aryl or mixed alkyl-aryl) is described. The dependence of hydro- formylation on the equilibrium RhX(C0)(Pl=h3)2 E2A 1Lnh(CC)('Ph3)2 + EX has been demonstrated by using alkyl amines as co-catalysts when the aminehydrohalide can be recovered from the reaction mixture.