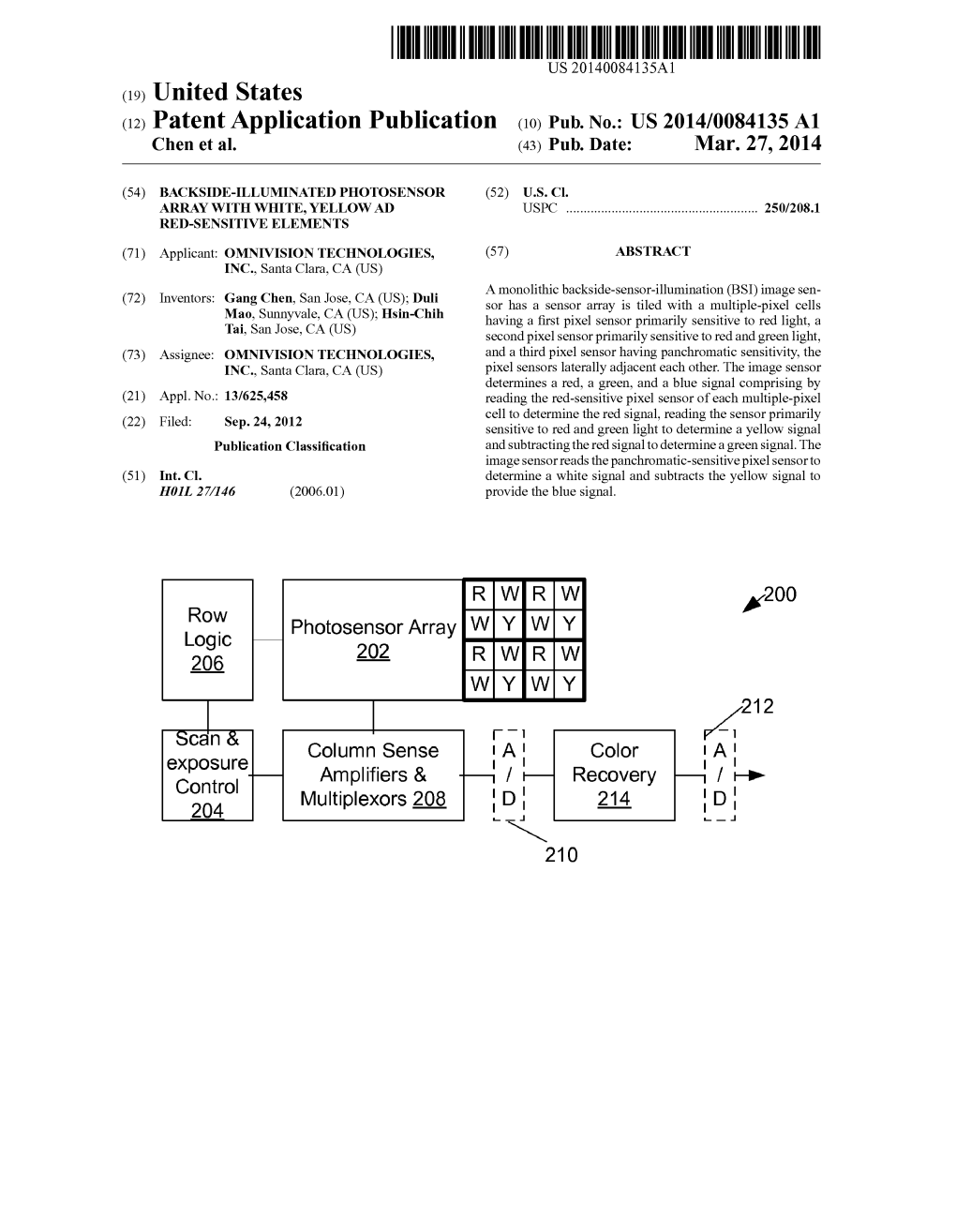

(12) Patent Application Publication (10) Pub. No.: US 2014/0084135 A1 Chen Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Sept 13Th, 2021 PROGRAM

2021 INTERNATIONAL IMAGE SENSOR WORKSHOP Online event Sept 20-23, 2021 Paper publication date: Sept 13th, 2021 PROGRAM Monday, Sept 20th 2021 15:00 Opening Session 01 Small Pixels Session chair: TBA 15:12 The-State-of-the-Art of CMOS Image Sensors R01 Ziad Shukri, TechInsights Inc., Ottawa, Canada 15:18 A 40/22nm 200MP Stacked CMOS Image Sensor with 0.61um Pixel R02 Masayuki Uchiyama2, Geunsook Park1; Tomoyasu Tate1, Masashi Minagawa2, Shino Shimoyamada2, Zhiqiang Lin1, King Yeung1, Lien Tu1, Wu-Zang Yang3, Alan Hsiung1, Vincent Venezia1, Lindsay Grant1 1 OmniVision Technologies, Santa Clara, CA, USA 2 OmniVision Technologies Japan, Kanagawa, Japan 3 OmniVision Technologies Taiwan, Hsinchu, Taiwan 15:24 0.64μm-pitch CMOS Image Sensor with Low Leakage Current of Vertical Transfer Gate R03 Dongmo Im, Jameyung Kim, Juhee Lee, Sungbong Park, Kwansik Cho, Hyunchul Kim, Chang-Rok Moon and Hyoung-Sub Kim Semiconductor R&D Center, Samsung Electronics Co., Republic of Korea. 15:30 An application of sub-half-micron pixel with preserved color pixel concept for next- R04 generation color image acquisition Yuichiro Yamashita1, Yuichiro Yamashita1, Rihito Kuroda2,3, Shigetoshi Sugawa3, Dun Nian Yaung1 1 CMOS Image Sensor Division, Taiwan Semiconductor Manufacturing Company, Hsinchu, Taiwan, R.O.C. 2 Graduate School of Engineering, Tohoku University, Sendai, Japan, 3 New Industry Creation Hatchery Center, Tohoku University, Sendai, Japan 15:36 A study on modulation transfer function and signal-to-noise ratio for Tetracell CMOS R05 image sensors with -

Omnivision Chips Power New Camera Phone Designs From

Investor Relations: Media Contact: Company Contact: Steven Horwitz Martijn Pierik Scott Foster OmniVision Technologies Impress Public Relations OmniVision Technologies Ph: 408.542.3263 Ph: 602.366.5599 Ph: 408.542.3077 [email protected] [email protected] OMNIVISION CHIPS POWER NEW CAMERA PHONE DESIGNS FROM KYOCERA WIRELESS SUNNYVALE, Calif. — May 30, 2006 — OmniVision Technologies, Inc. (NASDAQ: OVTI), one of the world’s leading suppliers of CMOS image sensors, today announced that Kyocera Wireless Corp., a leading global supplier of CDMA wireless handsets and devices, will use OmniVision CameraChips for new camera phones slated for release in the second half of 2006, including the 1.3 Megapixel K340 Series and the VGA-resolution K320 Series. “At Kyocera Wireless we believe deeply in the genius of simplicity, whether it’s the intuitive handsets we design and sell or the enabling technologies we source from companies like OmniVision,” said Jim Kelly, executive vice president and chief operating officer at Kyocera Wireless Corp. “OmniVision has done an excellent job of providing leading-edge CMOS image sensor technology in form factors that meet our exact requirements and provide the best performance and the highest image quality.” The new phones from Kyocera Wireless will feature both VGA and 1.3 Megapixel resolution cameras. Some will utilize a smart socket design that allows interchangeability between OmniVision’s VGA and 1.3 megapixel sensors, giving Kyocera Wireless extra flexibility to better meet the specific design requirements of its carriers and their customers. The Kyocera camera phone designs will serve CDMA network customers around the world including in the North American, Latin American and Indian markets. -

In Re Omnivision Technologies, Inc. Litigation 11-CV-05235-Lead

Case5:11-cv-05235-RMW Documentl05 FiIed04/23/12 Pagel of 100 1 BARRACK RODOS & BACINE STEPHEN R BASSER (121590) 2 SAMUEL M. WARD (216562) 600 West Broadway, Suite 900 3 San Diego, CA 92101 Telephone: (619) 230-0800 4 Facsimile: (619) 230-1874 S BRAN STETrER, STRANCH & JENNINGS, PLLC 6 J. Gerard Stmnch, W 7 James G. Stmnch, ifi 227 Second Avenue North, Fourth Floor 8 Nashville, TN 37201-1631 Telephone: (615) 254-8801 9 Facsimile: (615) 250-3937 10 Co-Lead Counsel for Lead Plaintiffs Oakland County Employees'Retirement System, 11 Laborers'District Council Contractors'Pension Fund of Ohio, and Woburn Retirement System and the Proposed Class 12 [Additional counsel appear on signature page] 13 14 UNITED STATES DISTRICT' COURT 15 NORTHERN DISTRICT' OF CALWORNIA 16 SAN JOSE DIVISION 17 In re OMNIVISION TECHNOLOGIES, Case No.: 5:11-cv-05235-RMW 18 INC. LITIGATION LEAD PLAINTIFFS' CONSOLIDATED 19 CLASS ACTION COMPLAINT This Document Relates to: 20 ALL ACTIONS. 21 22 23 24 25 26 27 28 LEAD PLTFS' CONS. CLASS ACHON COMPLAINT F1 Case No.: 5:11-cv-05235-RMW Case5:11-cv-05235-RMW Document105 FiIed04/23/12 Page2 of 100 TABLE OF CONTENTS 2 IINTRODUCTION.....................................................................................................................1 3 I JURISDICTION AND VENUE...............................................................................................12 4 IPARTIES................................................................................................................................13 S I FRAUDULENT SCHEME -

Omnivision Technologies, Inc 10-K

To my fellow stockholders, Fiscal 2011 was an exciting and rewarding year for OmniVision as major tasks were accomplished and many performance records were set. Our key objectives in fiscal 2011 were threefold: • Continue the successful ramp of our OmniBSI devices, • Continue the development and implementation of our OmniBSI-2 technology, and • Capitalize on the growth and expansion opportunities presented by the image sensor markets with our advanced proprietary technology. We believe we have accomplished these goals, and are now resolved to maintain the momentum we have achieved. Fiscal Year Financial Results In fiscal 2011, revenues reached $956.5 million, approaching the $1 billion mark for the first time in our company history. Our net income for fiscal 2011 was $124.5 million, or $2.11 per diluted share. All of these financial metrics showed significant, if not record, improvement over fiscal 2010. Our balance sheet further demonstrated our focus on financial performance and the company’s overall strength in a competitive market. We ended the year with cash, cash equivalents and short-term investments of $466.9 million. Technology Achievements OmniVision takes great pride in its successful record of innovation. Specifically, our expertise in implementing the OmniBSI technology has positioned OmniVision as a leading component supplier, providing image sensors to a wealth of products, including high-end smartphones, notebooks, webcams, portable multi-media devices and even commercial enterprise applications. Our portfolio of image sensors now extends from VGA up to 14 megapixels, all meeting demanding performance standards. It is this wide range of offerings, as well as the depth of our expertise, that enabled the company to ship more than 680 million CMOS image sensors last year. -

OV48B PB V1.3

OV48B 48-megapixel product brief OmniVision's First 48 Megapixel, 0.8 µm Image Sensor lead free available in a lead-free OmniVision's OV48B is its first 48 megapixel (MP) image This sensor also features both DPHY and CPHY MIPI package sensor with the industry's smallest die size, featuring a interfaces, which enables fast frame rates using fewer pins. 0.801 µm pixel size to enable high resolution smartphone The OV48B includes 2x2 microlens phase detection cameras with a 1/2" optical format. Built on OmniVision's autofocus (ML-PDAF) to boost accuracy, especially in low PureCel®Plus stacked die technology, this sensor provides light. leading edge still image capture and video performance for both mainstream and high end smartphones. Additionally, it Output formats include: offers a wide range of features such as digital crop zoom • 48MP at 15 frames per second (fps) with remosaic and a CPHY interface, making it a versatile sensor for all • 12MP with 4-cell binning at 30 fps types of rear facing cameras in multi-camera • 4K2K video at 60 fps configurations, including main, wide angle and telephoto. • 1080p video at 240 fps • 720p video at 480 fps The OV48B integrates an on-chip 4-cell color filter array and hardware re-mosaic, which provides high quality, 48MP Find out more at www.ovt.com. Bayer output in real time. In low light conditions, this sensor can use near-pixel binning to output a 12MP image with four times the sensitivity. The OV48B can consistently capture the best quality images and videos without motion blur, as well as enabling digital crop zoom with 12MP resolution and fast mode switch. -

Case 2:19-Cv-10439-DPH-DRG ECF No. 25 Filed 04/29/19 Pageid.595 Page 1 of 59

Case 2:19-cv-10439-DPH-DRG ECF No. 25 filed 04/29/19 PageID.595 Page 1 of 59 UNITED STATES DISTRICT COURT EASTERN DISTRICT OF MICHIGAN NORTH PLATE SEMICONDUCTOR, Case No. 2:19-cv-10439-DPH-DRG LLC, Plaintiff, Judge: Hon. Denise Page Hood v. Magistrate Judge: OMNIVISION TECHNOLOGIES Hon. David R. Grand INC., TEXAS INSTRUMENTS INCORPORATED, SMART EYE INTERNATIONAL INC., SMK ELECTRONICS CORPORATION, U.S.A. Defendants. JURY TRIAL DEMANDED AMENDED COMPLAINT FOR PATENT INFRINGEMENT Plaintiff North Plate Semiconductor, LLC (“NPS” or Plaintiff”) hereby asserts a claim for patent infringement against Defendants OmniVision Technologies, Inc. (“OmniVision”), Texas Instruments Incorporated (“Texas Instruments”), Smart Eye International Inc. (“Smart Eye”), SMK Electronics Corporation, U.S.A. (“SMK”)(collectively referred to as “Defendants”), and in support thereof allege as follows: NATURE OF CASE 1. This is an action for patent infringement arising under the patent laws of the United States, 35 U.S.C. §1 et seq., specifically including 35 U.S.C. §271. Case 2:19-cv-10439-DPH-DRG ECF No. 25 filed 04/29/19 PageID.596 Page 2 of 59 2. As set forth below, Plaintiff holds the rights in U.S. Patent Nos. 6,211,509 (“the ‘509 patent”); 6,150,676 (“the ‘676 patent); 6,521,926 (“the ‘926 patent”); 7,928,483 (“the ‘483 patent”); 8,854,521 (“the ‘521 patent”); RE46123 (“the ‘123 patent”); 8,178,913 (“the ‘913 patent”) (cumulatively “Patents-in-Suit”). The United States patent laws grant the holder of a patent the right to exclude infringers from making, using, selling or importing the invention claimed in a patent, to recover damages for the infringer’s violations of these rights, and to recover treble damages where the infringer willfully infringed the patent. -

Omnivision Expands Native 1080P High Definition Camerachip™ Line-Up with 1/6-Inch Ov2722

OMNIVISION EXPANDS NATIVE 1080P HIGH DEFINITION CAMERACHIP™ LINE-UP WITH 1/6-INCH OV2722 OMNIBSI+™ PIXEL ENABLES HIGH-PERFORMANCE HD VIDEO SOLUTION FOR SMARTPHONE, TABLET, NOTEBOOK AND ULTRABOOK APPLICATIONS SANTA CLARA, Calif., — May 29, 2012 — OmniVision Technologies, Inc. (NASDAQ: OVTI), a leading developer of advanced digital imaging solutions, today introduced the OV2722, the Company’s second-generation native 1080p high-definition (HD) CMOS image sensor, designed specifically for ultra-portable applications where high performance and low profile are critical. Using OmniVision’s new OmniBSI+ pixel architecture, the OV2722 delivers improved sensitivity and image quality with a module height of less than 3 mm, making it an ideal choice for the burgeoning smartphone, tablet and Ultrabook™ markets. “We believe that current market trends are quickly moving beyond 720p, and we are seeing strong demand for premium quality 1080p HD video sensors that can meet the criteria and specifications of online video sharing platforms such as Skype™, and unified communications platforms such as Microsoft® Lync®,” said Nick Nam, director of product marketing at OmniVision. “In addition, many high-end cameras are required to have extremely small form factors so that they can fit inside next- generation smartphones, tablets, notebooks and Ultrabooks. The OV2722 is specifically crafted to meet these stringent performance requirements and design specifications, making it the ideal choice for these high-end devices.” The OV2722 is a 1/6-inch native 1080p HD CMOS image sensor, offering full field of view video with optimized image quality, sensitivity, color reproduction and clarity without scaling or cropping. Built on the new 1.4-micron OmniBSI+ pixel, the OV2722 offers significant performance improvements over the first generation, OmniBSI™-based OV2720, including a 60 percent increase in full-well capacity, a 10 percent increase in quantum efficiency and a 10 percent improvement in low-light performance. -

2017 International Image Sensor Workshop

2017 INTERNATIONAL IMAGE SENSOR WORKSHOP Grand Prince Hotel Hiroshima May 30th - June 2nd, 2017 Hiroshima, Japan PROGRAM Tuesday, May 30th 2017 08:00-08:30 Registration Welcome 08:30-08:45 Opening Session 01 Stacked Image Sensors Session chair: Yusuke Oike (Sony) Dun-Nien Yaung (TSMC) 08:45-09:00 An Advanced CuCu Hybrid Bonding For Novel Stacked CMOS Image Sensor R1 Y. Kagawa 1 , N. Fujii 2 , K. Aoyagi 2 , Y. Kobayashi 1 , S. Nishi 1 , N. Todaka 1 , S. Takeshita 1 , J. Taura 1 , H. Takahashi 2 , Y. Nishimura 2 , K. Tatani 2 , M. Kawamura 1 , H. Nakayama 1 , T. Nagano 2 , K. Ohno 2 , H. Iwamoto 2 , S. Kadomura 1 , T. Hirayama 2 . 1 Sony Semiconductor Manufacturing, Japan; 2 Sony Semiconductor Solutions, Japan 09:00-09:15 A 3D Stacked Programmable Image Processing Engine in a 40nm Logic Process with a Detector Array in a 45nm CMOS Image Sensor Technologies R2 Biay ‐ Cheng Hseih 1 , Keith Honea 1 , Sami Khawam 1 , Sergio Goma 1 , RJ Lin 2 , Chin ‐ Hao Chang 2 , Charles Liu 2 , Shang ‐ Fu Yeh 2 , Hong ‐ Yi Tu 2 , Kuo ‐ Yu Chou 2 , Calvin Chao 2 . 1 Qualcomm Technologies Inc., USA; 2 TSMC, Taiwan, ROC 09:15-09:30 1.0um Pixel Improvements with Hybrid Bond Stacking Technology R3 V.C. Venezia, C. Shih, W.Z. Yang, Y. Zang, Z. Lin, Lindsay Grant, and Howard Rhodes. Omnivision Technologies, USA 09:30-09:45 Development of Vertical Thin Poly-Si Channel Structured TG for 3D CIS Pixel Applications R4 Young-Jun Kwon 1 , Sung-Kun Park 1 , Sung-Wook Cho 1 , Kyoung-In Lee 1 , Sung-Man Kim 1 , Chris Hong 1 , In-Wook Cho 1 , Jae-Hyun Park 2 , and Kyung-Dong Yoo 2 . -

Expanded Imaging Processing Options

Expanded Imaging Processing Options Mathew Arcoleo May. 2021 1 © 2021 OmniVision | Security B: Highly Confidential Safe Harbor Statement Except for historical information, the matters discussed in this presentation may contain forward- looking statements. These forward-looking statements are only estimates, and are subject to risks and uncertainties that may affect actual outcomes. Actual events or results may differ materially, and OmniVision disclaims any obligation to update information contained in any forward-looking statement. 2 © 2021 OmniVision | Security B: Highly Confidential Automotive Trends Higher performance expectation across sensor KPI High Dynamic Range (HDR) of 140 dB LED Flicker Mitigation (LFM) Low light performance More pixels and smaller pixel Additional functionality for next-generation use cases Cybersecurity, advanced ROI Global shutter with high Near-Infrared (NIR) Quantum Efficiency (QE), and small form factor Low power across automotive segment 3 © 2021 OmniVision | Security B: Highly Confidential Synergy Across Segments Sub-micron Pixel Global Shutter Smear/ Increase Sensitivity Distortion Free Capture 4-cell 9-cell 16-cell RCCB RYYB Mobile B G B G G R Non-Bayer CF G R Nyxel® Split-pixel/DCG Enhancing NIR QE 4-Cell HDR Imaging HDR GS Nyxel® Security Auto 4 © 2021 OmniVision | Security B: Highly Confidential OX08B40 5 © 2021 OmniVision | Security B: Highly Confidential OX08B40 Target for Front and Surround Sensing Application in ADAS/AD 1st 8.3MP sensor with LFM 1st 8.3MP sensor using optimal HDR scheme for -

Company Vendor ID (Decimal Format) (AVL) Ditest Fahrzeugdiagnose Gmbh 4621 @Pos.Com 3765 0XF8 Limited 10737 1MORE INC

Vendor ID Company (Decimal Format) (AVL) DiTEST Fahrzeugdiagnose GmbH 4621 @pos.com 3765 0XF8 Limited 10737 1MORE INC. 12048 360fly, Inc. 11161 3C TEK CORP. 9397 3D Imaging & Simulations Corp. (3DISC) 11190 3D Systems Corporation 10632 3DRUDDER 11770 3eYamaichi Electronics Co., Ltd. 8709 3M Cogent, Inc. 7717 3M Scott 8463 3T B.V. 11721 4iiii Innovations Inc. 10009 4Links Limited 10728 4MOD Technology 10244 64seconds, Inc. 12215 77 Elektronika Kft. 11175 89 North, Inc. 12070 Shenzhen 8Bitdo Tech Co., Ltd. 11720 90meter Solutions, Inc. 12086 A‐FOUR TECH CO., LTD. 2522 A‐One Co., Ltd. 10116 A‐Tec Subsystem, Inc. 2164 A‐VEKT K.K. 11459 A. Eberle GmbH & Co. KG 6910 a.tron3d GmbH 9965 A&T Corporation 11849 Aaronia AG 12146 abatec group AG 10371 ABB India Limited 11250 ABILITY ENTERPRISE CO., LTD. 5145 Abionic SA 12412 AbleNet Inc. 8262 Ableton AG 10626 ABOV Semiconductor Co., Ltd. 6697 Absolute USA 10972 AcBel Polytech Inc. 12335 Access Network Technology Limited 10568 ACCUCOMM, INC. 10219 Accumetrics Associates, Inc. 10392 Accusys, Inc. 5055 Ace Karaoke Corp. 8799 ACELLA 8758 Acer, Inc. 1282 Aces Electronics Co., Ltd. 7347 Aclima Inc. 10273 ACON, Advanced‐Connectek, Inc. 1314 Acoustic Arc Technology Holding Limited 12353 ACR Braendli & Voegeli AG 11152 Acromag Inc. 9855 Acroname Inc. 9471 Action Industries (M) SDN BHD 11715 Action Star Technology Co., Ltd. 2101 Actions Microelectronics Co., Ltd. 7649 Actions Semiconductor Co., Ltd. 4310 Active Mind Technology 10505 Qorvo, Inc 11744 Activision 5168 Acute Technology Inc. 10876 Adam Tech 5437 Adapt‐IP Company 10990 Adaptertek Technology Co., Ltd. 11329 ADATA Technology Co., Ltd. -

Omnivision Technologies, Inc

TM 2009 Annual Report To my fellow stockholders, The past twelve months have been challenging for OmniVision and many other companies. We completed our 2009 fiscal year on April 30, 2009 as the global economic downturn continued to impact companies and markets worldwide. Against this background, our fiscal 2009 revenues decreased for the first time since 2002 on a year-over-year basis. Our fiscal 2009 revenues were $507.3 million and we recorded a net loss of $37.3 million, or $0.74 per share. Despite the challenging economic conditions, we are pleased with a number of our accomplishments during the past year, which include significant new technological and product introductions, continuation of our market share leadership, and further strengthening of our financial position. We also believe that this challenging environment creates an opportunity for us to capitalize on our long-term corporate strategy and to continue to gain market share. Backed by our strong balance sheet with over $275 million in cash, cash equivalents and short-term investments at fiscal 2009 year-end, we remain confident regarding our long-term growth prospects and committed to delivering value for our stockholders. Our Corporate Strategy At the heart of our corporate strategy are three key elements: • the wise investment in the development of new technology that enables us to continue to introduce market-leading products; • the development of new and emerging product markets and geographies; and • our continuing seamless collaboration with our supply chain partners, TSMC and VisEra, and XinTec, to efficiently and effectively manage our supply chain. Continuing Investment in New Technology First and foremost, we are a technology company. -

Woburn Retirement System, Et Al. V. Omnivision Technologies, Inc., Et Al

Case5:11-cv-05235-RMW Document1 Filed10/26/11 Page1 of 24 Al I Nancy L. Tompkins (Bar. No. 183623) KERR & WAGSTAFFE LLP 2 100 Spear Street, 18th Floor San Francisco, California 94105 3 Telephone: (415) 371-8500 Facsimile: (415) 371-0500 4 Email: tompkinskerrwagstaffe.com 5 Local Counsel for Plaintiff Woburn Retirement System 6 Christopher J. Keller 7 Michael W. Stocker (Bar No. 179083) Rachel A. Avan 8 LABATON SUCHAROW LLP E-filing 0 140 Broadway 9 New York, New York 10005 Telephone: (212) 907-0700 10 Facsimile: (212) 818-0477 Email: [email protected] 11 [email protected] [email protected] 12 Counsel for Plaintiff 13 Woburn Retirement System 14 15 UNITED STATES DISTRICT COURT 16 NORTHERN DISTRICT OF CALIFORNIA 17 RMpl Mao 18 WOBURN RETIREMENT SYSTEM, CaseTo) Individually and On Behalf of All Others )V 19 Similarly Situated, ) CLASS ACTION COMPLAINT ) FOR VIOLATION OF THE 20 Plaintiff, ) FEDERAL SECURITIES LAWS 21 DEMAND FOR JURY TRIAL 22 ) OMNI VISION TECHNOLOGIES, INC., ) 23 SHAW HONG, ANSON CHAN, and ) AURELIO "RAY" CISNEROS, 24 ) ) 25 Defendants. ) 26 27 28 CLASS ACTION COMPLAINT Case5:11-cv-05235-RMW Document1 Filed10/26/11 Page2 of 24 1 Plaintiff Woburn Retirement System ("Woburn" or "Plaintiff') makes the following 2 allegations based upon the investigation of Plaintiffs counsel, which included a review of U.S. 3 Securities and Exchange Commission ("SEC") filings by Omni Vision Technologies, Inc. 4 ("OmniVision" or the "Company"), as well as regulatory filings and reports, securities analysts' 5 reports and advisories about the Company, press releases and other public statements issued by 6 the Company, and media reports about the Company.