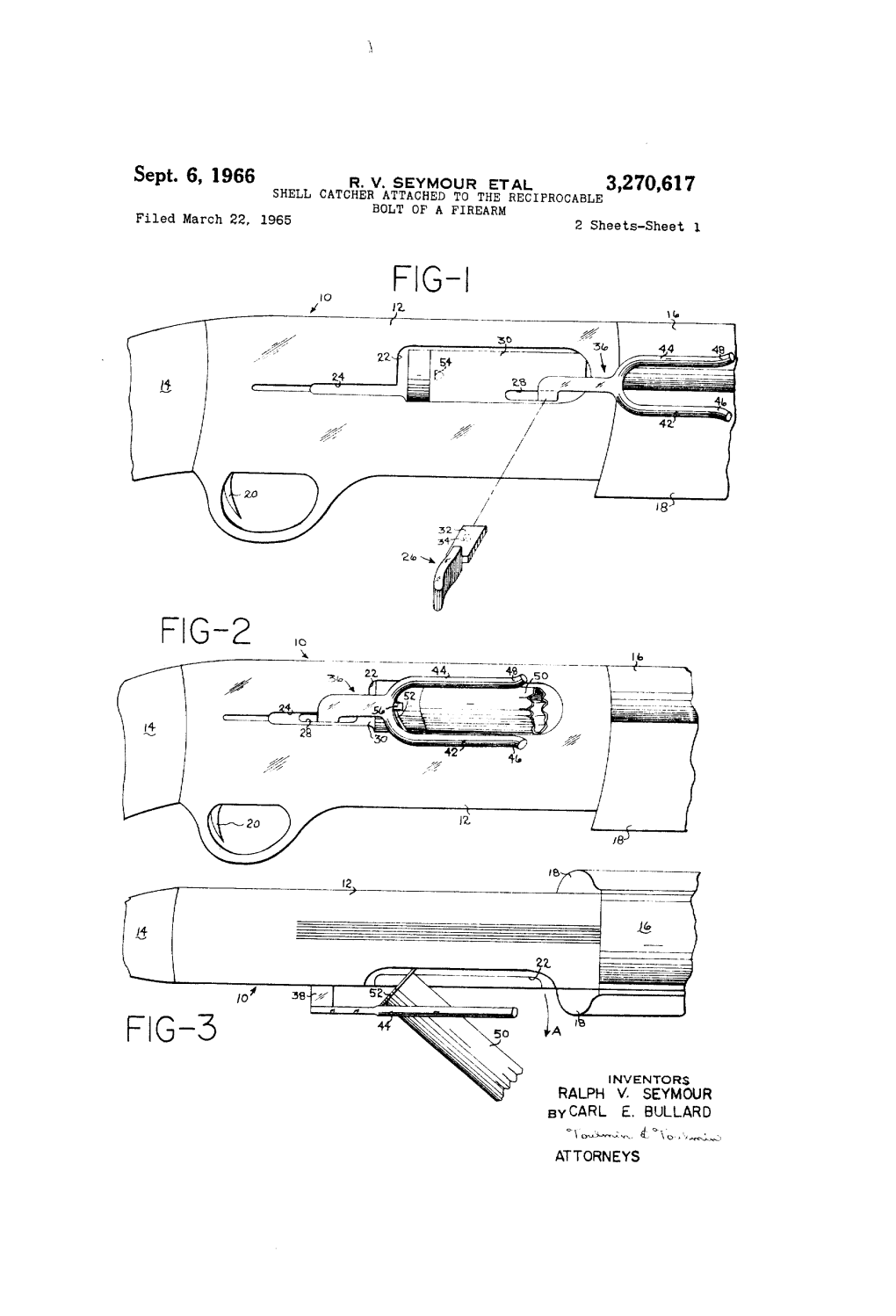

Sept. 6, 1966 R. W. SEYMOUR ETAL 3,270,617 SHELL CATCHER ATTACHED to the RECIPROCABLE BOLT of a FIREARM Filed March 22, 1965 2 Sheets-Sheet

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

A Basic Firearm Tutorial by John Kraemer, F-ABMDI April 2009

A Basic Firearm Tutorial By John Kraemer, F-ABMDI April 2009 Statistics for Firearm-Related Deaths According to a 2005 study conducted by the Centers for Disease Control and Prevention (CDC), there were almost 31, 000 firearm‐related deaths within the United States. Of the 31, 000 deaths, 55% of those deaths were certified as suicides, 40% certified as homicides, 3% certified as accidents, and the remaining 2% were certified as undetermined. A previous study by the CDC covering the years 1993 to 1998 also found that most firearm‐related deaths were again caused by self‐inflicted acts and men and individuals between the ages of 15 and 34 comprised a majority of those firearm‐related deaths. Every medical examiner or coroner’s office across the country has investigated a firearm‐ related death. Depending on your jurisdiction, these types of deaths may comprise a large portion of your caseload or a small portion. Regardless of the number of firearm‐related deaths your office investigates, every medicolegal death investigator must be knowledgeable in the safe handling of firearms, basic ballistics terminology and the parts of a particular firearm, whether it be a semi‐automatic handgun, revolver, shotgun or rifle. General Safety Practices The safe approach to and subsequent handling of firearms is your personal responsibility. Safety is the number one priority when handling such weapons. At any death scene involving a firearm, the death investigator MUST ALWAYS ASSUME THE FIREARM IS LOADED! Most accidental discharges of a firearm are the result of not following safe gun handling practices and failure to use common sense. -

Why the Evolution of the Firearms Industry Necessitates Digital Records Management TABLE of CONTENTS

Why the Evolution of the Firearms Industry Necessitates Digital Records Management TABLE OF CONTENTS SUMMARY PAGE 03 INTRODUCTION PAGE 03 BACKGROUND PAGE 04-09 Timeline of Firearms Manufacturing in the United States PAGE 04 Gun Laws in the United States PAGE 06 Firearm Sales in the United States PAGE 06 The Growth of Digital Records Management PAGE 07 Required Firearms Record Forms PAGE 09 CONCLUSION PAGE 09 ABOUT E4473 PAGE 10 FIGURES PAGE 05, 10-11 Figure 1: Firearms Manufactured 1986 - 2018 PAGE 05 Figure 2: Number of NFA Forms Processed by Fiscal Year 2005 - 2019 PAGE 10 Figure 3: NFA Firearms Processed by Form Type 1990 - 2019 PAGE 11 Figure 4: Google Search Trends and Background Checks PAGE 11 SUMMARY Firearms manufacturing and ownership have a long history in the United States. It’s difficult to sepa- rate the evolution of the gun industry from the development of the American identity. As firearms have become more sophisticated, laws pertaining to gun ownership and gun control have grown. The exact number of individual gun laws in the United States is disputed. For most of our history, gun laws have been enacted at the local or state level, with the first national law passed in 1934. With those laws come recordkeeping requirements. The Bureau of Alcohol, Tobacco, Firearms, and Explo- sives (ATF) currently has 32 forms available for download on its website. This white paper explores the evolution and growth of the firearms industry, along with its correspond- ing regulations and requirements, and shows how that growth has led to multiple ways of processing and retaining firearms records. -

A Short History of Firearms

Foundation for European Societies of Arms Collectors A short history of firearms Prepared for FESAC by: , ing. Jaś van Driel FARE consultants P.O. box 22276 3003 DG Rotterdam the Netherlands [email protected] Firearms, a short history The weapon might well be man’s earliest invention. Prehistoric man picked up a stick and lashed out at something or someone. This happened long before man learned to harness fire or invented the wheel. The invention of the weapon was to have a profound impact on the development of man. It provided the third and fourth necessities of life, after air and water: food and protection. It gave prehistoric man the possibility to hunt animals that were too big to catch by hand and provided protection from predators, especially the greatest threat of all: his fellow man. The strong man did not sit idly while intelligent man used the weapon he invented to match his brute force and soon came up with a weapon of his own, thus forcing intelligent man to come up with something better. The arms race had started. This race has defined the history of mankind. To deny the role that weapons in general and firearms in particular have played in deciding the course of history is like denying history itself. The early years During the Stone Age axes, knives and spears appeared and around 6000 BC the bow made its debut. This was the first weapon, after the throwing spear, that could be used at some distance from the intended target, though possibly slings also were used to hurl stones. -

Pistols, Crime, and Public: Safety in Early America Clayton E. Cramer

WLR44-4_OLSON-4-25-08 6/3/2008 3:46:03 PM PISTOLS, CRIME, AND PUBLIC: SAFETY IN EARLY AMERICA CLAYTON E. CRAMER1 & JOSEPH EDWARD OLSON2 There is a vigorous debate under way about the scope of the Second Amendment. What are the limits of that right? What “arms” does it protect? Does it protect an individual right to possess and perhaps to carry firearms? The District of Columbia, in its attempt to defend its 1976 gun control law, has argued that the widespread possession of handguns (“pistols”) represents an especially serious public safety hazard, and that even if arguendo, the Second Amendment protects an individual right, it would not extend to pistols, which the District of Columbia characterizes as “uniquely dangerous weapons” that present “unique dangers to innocent persons.”3 This paper examines what was likely the Framer’s original public meaning of the Bill of Rights provision that protects “the right of the people to keep and bear arms,” with no apparent limitations concerning handguns. We do so by examining what the history of pistols in early America tells us about foreseeable technological developments. I. GUNS, ARMS, FIRE-ARMS, PISTOLS: SOME DEFINITIONS A few definitions are appropriate because there have been a few subtle changes in the meaning of some of the terms over the last two centuries. “Gun” had a more restricted meaning in the eighteenth century than it does today, referring in some contexts to privately owned cannon,4 but most often to what today we call long guns: 1. B.A. (History with Distinction), Sonoma State University; M.A. -

I. Ok, Now That We've Forced All of Our Anti-Gun Friends to Concede the Fact

I. Ok, now that we’ve forced all of our anti-gun friends to concede the fact that gun rights apply to individuals, let’s move on to the other big question about the Second Amendment: did the founders intend for the people to have any weapons (including military weapons), or did they just mean for us to have muskets? A. This may sound like a silly false dichotomy, but several news pundits and celebrities have actually claimed that the Second Amendment is for muskets, and several others who realize how stupid that sounds still say the same thing another way by claiming that the founders never imagined something as powerful as an AR-15. 1. Examples of people saying this a) Msnbc (1) https://www.youtube.com/watch?v=oG-xPA9reHs B. This is the claim gun control activists make when they accept (begrudgingly or otherwise) that the Constitution guarantees individual gun ownership. C. I have several points to make about this perception of the Second Amendment. D. First of all, The founders were not stupid. This perception assumes that our founding fathers had no sense of history and no imagination whatsoever. They obviously knew that weapons in the future would be more lethal than weapons of their time. It doesn’t matter whether they specifically imagined an AR-15. They chose their words very carefully. They intended for the right to be open ended. If they wanted us to only have muskets, they would have said, “the right of the people to keep and bear muskets, shall not be infringed.” E. -

SBN 144258 Sean A. Brady – SBN 262007 2 Anna M

Case 3:17-cv-01017-BEN-JLB Document 50-12 Filed 03/05/18 PageID.5013 Page 1 of 67 1 C.D. Michel – SBN 144258 Sean A. Brady – SBN 262007 2 Anna M. Barvir – SBN 268728 Matthew D. Cubeiro – SBN 291519 3 MICHEL & ASSOCIATES, P.C. 180 E. Ocean Boulevard, Suite 200 4 Long Beach, CA 90802 Telephone: (562) 216-4444 5 Facsimile: (562) 216-4445 Email: [email protected] 6 Attorneys for Plaintiffs 7 8 IN THE UNITED STATES DISTRICT COURT 9 FOR THE SOUTHERN DISTRICT OF CALIFORNIA 10 VIRGINIA DUNCAN, et al., Case No: 17-cv-1017-BEN-JLB 11 Plaintiffs, EXHIBITS 27-30 TO THE DECLARATION OF ANNA M. 12 v. BARVIR IN SUPPORT OF PLAINTIFFS’ MOTION FOR 13 XAVIER BECERRA, in his official SUMMARY JUDGMENT OR, capacity as Attorney General of the State ALTERNATIVELY, PARTIAL 14 of California, SUMMARY JUDGMENT 15 Defendant. Hearing Date: April 30, 2018 Hearing Time: 10:30 a.m. 16 Judge: Hon. Roger T. Benitez Courtroom: 5A 17 18 19 20 21 22 23 24 25 26 27 28 435 EXHIBITS 27-30 TO THE DECLARATION OF ANNA M. BARVIR 17cv1017 Case 3:17-cv-01017-BEN-JLB Document 50-12 Filed 03/05/18 PageID.5014 Page 2 of 67 1 EXHIBITS TABLE OF CONTENTS 2 3 Exhibit Description Page(s) 4 1 Expert Report of James Curcuruto 00019-26 5 2 Expert Report of Stephen Helsley 00027-38 6 3 Expert Rebuttal Report of Professor Gary Kleck 00039-102 7 8 4 Expert Rebuttal Report of Professor Carlisle Moody 00103-167 9 5 Expert Report of Dr. -

Christopher Miner Spencer Collection

Christopher Miner Spencer Collection Finding Aid Windsor Historical Society 96 Palisado Avenue, Windsor, CT 06095 Creator: Christopher Miner Spencer, Vesta Spencer Taylor, and others Dates: 1834, 1854 --1918, 1953 Extent: 1 linear foot (2 DC) Accession #: 1922.4, 1953.12, 1991.1 Biographical Note Christopher Miner Spencer was born in Manchester, CT on June 20, 1833. He was recognized as an inventive genius, conceiving and patenting more efficient metal products and machinery in the formative early years of American manufacturing. He acquired a total of 42 patents in his lifetime, as well as building a steam-powered buggy in 1862 and taking up aviation only a few years before his death. He lived in Windsor, CT for many years with his wife Georgette Taylor Spencer, sons Percival H., Roger M., and daughter Vesta (Mrs. Charles Taylor). He died January 14, 1922 in Windsor, CT. At age 14, he apprenticed at the Cheney Brothers’ silk manufacturing company in Manchester, CT and gained skill as a machinist. He worked in a variety of machinery shops as a young man, and began to develop experimental and innovative machinery in his spare time. He received his first patent for an automatic silk-winding machine, and in 1860 another for his concept of a breech-loading repeating firearm. The Spencer Repeating Rifle Company was incorporated in 1862 in order to produce the firearm for the Union Army’s use during the Civil War. The rifle and its cartridges were superior to the traditional muzzle-loading firearms. Spencer had a succession of inventions that he patented and joined with others to manufacture. -

Glossary of Firearms Terminology

European Firearm Experts (EFE) Group Glossary of Firearms Terminology January 2013 Aim One of the recommendations of the European Union Threat Assessment - Assessing the Threat from the Criminal Use and Supply of Firearms within the European Union (November 2011) written by the UK on behalf of the EFE was the need to create a standard glossary of firearms terminology. The Glossary of Firearms Terminology is an EFE initiative that has been lead by the UK as part of an EFE Working Group. It is not a document intended to change terminology in Member State’s domestic legislation, but rather to ensure that EFE members are able to communicate effectively when discussing firearms and is intended for use by the EFE representatives, who are Law Enforcement and Customs officers, not technical firearm specialists. This document is intended to be a living document that will be updated as required centrally via the EFE and has been officially disseminated in January by the EFE for use by all EFE Member States. Any feedback can be directed to [email protected] Ammunition Ammunition - a collective term for all items that can be discharged from a firearm. A loaded cartridge consists of a primed case, propellant and with / or without one or more projectiles. Ball Ammunition - ammunition loaded with full metal jacketed (FMJ) bullets BB - this refers to the size of birdshot with a nominal diameter of.180” in shotgun cartridges. It is also used to refer to air weapon ammunition of.177” (4.5mm) steel projectiles in diameter and also to the plastic BBs used in airsoft or soft air weapons. -

Volcanic and Henry Firearms

VOLCANIC AND HENRY FIREARMS. by DR. JAMES R. LUCIE Ladies and Gentlemen: When Pappy Knode called me long distance and even paid for the call to ask if I would prepare a speech to give before this group, I knew he was in trouble. And despite the fact that he won't ever sell me any of his good guns but sells them to all my friends around me, I figured I'd better lend him a helping hand. My reasoning was that I should speak in order to get him away from the mike in order that he could work on his camera. I think he has more troubles with that camera than I do with speeches. I selected Volcanic and Henry firearms as this is where my first interest in guns began and I initially put as much time and study into this particular field as I could afford, 1'11 never forget the first time I ventured out of this field and into the Colt world and Hank Stewart had to pull me out of a fake deal that I'd gotten into clear up to my ears. I think it was a couple of years before I poked my nose out again. At any rate, conversation with advanced collectors reveals there is historical confusion concerning the embryology of Smith and Wesson and Volcanic fire- DR. JAMES R. LUCIE arms so if you will bear with me for a few moments, I would like to resume' a little background. Later I will illustrate a few points. In June 1854 Horace Smith and Daniel Wessonset up manufacturing partnership in Norwich, Connecticut under the name of Smith and Wesson. -

How Handguns Were Created

th th A Brief Anthology of the Pistol; 16 through 19 Centuries By Walt Kirst The development of firearms in general and handguns in particular, has been one of innovation and experimentation. The first handguns were nothing more than long guns reduced in size to be more easily held in one hand. Early handguns were simply abbreviated stocks that were similar to the wrist of a rifle. As time progressed the general shape of handguns curved like the head of a cane and took on a shape that is still with us today, that of a “pistol grip.” Handguns remained single barrel for the most part like their long gun parents. While some multi-barrel guns showed up (both long guns and handguns) they remained similar in design and featured one shot per barrel. The idea of multi shots per barrel was the stuff that fired the creative genius of gun makers. Samuel Colt brought about a departure from the long gun theme with his invention of the “revolving gun.” Colt was 21 years old when he was granted his patent number 9430X on February 25, 1836. Colt started his Patent Arms Manufacturing Co. in Patterson, New Jersey in 1836. The Paterson revolvers were introduced and gone was the single shot per barrel and now there were multi shots for the barrel. Colt even tried to expand his revolving gun design to rifles and had some success with them in later years. Technological advances helped Colt so that his Paterson gun was viable. In the 1820’s the percussion cap was developed. -

2018 -- H 7766 State of Rhode Island

2018 -- H 7766 ======== LC004984 ======== STATE OF RHODE ISLAND IN GENERAL ASSEMBLY JANUARY SESSION, A.D. 2018 ____________ A N A C T RELATING TO CRIMINAL OFFENSES -- WEAPONS Introduced By: Representatives Knight, Ajello, Tanzi, Blazejewski, and Diaz Date Introduced: February 28, 2018 Referred To: House Judiciary It is enacted by the General Assembly as follows: 1 SECTION 1. Title 11 of the General Laws entitled "CRIMINAL OFFENSES" is hereby 2 amended by adding thereto the following chapter: 3 CHAPTER 47.1 4 RHODE ISLAND ASSAULT WEAPONS BAN ACT OF 2018 5 11-47.1-1. Short title. 6 This chapter shall be known and may be cited as the "Rhode Island Assault Weapons Ban 7 Act of 2018". 8 11-47.1-2. Definitions. 9 When used in this chapter, the following words and phrases are construed as follows: 10 (1) "Assault weapon" means any semiautomatic assault rifle, semiautomatic assault pistol 11 and/or semiautomatic assault shotgun. 12 (2) "Barrel shroud" means: 13 (i) A shroud that is attached to, or partially or completely encircles, the barrel of a firearm 14 so that the shroud protects the user of the firearm from heat generated by the barrel; and 15 (ii) Does not include: 16 (A) A slide that partially or completely encloses the barrel; or 17 (B) An extension of the stock along the bottom of the barrel which does not encircle or 18 substantially encircle the barrel. 19 (3) "Belt-fed semiautomatic firearm" means any repeating firearm that: 1 (i) Utilizes a portion of the energy of a firing cartridge to extract the fired cartridge case 2 and chamber the next round; 3 (ii) Requires a separate pull of the trigger to fire each cartridge; and 4 (iii) Has the capacity to accept a belt ammunition feeding device. -

Firearms Action Handling V

INSTRUCTOR GUIDE LESSON 7: FIREARMS ACTION HANDLING V. 2/2017 Basic Hunter Education 2014 Standards – Section 2 Objectives 11, 15, 16, & 17 Instructor This lesson introduces students to the knowledge and skills of Notes safe firearm handling and proper loading and unloading practices. This lesson corresponds with Chapter 2 (pages 21-23) in the student manual. Teach this lesson as part of a round robin with a small group (4-8) of students. Teaching Methods Used In This Lesson Student hands-on activity Time Suggested 20 Minutes Materials Firearms action kit w/ dummy ammo Required Table Note: If possible, have multiple examples of firearms for your action type. Station 1. Discuss with your fellow instructors which action type will Set-up be taught by which instructor. 10 minutes 2. Set up a table at your station and stage the ammunition and Section 2: Objectives 11, 15, 16, & 17 Page 1 the firearm you are demonstrating with the muzzle pointed in a safe direction. Vocabulary Builder Note: Do not read the vocabulary to the students. These are terms commonly used during this lesson, and the definitions are for instructor reference only. Action – The part of the firearm that loads, fires, and ejects the cartridge or shot shell. Action release – A button mechanism on some firearms that must be pressed in order to open the action. Barrel selector – A mechanism on some multi-barrel break action firearms that allow you to select which barrel fires first. Barrel stamp – A stamp pressed into the side of the barrel of a firearm that typically states the manufacturer, the gauge or caliber, and the chamber size.