Locomotive Parking Brake

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

A Review Paper on Drum Brake

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 18, Issue 3 Ser. II (May – June 2021), PP 48-51 www.iosrjournals.org A review paper on Drum brake Shubhendra Khapre1 Dr. Rajesh Metkar2 1Dept. of Mechanical Engg, GCOEA 2Prof. Dept. of Mechanical Engg, GCOEA Abstract: In the automobile, there is a most common and important factor is safety like, braking system, airbags, good suspension, good handling, and safe cornering, etc. from the all safety system the most important and critical system is a brake system. A brake is a mechanical device that inhibits motion. A drum brake is a brake that uses friction caused by a set of shoes or pads that press against a rotating drum-shaped part called a brake drum. In this paper, we have studied the brake shoe of motor vehicles. A brake shoe is the part of a braking system which carries the brake lining in the drum brakes used on automobile or brake block in train brakes and bicycle brakes. A brake shoe is also known as a device which can be slow down railroad cars. Keywords: Breaking system, Suspension, Brake shoe, Brake lining. --------------------------------------------------------------------------------------------------------------------------------------- Date of Submission: 02-06-2021 Date of Acceptance: 15-06-2021 --------------------------------------------------------------------------------------------------------------------------------------- I. Introduction We know about the braking system, there are few types of brakes like a drum brake, disc brake. The drum brake consists of backing plates, brake drum, wheel cylinder, brake pads, brake shoe, etc. The drum brake is used in various motor vehicles like passenger cars, lightweight trucks, most of the two-wheelers. -

Drum Brakes Inspection & Service

Drum Brakes Inspection & Service First you must get the drum off! • Some slide right off, • Some have to be hit with a hammer. • Some have holes to install two bolts (Tighten each bolt equally) Remove A Brake Drum Use penetrant around axle hub May need to hammer floating drum Wet down inside of drum to control dust before hammering Only hammer on the axle flange! (ask to be shown) May need to adjust brake shoes inward Remove A Brake Drum For a fixed brake drum you will need to carefully adjust the wheel bearings when done! There are many tricks to removing stuck brake drums. Before you break something ASK! Understand each piece and avoid mistakes Terminology Anchor Wheel Cylinder Brake Shoes Primary Secondary Return Springs Shoe hold downs Terminology Parking Brake Strut Parking Brake Cable Self Adjusters Backing Plate (often neglected) Backing Plates Backing plates are often overlooked and usually have grooved & worn shoe support pads Be sure to thoroughly clean backing plate and lightly lube the support pads • contact points on backing plate are called a shoe pad. They should be filed flat to prevent shoes from hanging up in deep grooves or better yet just replace the backing plate. Always lube Shoe Support Tabs with a thin layer of Synthetic Disc Brake Lubricant (or suitable lube) Be careful… do not use too much. Grease on brake shoes is BIG TROUBLE! Dual-Servo or Leading-Trailing • Drum brakes on Rear Wheel drive are most often Dual Servo. • They have a Primary and Secondary brake shoe • The Primary shoe friction material is shorter and it faces the front of the vehicle Dual Servo braking action Both brake shoes will pivot Primary shoe will wedge the secondary out into the drum Primary and secondary shoe will fit backwards, but not properly work Which is the primary shoe? Where is the front of this vehicle? Dual-Servo or Leading-Trailing • Drum brakes on Front Wheel drive are most often Leading-Trailing. -

Friction Material Basics and Brake Shoe Remanufacturing Procedures

an brand SP-01100 IssuedRev 07/08 6/01 Friction Material Basics and Brake Shoe Remanufacturing Procedures Handbook for a Better Understanding of How Friction Materials are Specified Table of Contents Section 1 .................................................................................................................................. 3 Friction Basics / The Fundamentals of Braking How friction material works and it’s role in a brake system. Section 2 ................................................................................................................................ 25 Meritor Lining Qualification and Application What the ArvinMeritor lining approval process means in regard to friction quality and how to understand the technical selling points and interpret a spec sheet. Section 3 ................................................................................................................................ 48 Air Cam Foundation Brake Troubleshooting Friction material is one of many components in a brake system. What are the most common causes of brake problems? Section 4 ................................................................................................................................ 72 Brake Shoe Remanufacturing Procedures The proper inspection procedures, brake shoe checks, lining selection and installation, and final inspection. Provides a set of standards for remanufacturing brake shoes. 2 SECTION 1 - FRICTION BASICS FUNDAMENTALS OF BRAKING The discovery of the wheel was a tremendous technological “leap -

Design and Manufacturing of Brake Shoe

International Journal of Science and Research (IJSR) ISSN: 2319-7064 ResearchGate Impact Factor (2018): 0.28 | SJIF (2018): 7.426 Design and Manufacturing of Brake Shoe Praveen Pachauri1, Arshad Ali2 1ME Prof., Mechanical Department, Noida Institute of Engineering & Technology, Gr. Noida, India 2UG, Mechanical Engineering, Noida Institute of Engineering & Technology, Gr. Noida, India Abstract: The aim of this article is to design and manufacturing of Hero Honda Splendor brake shoe. Analysis is done by changing the material of the brake shoe, under different braking time and operational conditions. Brake shoe is optimized to obtain different stresses, deformation values on different braking time. Optimized results obtained are compared for Aluminium alloy and Gray cast iron material. It concludes that the aluminium alloys can be a better candidate material for the brake shoe applications of light commercial vehicles and it also increases the braking performance. Keywords: Brake shoe, Al alloy brake shoe, Grey cast iron brake shoe, Finite Element Analysis, and Solid works 1. Introduction when brakes are not applied. The brake drum Braking System closes inside it the whole mechanism to protect it Drum brakes were the first types of brakes used on motor from dust and first. A plate holds whole assembly and fits to vehicles. Nowadays, over 100 years after the first usage, car axle. It acts as a base to fasten the brake shoes and other drum brakes are still used on the rear wheels of most operating mechanism. Braking power is obtained when the vehicles. The drum brake is used widely as the rear brake brake shoes are pushed against the inner surface of the drum particularly for small car and motorcycle. -

Productivity Through Technology

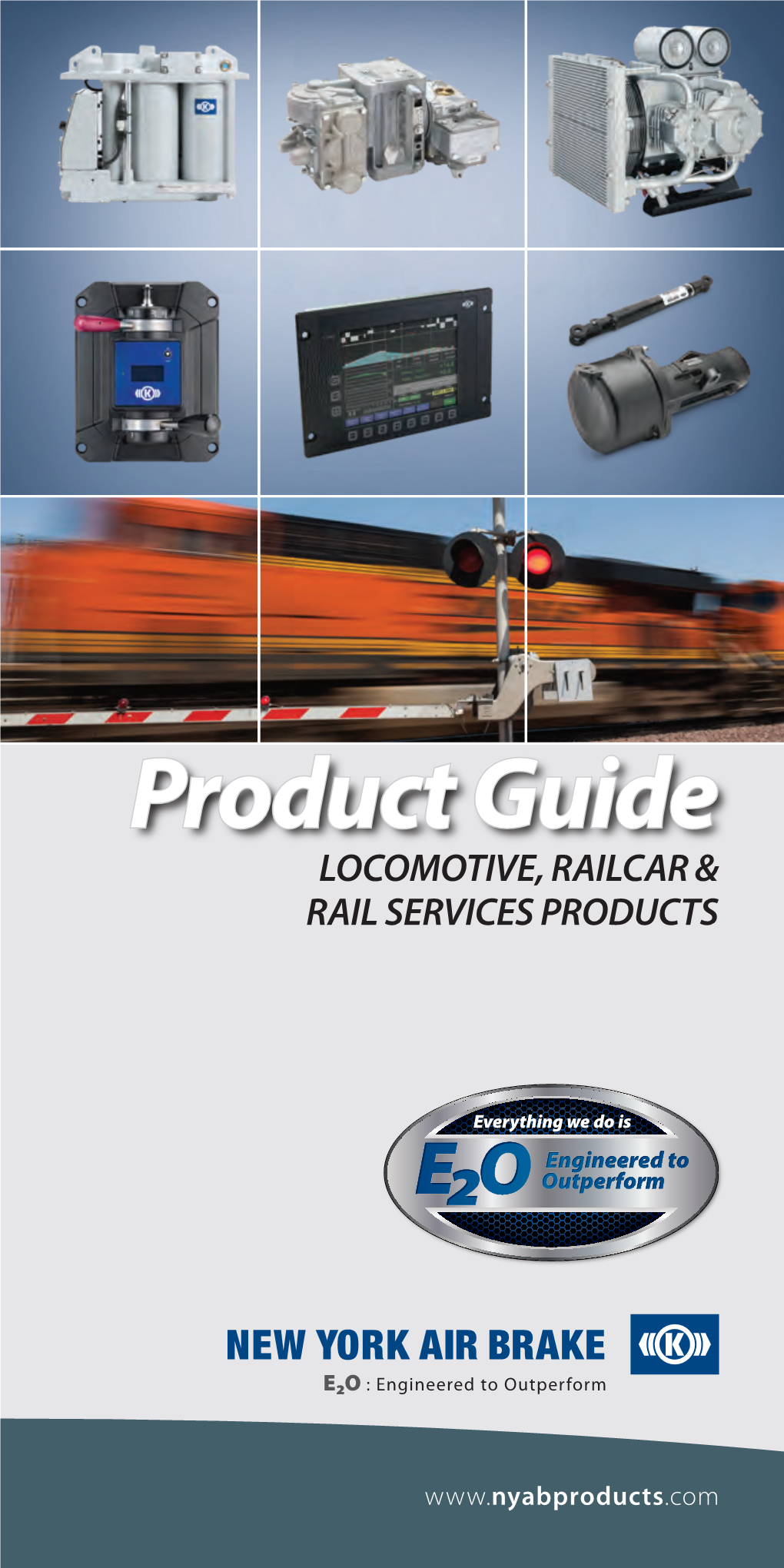

Systems for Heavy Haul Rail Vehicles Productivity through Technology www.nyab.com Productivity through Technology Who we are Products and services This capability brochure provides a brief overview of New York Air Brake’s expanding product line and services, designed for the AAR heavy haul railroad market. New York Air Brake Corporation, located in Watertown, New York, has served railroad customers for over 110 years, supplying innovative air brake and train control systems to the railroad industry worldwide. New York Air Brake (NYAB) is part of the Knorr-Bremse Group, headquartered in Munich, Germany. Knorr-Bremse is a global leader in the field of brake systems for rail and commercial highway vehicles, and operates 45 production and sales facilities in 26 countries. NYAB North American Operations AAR Worldwide NYAB Facilities Knorr-Bremse SfS. GmbH. Headquarters 2 | Systems for Heavy Haul Rail Vehicles Zero defect goal The way to achieve a Zero Defect workplace We all make mistakes, but: Mistakes must not leave the company Detect errors and correct them before Basic they become defects mindset Find discrepancies as early as possible in the process We will achieve Zero Defect through Systematic and proactive root cause Methods analysis Early correction and ongoing monitoring Zero Defect Philosophy Is important for everyone Allows no compromises Commitment to quality NYAB is a leading supplier of heavy haul AAR air brake and advanced train handling technologies to the heavy haul railroad industry. Safety is the primary driver in our business, driving our Processes and product quality NYAB excellence brings focus on important focus on Zero Defects in all aspects of our business. -

Now Introducing New Brake Shoe Kits Otr Has a Complete Line of Brake Shoes from Short to Long Haul, Severe Service, Rsd, and More

NOW INTRODUCING NEW BRAKE SHOE KITS OTR HAS A COMPLETE LINE OF BRAKE SHOES FROM SHORT TO LONG HAUL, SEVERE SERVICE, RSD, AND MORE. Available at At OTR we are dedicated to providing the highest quality heavy-duty parts on or off road. Extensive customer research, independent testing, and product development go into each of our parts to ensure they keep your drivers safe and your trucks on the road. TRUCKING IS OUR BUSINESS™ OTR offers a full line of premium quality brake components backed by a nationwide warranty. Whether you need a 20K GAWR brake drum, automatic slack adjuster, air disc brakes or service chambers, OTR has what you need to get the job done. OTR New Brake Shoe Kits ......1 Heavy Haul (23HH) ............8 RSD (20,000 GAWR)...........2 Heavy Haul Pro (23HP).........9 RSD (23,000 GAWR)...........3 Severe Service (23SS, 26SS) ..10 Linehaul (20LH) ...............4 Color & Part Number Guides......11 Fleet (20FL) ..................5 Formula Cross Reference .....12 Fleet Pro (20 FP) ..............6 Application Guide ............13 Linehaul (23LH) ...............7 QUALITY • INNOVATION • DURABILITY AIR BRAKE SYSTEMS • A/C • AIR INTAKE & EXHAUST • BRAKES • CAB • CHROME COOLING SYSTEM • ELECTRICAL • FILTRATION • HYDRAULICS • LIGHTING • LUBRICATION POWERTRAIN • STARTERS & ALTERNATORS • STEERING • SUSPENSION • TOOLS • WHEEL END OTR NEW BRAKE SHOE KITS VOCATION SPECIFIC FRICTION MATERIAL • Meets or exceeds all FMVSS121 requirements • Exceptional flex strength and elements of elasticity to prevent cracking • Superior drum compatibility, -

Bnsf Contract Ccb Brake Equipment Maintenance Manual

New York Air Brake CCB Brake System BNSF CONTRACT CCB BRAKE EQUIPMENT MAINTENANCE MANUAL IP-157-C For the DASH 9 LOCOMOTIVE Operated by BURLINGTON NORTHERN SANTA FE JUNE 1999 CCB BNSF CONTRACT LOCOMOTIVE MAINTENANCE MANUAL INSERT LATEST CHANGED PAGES. DESTROY SUPERSEDED PAGES. LIST OF EFFECTIVE PAGES NOTE: The portion of the text effected by the changes is indicated by a vertical line in the outer margin of the page. The total number of pages in this Maintenance and Instruction Manual, is 310, consisting of: PAGE NO. CHANGE NO. ISSUE Title 1 June/99 A 1 June/99 B 1 June/99 i through vi 1 June/99 1-1 through 1-80 1 June/99 2-1 0 October/96 2-2 (Blank) 0 October/96 C.W. 135 1 January/83 C.W. 217 3 June/96 C.W. 218 1 April/94 C.W. 219 2 October/95 C.W. 220 2 October/95 C.W. 221 2 October/95 C.W. 222 2 October/95 C.W. 223 2 October/95 C.W. 224 2 June/96 C.W. 225 2 June/96 C.W. 226 3 June/96 C.W. 227 2 June/96 C.W. 228 2 June/96 C.W. 229 2 June/96 C.W. 230 2 June/96 C.W. 231 3 June/96 C.W. 232 1 April/94 C.W. 233 4 June/96 C.W. 236 2 October/95 C.W. 239 3 November/97 C.W. 243 3 June/96 C.W. 248 1 March/95 C.W. -

Splunk® at New York Air Brake Optimized Operations and Billions in Savings for Top Railroads

CASE STUDY Splunk® at New York Air Brake Optimized Operations and Billions in Savings for Top Railroads The Business New York Air Brake (NYAB), a Knorr-Bremse company, is a leading supplier to the railroad industry of braking systems and components, training simulators and train “Railroads used to rely solely on industry control systems. Train Dynamic Systems (TDS), a unit of New York Air Brake, is standards and engineer experience. considered the worldwide leading industry expert in train dynamics, train control Thanks to Splunk, our systems allow our and training simulators. customers to provide engineers with real- time feedback and use operational insight Challenges to achieve optimal runs every time.” Director of Engineering The $60 billion U.S. freight rail industry railroads moved more than 1.7 trillion ton- Train Dynamic Systems miles of freight in 2012 using 3.6 billion gallons of fuel at a cost of approximately (a division of NYAB) $11.5 billion. While railroads are considered the most efficient form of freight transport—it takes just one gallon of fuel to move a ton of freight nearly 500 miles— reduced fuel consumption is still a primary objective for the industry. Based in Irving, Texas, NYAB division Train Dynamic Systems (TDS) is helping many OVERVIEW of the world’s top railroads achieve substantial improvements in fuel efficiency and other operational metrics with its LEADER (Locomotive Engineer Assist/Display & INDUSTRY Event Recorder) train management system. The LEADER system uses data captured • Freight railroad brakes and control from onboard train systems to help railroads achieve ‘golden runs’ where fuel systems economy, in-train forces and schedule compliance are optimized. -

A Study on the Effect of Out-Of-Roundness of Drum Brake Rotor on the Braking Force Using the Finite Element Method

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Repository@USM A STUDY ON THE EFFECT OF OUT-OF-ROUNDNESS OF DRUM BRAKE ROTOR ON THE BRAKING FORCE USING THE FINITE ELEMENT METHOD by MUHAMMAD NAJIB BIN ABDUL HAMID Thesis submitted in fulfilment of the requirements for the degree of Master of Science JUNE 2007 ACKNOWLEDGEMENTS I would like to express my truly gratitude and highest appreciation to my supervisor Assoc. Prof. Dr Zaidi Mohd Ripin for his precious guidance, support, training, advice and encouragement throughout my Master of Science study. My special acknowledgement is also dedicated to Universiti Sains Malaysia for providing me with the scholarship through the Graduate Assistant scheme during my study. I also would like to thank all the technicians for their valuable support and help. I would like to express my gratefulness to my beloved family for their support especially to my parents who have done most excellent in providing me with education. I would also acknowledge my entire friends at School of Mechanical Engineering for their great and favorable support. A truly thankfulness are dedicated to all who involve in this project directly and indirectly. Thank you very much. ii TABLE OF CONTENTS Page ACKNOWLEDGEMENTS ii TABLE OF CONTENTS iii LIST OF TABLES v LIST OF FIGURES vi LIST OF NOMENCLATURES viii LIST OF PUBLICATIONS & SEMINARS x ABSTRAK xi ABSTRACT xii CHAPTER ONE : INTRODUCTION 1.0 Background 1 1.1 Problem statement 2 1.2 Research scope and objective 2 1.3 Thesis outline 3 -

Parking Brakes for Passenger Locomotives and Cars

APTA STANDARDS DEVELOPMENT PROGRAM APTA PR-M-S-006-98, Rev. 3 STANDARD First Published: March 4, 1999 American Public Transportation Association First Revision: February 13, 2004 1300 I Street, NW, Suite 1200 East, Washington, DC 20006 Second Revision: June 2, 2007 Third Revision: June 1, 2017 PRESS Mechanical Working Group Parking Brakes for Passenger Locomotives and Cars Abstract: This document provides standards for parking brake systems for passenger locomotives and passenger cars. Keywords: grade holding, handbrake Summary: Design standards for parking brake systems for passenger locomotives and cars for the passenger railroad industry are provided. Scope and purpose: This standard applies to North American passenger locomotive and car parking brake systems and is intended to promote safe, efficient and reliable operation. This standard recognizes the existence of service proven equipment that may not meet all provisions of this standard, primarily in areas of required brake actuating force and design safety factors. In these cases, the existing requirements are accepted and indicated accordingly; however, it is intended that all new designs shall meet the updated requirements. Specific areas addressed are grade-holding requirements; prevention of equipment damage; and human interface for parking brake operation, as well as annunciation, manual release provisions, validation and related safety issues. This document represents a common viewpoint of those parties concerned with its provisions, namely operating/ planning agencies, manufacturers, consultants, engineers and general interest groups. The application of any standards, recommended practices or guidelines contained herein is voluntary. In some cases, federal and/or state regulations govern portions of a transit system’s operations. In those cases, the government regulations take precedence over this standard. -

NEW YORK AIR BRAKE CORPORATION a KNORR BRAKE COMPANY 748 Starbuck Avenue, Watertown, New York 13601

NEW YORK AIR BRAKE CORPORATION A KNORR BRAKE COMPANY 748 Starbuck Avenue, Watertown, New York 13601 C.W. 307 COMPONENT WRITE-UP OF CCB-26 LOCOMOTIVE BRAKE SYSTEM ISSUE NO. 1 C.W. 307 JUNE 28, 2006 14 PAGES GENERAL The CCB-26 system is a microprocessor based electronic air brake system designed to function as a direct replacement for an AAR freight 26L system, with an added pneumatic penalty brake function with provisions for pipes #3 (suppressible) & #10 (non-suppressible). This system is not intended for locomotives that have a locomotive computer and/or screen interface requirements. CCB-26 does not require an interface for cab electronics or screen displays. Instead, the engineers interface contains the basic two duplex gauges for pressure display and rotary selectors for mode selection. This system contains simple electronic modules that enable full closed loop pressure control, which allow for full time diagnostic health and performance monitoring and can take action to make a safe stop if system failure is detected. Equalizing reservoir, brake pipe control and IA&R pipe control are managed by computer electronics. Brake cylinder control is fully pneumatic and actuating pipe control is electro-pneumatic. This system does not include passenger mode (graduated release) functionality. The system performs several diagnostic functions like self test, calibrations, and a fault flagging via PTU software typically run on a laptop. Faults are detected and displayed on an LCD screen mounted on the driver’s brake valve (EBV). A “one wrench” maintenance philosophy allows for rapid replacement of failed modules based upon the displayed fault information. -

LOCOMOTIVE ENGINEER TRAINING HANDBOOK February, 2006

LOCOMOTIVE ENGINEER TRAINING HANDBOOK February, 2006 Locomotive Control Stand Orientation An important part of your Locomotive Engineer training will be operating locomotive simulators, and your first simulator activity will be very early in the class. The following pages are an introduction to some of the controls on a locomotive control stand. While there are some differences between locomotives, there are also many common items that are covered in the following pages. This material is intended more as an introduction; it will make your first simulator activities easier and will help you prepare for more material that will be covered in lessons on air brakes, preparing locomotives for service, dynamic braking and train handling. Your assignment for tonight is to read this material and answer the questions at the end. The assignment will be checked for completeness at the start of day one orientation. LET Staff The reverser handle is the lowest handle on the control stand. It has three positions: left, centered, and right. When the handle is moved to the right, circuits are set up for the locomotive to move in that direction. When the handle is moved to the left, the locomotive will move in that direction when power is applied. With the reverser handle centered, mechanical interlocking prevents movement of the dynamic brake handle, but the throttle can be moved. In such case, power will not be applied to the traction motors. Reverser Handle The reverser handle is centered and removed from the panel to lock the throttle in IDLE position and the dynamic brake handle in OFF position.