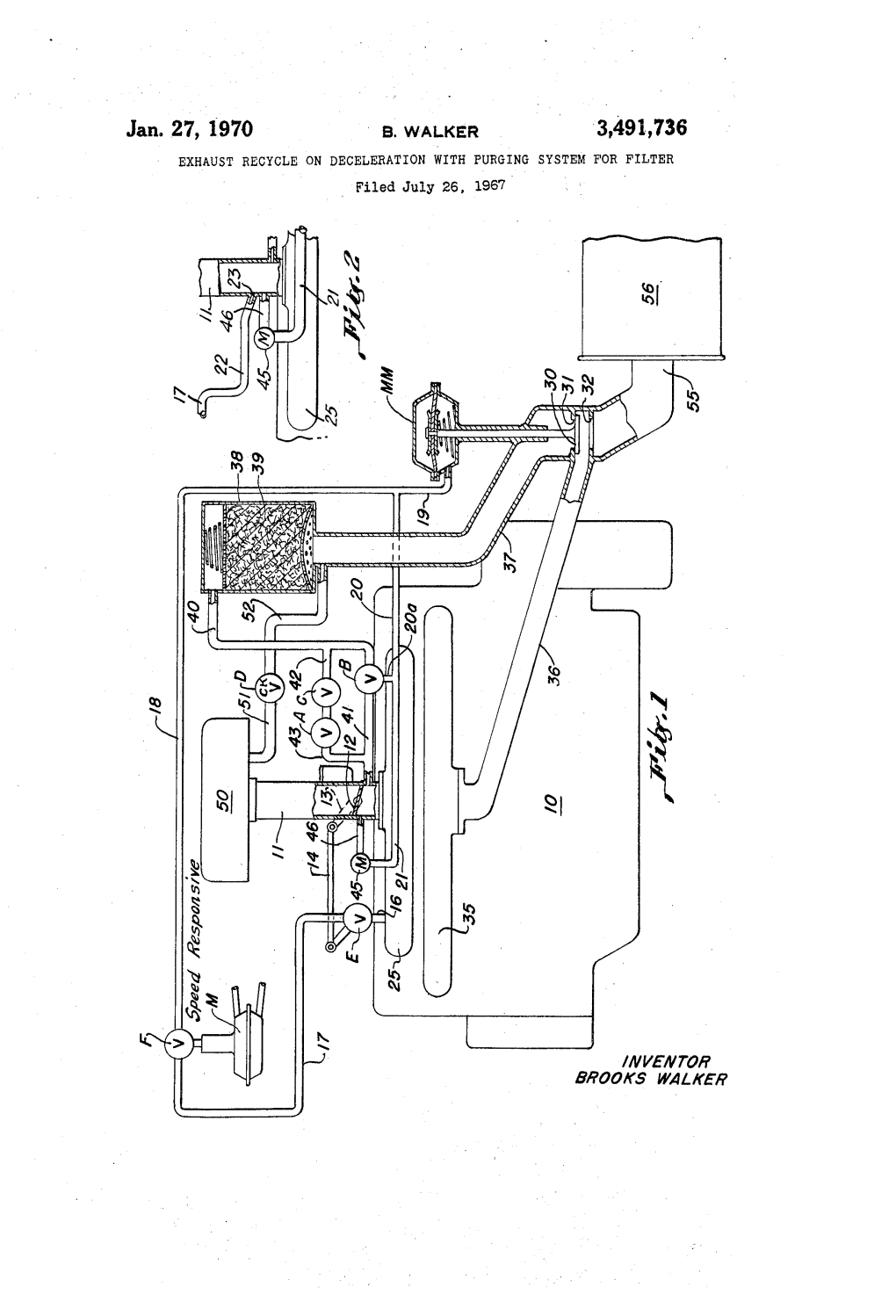

Jan. 27, 1970 B, WAKER 3,491,736 EXHAUST RECYCLE on DECELERATION with PURGING SYSTEM for FILTER Filed July 26, 1967

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Exhaust/Emissions Systems Overview Emissions Testing

Exhaust/Emissions Systems Overview Below is an overview of this system's operation Emissions Testing Many states require emissions tests on vehicles. This means that you drive to a facility where the test people take a sample of your emissions and run it through some analysis. The results are printed,and you pass or fail depending on the percentage of toxic emissions that turn up in your car's sample. The only way to "study" or prepare for this test is to take good care of your car, including its emission system. If you use preventative maintenance, and keep your car tuned properly, you will pass. If you tamper with your emissions system, you will not pass. You can have your car checked independently before your emissions test if you want to resolve problems before going to the emissions test station. One other good thing to do is to save your printouts from the test from year to year. If you compare them, you will be able to monitor your car (if its score is getting worse) and catch any problems before the emissions people catch you. The Emission Control System The purpose of the emission control system is just that; it controls the emissions and exhaust from your vehicle. The idea is to turn the harmful gases your car manufactures into harmless ones that don't ruin the environment, or us. Some of the problem gases are: • hydrocarbons (unburned) • carbon monoxide • carbon dioxide • nitrogen oxides • sulfur dioxide • phosphorus • lead and other metals To help control these substances, we (along with federal regulations) have made changes in our gasoline to eliminate them. -

Engine Exhaust Noise Control

Return to www.enoisecontrol.com Engine Exhaust Noise Control Jerry G. Lilly, P.E. JGL Acoustics, Inc. Issaquah, WA [email protected] ASHRAE TC 2.6 Engine Exhaust Noise Control nReactive Mufflers nAbsorptive Silencers nReactive/Absorptive Mufflers nTail Pipe Design nTuned Resonators nProject Examples The above are the subjects that we will discuss. Some data will also be presented from field tests: One an example of a project failure and the other a big success. ASHRAE TC 2.6 Engine Exhaust Considerations The exhaust system of a generator has several inherent design problems that must be considered. These characteristics impose severe limitations on what can be done to silence the engine exhaust noise: nVery High Noise (100 to 120 dBA @ 1 m) o nHigh Temperatures (950 to 1050 F) nHigh Velocities (5,000 to 15,000 fpm) nCombustion By-Products (soot & corrosion) nPipe Thermal Expansion ASHRAE TC 2.6 Performance Characteristics n Insertion Loss (dB) depends on design, size and frequency n Pressure Drop (inches H2O or Hg) depends on velocity & design n Self-Generated Noise (dB ref. 1 picowatt) depends on velocity & design Insertion loss (IL) is defined as the reduction of noise level that occurs when a silencing element is inserted into the system. Because engines generate strong tonal components, the IL of any one muffler will not be the same with different engines, different loads, or different piping configurations. Pressure drop is more predictable, however. Specific data on self noise is generally not available. ASHRAE TC 2.6 Engine exhaust noise varies significantly with loading. Typically the noise level at full load is about 10 dB higher than the no-load condition. -

Technology Overview

VQ35HR•VQ25HR Engine Technology Overview V6 GASOLINE ENGINE Advanced technology takes the next generation of Nissan’s world-renowned VQ engine to new pinnacles of high-rev performance and environmental friendliness. Nissan’s latest six-cylinder V-type Major technologies engine inherits the high-performance DNA that has made Nissan’s VQ Taking the award-winning VQ series another step series famous. Taking the acclaimed toward the ultimate powertrain, Nissan’s next- VQ engine’s “smooth transition” generation VQ35HR & VQ25HR are thoroughly concept to higher revolutions than reengineered to boost the rev limit and deliver greater ever, this VQ is a powerful and agile power, while achieving exceptional fuel economy and new powerplant for Nissan’s front- clean emissions. engine, rear-wheel-drive vehicles. Higher revolution limit By greatly reducing friction, Nissan engineers achieved a smooth transition to the high-rev limit, New VQ Engine which has been boosted to a 7,500rpm redline. Advantages Lengthened connecting rods Smooth transition up to high-rev redline Lengthening the connecting rods by 7.6mm reduces Lengthened connecting rods, addition of a ladder piston sideforce on the cylinder walls. This reduces frame and other improvements greatly reduce friction for smoother piston action to support high- friction. The result is effortless throttle response rev performance. all the way to the 7500-rpm redline. New ladder frame Top level power performance in class The lower cylinder block that supports the crankshaft Improved intake and exhaust systems, raised uses a ladder-frame structure for increased stiffness. combustion efficiency, and other enhancements This suppresses vibration to minimize friction at high achieve class-leading power. -

Divided Exhaust Period on Heavy-Duty Diesel Engines

Divided Exhaust Period on Heavy-Duty Diesel Engines Stefan Gundmalm Licentiate thesis TRITA – MMK 2013:01 Department of Machine Design ISSN 1400-1179 Royal Institute of Technology ISRN/KTH/MMK/R-13/01-SE SE-100 44 Stockholm ISBN 978-91-7501-605-4 TRITA – MMK 2013:01 ISSN 1400-1179 ISRN/KTH/MMK/R-13/01-SE ISBN 978-91-7501-605-4 Divided Exhaust Period on Heavy-Duty Diesel Engines Stefan Gundmalm Licentiate thesis Academic thesis, which with the approval of Kungliga Tekniska Högskolan, will be presented for public review in fulfilment of the requirements for a Licentiate of Engineering in Machine Design. The public review is held at Kungliga Tekniska Högskolan, Brinellvägen 83, room B319 Gladan, 25th of January 2013 at 10:00. Abstract Due to growing concerns regarding global energy security and environmental sustainability it is becoming increasingly important to increase the energy efficiency of the transport sector. The internal combustion engine will probably continue to be the main propulsion system for road transportation for many years to come. Hence, much effort must be put in reducing the fuel consumption of the internal combustion engine to prolong a future decline in fossil fuel production and to reduce greenhouse gas emissions. Turbocharging and variable valve actuation applied to any engine has shown great benefits to engine efficiency and performance. However, using a turbocharger on an engine gives some drawbacks. In an attempt to solve some of these issues and increase engine efficiency further this thesis deals with the investigation of a novel gas exchange concept called divided exhaust period (DEP). -

JINTAKE and EXHAUST SYSTEM 1. General

ENGINE — 2AZ-FE ENGINE EG-49 JINTAKE AND EXHAUST SYSTEM 1. General D The two resonators, the side branch and PET* (Polyethylene Terephthalate) material have been newly adopted to air cleaner inlet and air cleaner hose. D The adoption of ETCS-i (Electronic Throttle Control System-intelligent) has realized excellent throttle control. D The intake manifold has been made of plastic to reduce the weight and the amount of heat transferred from the cylinder head. D 2-way exhaust control system is provided to reduce noise and vibration in the main muffler. *: Using porous material that permits it to breath, air intake pulsating pressure will be let out to the outside of air cleaner inlet. Intake Manifold Main Muffler Exhaust Manifold TWC TWC 208EG11 Air Cleaner EG-50 ENGINE — 2AZ-FE ENGINE 2. Air Cleaner D A flameless, full-fabric air filter has been adopted to reduce weight and to simplify its disposal. D The two resonators, the side branch and PET material have been newly adopted to air cleaner inlet and air cleaner hose to reduce the intake air noise. Mass Air Flow Meter Resonator Side Branch PET Material Air Cleaner Inlet Resonator 208EG12 3. Throttle Body D The adoption of the link-less type ETCS-i has realized excellent throttle control. For details of ETCS-i control, refer to see page EG-40. D A DC motor with excellent response and minimal power consumption is used for the throttle control motor. The ECM performs the duty ratio control of the direction and the amperage of the current that flows to the throttle control motor in order to regulate the opening angle of the throttle valve. -

Structural Analysis of Passenger Car Exhaust System by Using Hypermesh

International Journal of Emerging Technologies in Engineering Research (IJETER) Volume 3, Issue 2, November (2015) www.ijeter.everscience.org Structural Analysis of Passenger Car Exhaust System by Using Hypermesh Venugopala Reddy Kussam Research Scholar, Nova College of Engineering and Technology, Jangareddy Gudem, West Godavari (Dt), India. Jithendra Kumar B Associate Professor, Nova College of Engineering and Technology, Jangareddy Gudem, West Godavari (Dt), India. Abstract – The Automobile exhaust system is used for silencing Dr. S. Rajadurai et al., [02] this paper deals, to evaluate the the noise caused by the high pressure exhaust gases are releasing durability of exhaust system components by CAE Simulation. in to the atmosphere. It is important to control the emissions and Finite element simulation are carried out and the results are a part of combustion. Exhaust systems are a special type of size explained for the typical exhaust system components and geometry, the constraints placed in the design of a car. It is considering the durability loads such as engine vibration found that the induced vibrations are spread along the exhaust system and the forces are transmitted to the car body. To reduce loading, proving ground road loads. The durability issues the forces, adding of decoupling elements like flex-couplings and associated with the exhaust system components such as isolators are used. The vibrations could induce structural noise in muffler-pipe system, brackets and hanger designs are analyzed. the passenger car. The adopting procedure includes a correlation Johan Wall Karlskrona, [03] describes the Low vibration levels and model updating step can be done by using Finite element method and optimization technique. -

Catalytic Converter Theft Information Bulletin

CATALYTIC CONVERTER THEFT INFORMATION BULLETIN FRANKLIN-BINGHAM FARMS POLICE DEPARTMENT Crime Prevention Bureau (248) 626-9672 WHAT IS A CATALYTIC CONVERTER? A catalytic converter is an air pollution abatement device that removes pollutants from motor vehicle exhaust, either by oxidizing them into carbon dioxide and water or reducing them into nitrogen and oxygen. The catalytic converter device uses a catalyst to convert three harmful compounds in the car exhaust into harmless compounds. The three compounds are: -Hydrocarbons -Carbon monoxide -Nitrogen oxides In a catalytic converter, the catalyst (in the form of platinum and palladium) is coated onto a ceramic honeycomb or ceramic beads that are housed in a muffler-like package attached to the exhaust pipe. The catalyst helps to convert carbon monoxide into carbon dioxide. It converts the hydrocarbons into carbon dioxide and water. It also converts the nitrogen oxides back into nitrogen and oxygen. PHOTO FROM “HOW IT WORKS.COM” WHY ARE CATALYTIC CONVERTERS POPULAR WITH THIEVES? Converters use the metals Platinum and Palladium as the catalyst. Both of these metals are extremely expensive and provide for high reward versus the risk in committing the theft. Per CNNMONEY.COM, on 03/04/10: Gold sold for $1,133.10 per troy ounce while Platinum sold for $1,582.40 per troy ounce. 2 WHAT DO CATALYTIC CONVERTERS LOOK LIKE? The following are some very basic photos of converters: Attached Catalytic Converter Unit Catalytic Converter Unit Oxygen Sensors The converter is between the exhaust system and the engine and is normally in front of the middle of the vehicle. -

Download the Carb Tuning Guide

S&S® CYCLE, INC. WWW.SSCYCLE.COM 6- Overflow Tube Fitting 7- Fuel Inlet 3 8- Bowl Vent Hole 9- Bowl Plug 13 2 8 10 1 11 4 5 12 14 1- Idle Speed Screw 6 10- Accelerator Pump Pushrod 2- Idle Mixture Screw 7 11- Intermediate Jet SUPER E & G CARBURETOR 3- Accelerator Pump Adjustment Screw 12- Main Jet 4- Enrichment Device 13- Main Jet Air Bleed TUNING GUIDE 5- Serial Number 9 14- Auxiliary Bowl Vent Plug QUICK TUNING STEPS 1- Verify carburetor is set to stock settings: 6- Ride motorcycle in various rpm ranges, and then try to 9- Since 2004 S&S shorty carbs have been fitted with an Approximate Jetting a- Idle mixture screw, 11/4 turns from lightly seated. maintain a consistent 40- to 50-mph. If the engine has adjustable main jet air bleed (#13). Changing this jet For S&S® Super E & G Carburetors b- Idle speed screw, ½ turn clockwise from a flat spot, or is popping/sneezing in the air cleaner, it to a larger size will delay the signal to the main jet, engagement point. can indicate a lean condition. If you notice stumbling or therefore aiding with high speed tuning as described Displacement 883cc 74 to 96 to 111 to c- Accelerator adjustment screw, two turns sputtering, it can indicate a rich condition. in step 8. This also aides with tuning an engine that is 88ci 107 ci 124 ci counter-clockwise from seated. 7- Low rpm operation is controlled by the intermediate fitted with an exhaust system that is not intended for Intermediate .265 – .0295 .031 .031 2- Start bike, bring to operating temperature. -

Exhaust Systems

BEST PRACTICES Internal Combustion’s Backside For new and refit vessels, here are the fundamentals of exhaust system design and analysis. Text and photographs xhaust systems are critical to any Design Basics by Steve D’Antonio Evessel’s design. They can affect The typical inboard powerboat or everything from noise, vibration, sailing vessel auxiliary is equipped with watertight integrity, and engineroom a wet exhaust system. Nearly every wet temperature to performance, fuel exhaust system includes a dry segment economy, and crew safety. Failing to between the engine’s exhaust manifold follow engine and generator manufac- or turbocharger and the point of water turer installation guidelines is, in my injection, called the mixing elbow. experience, by far the most common Because dry/wet exhaust systems are far cause of system breakdown, poor ves- more common, this article will focus on sel performance, and warranty dis- them, rather than on pure dry exhaust putes. Fortunately, there’s very little systems, which are all dry, and are used new about exhaust system design and mostly in commercial applications. installation, so it’s relatively easy to In wet exhaust systems, an envelop- avoid the most common problems. ing showerhead arrangement thoroughly 60 PROFESSIONAL BOATBUILDER mixes hot exhaust gases with cooling Cooling is accomplished by mixing the are cooled by the aforementioned mix- water, and they are ejected through a gases with the same seawater that ing elbow, or “injection elbow,” combination of metallic and/or fiber- cooled the engine, after that water has installed immediately after the exhaust glass pipes, flexible hoses, and metallic passed through the cooling jacket (or manifold or turbo outlet. -

The Influence of Piston Internal Combustion Engines Intake And

Available online at www.sciencedirect.com Available online at www.sciencedirect.com ScienceDirect AvailableScienceDirect online at www.sciencedirect.com Procedia Engineering 00 (2017)000–000 Procedia Engineering 00 (2017)000–000 www.elsevier.com/locate/procedia ScienceDirect www.elsevier.com/locate/procedia Procedia Engineering 206 (2017) 80–85 International Conference on Industrial Engineering, ICIE 2017 International Conference on Industrial Engineering, ICIE 2017 The Influence of Piston Internal Combustion Engines Intake and The ExhaustInfluence Systems of Piston Configuration Internal Combustion on Local Engines Heat Transfer Intake and Exhaust Systems Configuration on Local Heat Transfer L.V. Plotnikova,*, B.P. Zhilkina, Yu.M. Brodova L.V. Plotnikova,*, B.P. Zhilkina, Yu.M. Brodova aUral Federal University named after the first President of Russia B.N.Yeltsin, 19, ul. Mira, Ekaterinburg 620002, The Russian Federation aUral Federal University named after the first President of Russia B.N.Yeltsin, 19, ul. Mira, Ekaterinburg 620002, The Russian Federation Abstract Abstract The improvement of work processes of piston engines to boost the technical and economic parameters is the main objective in Thethe field improvement of power ofengineering. work processes The improvement of piston engines of the to gas boost exch theange technical processes and (intake economic and exhausparameterst processes) is the main quality objective is one ofin the fieldpossible of power profiles engineering. to improve The theimprovement efficiency of and the reliabilitygas exchange of processespiston internal (intake combustion and exhaus t engines.processes) The quality study is ofone the of theinstantaneous possible profileslocal heat to transfer improve at flowthe unsteadinessefficiency and is onereliability of the objectives of piston of internal the experimental combustion studies engines. -

Advisory Circular

Advisory Circular Subject: Inspection and Care of General Date: 7/23/07 AC No: 91-59A Aviation Aircraft Exhaust Systems Initiated by: AFS-300 1. PURPOSE. a. This advisory circular (AC) emphasizes the safety hazards of poorly maintained aircraft exhaust systems (reciprocating powerplants) and highlights points at which exhaust system failures occur. Further, it provides information on the kinds of problems to be expected and recommends pilots perform ongoing preventive maintenance and mechanics perform maintenance. b. This AC provides an acceptable means of complying with the regulations; however, it is not the only means of compliance. This AC is not mandatory and does not constitute a regulation. When this AC uses mandatory language (e.g., “must” or “may not”) it is paraphrasing a regulatory requirement or prohibition. When this AC uses permissive language (e.g., “should” or “may”), it describes an acceptable means, but not the only means, of complying with regulations. However, if you use the means described to comply with a regulatory requirement, you must follow it in all respects. 2. CANCELLATION. AC 91-59, Inspection and Care of General Aviation Aircraft Exhaust Systems, dated August 20, 1982, is canceled. 3. RELATED READING MATERIALS (current editions). a. AC 20-32, Carbon Monoxide (CO) Contamination in Aircraft Detection and Prevention. b. AC 20-106, Aircraft Inspection for the General Aviation Aircraft Owner. c. AC 43-12, Preventive Maintenance. d. AC 43.13-1, Acceptable Methods, Techniques, and Practices—Aircraft Inspection and Repair. e. AC 43-16, General Aviation Airworthiness Alerts. f. AC 65-12, Airframe and Powerplant Mechanics Powerplant Handbook. -

Late Intake Valve Closing and Exhaust Rebreathing in a V8 Diesel Engine for High Efficiency Clean Combustion

DEER Conference 2010 Late Intake Valve Closing and Exhaust Rebreathing in a V8 Diesel Engine for High Efficiency Clean Combustion High-Efficiency Clean Combustion Engine Designs for Compression Ignition Engines GM-DOE AGREEMENT No. DE-FC26-05NT42415 Manuel A. Gonzalez D. General Motors Powertrain. Advanced Diesel September 29, 2010 Advanced Diesel DEER Conference 2010 1 Outline ● Objectives ● Technical Approach & Hardware ● Discussion of Variable Compression Ratio - Late Intake Valve Closing & Two Stage Turbo Charging ● Discussion of Internal EGR - Exhaust Rebreathing ● Estimated overall driving cycle impacts ● Summary ● Acknowledgements Advanced Diesel DEER Conference 2010 2 Objectives ● Investigate the use of variable valve actuation (VVA) as a means to improve the efficiency of a light duty diesel engine approaching and exceeding Tier 2 Bin 5 NOx emission levels Multi-cylinder engine testing using a “simple mechanism” VVA system – steady state engine-out emission targets combined with aftertreatment technology for beyond Tier 2 Bin 5 tailpipe targets and enhanced fuel economy ─ Late Intake Valve Closing (LIVC) Study ─ Exhaust Rebreating Study ● Barriers addressed To operate at Low Temperature Combustion (LTC) conditions using “VVA simple mechanisms” for control of effective compression ratio and internal EGR (IEGR) Expand the useful range of the Early Premixed Charge Compression Ignition (PCCI) LTC mode in order to reduce fuel consumption To reduce engine out emissions To minimize the fuel energy required to raise exhaust gas temperature