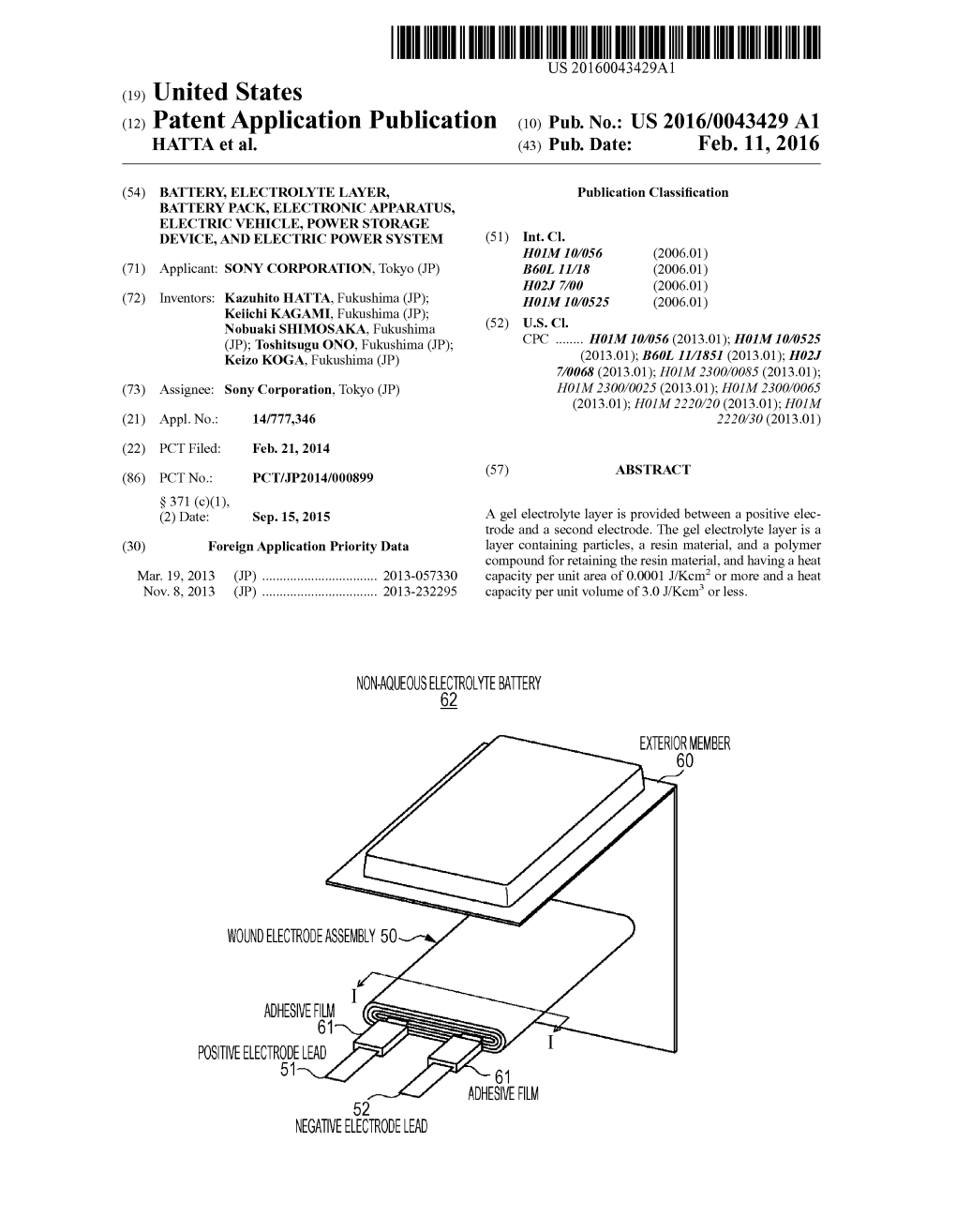

US 2016/0043429 A1 HATTA Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Analysis of the Thermal Behaviour of CL-20, Potassium Perchlorate, Lithium Perchlorate and Their Admixtures by DSC and TG

Central European Journal of Energetic Materials ISSN 1733-7178; e-ISSN 2353-1843 Copyright © 2018 Institute of Industrial Organic Chemistry, Poland Cent. Eur. J. Energ. Mater. 2018, 15(1): 115-130; DOI: 10.22211/cejem/78089 Analysis of the Thermal Behaviour of CL-20, Potassium Perchlorate, Lithium Perchlorate and Their Admixtures by DSC and TG Jing-yuan Zhang, Xue-yong Guo,* Qing-jie Jiao, Hong-lei Zhang, Hang Li State Key Laboratory of Explosion Science and Technology, Beijing Institute of Technology, Beijing 100081, China * E-mail: [email protected] Abstract: The thermal decomposition characteristics of CL-20, potassium perchlorate (KP), lithium perchlorate (LP), a CL-20/KP mixture, and a CL-20/LP mixture were studied using thermogravimetry-differential scanning calorimetry (TG-DSC). The DSC curves for KP exhibited three endothermic peaks and one exothermic peak. The first two endothermic peaks correspond to the rhombic- cubic transition and the fusion of KP, respectively, the third indicates the fusion of KCl, while the exothermic peak is attributed to the decomposition of KP. The DSC curves obtained from LP showed four endothermic peaks and one exothermic peak. The first two endothermic peaks indicate the loss of adsorbed water and water of crystallization, while the third and fourth are associated with the fusion of LP and LiCl, respectively; the exothermic peak is due to the decomposition of LP. The presence of KP had little effect on the thermal decomposition of CL-20 while the addition of LP increased the temperature at which CL-20 exhibits an exothermic peak. In addition, the thermal decomposition of LP appeared to be catalyzed by the presence of CL-20. -

Recovery of Lithium from Spent Lithium Ion Batteries

Recovery of Lithium from Spent Lithium Ion Batteries Gabriel Chinyama Luzendu Chemical Engineering, masters level 2016 Luleå University of Technology Department of Engineering Sciences and Mathematics MASTER’S DEGREE PROJECT IN CHEMICAL ENGINEERING WITH SPECIALIZATION IN MINERALS AND METALLURGICAL ENGINEERING X7009K RECOVERY OF LITHIUM FROM SPENT LITHIUM ION BATTERIES Author: Gabriel Chinyama Luzendu Supervisors: Fredrik Engström & Jakob Kero Examiner: Caisa Samuelsson 31/08/2016 Division of Minerals and Metallurgical Engineering Department of Civil, Environmental & Natural Resource Engineering Luleå University of Technology Luleå, Sweden Declaration By submitting this thesis, I solemnly declare that the work contained therein is my own original work and that I am the sole author thereof and that it contains no material that has been accepted for the award of any other degree or diploma in any university. I also wish to declare that to the very best of my knowledge, it contains no material published previously or inscribed by another person, except where due reference is made in the text and that publication by Luleå University of Technology will not infringe any third party rights. Gabriel Chinyama Luzendu August, 2016 © Gabriel Chinyama Luzendu 2 Acknowledgement This thesis has been carried out at Luleå University of Technology, Division of Minerals and Metallurgical Research Laboratory. Further acknowledgement goes to the Swedish Institute for the financial support through the scholarship for my studies. I also wish to acknowledge my examiner Associate Professor Fredrik Engström and Jakob Kero for the knowledge, guidance and advice they shared with me during this thesis. Special thanks go to Professor Caisa Samuelsson for the opportunity to do the thesis in the department. -

Breakthrough Chemistry Simulations for Lithium Processing Contents

think simulation | getting the chemistry right Breakthrough chemistry simulations for lithium processing Using simulation to maximize your investment return in lithium extraction and processing Contents Introduction ............................................................................................................................................ 2 Process simulation deficiencies ................................................................................................................ 2 OLI Systems electrolyte thermodynamics .................................................................................................2 OLI Systems lithium initiative .................................................................................................................... 2 Lithium phase 1 and potash chemistry is complete ................................................................................... 2 Fundamental sulfate – chloride systems .............................................................................................. 3 Fundamental hydroxide and carbonate systems .................................................................................. 3 Lithium in acid environments for processing and recycling ................................................................... 3 Lithium borate systems for Li production ............................................................................................. 4 Systems related to Li hydrometallurgical processing, purifications and recycling .................................. -

Www .Fancycn.Cn 6FN CYRESOURCE

FANCY RESOURCE www .fancycn.cn 6FN CYRESOURCE Company Introduction Fancy Mineral Resource Co, Ltd.(referred as “FR”) is As an energy conservation and environmental protection a manufacturing enterprise concentrated on converting enterprise, Fancy Resource, a hi-tech enterprise engaged in mineral resources into materials of industrial development and applications of mineral resources, has possessed applications, which dedicated itself to global resource mineral resources and strong Science and Technology Research & exploration & development, minerals application R&D, Development capabilities, specialized in scaled and refined production and end products sales for a long term, has a production of industrial mineral materials. After years’ continuous group of talented personnel and masters specialized high-speed development, Fancy Resource has achieved good mineral extraction technologies and R&D capabilities. results in terms of company size and operation profit. Envisioning For recent years, FR has specialized on the R&D of new the future, guided by national industrial policies and also according energy, new material , production process and the level to industry development and market demands, Fancy Resource will of industrialization development. As production bases continue to strengthen its efforts in the construction of New Energy both at home and abroad putting into operation in and New Materials Industry Chain, with mineral resources as its succession, Fancy will possess a broader extension guarantee and technological innovation -

Polyorganosiloxanes: Molecular Nanoparticles, Nanocomposites and Interfaces

University of Massachusetts Amherst ScholarWorks@UMass Amherst Doctoral Dissertations Dissertations and Theses November 2017 POLYORGANOSILOXANES: MOLECULAR NANOPARTICLES, NANOCOMPOSITES AND INTERFACES Daniel H. Flagg University of Massachusetts Amherst Follow this and additional works at: https://scholarworks.umass.edu/dissertations_2 Part of the Materials Chemistry Commons, Polymer and Organic Materials Commons, and the Polymer Chemistry Commons Recommended Citation Flagg, Daniel H., "POLYORGANOSILOXANES: MOLECULAR NANOPARTICLES, NANOCOMPOSITES AND INTERFACES" (2017). Doctoral Dissertations. 1080. https://doi.org/10.7275/10575940.0 https://scholarworks.umass.edu/dissertations_2/1080 This Open Access Dissertation is brought to you for free and open access by the Dissertations and Theses at ScholarWorks@UMass Amherst. It has been accepted for inclusion in Doctoral Dissertations by an authorized administrator of ScholarWorks@UMass Amherst. For more information, please contact [email protected]. POLYORGANOSILOXANES: MOLECULAR NANOPARTICLES, NANOCOMPOSITES AND INTERFACES A Dissertation Presented by Daniel H. Flagg Submitted to the Graduate School of the University of Massachusetts in partial fulfillment of the degree requirements for the degree of DOCTOR OF PHILOSOPHY September 2017 Polymer Science and Engineering © Copyright by Daniel H. Flagg 2017 All Rights Reserved POLYORGANOSILOXANES: MOLECULAR NANOPARTICLES, NANOCOMPOSITES AND INTERFACES A Dissertation Presented by Daniel H. Flagg Approved as to style and content by: Thomas J. McCarthy, Chair E. Bryan Coughlin, Member John Klier, Member E. Bryan Coughlin, Head, PS&E To John Null ACKNOWLEDGEMENTS There are countless individuals that I need to thank and acknowledge for getting me to where I am today. I could not have done it alone and would be a much different person if it were not for the support of my advisors, friends and family. -

Quantification of Lithium Via Redox Titration and Ph Titration – a Method Comparison

Quantification of Lithium via Redox Titration and pH Titration – A Method Comparison by Joseph J. Hebert A THESIS submitted to Oregon State University Honors College in partial fulfillment of the requirements for the degree of Honors Baccalaureate of Science in Chemical Engineering and Chemistry (Honors Associate) Presented May 26, 2020 Commencement June 2020 AN ABSTRACT OF THE THESIS OF Joseph J. Hebert for the degree of Honors Baccalaureate of Science in Chemical Engineering and Chemistry presented on May 26, 2020. Title: Quantification of Lithium via Redox Titration and pH Titration - A Method Comparison. Abstract approved:_____________________________________________________ Michael Lerner Lithium serves an unparalleled role for high energy-density storage applications and is vital for the continued advancement of the world economy. However, global supply is heavily reliant on lithium deposits situated in select locations, creating unpredictability in the price and concerns for the sustained production of the resource. Additionally, future demands for applications in the small electronics, automotive, and renewable energy industries threaten to place further strain on the lithium supply. Thus, the implementation of lithium battery recycling methods is critical meet this expected surge in demand for lithium-based battery technologies. Several economic obstacles and safety considerations have halted the advancement of these necessary recycling techniques. A prominent barrier to recycling efforts revolves around the reactivity of active lithium compounds that remain in used lithium batteries. As a result, significant safety precautions must be taken when handling and transporting lithium-based batteries, adding to the costs associated with recycling methods. Current research has been dedicated to developing a passivation method for the remaining active lithium in used cells, seeking to lower the classification, and subsequently the costs, associated with these materials. -

Graphite and Lithium

www.oeko.de Environmental and socio-economic challenges in battery supply chains: graphite and lithium Short study prepared within the framework of the BMBF Darmstadt, joint project Fab4Lib - Research on measures to increase 29.07.2020 material and process efficiency in lithium-ion battery cell production along the entire value chain (FKZ 03XP0142E) Authors Geschäftsstelle Freiburg Postfach 17 71 79017 Freiburg Peter Dolega Hausadresse Dr. Matthias Buchert Merzhauser Straße 173 Dr. Johannes Betz 79100 Freiburg Telefon +49 761 45295-0 Oeko-Institut Büro Berlin Schicklerstraße 5-7 10179 Berlin Telefon +49 30 405085-0 Büro Darmstadt Rheinstraße 95 64295 Darmstadt Telefon +49 6151 8191-0 [email protected] www.oeko.de Fab4Lib Table of contents List of figures 4 List of abbreviations 5 1. Battery supply chains - towards sustainable cell manufacturing in the EU 7 2. Graphite 7 2.1. Natural graphite 8 2.2. Synthetic graphite 11 3. Lithium 12 3.1. Brines – Lithium triangle 13 3.2. Spodumene – Lithium from Australia 14 4. The future of battery supply chains 20 5. References 20 3 Fab4Lib List of figures Figure 2-1: Overview over the production process of natural graphite. 9 Figure 2-2: Overview over the production process of synthetic graphite. 11 Figure 3-1: Map of currently active lithium brines 13 Figure 3-2: Global lithium production from 2016 to 2018 by country 14 Figure 3-3: Map of Australian lithium mines 15 Figure 3-4: Location of Australian lithium mines in areas of critical habiat 18 Figure 3-5: Greenbushes and critical habitat in the surroundings -

Batteries for Electric and Hybrid Heavy Duty Vehicles

Notice This document is disseminated under the sponsorship of the U.S. Department of Transportation in the interest of information exchange. The United States Government assumes no liability for its contents or use thereof. The United States Government does not endorse products of manufacturers. Trade or manufacturers’ names appear herein solely because they are considered essential to the objective of this report. The mention of commercial products, their use in connection with material reported herein is not to be construed as actual or implied endorsement of such products by U.S. Department of Transportation or the contractor. For questions or copies please contact: CALSTART 48 S Chester Ave. Pasadena, CA 91106 Tel: (626) 744 5600 www.calstart.org Energy Storage Compendium: Batteries for Electric and Hybrid Heavy Duty Vehicles March 2010 CALSTART Prepared for: U.S. Department of Transportation Abstract The need for energy storage solutions and technologies is growing in support of the electrification in transportation and interest in hybrid‐electric and all electric heavy‐duty vehicles in transit and the commercial vehicles. The main purpose of this document is to provide an overview of advanced battery energy storage technologies available currently or in development for heavy‐duty, bus and truck, applications. The same set of parameters, such as energy density, power density, lifecycle and weight were used in review of the specific battery technology solution. The important performance requirements for energy storage solutions from the vehicle perspective were reviewed and the basic advantages of different cell chemistries for vehicle batteries were summarized. A list of current battery technologies available for automotive applications is provided. -

Global Lithium Sources—Industrial Use and Future in the Electric Vehicle Industry: a Review

resources Review Global Lithium Sources—Industrial Use and Future in the Electric Vehicle Industry: A Review Laurence Kavanagh * , Jerome Keohane, Guiomar Garcia Cabellos, Andrew Lloyd and John Cleary EnviroCORE, Department of Science and Health, Institute of Technology Carlow, Kilkenny, Road, Co., R93-V960 Carlow, Ireland; [email protected] (J.K.); [email protected] (G.G.C.); [email protected] (A.L.); [email protected] (J.C.) * Correspondence: [email protected] Received: 28 July 2018; Accepted: 11 September 2018; Published: 17 September 2018 Abstract: Lithium is a key component in green energy storage technologies and is rapidly becoming a metal of crucial importance to the European Union. The different industrial uses of lithium are discussed in this review along with a compilation of the locations of the main geological sources of lithium. An emphasis is placed on lithium’s use in lithium ion batteries and their use in the electric vehicle industry. The electric vehicle market is driving new demand for lithium resources. The expected scale-up in this sector will put pressure on current lithium supplies. The European Union has a burgeoning demand for lithium and is the second largest consumer of lithium resources. Currently, only 1–2% of worldwide lithium is produced in the European Union (Portugal). There are several lithium mineralisations scattered across Europe, the majority of which are currently undergoing mining feasibility studies. The increasing cost of lithium is driving a new global mining boom and should see many of Europe’s mineralisation’s becoming economic. The information given in this paper is a source of contextual information that can be used to support the European Union’s drive towards a low carbon economy and to develop the field of research. -

Procedures for Trace Analysis of Dissolved Inorganic and Organic Constituents in Water Digital Object Identifier

University of Kentucky UKnowledge KWRRI Research Reports Kentucky Water Resources Research Institute 1971 Procedures for Trace Analysis of Dissolved Inorganic and Organic Constituents in Water Digital Object Identifier: https://doi.org/10.13023/kwrri.rr.42 Gary D. Christian University of Kentucky Charles E. Matkovich University of Kentucky W. Lynn Schertz University of Kentucky Right click to open a feedback form in a new tab to let us know how this document benefits oy u. Follow this and additional works at: https://uknowledge.uky.edu/kwrri_reports Part of the Inorganic Chemicals Commons, Organic Chemicals Commons, and the Water Resource Management Commons Repository Citation Christian, Gary D.; Matkovich, Charles E.; and Schertz, W. Lynn, "Procedures for Trace Analysis of Dissolved Inorganic and Organic Constituents in Water" (1971). KWRRI Research Reports. 153. https://uknowledge.uky.edu/kwrri_reports/153 This Report is brought to you for free and open access by the Kentucky Water Resources Research Institute at UKnowledge. It has been accepted for inclusion in KWRRI Research Reports by an authorized administrator of UKnowledge. For more information, please contact [email protected]. PROCEDURES FOR TRACE ANALYSIS OF DISSOLVED INORGANIC AND ORGANIC CONSTITUENTS IN WATER Gary D. Christian Principal Investigator Charles E. Matkovich W. Lynn Schertz Research Assistants University of Kentucky Water Resources Institute Lexington, Kentucky WASHINGTON WA-TSII RESEARCH CENTl!li uaiiwtv Project Number A-013-KY (Completion Report) Agreement Nos. 14-01-0001-1636 14-31-0001-3017 July 1968 - June 1971 The work upon which this report is based was supported by funds provided by the United States Department of the Interior, Office of Water Resources Research, as authorized under the Water Resources Act • of 1964. -

Safety Data Sheet Acc

Page 1 of 13 Safety Data Sheet acc. to OSHA HCS (29 CFR 1910.1200) Printing date 01/22/2015 Reviewed on 01/22/2015 1 Identification · Product identifier · Trade name: Li-MnO2 Button Cell · Article number: CR2032 · Application of the substance / the mixture Lithium-based battery product. · Details of the supplier of the Safety Data Sheet · Manufacturer/Supplier: Jintan Chaochuang Battery Company Limited Xiyang Industrial Estate, Maolu Town Jintan City, Jiangsu Province, China Phone: +86-519-82483588 Fax: +86-755-29369623 · Emergency telephone number: +86-519-82483588 2 Hazard(s) identification · Classification of the substance or mixture GHS02 Flame Water-react. 3 H261 In contact with water releases flammable gas. · Additional information: There are no other hazards not otherwise classified that have been identified. 0 percent of the mixture consists of ingredient(s) of unknown toxicity. · Label elements · GHS label elements The product is classified and labeled according to the Globally Harmonized System (GHS). · Hazard pictograms GHS02 · Signal word Warning · Hazard-determining components of labeling: lithium · Hazard statements H261 In contact with water releases flammable gas. · Precautionary statements P280 Wear protective gloves and eye protection. P370+P378 In case of fire: Use for extinction: Fire-extinguishing powder. P402+P404 Store in a dry place. Store in a closed container. P501 Dispose of contents/container in accordance with local/regional/national/international regulations. · Additional information: Information references exposures to battery contents, and not exposures to whole units. Exposures to whole units are unlikely to produce health hazards. (Contd. on page 2) 40.0.6 Page 2 of 13 Safety Data Sheet acc. -

Lithium Perchlorate

Lithium perchlorate sc-215260 Material Safety Data Sheet Hazard Alert Code EXTREME HIGH MODERATE LOW Key: Section 1 - CHEMICAL PRODUCT AND COMPANY IDENTIFICATION PRODUCT NAME Lithium perchlorate STATEMENT OF HAZARDOUS NATURE CONSIDERED A HAZARDOUS SUBSTANCE ACCORDING TO OSHA 29 CFR 1910.1200. NFPA FLAMMABILITY0 HEALTH2 HAZARD INSTABILITY2 OX SUPPLIER Santa Cruz Biotechnology, Inc. 2145 Delaware Avenue Santa Cruz, California 95060 800.457.3801 or 831.457.3800 EMERGENCY ChemWatch Within the US & Canada: 877-715-9305 Outside the US & Canada: +800 2436 2255 (1-800-CHEMCALL) or call +613 9573 3112 SYNONYMS Cl-Li-O4, LiClO4, "perchloric acid, lithium salt" Section 2 - HAZARDS IDENTIFICATION CHEMWATCH HAZARD RATINGS Min Max Flammability 0 Toxicity 2 Min/Nil=0 Body Contact 2 Low=1 Reactivity 2 Moderate=2 High=3 Chronic 2 Extreme=4 CANADIAN WHMIS SYMBOLS EMERGENCY OVERVIEW RISK Contact with combustible material may cause fire. Irritating to eyes, respiratory system and skin. POTENTIAL HEALTH EFFECTS ACUTE HEALTH EFFECTS SWALLOWED ■ Accidental ingestion of the material may be damaging to the health of the individual. ■ Lithium, in large doses, can cause dizziness and weakness. If a low salt diet is in place, kidney damage can result. ■ Symptoms of exposure to perchlorates include shortness of breath, difficulty breathing and a bluish discolouration of the skin. The effects may be delayed for several hours following exposure. ■ Nausea and vomiting are almost always apparent after chlorate poisonings usually with upper stomach pain. Diarrhoea may also occur. EYE ■ This material can cause eye irritation and damage in some persons. SKIN ■ This material can cause inflammation of the skin oncontact in some persons.