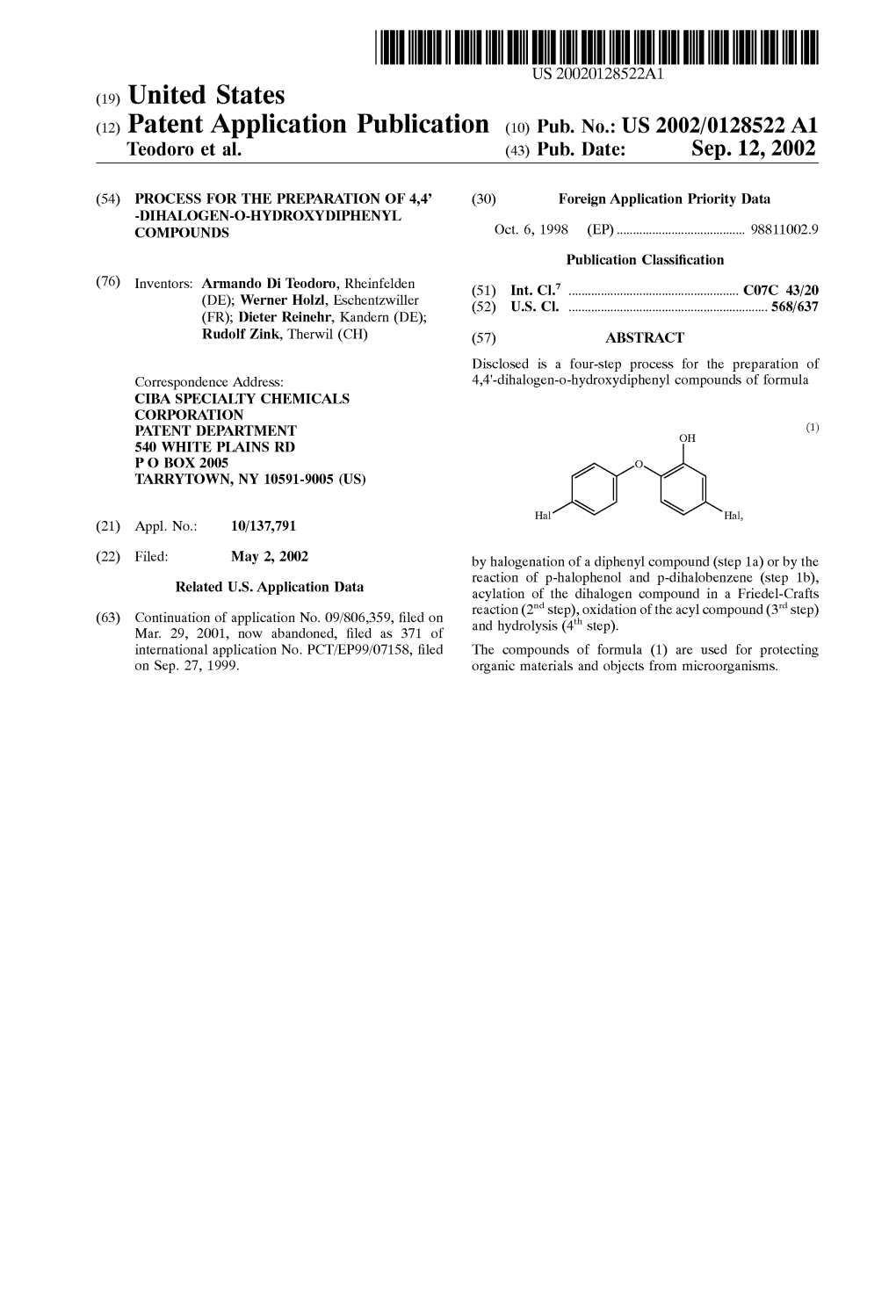

(12) Patent Application Publication (10) Pub. No.: US 2002/0128522 A1 Te0doro Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Comparative Study of Shaving and Depilatory Cream for Hair Removal in Inguinal Hernia Surgical Site Preparation

RESEARCH PAPER Medical Science Volume : 6 | Issue : 2 | FEBRUARY 2016 | ISSN - 2249-555X Comparative Study of Shaving and Depilatory Cream for Hair Removal in Inguinal Hernia Surgical Site Preparation KEYWORDS depilatory cream; shaving; surgical site infection Dr Manish Bansal Gp capt G S Sethi Department of Surgery, Command Hospital (WC), Department of Surgery, Command Hospital (WC), Chandimandir, Panchkula, Haryana, India Chandimandir, Panchkula, Haryana, India ABSTRACT Introduction: Hair interferes with exposure of incision, suturing and wound dressings. Hair removal is thought to reduce the risk of surgical site infections. Three methods of hair removal are used: shaving, clipping and chemical depilation. Aims and objectives: This study aimed to evaluate shaving and depilatory cream for hair removal in inguinal hernia sur- gical site preparation and to compare incidence of surgical site infection, safety, time needed and cost of hair removal. Material and methods: The study was a prospective & comparative study carried out on 100 patients undergoing in- guinal hernia surgical repair at Command Hospital (WC), Chandimandir. Patients were randomized into two groups, i.e., razor shaving group and depilatory cream group. Results: 9 patients (9%) had surgical site infection including 1(2%) in depilatory cream group and 8(16%) in razor group. Infection was significantly associated with razor than depilatory cream. INTRODUCTION There has been no consistent agreement between recom- Postoperative wound infection may lead to significant mendations -

OCTE Safedoc Hairstyling and Aesthetics

OCTE SAFEdoc H&A Safe Activity Foundations in Education Document (SAFEdoc) Hairstyling and Aesthetics TXJ2O, TXJ3E/4E Also Applicable for Emphasis Courses: TXA3E Hairstyling and Aesthetics: Aesthetics TXH3E Hairstyling and Aesthetics: Hairstyling TXA4E Hairstyling and Aesthetics: Aesthetics TXH4E Hairstyling and Aesthetics: Hairstyling Revision May 2013 This resource was produced by the Ontario Council for Technological Education (OCTE) In support by the Ministry of Education It may be used in its entirety, in part, or adapted. H&A SAFEdoc OCTE SAFEdoc H&A Table of Contents Diclaimer SECTION 1: GENERAL ............................................................................................................ 1 Safe Activity Foundation in Education: Hairstyling & Aesthetics ................................................. 1 Usage of the SAFEdocs ............................................................................................................. 2 Communication .........................................................................................................................12 Safety Expectations ..................................................................................................................13 TXJ2O - Hairstyling And Aesthetics ..........................................................................................13 TXJ3E - Hairstyling And Aesthetics ...........................................................................................13 TXJ4E - Hairstyling And Aesthetics ...........................................................................................14 -

A Method to Improve the Efficacy of Topical Eflornithine Hydrochloride Cream

HHS Public Access Author manuscript Author ManuscriptAuthor Manuscript Author Drug Deliv Manuscript Author . Author manuscript; Manuscript Author available in PMC 2017 June 01. Published in final edited form as: Drug Deliv. 2016 June ; 23(5): 1495–1501. doi:10.3109/10717544.2014.951746. A method to improve the efficacy of topical eflornithine hydrochloride cream Amit Kumar1, Youssef W. Naguib1, Yan-chun Shi2, and Zhengrong Cui1,2,* 1The University of Texas at Austin, College of Pharmacy, Pharmaceutics Division, Austin, TX 78712 2Inner Mongolia Medical University, Research Center of Molecular Biology, Hohhot, Inner Mongolia, China Abstract Context—Facial hirsutism is a cosmetic concern for women and can lead to significant anxiety and lack of self-esteem. Eflornithine cream is indicated for the treatment of facial hirsutism. However, limited success rate and overall patient’s satisfaction, even with a long-term and high frequency application, leave room for improvement. Objective—The objective of this study is to test the effect of microneedle treatment on the in vitro skin permeation and the in vivo efficacy of eflornithine cream in a mouse model. Materials and method—In vitro permeation study of eflornithine was performed using Franz diffusion cell. In vivo efficacy study was performed in a mouse model by monitoring the re-growth of hair in the lower dorsal skin of mice after the eflornithine cream was applied onto an area pretreated with microneedles. The skin and the hair follicles in the treated area were also examined histologically. Results and discussion—The hair growth inhibitory activity of eflornithine was significantly enhanced when the eflornithine cream was applied onto a mouse skin area pretreated with microneedles, most likely because the micropores created by microneedles allowed the permeation of eflornithine into the skin, as confirmed in an in vitro permeation study. -

CLINICAL EVALUATION of HANDHELD SELF-TREATMENT DEVICE for HAIR REMOVAL James M

788 COPYRIGHT © 2007 JOURNAL OF DRUGS IN DERMATOLOGY CLINICAL EVALUATION OF HANDHELD SELF-TREATMENT DEVICE FOR HAIR REMOVAL James M. Spencer MD Spencer Dermatology and Skin Surgery, St. Petersburg, FL Abstract Background and Objectives: Laser and light-based methods for hair removal, though effective, are expensive and may be associated with adverse effects. Our objective was to evaluate the efficacy and safety of a thermal, handheld self-treat- ment device (no!no!™ Thermicon™, Radiancy Inc, Orangeburg, NY) for removing unwanted hair. Methods: Twelve of the 20 enrolled subjects underwent 6 supervised and 6 unsupervised self-treatments of their lower legs and umbilicus-bikini areas at twice-weekly intervals for 6 weeks. Follow-up visits were scheduled at 2, 6, and 12 weeks after the final treatment. Results were evaluated by pretreatment, post-treatment, and follow-up hair counts. Results: For legs, the median clearance percentages were 48% post-treatment and 43.5% at 12 weeks. For the umbili- cus-bikini area, the median clearance percentage was 15.0 % at 12 weeks. Conclusions: The efficacy and safety of the no!no! Thermicon device for hair removal of the legs appear to be compa- rable to those of laser devices. Introduction a thermal mechanism. The hair is heated, the heat is con- Traditional hair-removal methods such as waxing, shaving, ducted to the hair follicle, and the follicle is destroyed by heat. and chemical depilatory treatments are often inconvenient. Removing hair with laser or light-based treatments is expen- Permanent methods such as electrolysis are painful, expen- sive and requires multiple visits to medical clinics or spas. -

Primary Generalized and Localized Hypertrichosis in Children

STUDY Primary Generalized and Localized Hypertrichosis in Children Roopal A. Vashi, MD; Anthony J. Mancini, MD; Amy S. Paller, MD Objective: To review the causes, presentation, and sets of hypertrichosis cubiti, anterior cervical hypertri- therapy of primary generalized and localized symmetri- chosis, posterior cervical hypertrichosis, and faun tail cal hypertrichosis in children. deformity. All patients with generalized hypertrichosis manifested the condition at birth; the age of onset in chil- Design: Retrospective medical record review. dren with localized symmetrical primary hypertrichosis ranged from birth to 4 years. One girl with generalized Setting: Academic specialty referral clinic for pediatric hypertrichosis had gingival hyperplasia and the girl with dermatological disorders. faun tail deformity had bony diastematomyelia with spina bifida occulta. The medical histories and physical ex- Patients: Case series of 11 prepubertal male and fe- amination findings of all of the children were otherwise male patients who had idiopathic hypertrichosis be- unremarkable. All patients were referred for diagnostic tween July 1, 1990, and November 30, 1999. and therapeutic considerations. Interventions: None. Conclusions: Primary hypertrichotic conditions, whether localized or generalized, are rare in pediatric patients and Main Outcome Measures: Clinical distribution of in- of unknown origin. Although otherwise benign, these dis- creased hair growth and types of hair removal methods orders may result in cosmetic disfigurement and psy- used. chosocial trauma for patients and families. Patients and their families should be adequately advised of the avail- Results: Seven girls and 4 boys, ranging in age from 4 able treatment methods for both temporary and perma- months to 11 years, were evaluated. Four patients showed nent hair removal. -

Use of Chemical Depilatory Agents on Laboratory Animals the University of Texas at Austin Institutional Animal Care and Use Committee

Guidelines for the Use of Chemical Depilatory Agents on Laboratory Animals The University of Texas at Austin Institutional Animal Care and Use Committee These guidelines have been written to assist faculty, staff, and students in performing vertebrate animal procedures in a humane manner and complying with pertinent regulatory requirements. Under some circumstances deviations from these procedures may be indicated but such variances must be approved in advance by the IACUC. This document provides information to researchers who use chemical depilatory agents in order to remove hair on animals used for research, teaching, or other purposes at the University of Texas at Austin. It is organized into three sections: Section A – Background Information Section B – Use of Chemical Depilatory Agents Section C – References and Acknowledgements Section A – Background Information Chemical depilatory agents (e.g. Nair, Veet, etc.) may be used on animals designated for IACUC approved procedures, including but not limited to surgery, imaging, blood collection, or routine cleaning of cranial implants. An advantage of using a depilatory is its ease of use in areas that are difficult to shave; however, researchers should take precautions when using depilatories in order to ensure the health and well-being of the animal. Application of depilatories should be in accordance with the manufacturer’s directives. Section B – Use of Chemical Depilatory Agents Appropriate hair removal is often best performed when the animal is anesthetized, although that is not always possible. In the instance that the animal cannot be anesthetized, it should be properly restrained. The depilatory may be applied directly to the animal’s hair/fur, or the researcher may shave or clip the area of interest prior to application. -

Evaluation of Patient Satisfaction After Treatment with the Alexandrite Laser for Hirsutism

ORIGINAL ARTICLE Evaluation of patient satisfaction after treatment with the alexandrite laser for hirsutism Farideh Jowkar, MD 1,2 Background: Laser treatment is a rapid, non-invasive procedure for Najmeh Radgoodarz, MDi 3 long-term hair removal. Lasers operate based on the principle of Nasrin Saki, MD 1,2 selective photothermolysis and target melanin in the hair follicle. We intend to determine the level of hirsute patient satisfaction Alireza Heiran 4 with the alexandrite laser hair removal procedure. 1. Molecular Dermatology Research Methods: In this cross-sectional study 82 hirsute patients with Center, Shiraz University of Medical unwanted hair on their faces were enrolled. The patients received Sciences, Shiraz, Iran treatment with a 755 nm alexandrite laser (GentleLASE, Candela 2. Department of Dermatology, Shiraz Corporation, USA). We documented their level of satisfaction with University of Medical Sciences, this laser in terms of hair removal. Laser therapy, electrolysis, Shiraz, Iran and depilation were compared. 3. Department of Internal Medicine, Tehran University of Medical Results: Patients ≥30 years old expressed greater satisfaction Sciences, Tehran, Iran compared to those <30 years of age (P=0.03). Patients with medically 4. Student Research Committee, related hirsutism had the same satisfaction as the idiopathic Shiraz University of Medical hirsute group (P=0.81). Patients rated laser hair removal as 4.12 Sciences, Shiraz, Iran compared to depilation and 3.96 compared to electrolysis. From total patients, 60.97% would recommend laser treatment to other Corresponding Author: hirsute patients. There were 79.3% of patients who expressed Nasrin Saki, MD satisfaction with alexandrite laser hair removal. -

Original Article Evaluation of Two Methods of Preoperative Hair

Original Article Evaluation of two methods of preoperative hair removal and their relationship to postoperative wound infection Adewale O. Adisa, Olukayode O. Lawal, Olusanya Adejuyigbe Department of Surgery, Obafemi Awolowo University, Ile-Ife, Nigeria Abstract Introduction: When a surgical operation is to be conducted through a hair bearing part of the body, hair removal is often performed. This study aimed to evaluate the relationship of two methods of preoperative hair removal to postoperative wound infection in a developing country where razor shaving is very popular. Methodology: Consecutive consenting patients scheduled to have such operations were randomized into two groups. One group had hair removal by shaving with a razor blade while the other had hair removed by depilatory cream. Adequacy of hair removal and presence of skin injuries and/or reactions were noted preoperatively. Details of the procedures were recorded and patients were then assessed for postoperative wound infection. Results: A total of 165 patients were studied. Of the 79 patients who had hair removal by depilatory cream, hair was completely removed in 70 (88.6%) compared to 53 (61.6%) of the 86 patients who had razor hair shaving (p < 0.0001). Skin injuries were noted in 24 (27.9%) of the razor group and 3 (3.8%) of patients who had depilatory cream, (p = 0.001). Thirteen patients (7.9%) had postoperative wound infection including 2 (2.5%) in the depilatory cream group and 11 (12.8%) of the razor group. A significant association was found between preoperative skin injuries and postoperative wound infections. Conclusion: Preoperative hair removal with razor shaving predisposes to skin injuries which in turn significantly influence postoperative wound infection rates. -

Product Safety Data Sheet

Product Safety Data Sheet Document D0001906 Versio 3.0 Code: n: Description: LOTION VELOCE Status: Published Project Veloce Project 08028 Name: Numbe r: Category: Personal Care Segme New Form nt: (Depilatories & Related Products) Formula FILL FORMULA Type: PSDS PSDS 1. PRODUCT AND COMPANY IDENTIFICATION Product Name Veet DepilatoryRapid Action Lotion Hair3 Removalmins Cream Product Type ChemicalChemical Depilatories Depilatories Formulation Reference 00019540001904 - Project Veloce Aloe Vera Extract Variant 0001954 - Project Veloce Silk Extract Varient UPC Codes 62200-76716 Variants Veet DepilatoryVeet Depilatory Lotion Lotion with aloe with vera silk extract Veet Depilatory Lotion with silk extract. Use To removeTo remove unwanted unwanted body body hair hair Appearance MarketedMarketed Product: Product Squeezable: Squeezable plastic plastic tube. tube. Supplier Reckitt Benckiser Depilatory(Canada) Inc.Care R&D, 1680 Tech Avenue Unit #2 DansomMississauga, Lane, ON L4W 5S9 Hull, HU8 7DS, UK Point of Contact in Case of Emergency In TelCase: ++ of44 Emergency:(0) 1482 326151 1-800-888-0192 Transportation Emergencies: 24 Hour Number: North America: Fax: ++ 44 (0) 1482 582532 CHEMTREC: 1-800-424-9300 Technical Services OutsideReckitt North Benckiser America: Depilatory 1-703-527-3887 Care R&D, Dansom Lane, Hull, HU8 7DS, UK. Tel: + 44 (0) 1482 326151 Fax: + 44 (0) 1482 582532 Point of Contact in Case of Emergency Dr Tim Baxter 03/12/2009 17:52:00 GMT Page 1 Product Safety Data Sheet - D0001906 Tel: +44 (0) 1482 582069 2. COMPOSITION Aqua, -

Hypertricosis Not Uncommon After Laser Removal of Facial Hair

48 Dermatologic Surgery S KIN & ALLERGY N EWS • June 2007 Hypertricosis Not Uncommon For Hidradenitis After Laser Removal of Facial Hair Suppurativa, Hair Removal Aids Tx ARTICLES BY laser or intense pulsed light. They re- Several dermatologists who heard MITCHEL L. ZOLER ceived 3-23 treatments. the report at the meeting said that G RAPEVINE, TEX — Hair removal by intense Philadelphia Bureau At follow-up, an average of 10% of their own anecdotal experience con- pulsed light is a useful adjunctive treatment for re- the women had increased facial hair, firmed Dr. Willey’s report. fractory hidradenitis suppurativa, based on experi- G RAPEVINE, TEX. — Facial-hair 8% had no change, 78% had reduced “You can predict which women will ence with 10 patients at one center. removal with laser energy can back- hair growth, and 3% had complete have this. They all have fine, almost Five of the treated patients had clear improvement fire and trigger hypertrichosis if the hair removal. The remaining 1% had downy hair on dark skin that is type in their clinical status after 3-4 hair-removal treat- regimen is not optimized, Dr. An- incomplete information and weren’t III or higher,” said Dr. Jeffrey S. Dover, ments, with reduced or resolved lesions in the treat- drea Willey said at the annual meet- included in the analysis. a dermatologist in private practice in ed area. The remaining five patients had improvement ing of the American Society for Laser Women with hypertrichosis after Chestnut Hill, Mass. after four to eight treatments, Dr. Agneta Troilius said Medicine and Surgery. -

ANNEX II: Frame Formulations

ANNEX II: Frame formulations FRAME FRAME FORMULATION NAME FORMULATION NUMBER 1. SKIN CARE SKIN CARE CREAM, LOTION, GEL 1.1 SKIN CARE CREAM, LOTION, GEL - WITH HIGH LEVEL OF SILICONES 1.2 SKIN CARE CREAM, LOTION, GEL - WITH HIGH LEVEL OF HUMECTANTS 1.3 SKIN CARE CREAM, LOTION, GEL - WITH HIGH LEVEL OF BULKING AGENTS 1.4 SKIN CARE CREAM, LOTION, GEL - WITH HIGH LEVEL OF FATTY COMPOUNDS 1.5 SKIN CARE CREAM, LOTION, GEL - WITH HIGH LEVEL OF UV FILTERS 1.6 SKIN CARE CREAM, LOTION, GEL – WITH HIGH LEVEL OF PERFUME 1.7 ZINC OXIDE BASED CREAM 1.8 SKIN GEL (HYDRO-ALCOHOLIC BASED) 1.9 SKIN OIL 1.10 TONIC, COSMETIC WATER 1.12 CHEMICAL EXFOLIATION PRODUCTS 1.13 SKIN CARE (SILICONE BASED) 1.14 PETROLEUM JELLY 1.15 1 TALCUM POWDER (LOOSE OR PRESSED) 1.16 LIP CARE (STICK, CREAM, GEL) 1.17 2. SKIN CLEANSING FOAMING SKIN CLEANSER 2.1 FOAMING SKIN CLEANSER – WITH HIGH LEVEL OF OILS AND/OR HUMECTANT 2.2 MAKE-UP REMOVER - NON FOAMING CLEANSER (INCLUDING TWO-PHASE 2.3 PRODUCTS) MAKE-UP REMOVER - NON FOAMING OIL CLEANSER 2.4 GENTLE CLEANSING GEL 2.5 SKIN CLEANSING CREAM, LOTION, SCRUB, GEL 2.6 BODY SCRUB (GEL, CREAM) 2.7 SOAP – TOILET 2.8 LIQUID SOAP 2.9 BATH AND SHOWER GEL, CREAM, MILK, PASTE 2.10 SLIGHTLY FOAMING SHOWER CREAM, MILK 2.11 BATH SALTS / CUBES 2.12 BATH AND SHOWER OIL (INCLUDING BATH BEADS) 2.13 FOOTBATH 2.14 SYNDET BAR 2.15 COMBO BAR 2.16 2 3. HAIR REMOVAL CHEMICAL DEPILATORY – CREAM, GEL 3.1 PHYSICAL DEPILATORY WAX – RESIN BASED 3.2 PHYSICAL DEPILATORY WAX – SUGAR BASED 3.3 4. -

The Evolution of Hair Removal SPONSORE D CONTE NT Did You Know Cosmetic January 5, 2011 Terri Wojak Lasers Can Double Your January 2011 Issue of Skin Inc

T R E AT ME NT S > H AI R R E MO V AL The Evolution of Hair Removal SPONSORE D CONTE NT Did You Know Cosmetic January 5, 2011 Terri Wojak Lasers Can Double Your January 2011 issue of Skin Inc. magazine Income? — National Laser Institute All About Meridian Massage for Facial Rejuvenation (VIDEO) — PurErb Skincare History demonstrates that hair removal methods have been around for a long time. When most people think of evolution, they automatically picture a hairy caveman; however, hair removal has been around since the Stone A Natural Alternative to Age, approximately 10,000 BC, from which there are ancient paintings Harsh Scrubs — Circadia showing cavemen using two seashells as tweezers. by Dr. Pugliese As far back as 30,000 BC, flint, a hard form of mineral quartz with sharp edges, was used as a shaving device. Technology has come a long way A D V ER T IS EM ENT since then. One example is laser hair removal systems that have been developed to permanently reduce the amount of hair that grows. According to the American Society of Aesthetic Plastic Surgery, laser hair removal is the third most popular nonsurgical cosmetic procedure performed in the United States,and according to www.surgery.org, the organization’s website, there were 1,280,031 laser hair removal procedures performed in 2009. Even though hair removal has evolved since the Stone Age, it still has a long way to go. New devices are constantly being developed that are more effective and easier to use than what was available as recently as several years ago.