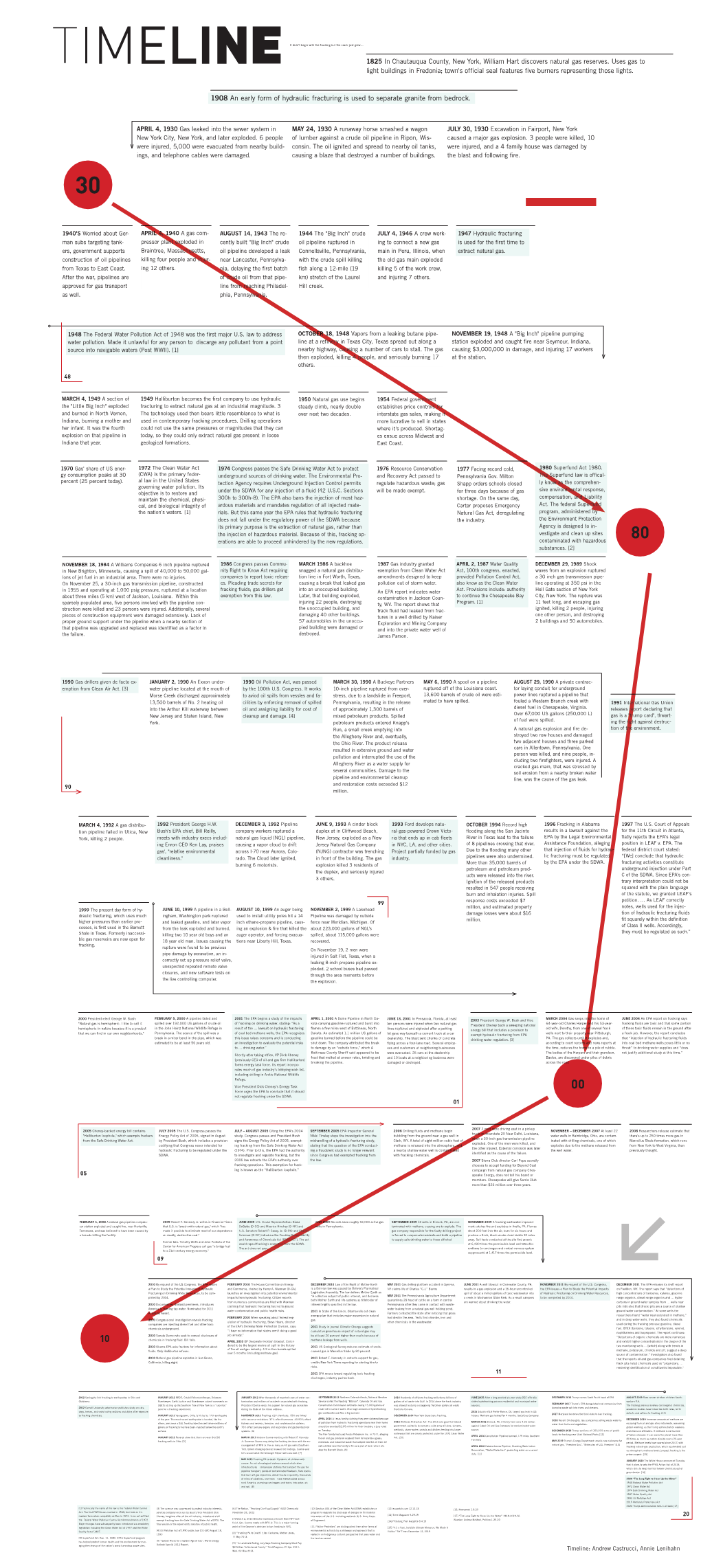

1908 an Early Form of Hydraulic Fracturing Is Used to Separate Granite from Bedrock

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Facts About Alberta's Oil Sands and Its Industry

Facts about Alberta’s oil sands and its industry CONTENTS Oil Sands Discovery Centre Facts 1 Oil Sands Overview 3 Alberta’s Vast Resource The biggest known oil reserve in the world! 5 Geology Why does Alberta have oil sands? 7 Oil Sands 8 The Basics of Bitumen 10 Oil Sands Pioneers 12 Mighty Mining Machines 15 Cyrus the Bucketwheel Excavator 1303 20 Surface Mining Extraction 22 Upgrading 25 Pipelines 29 Environmental Protection 32 In situ Technology 36 Glossary 40 Oil Sands Projects in the Athabasca Oil Sands 44 Oil Sands Resources 48 OIL SANDS DISCOVERY CENTRE www.oilsandsdiscovery.com OIL SANDS DISCOVERY CENTRE FACTS Official Name Oil Sands Discovery Centre Vision Sharing the Oil Sands Experience Architects Wayne H. Wright Architects Ltd. Owner Government of Alberta Minister The Honourable Lindsay Blackett Minister of Culture and Community Spirit Location 7 hectares, at the corner of MacKenzie Boulevard and Highway 63 in Fort McMurray, Alberta Building Size Approximately 27,000 square feet, or 2,300 square metres Estimated Cost 9 million dollars Construction December 1983 – December 1984 Opening Date September 6, 1985 Updated Exhibit Gallery opened in September 2002 Facilities Dr. Karl A. Clark Exhibit Hall, administrative area, children’s activity/education centre, Robert Fitzsimmons Theatre, mini theatre, gift shop, meeting rooms, reference room, public washrooms, outdoor J. Howard Pew Industrial Equipment Garden, and Cyrus Bucketwheel Exhibit. Staffing Supervisor, Head of Marketing and Programs, Senior Interpreter, two full-time Interpreters, administrative support, receptionists/ cashiers, seasonal interpreters, and volunteers. Associated Projects Bitumount Historic Site Programs Oil Extraction demonstrations, Quest for Energy movie, Paydirt film, Historic Abasand Walking Tour (summer), special events, self-guided tours of the Exhibit Hall. -

Frackonomics: Some Economics of Hydraulic Fracturing

Case Western Reserve Law Review Volume 63 Issue 4 Article 13 2013 Frackonomics: Some Economics of Hydraulic Fracturing Timothy Fitzgerald Follow this and additional works at: https://scholarlycommons.law.case.edu/caselrev Part of the Law Commons Recommended Citation Timothy Fitzgerald, Frackonomics: Some Economics of Hydraulic Fracturing, 63 Case W. Rsrv. L. Rev. 1337 (2013) Available at: https://scholarlycommons.law.case.edu/caselrev/vol63/iss4/13 This Symposium is brought to you for free and open access by the Student Journals at Case Western Reserve University School of Law Scholarly Commons. It has been accepted for inclusion in Case Western Reserve Law Review by an authorized administrator of Case Western Reserve University School of Law Scholarly Commons. Case Western Reserve Law Review·Volume 63 ·Issue 4·2013 Frackonomics: Some Economics of Hydraulic Fracturing Timothy Fitzgerald † Contents Introduction ................................................................................................ 1337 I. Hydraulic Fracturing ...................................................................... 1339 A. Microfracture-onomics ...................................................................... 1342 B. Macrofrackonomics ........................................................................... 1344 1. Reserves ....................................................................................... 1345 2. Production ................................................................................... 1348 3. Prices .......................................................................................... -

Advantages, Disadvantages and Economic Benefits Associated with Crude Oil Transportation

Issue Brief 2 02/20/2015 Advantages, Disadvantages and Economic Benefits Associated with Crude Oil Transportation Overview Oil production is an important source of energy, employment, and government revenue in the United States and Canada. Production of crude oil is undergoing a boom in North America due to development of unconventional1 crude sources, including the Alberta oil sands and several geologic shale plays, primarily the Bakken fields in North Dakota and Montana, in addition to the Permian and Eagle Ford fields in Texas. In recent years, domestic production of crude oil in the United States has increased at tremendous rates and is predicted to continue this trend, with total production reaching an estimated 7.4 million barrels per day (bbl/d) in 2013, up from 5.35 million bbl/d five years prior in 2009.2 The forecasted output for 2015 (9.3 million bbl/d) represents what will be the highest levels of domestic production in the United States since 1972.3 This production is coupled with a decline of crude oil imports, with the share of total U.S. liquid fuels consumption met by net imports hitting a low of 33 percent in 2013, down from 60 percent in 2005.4 Canadian crude oil production has also increased dramatically with 3.3 million bb/d produced in 2013, up from 2.57 million bbl/d in 2009.5 As the primary source of imported crude oil to the United States, the Canadian and U.S. oil economies are tightly linked despite declining U.S. imports.6 The rise in crude oil production has accelerated industry demand for transportation to move crude oil from extraction locations to refineries in both nations. -

The Costs of CO2 Transport

The Costs of CO2 Transport Post-demonstration CCS in the EU This document has been prepared on behalf of the Advisory Council of the European Technology Platform for Zero Emission Fossil Fuel Power Plants. The information and views contained in this document are the collective view of the Advisory Council and not of individual members, or of the European Commission. Neither the Advisory Council, the European Commission, nor any person acting on their behalf, is responsible for the use that might be made of the information contained in this publication. 2 Contents Executive Summary ........................................................................................................................................5 1 Study on CO2 Transport Costs ................................................................................................................8 1.1 Background .....................................................................................................................................8 1.2 Use of new, in-house data ..............................................................................................................8 1.3 Literature and references ................................................................................................................9 1.4 Reader’s guide to the report .............................................................................................................10 2 General CCS Assumptions....................................................................................................................11 -

Ensuring the Reliability of Pipeline Transport in Gas Projects in Uzbekistan

92 ABOUT SUSTAINABILITY CLIMATE ENVIRONMENTAL INDUSTRIAL SAFETY HR LOCAL THE COMPANY STRATEGY CHANGE PROTECTION AND HEALTH MANAGEMENT COMMUNITIES PROTECTION ENSURING THE RELIABILITY OF PIPELINE TRANSPORT IN GAS PROJECTS IN UZBEKISTAN Pipeline Transport Safety Improvement Practical experience in operating the Advanced corrosion monitoring methods Program does not apply to foreign Khauzak-Shady and Gissar fields has (FSM matrix, Ultracorr, Hydrosteel 6000) oil and gas organizations; however, shown that the approaches used to are used in the fields, and an automated specialists from the Network Group ensure the reliability of pipelines in a very electrochemical protection system is and LUKOIL Group entities work with harsh environment have contributed to being designed. The Wavemaker system colleagues from foreign organizations on trouble-free operation for the past 10 has been installed, which allows an object projects in which LUKOIL is an operator, years. to be monitored at a distance of up to and provide necessary consultations. To ensure the integrity of equipment, 100 meters in both directions from an Gas fields in Uzbekistan are characterized the corporate standards of installed sensor; consequently, diagnoses by having high gas pressure (up to 200 LLC LUKOIL Uzbekistan Operating Company can be performed in hard-to-reach areas. atm), high hydrogen sulfide H2S (up have been elaborated and agreed with There are plans to integrate data on the to 4.5%, Southern Gissar), and carbon the state inspection of the Republic of results of in-line diagnostics with the dioxide (up to 5%) content, as well as Uzbekistan. These standards regulate the geographic information system of LLC high chloride content in formation water procedures for monitoring the technical LUKOIL Uzbekistan Operating Company. -

Reliability of Russian Pipeline System

Sustainability Report for 2020 LUKOIL Group 79 RELIABILITY OF RUSSIAN PIPELINE SYSTEM Management system ELEMENTS OF THE MANAGEMENT CORPORATE SYSTEM DOCUMENTS OBJECTIVES The Company’s policy related to improving the functional Federal Law No. 116-FZ “On the Industrial Safety reliability of pipeline transport is governed by legal requirements of Hazardous Production Facilities” dated July 21, and corporate standards 1997, Federal rules and regulations on industrial safety “Safety rules in oil and gas industry” (approved by Rostekhnadzor order No. 534 dated December 15, 2020); “Rules for the Safe Operation of In-Field Pipelines” (approved by Rostekhnadzor order No. 515 dated November 30, 2017); other federal regulations and rules on industrial safety PRIORITIES/STANDARDS Our priority is to adopt an integrated approach to the safe Corporate regulations (STO LUKOIL 1.19.1-2012; operation of pipelines: inhibitor coating, the introduction of 1.19.2-2013 and 1.19.3-2013) corrosion-resistant pipes, timely diagnostics, and the prompt elimination of detected defects INDICATORS The pipeline failure rate for oilfield pipelines, number of failures Resolution of the Network Group “Improvements to per 1 km, per year the Oilfield Pipe and Tubing Reliability” of PJSC LUKOIL (further, Network Group) ASSESSMENT The principal source of expertise is the activities of LUKOIL’s Regulations on the Knowledge Management System of Improvement of the Oilfield Pipe and Tubing Reliability the Exploration and Production business segment Network Group, which forms part of the Corporate Knowledge (approved by the First Executive Vice President Ravil Management System Maganov on March 19, 2014) RESPONSIBILITY The system covers all management levels, from senior The approved annual work plan of the Network Group management to specialized units at LUKOIL Group entities. -

Issues and Trends Surrounding the Movement of Crude Oil in the Great Lakes-St

Issues and Trends Surrounding the Movement of Crude Oil in the Great Lakes-St. Lawrence River Region | 1 (page intentionally left blank) Issues and Trends Surrounding the Movement of Crude Oil in the Great Lakes-St. Lawrence River Region | 2 Table of Contents Issues and Trends Surrounding the Movement of Crude Oil in the Great Lakes-St. Lawrence River Region Acknowledgments ………………………………………………………………………… 4 Executive Summary………………………………………………………………………. 5 Summary Report ……….…………………………………………………………………. 9 o Background o Purpose of the Report o Developments and Responses from Regional Partners to Recent Oil Spills o Key Findings and Observations Appendices…………………………………………..………………………………………. 31 o Appendix 1: Summary of Comments Received o Appendix 2: Action Item from September 9, 2013, GLC Annual Meeting o Appendix 3: Summary of Issue Brief 1: Developments in Crude Oil Extraction and Movement o Appendix 4: Summary of Issue Brief 2: Advantages, Disadvantages, and Economic Benefits Associated with Crude Oil Transportation o Appendix 5: Summary of Issue Brief 3: Risks and Impacts Associated with Crude Oil Transportation o Appendix 6: Summary of Issue Brief 4: Policies, Programs and Regulations Governing the Movement of Oil Full report available at www.glc.org/projects/water-quality/oil-transport/ Issues and Trends Surrounding the Movement of Crude Oil in the Great Lakes-St. Lawrence River Region | 3 Acknowledgments Preparation of the Summary of Issues and Trends Surrounding the Movement of Crude Oil in the Great Lakes-St. Lawrence River Region and the four companion issue briefs required the time and effort of numerous individuals who worked together, shared ideas, edited several drafts and provided encouragement and support to each other throughout the process. -

Addendum to Environmental Review Documents Concerning Exports of Natural Gas from the United States

ADDENDUM TO ENVIRONMENTAL REVIEW DOCUMENTS CONCERNING EXPORTS OF NATURAL GAS FROM THE UNITED STATES AUGUST 2014 U.S. DEPARTMENT OF ENERGY This page intentionally left blank. ADDENDUM TO ENVIRONMENTAL REVIEW DOCUMENTS CONCERNING EXPORTS OF NATURAL GAS FROM THE UNITED STATES August 2014 This page intentionally left blank. Table of Contents List of Tables ............................................................................................................................................... I List of Figures ............................................................................................................................................. II List of Acronyms and Abbreviations ...................................................................................................... IV Introduction ................................................................................................................................................. 1 Purpose 3 Public Comments 3 Unconventional Natural Gas Production Activities in the United States 4 Water Resources ....................................................................................................................................... 10 Water Quantity 10 Water Quality 13 Construction 13 Drilling 13 Hydraulic Fracturing Fluids 14 Flowback and Produced Waters 18 Conclusions 19 Air Quality ................................................................................................................................................. 20 Regulations 20 Emission Components and -

The Canadian Oil Transport Conundrum

STUDIES IN ENERGY TRANSPORTATION September 2013 The Canadian Oil Transport Conundrum by Gerry Angevine, with an Introduction by Kenneth P. Green Contents An Overview of Oil Transportation in Canada By Kenneth P. Green Introduction / 1 Overview / 3 Conclusion / 14 References / 15 About the author / 19 Challenges Posed by Pipeline Infrastructure Bottlenecks By Gerry Angevine Introduction / 20 Transportation bottlenecks faced by Canada’s oil producers / 21 Conclusion / 33 References / 34 About the author / 37 Publishing information / 38 Supporting the Fraser Institute / 40 Purpose, funding, & independence / 41 About the Fraser Institute / 42 Editorial board / 43 An Overview of Oil Transportation in Canada By Kenneth P. Green Introduction Recent events have elevated the importance of how we transport energy—spe- cifically oil—to high profile status. The long-stalled approval of the Keystone XL pipeline is probably the highest profile political event that has caused oil trans- port to surge to the fore in energy policy discussions today, but more prosaic economic issues also have played a role. Most importantly, because of limita- tions in the ability to ship oil to coastal refiners and overseas markets, Canada is forced to sell crude oil into the US market at a considerable discount relative to world oil price markers such as Brent.1 This is costing Canadians at least $15 billion each year (Beltrame, 2003, Apr. 13). Among other things, this shortfall has been blamed (wrongly, we believe) for problems with the balance sheet of Alberta’s government, bringing the issue to still greater prominence (Milke, 2013). Economic research has shown that eliminating bottlenecks (whether physical or political) can reduce oil price discounting similar to that which Canada currently endures (Bausell Jr. -

Rosneft Annual Report 2012

ROSNEFT ANNUAL REPORT RESPONSIBILITY 2012 TO BE A LEADER ROSNEFT IS THE LEADER OF THE RUSSIAN OIL INDUSTRY AND ONE OF THE WORLD’S LARGEST PUBLICLY TRADED OIL AND GAS CORPORATIONS BUSINESS GEOGRAPHY: Nearly all regions of Russia and a number of foreign countries. MAIN BUSINESSES: Exploration and producton of oil and gas, production of petroleum products and petrochemicals, sale of outputs in Russia and abroad. MAIN ASSETS: • PRMS proved reserves: 18.3 billion barrels of crude oil and 992 bcm of gas; • 424 producing fields with annual output above 890 million barrels of oil and 16 bcm of gas; • 7 oil refineries in Russia with aggregate refining capacity of 54 mln t of oil per annum; • Stakes in 4 refineries in Germany with net capacity of 11.5 mln t of oil per annum; • 1,691 operating filling stations under the Rosneft brand in 46 regions of Russia and 3 filling stations in Abkhazia. COMPETITIVE ADVANTAGES: • Resource base of unique scale and quality; • Russia’s largest greenfield projects; • Lowest unit lifting costs; • Status of a Company of strategic importance for the Russian Federation. FUTURE: A global energy Company, providing consistently high returns to shareholders through sustainable growth, efficiency gains and innovation, including the design and application of new technologies. DEVELOPMENT PRIORITIES: • Maintaining production levels at existing fields and devel- opment of new fields, both onshore and offshore; • Bringing hard-to-recover reserves into production; • Efficient monetization of associated and natural gas reserves; • Completing modernization of refining capacities; • Increasing marketing efficiency in Russia and internationally; • Achieving technology leadership thanks to in-house re- search and development work and strategic partnerships; • Implementing best practice in protection of the environ- ment and industrial safety. -

Supply Chain Performance Dashboard

Eindhoven University of Technology MASTER Shell chemicals supply chain performance dashboard van der Steen, J.M.L. Award date: 2019 Link to publication Disclaimer This document contains a student thesis (bachelor's or master's), as authored by a student at Eindhoven University of Technology. Student theses are made available in the TU/e repository upon obtaining the required degree. The grade received is not published on the document as presented in the repository. The required complexity or quality of research of student theses may vary by program, and the required minimum study period may vary in duration. General rights Copyright and moral rights for the publications made accessible in the public portal are retained by the authors and/or other copyright owners and it is a condition of accessing publications that users recognise and abide by the legal requirements associated with these rights. • Users may download and print one copy of any publication from the public portal for the purpose of private study or research. • You may not further distribute the material or use it for any profit-making activity or commercial gain Eindhoven University of Technology School of Industrial Engineering & Innovation Sciences Master’s Thesis, by Jasper van der Steen Shell Chemicals Supply Chain Performance Dashboard In partial fulfilment of the requirements for the degree of Master of Science in Operations Management and Logistics Special master’s track: Manufacturing Systems Engineering Supervision: Prof. Dr. A.G. de Kok, Eindhoven University of Technology Dr. V.J.C. Lurkin, Eindhoven University of Technology R. Beusmans, Royal Dutch Shell plc Rotterdam, 26 Sep 2019 Abstract For companies that operate at the scale of Shell, it can be extremely complicated to monitor all supply chain activities. -

View Annual Report 2009

Annual Report Full-scale efficiency Rosneft is the leading Russian petroleum company and ranks among the world’s top publicly traded oil and gas corporations Regions of operations: the Company’s operations extend to almost all regions of Russia and several foreign states Core activities exploration and production of oil and gas, production of petroleum products and petrochemicals, and marketing of outputs in Russia and abroad Strong and Diversified Portfolio: proved reserves: 18.1 bln barrels of oil and 816 bcm of gas 395 producing fields with output of 2.2 mln barrels of oil per day and over 12 bcm of gas per year 97 exploration blocks, access to over 47 bln barrels of oil equivalent of prospective recoverable resources 7 refineries with an aggregate capacity of 1.1 mln barrels per day 1,690 filling stations in 39 regions of Russia Sustained Competitive Edge unique and highly efficient reserve base Russia’s biggest new upstream projects lowest upstream operating expenses per tonne Russian strategic enterprise more than 20% of Russia’s oil production and refinery throughput proprietary export terminals Strategic objective: to be among the world’s top 3 oil and gas companies by overall efficiency and scale of operations Rosneft Oil Company Annual Report 2009 Contents Chairman’s Address 4 President’s Address 8 Key Events in 2009 12 Vankor: A Key Oil Project for Modern Russia 14 Company Profile 28 History 30 Structure 32 Rosneft Today 34 Development Prospects and Strategy 38 Performance Review 40 Licensing 42 Geological Exploration 45 Reserves