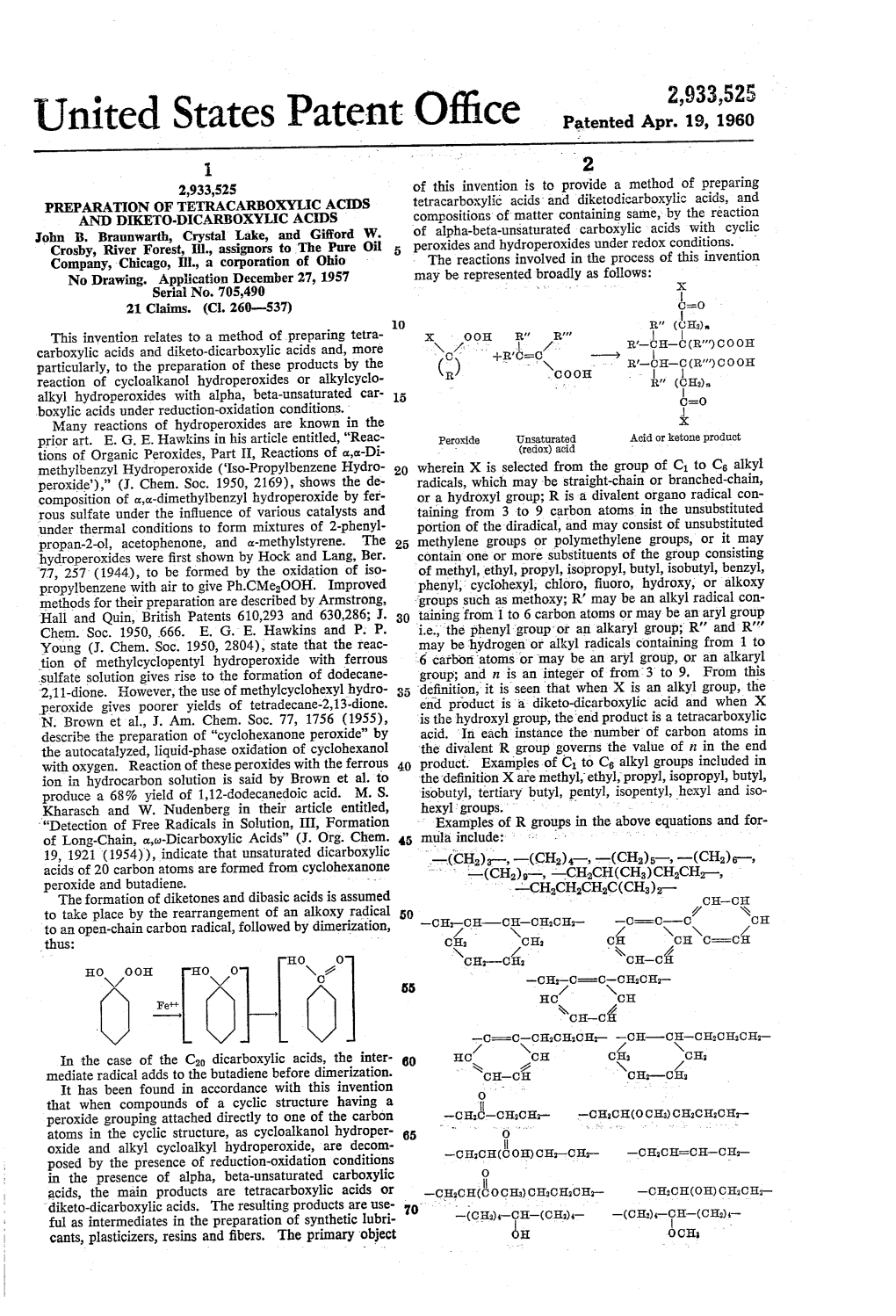

United States Patent Office Patented Apr

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Part 1. Synthesis of N-15 Labeled (R)-Deuterioglycine

PART 1. SYNTHESIS OF N-15 LABELED (R)-DEUTERIOGLYCINE PART 2. SYNTHESES OF CARBON-LINKED ANALOGS OF RETINOID GLYCOSIDE CONJUGATES DISSERTATION Presented in Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy in the Graduate School of The Ohio State University By Joel R. Walker * * * * * The Ohio State Univeristy 2003 Dissertation Committee: Approved by Robert W. Curley, Jr., Ph.D., Adviser Werner Tjarks, Ph.D. ________________________ Adviser Karl A. Werbovetz, Ph.D. College of Pharmacy ABSTRACT (R)-Glycine-d-15N has been used to permit assignments of the prochiral α-protons of glycine residues in the FK-506 binding protein. A key and low yielding step in the synthetic route to (R)-glycine-d-15N occurred in the ruthenium tetraoxide-mediated degradation of N-t-BOC-p-methoxybenzyl amine to the N-t-BOC-glycine after both 2H and 15N are incorporated. In order to improve this step, investigation of the oxidation reaction conditions along with various aromatic ring carboxylate precursors were undertaken. It was found that using ruthenium chloride, periodic acid as the stoichiometric re-oxidant, and N-(p-methoxyphenylmethylamine)-2,2,2-trichloroethyl carbamate were the optimal conditions and substrate. This improvement was paramount for the applicability of this route for large scale production of labeled glycine that could be used in other biological applications. The retinoic acid analog N-(4-hydroxyphenyl)retinamide (4-HPR) is an effective chemopreventative and chemotherapeutic for numerous types of cancer. In vivo, 4-HPR is metabolized to 4-HPR-O-glucuronide (4-HPROG), which has been shown to be more effective than the parent molecule in rat mammary tumor models. -

View and Critique My Work

UNIVERSITY OF CINCINNATI Date:___________________ I, _________________________________________________________, hereby submit this work as part of the requirements for the degree of: in: It is entitled: This work and its defense approved by: Chair: _______________________________ _______________________________ _______________________________ _______________________________ _______________________________ Biodegradation and Environmental Fate of Nonylphenol A thesis submitted to the Division of Graduate Studies and Research of the University of Cincinnati in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE in Chemical Engineering from the Department of Chemical and Materials Engineering of the College of Engineering August 2004 By Marcus A. Bertin B.S., (ChemE), University of Cincinnati Cincinnati, Ohio, 2001 Under the Advisement of Dr. Panagiotis G. Smirniotis Abstract Concern for the fate of nonylphenol (NP) has increased in recent years due to reports that it is an endocrine disrupting compound and that it is persistent in the environment. The biodegradation of NP was examined through the use of microcosms and respirometers. NP biodegradation was examined under aerobic, nitrate reducing, sulfate reducing, and methanogenic conditions. Through the use of gas chromatography- mass spectroscopy, the technical mixture of NP was differentiated into 23 isomers. Since no standards are available, a novel technique was used to quantify the isomers of NP. Under aerobic conditions, biodegradation rates for some isomers differed significantly, indicating that some isomers are more resistant to biodegradation. Comparisons between known isomer structures and biodegradation rates show that correlations exist between the branching of the alkyl chain and biodegradability. Under anoxic conditions, NP degradation using cultures obtained from the anaerobic digester of a local wastewater treatment plant did not occur. -

Effect of Red Fruit Oil on Ovarian Follicles Development in Rat Exposed to Cigarette Smoke

Biosaintifika 10 (2) (2018) 401-407 Biosaintifika Journal of Biology & Biology Education http://journal.unnes.ac.id/nju/index.php/biosaintifika Effect of Red Fruit Oil on Ovarian Follicles Development in Rat Exposed to Cigarette Smoke Isrotun Ngesti Utami, Enny Yusuf Wachidah Yuniwarti, Tyas Rini Saraswati DOI: http://dx.doi.org/10.15294/biosaintifika.v10i2.13236 Department of Biology, Faculty of Science and Mathematics, Universitas Diponegoro, Indonesia History Article Abstract Received 2 January 2018 Red fruit oil (Pandanus conoideus Lam) contains active substances in the form of Approved 12 June 2018 alpha-tocopherol, beta-carotene and unsaturated fatty acids that can potentially be Published 30 August 2018 antioxidants. This study aims to examine the effect of red fruit oil (Pandanus conoi- deus) on the development of ovarian follicles of rat exposed to cigarette smoke, (in Keywords increasing the number of primary follicles, secondary follicles, tertiary follicles and Development of ovarian ovarian weight). This study used Completely Randomized Design with 20 female follicles; Red fruit oil; To- bacco smoke; Ovarian weight rats (3 months old) divided into 4 treatment groups: P0 (Positive control), P1 (nega- tive control of exposure to cigarette smoke for 8 days), P2 (exposure to cigarette smoke for 8 days + 0.1 ml red fruit oil) and P3 (exposure of cigarette smoke for 8 days + 0.2 ml red fruit oil) with 5 time repetition and 28 days red fruit treatment for the research parameters were the number of primary follicles, secondary follicles, tertiary follicles and ovarian weight. The data obtained were analyzed using one- way ANOVA with 95% confidence level (P < 0.05). -

Syntheses and Eliminations of Cyclopentyl Derivatives David John Rausch Iowa State University

Iowa State University Capstones, Theses and Retrospective Theses and Dissertations Dissertations 1966 Syntheses and eliminations of cyclopentyl derivatives David John Rausch Iowa State University Follow this and additional works at: https://lib.dr.iastate.edu/rtd Part of the Organic Chemistry Commons Recommended Citation Rausch, David John, "Syntheses and eliminations of cyclopentyl derivatives " (1966). Retrospective Theses and Dissertations. 2875. https://lib.dr.iastate.edu/rtd/2875 This Dissertation is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for inclusion in Retrospective Theses and Dissertations by an authorized administrator of Iowa State University Digital Repository. For more information, please contact [email protected]. This dissertation has been microfilmed exactly as received 66—6996 RAUSCH, David John, 1940- SYNTHESES AND ELIMINATIONS OF CYCLOPENTYL DERIVATIVES. Iowa State University of Science and Technology Ph.D., 1966 Chemistry, organic University Microfilms, Inc., Ann Arbor, Michigan SYNTHESES AND ELIMINATIONS OF CYCLOPENTYL DERIVATIVES by David John Rausch A Dissertation Submitted to the Graduate Faculty in Partial Fulfillment of The Requirements for the Degree of DOCTOR OF PHILOSOPHY Major Subject: Organic Chemistry Approved : Signature was redacted for privacy. Signature was redacted for privacy. Head of Major Department Signature was redacted for privacy. Iowa State University Of Science and Technology Ames, Iowa 1966 ii TABLE OF CONTENTS VITA INTRODUCTION HISTORICAL Conformation of Cyclopentanes Elimination Reactions RESULTS AND DISCUSSION Synthetic Elimination Reactions EXPERIMENTAL Preparation and Purification of Materials Procedures and Data for Beta Elimination Reactions SUMMARY LITERATURE CITED ACKNOWLEDGEMENTS iii VITA The author was born in Aurora, Illinois, on October 24, 1940, to Mr. -

The Path of Carbon in Photosynthesis

Lawrence Berkeley National Laboratory Lawrence Berkeley National Laboratory Title THE PATH OF CARBON IN PHOTOSYNTHESIS Permalink https://escholarship.org/uc/item/1sx1t7t0 Authors Bassham, J.A. Calvin, Melvin Publication Date 2008-05-21 eScholarship.org Powered by the California Digital Library University of California UCRL-9583 UNIVERSITY OF CALIFORNIA TWO-WEEK LOAN COPY This is a Library Circulating Copy which may be borrowed for two weeks. For a personal retention copy, call Tech. Info. Diuision, Ext. 5545 BERKELEY, CALIFORNIA UCRL-9583 Limited Distribution UNIVERSITY OF CALIFORNIA Lawrence Radiatio;n Laboratory Berkeley, California Contract No. W-7405-eng-48 THE PATH OF CARBON IN PHOTOSYNTHESIS J. A. Bassham and Melvin Calvin October 1960 ·1······.' 8 Oct. 1960 UCBL-95 3 Bj.ogenesis of Natural Subotances edited by Marshall Gates. To be published by Interscience Publishers Chapter 1 THE PNfH OIl' CARBON IN PHOI'OSYNTlillSrs J. A. Bassham and Melvin Calvin Department of Chemistry and Lawrence Radiation Laboratory* Univel'Si ty ot' California, Berkeley, California Contents :Page No. I Introduction 1 II Carbon Reduction Cycle of Photosynthesis :> III Evidence for tile Carbon Reduction Cycle 7 IV The Carbo~ylation Reaotions 14 V Balance among Synthetic Pathways 17 VI Photosynthesis va. Other forme of Biosynthesis 19 \. VII Amino Acid 'Synthesis 20 VIII Carboxylic Acids Malic and Fumaric Acids 27 GlYCOliC' Acid, Acetic Acid and Glyoxylic Acid 28 Acetate IX Carbohydrates Monosaccharides Dlsaccharidea and Polysaccharides 40 x Fata 42 Fatty Acids 45 Glycerol Phosphate 44 XI Aromatic Nuclei 47 XII Other BiosJluthetic Products 47 References 50 * The preparation of this chep't;er was sponsored by the U.S. -

Computational Investigation of the Sn2 Reactivity of Halogenated Pollutants

COMPUTATIONAL INVESTIGATION OF THE SN2 REACTIVITY OF HALOGENATED POLLUTANTS A DISSERTATION SUBMITTED TO THE DEPARTMENT OF CIVIL AND ENVIRONMENTAL ENGINEERING AND THE COMMITTEE OF GRADUATE STUDIES OF STANFORD UNIVERSITY IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF DOCTOR OF PHILOSOPHY Brett Taketsugu Kawakami December 2010 © 2011 by Brett Taketsugu Kawakami. All Rights Reserved. Re-distributed by Stanford University under license with the author. This dissertation is online at: http://purl.stanford.edu/cs274qq3228 ii I certify that I have read this dissertation and that, in my opinion, it is fully adequate in scope and quality as a dissertation for the degree of Doctor of Philosophy. Martin Reinhard, Primary Adviser I certify that I have read this dissertation and that, in my opinion, it is fully adequate in scope and quality as a dissertation for the degree of Doctor of Philosophy. Lynn Hildemann I certify that I have read this dissertation and that, in my opinion, it is fully adequate in scope and quality as a dissertation for the degree of Doctor of Philosophy. James Leckie Approved for the Stanford University Committee on Graduate Studies. Patricia J. Gumport, Vice Provost Graduate Education This signature page was generated electronically upon submission of this dissertation in electronic format. An original signed hard copy of the signature page is on file in University Archives. iii Table of Contents Abstract............................................................................................................................ -

Melvin Calvin

M ELVIN C A L V I N The path of carbon in photosynthesis Nobel Lecture, December 11, 1961 Introduction It is almost sixty years since Emil Fischer was describing on a platform such as this one, some of the work which led to the basic knowledge of the struc- ture of glucose and its relatives 1 . Today we will be concerned with a de- scription of the experiments which have led to a knowledge of the principal reactions by which those carbohydrate structures are created by photo- synthetic organisms from carbon dioxide and water, using the energy of light. The speculations on the way in which carbohydrate was built from carbon dioxide began not long after the recognition of the basic reaction and were carried forward first by Justus von Liebig and then by Adolf von Baeyer and, finally, by Richard Willstätter and Arthur Stall into this century. Actually, the route by which animal organisms performed the reverse reaction, that is, the combustion of carbohydrate to carbon dioxide and water with the utili- zation of the energy resulting from this combination, turned out to be the first one to be successfully mapped, primarily by Otto Meyerhof 2 and Hans Krebs 3. Our own interest in the basic process of solar energy conversion by green plants, which is represented by the overall reaction began some time in the years between 1935 and 1937, during my post- doctoral studies with Professor Michael Polanyi at Manchester. It was there I first became conscious of the remarkable properties of coordinated metal compounds, particularly metalloporphyrins as represented by heme and chlorophyll. -

PATEN Orrlcl-Z

Patented Feb. 15, 1938 2,108,427 Ow UNITED STATES PATEN orrlcl-z 2,108,427 PREPARATION OF ALPHA, BETA UNSATU RATED 'KETON ES Albert Bernard Boese, Jr., Pittsburgh, Pa., as signor to Carbide and Carbon Chemicals Cor poration, a corporation of New York ' No Drawing. Application May 8, 1936, Serial No. 78,661 . ‘ 11 Claims. (o1. 260-131) The invention relates to the production of Example I alpha, beta unsaturated ketones by condensing diketene with aromatic or aliphatic aldehydes To 20.6 grams of. propionaldehyde were added having at least two carbon atoms in the molecule. 29.9 grams of diketene.‘ No initial reaction was observed. After standing at room temperature 5 According to the invention, the selected alde 5 hyde and diketene preferably are mixed and re for 24 hours, the reaction mixture was heated acted in approximately equimolecular propor under reflux for 2% hours. The odors of propion tions. The liquid mixture is heated and refluxed aldehyde and diketene disappeared, and the at the boiling point for-a number of hours. solution became dark. A loss of weight of 15 10 Completion of the reaction usually may be deter grams occurred. The product then was frac mined by the disappearance of the odor of the tionally distilled under atmospheric pressure, and diketene and that of the aldehyde. The reaction the fraction boiling between 128° and 131° C. mixture then is fractionated, generally under at atmospheric pressure was separately con either atmospheric or subatmsopheric pressure, densed and recovered. It contained 21 grams of propylidene acetone, ‘thereby providing a yield of and the fraction containing the unsaturated 15 ketone is separately condensed and recovered. -

Direct Look at the Electric Field in Ketosteroid Isomerase and Its Variants

Direct Look at the Electric Field in Ketosteroid Isomerase and its Variants Matthew R. Hennefarth† and Anastassia N. Alexandrova*,†,‡ †Department of Chemistry and Biochemistry, University of California, Los Angeles, 607 Charles E. Young Drive East, Los Angeles, CA 90095-1569, USA ‡California NanoSystems Institute, University of California, Los Angeles, 570 Westwood Plaza, Los Angeles, California 90095-1569, USA E-mail: *[email protected] Phone: +1 310 825-3769 Abstract Enzymes catalyze a number of reactions with high efficiency and stereoselectivity. It is thought that strong, direct, and permanent electric fields within the active site of the enzyme contribute to the superb catalytic efficiency of enzymes. This effect is called electrostatic preorganization. Most often, electrostatic preorganization is analyzed by evaluating the local electric field at discrete points, such as a bond center, using, for example, vibrational Stark spectroscopy. However, the protein macromolecule creates a significantly more complicated heterogeneous electric field that affects the entire active site, whose total change density thus gets perturbed, with the implications for the catalytic mechanism. We present a global distribution of streamlines method to analyze the topology of the heterogeneous electric fields in within an enzyme active site. We focus on ketosteroid isomerase (KSI), an enzyme known to produce a field on the order of 100 MV/cm along the critical carbonyl bond in the steroid substrate. We investigate how mutations known to cause activity changes, as well as applied small external electric fields perturb the electric fields in the KSI active site. Where classical single-point analysis failed, using our method allowed us to properly correlate global changes in the electric field to changes in the reaction barrier. -

Structural Investigations of the Cancer-Associated

STRUCTURAL INVESTIGATIONS OF THE CANCER-ASSOCIATED LAMININ BINDING PROTEIN AND NOS L, A NOVEL COPPER BINDING PROTEIN by Lara Marie Taubner A dissertation submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy in Biochemistry MONTANA STATE UNIVERSITY Bozeman, Montana October 2005 COPYRIGHT by Lara Marie Taubner 2005 All Rights Reserved ii APPROVAL of a dissertation submitted by Lara Marie Taubner This dissertation has been read by each member of the dissertation committee and has been found to be satisfactory regarding content, English usage, format, citations, bibliographic style, and consistency, and is ready for submission to the College of Graduate Studies. Dr. Valérie Copié Approved for the Department of Chemistry and Biochemistry Dr. David Singel Approved for the College of Graduate Studies Dr. Joseph J. Fedock iii STATEMENT OF PERMISSION TO USE In presenting this thesis in partial fulfillment of the requirements for a doctorate’s degree at Montana State University, I agree that the Library shall make it available to borrowers under rules of the Library. I further agree that copying of this dissertation is allowable only for scholarly purposes, consistent with “fair use” as prescribed in the U.S. Copyright Law. Requests for extensive copying or reproduction of this dissertation should be referred to ProQuest Information and Learning, 300 North Zeeb Road, Ann Arbor, Michigan 48106, to whom I have granted “the exclusive right to reproduce and distribute my dissertation in and from microform along with the non-exclusive right to reproduce and distribute my abstract in any format in whole or in part.” Lara Marie Taubner October 2005 iv DEDICATION I would like to thank my mother, my father, and my sisters Kathleen and Sarah, for their unconditional love and support throughout these last years that has made this dissertation possible. -

Automatic 13C Chemical Shift Reference Correction for Unassigned Protein NMR Spectra

Journal of Biomolecular NMR https://doi.org/10.1007/s10858-018-0202-5 ARTICLE Automatic 13C chemical shift reference correction for unassigned protein NMR spectra Xi Chen1,2 · Andrey Smelter1,3,4 · Hunter N. B. Moseley1,2,3,4,5 Received: 10 April 2018 / Accepted: 1 August 2018 © The Author(s) 2018 Abstract Poor chemical shift referencing, especially for 13C in protein Nuclear Magnetic Resonance (NMR) experiments, fundamen- tally limits and even prevents effective study of biomacromolecules via NMR, including protein structure determination and analysis of protein dynamics. To solve this problem, we constructed a Bayesian probabilistic framework that circumvents the limitations of previous reference correction methods that required protein resonance assignment and/or three-dimensional protein structure. Our algorithm named Bayesian Model Optimized Reference Correction (BaMORC) can detect and correct 13C chemical shift referencing errors before the protein resonance assignment step of analysis and without three-dimensional structure. By combining the BaMORC methodology with a new intra-peaklist grouping algorithm, we created a combined method called Unassigned BaMORC that utilizes only unassigned experimental peak lists and the amino acid sequence. Unassigned BaMORC kept all experimental three-dimensional HN(CO)CACB-type peak lists tested within ± 0.4 ppm of the correct 13C reference value. On a much larger unassigned chemical shift test set, the base method kept 13C chemical shift ref- erencing errors to within ± 0.45 ppm at a 90% confidence interval. With chemical shift assignments, Assigned BaMORC can detect and correct 13C chemical shift referencing errors to within ± 0.22 at a 90% confidence interval. Therefore, Unassigned BaMORC can correct 13C chemical shift referencing errors when it will have the most impact, right before protein resonance assignment and other downstream analyses are started. -

United States Patent 0 " IC€ Patented Oct

3,532,740 United States Patent 0 " IC€ Patented Oct. 6, 1970 1 2 5 3,532,740 CH2 0 0 OXIDATIVE DEHYDROGENATION PROCESS Charles W. Hargis, Johnson City, and Howard S. Young, Kingsport, Tenn., assignors to Eastman Kodak Com CH3 pany, Rochester, N.Y., a corporation of New Jersey 2 N 0 Drawing. Continuation-impart of application Ser. N 0. and 152,630, Nov. 15, 1961. This application May 18, 1966, Ser. No. 550,931 Int. Cl. C07c 45/12 US. Cl. 260-486 24 Claims 10 are oxidized to the corresponding alpha,beta-unsaturated derivatives This application is a continuation-in-part of our co pending application Ser. No. 152,630, ?led Nov. 15, 1961, now abandoned, which was copending with and a con tinuation-in-part of our application Ser. No. 10,107, ?led Feb. 23, 1960, now abandoned. This invention relates to selective oxidation of un 1 2 saturated aliphatic hydrocarbon derivatives. More par and ' ticularly the invention relates to selective oxidation of B a an alkyl derivative having a functional group in which functional unsaturation occurs, to produce a correspond ing ole?nic derivative. We have found that selective oxidation of the alpha, The principal object of the invention is to provide a beta-carbon atoms of the alkyl radical is accomplished method for selective oxidation of a compound consisting by action of an oxidizing agent consisting of one of, or of a lower alkyl radical attached to a functional group 25 a mixture of, the oxides of arsenic, antimony, and bis in which functional unsaturation occurs, and by such muth.