USO09559388B2

(12) United States Patent (10) Patent No.: US 9,559,388 B2 Lee et al. (45) Date of Patent: Jan. 31, 2017

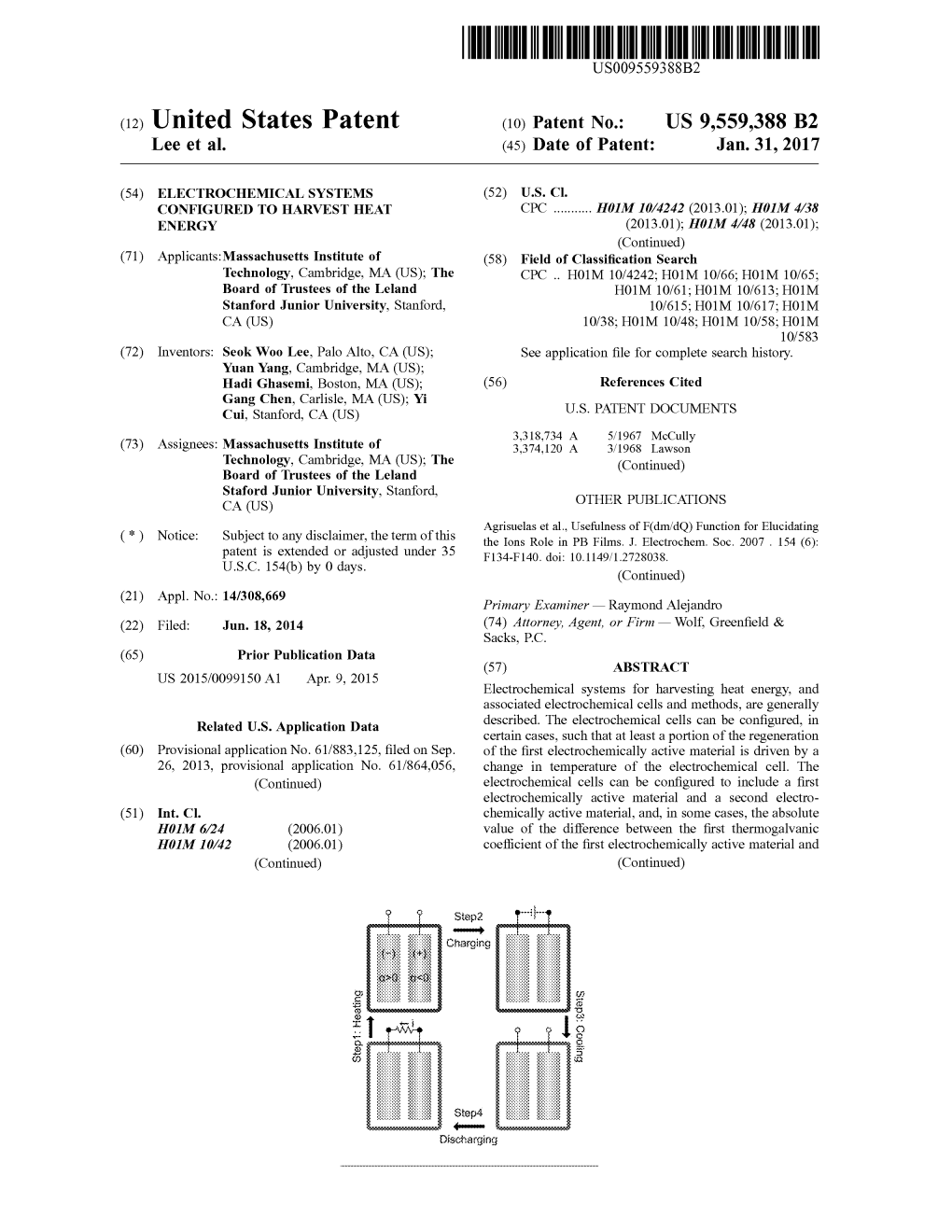

(54) ELECTROCHEMICAL SYSTEMS (52) U.S. Cl. CONFIGURED TO HARVEST HEAT CPC ...... H0IM 10/4242 (2013.01); H01 M 4/38 ENERGY (2013.01); H0 IM 4/48 (2013.01); (Continued) (71) Applicants: Massachusetts Institute of (58) Field of Classification Search Technology, Cambridge, MA (US); The CPC. H01M 10/4242; H01M 10/66; H01M 10/65; Board of Trustees of the Leland H01M 10/61; H01M 10/613; H01M Stanford Junior University, Stanford, 10/615; H01M 10/617; H01M CA (US) 10/38: H01M 10/48; H01M 10/58; H01M 107583 (72) Inventors: Seok Woo Lee, Palo Alto, CA (US); See application file for complete search history. Yuan Yang, Cambridge, MA (US); Hadi Ghasemi, Boston, MA (US); (56) References Cited Gang Chen, Carlisle, MA (US); Yi Cui, Stanford, CA (US) U.S. PATENT DOCUMENTS 3,318,734 A 5/1967 McCully (73) Assignees: Massachusetts Institute of 3,374,120 A 3, 1968 Lawson Technology, Cambridge, MA (US); The Board of Trustees of the Leland (Continued) Staford Junior University, Stanford, CA (US) OTHER PUBLICATIONS Agrisuelas et al., Usefulness of F(dm/dO) Function for Elucidating (*) Notice: Subject to any disclaimer, the term of this the Ions Role in PB Films. J. Electrochem. Soc. 2007. 154 (6): patent is extended or adjusted under 35 F134-F140. doi:10.1149,12728O38. U.S.C. 154(b) by 0 days. (Continued) (21) Appl. No.: 14/308,669 Primary Examiner — Raymond Alejandro (22) Filed: Jun. 18, 2014 (74) Attorney, Agent, or Firm — Wolf, Greenfield & Sacks, P.C. (65) Prior Publication Data (57) ABSTRACT US 2015/OO99150 A1 Apr. 9, 2015 Electrochemical systems for harvesting heat energy, and associated electrochemical cells and methods, are generally described. The electrochemical cells can be configured, in Related U.S. Application Data certain cases, such that at least a portion of the regeneration (60) Provisional application No. 61/883,125, filed on Sep. of the first electrochemically active material is driven by a 26, 2013, provisional application No. 61/864,056, change in temperature of the electrochemical cell. The (Continued) electrochemical cells can be configured to include a first electrochemically active material and a second electro (51) Int. C. chemically active material, and, in Some cases, the absolute HOLM 6/24 (2006.01) value of the difference between the first thermogalvanic HIM ID/242 (2006.01) coefficient of the first electrochemically active material and (Continued) (Continued)

Step3 ---

ad Charging

:

Step4 Discharging US 9,559,388 B2 Page 2 the second thermogalvanic coefficient of the second elec Gur et al., Engineering. Searching for a better thermal battery. trochemically active material is at least about 0.5 millivolts/ Science. Mar. 23, 2012; 335(6075): 1454-5. doi: 10.1126/science. Kelvin. 1218761. Hesson et al., “Thermodynamics and Thermal Efficiencies of Ther mally Regenerative Bimetallic and Hydride EMF Cell Systems,” in 15 Claims, 32 Drawing Sheets Regenerative EMF Cells. American Chemical Society. 1967. 64: 82-104. Hu et al., Harvesting waste thermal energy using a carbon nanotube-based thermo-electrochemical cell. Nano Lett. Mar. 10, Related U.S. Application Data 2010; 10(3):838-46. doi:10.1021/n 1903267n. filed on Aug. 9, 2013, provisional application No. Itaya et al., Catalysis of the reduction of molecular-oxygen to water 61/847,025, filed on Jul. 16, 2013, provisional appli at Prussian blue modified electrodes. J. Am ChemSoc. Jun. 1984. 106(12): 3423-9. DOI: 10.1021/jaO0324a.007. cation No. 61/836,593, filed on Jun. 18, 2013. Kraemer et al., High-performance flat-panel Solar thermoelectric (51) Int. Cl. generators with high thermal concentration. Nat Mater. May 1, HOLM 4/58 (2010.01) 2011; 10(7):532-8. doi:10.1038/nmat3013. Kuzminski et al., Thermoelectric effects in electrochemical sys HOLM 4/583 (2010.01) tems. Nonconventional thermogalvanic cells. J. Power Sources. HIM IO/66 (2014.01) Dec. 1994. 52(2) 231-42. doi:10.1016/0378-7753(94)02015-9. HOLM 4/38 (2006.01) Liu et al., Thermoelectric property studies on Cu-doped n-type HOLM 4/48 (2010.01) CuxBi2Te2.7Se0.3 nanocomposites. Adv Energy Mater. Jul. 2011. (52) U.S. Cl. 1(4): 577-87. DOI: 10.1002/aenm.201100 149. Epub Jun. 9, 2011. CPC ...... H0IM 4/58 (2013.01); H0IM 4/583 Lu et al., Prussian blue: a new framework of electrode materials for (2013.01); H0 IM 10/66 (2015.04) sodium batteries. Chem Commun (Camb). Jul. 4. 2012:48(52):6544-6. doi:10.1039/c2cc31777. Epub May 24, 2012. (56) References Cited Mortimer et al., Electrochemical polychromicity in iron hexacyanoferrate films, and a new film form of ferric ferricyanide. U.S. PATENT DOCUMENTS Journal of Electroanalytical Chemistry. Aug. 10, 1983. 151(1-2): 3,741,809 A 6, 1973 Anbar 133-47, doi:10.1016/S0022-0728(83)80429-X. 4,090,012 A 5, 1978 Elliott et al. Paradiso et al., Energy scavenging for mobile and wireless elec 4.410,606 A 10/1983 Loutfy et al. tronics. IEEE CS and IEEE ComSoc. Pervas. Comput. Jan.-Mar. 5,470,669 A * 1 1/1995 Ludwig ...... HOM 8, 182 2005. 4: 18-27. 136,206 Pasta et al. A high-rate and long cycle life aqueous electrolyte 7,943,250 B1 5/2011 Johnson et al. battery for grid-scale energy storage. Nat. Commun. Oct. 23, 2012. 7,981,556 B2 7, 2011 Shiroma et al. 3: 1149-55. doi:10.1038/ncommS2139. 2006/0134515 A1 6/2006 Kumashiro ...... HO1G 9/22 Pharr et al., Infrared spectroelectrochemical analysis of adsorbed 429,209 hexacyanoferrate species formed during potential cycling in the 2009, O123810 A1 5, 2009 Devoe et al. 2009/0226779 A1 9, 2009 Ohkawara ferrocyanide/ferricyanide redox couple. Anal Chem. Nov. 1997. 2011/0076542 A1 3/2011 Farmer 69(22):4673-9. DOI: 10.1021/ac961 1201. Poudel et al., High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science. May 2, OTHER PUBLICATIONS 2008:320(5876):634-8. doi: 10.1126/science. 1156446. Epub Mar. 20, 2008. Agrisuelas et al., Insights on the Mechanism of Insoluble-to-Soluble Quickenden et al. A review of power-generation in acqueous Prussian Blue Transformation. Journal of the Electrochemical Soci thermogalvanic cells. J of the Electrochem Soc. Apr. 5, 1995. ety. J. Electrochem. Soc. 2009. 156(10): p. 149-p. 156. doi:10.1149/ 142(11): 3985-94. doi:10.1149/12048446. Epub Nov. 1, 1995. 131772.58. Rattner et al., Energy harvesting, reuse and upgrade to reduce Anderson et al., Thermally and photochemically regenerative elec primary energy usage in the USA. Energy. 2011. 36(10): 6172-83. trochemical systems. Adv in Chem Series. Jan. 1, 1967. 64 (15): Rosi et al., Thermoelectricity and thermoelectric power generation. 213-276. Doi:10.1021 ba-1967-0064.ch015. Solid-State Electronics. 1968. 11: 833-68. Bell et al., Cooling, heating, generating power, and recovering waste Snyder et al., Complex thermoelectric materials. Nat Mater. Feb. heat with thermoelectric systems. Sci. Sep. 12, 2008. 321 (5895): 2008;7(2):105-14. doi:10.1038/nmat2090. 1457-61. DOI: 10.1126/science. 1158899. Stilwell et al., Electrochemical studies of the factors influencing the Biswas et al., High-performance bulk thermoelectrics with all-scale cycle stability of prussian blue films. Journal of Applied Electro hierarchical architectures. Nature. Sep. 20, 2012:489(7416):414-8. chemistry. Apr. 1992. 22(4): 325-31. doi: 10.1038/naturel 1439. Erratum in: Nature. Oct. 25, Tchanche et al., Low-grade heat conversion into power using 2012:490(7421):570. organic Rankine cycles—A review of various applications. Renew Chu et al., Opportunities and challenges for a Sustainable energy able & Sustainable Energy Reviews. 2011. 15: 3963-79. future. Nature. Aug. 16, 2012. 488 (7411):294-303, doi: 10.1038/ Wang et al., Nanotechnology-enabled energy harvesting for self nature 11475. powered micro-finanosystems. Angew Chem Int Ed Engl. Nov. 19. Debethune et al., The temperature coefficients of electrode poten 2012:51(47): 11700-21. doi:10.1002/anie.201201656. Epub Nov. 4, tials—the isothermal and thermal coefficients—the standard ionic 2012. Review. entropy of electrochemical transport of the hydrogen ion. J. Wessells et al., Copper hexacyanoferrate battery electrodes with Electrochem. Soc. 1959. 106(7), 616-625. doi:10.1149/12427448. long cycle life and high power. Nat Commun. Nov. 22, 2011:2:550. Disalvo et al. Thermoelectric cooling and power generation . doi:10.1038/ncommS1563. Science. Jul. 30, 1999:285(5428):703-6. DOI: 10.1126/science.285. Wessells et al., The effect of insertion species on nanostructured 5428.703. open framework hexacyanoferrate battery electrodes. J. Gunawan et al., Liquid thermoelectrics: review of recent and limited Electrochem. Soc. 2012. 159:A98-A103. new data of thermogalvanic cell experiments. Nanoscale Microscale Xu et al., Self-powered nanowire devices. Nat Nanotechnol. May Thermophys Engineering. Feb. 10, 2013, 17(4). 304-23. Published 2010:5(5):366-73. doi: 10.1038/nnano.2010,46. Epub Mar. 28, Sep. 5, 2013. DOI: 10.1080/15567265.2013.776149. 2010. US 9,559,388 B2 Page 3

(56) References Cited OTHER PUBLICATIONS Zebarjadi et al. Perspectives on thermoelectrics: from fundamentals to device applications. Energy & Environmental Science. 2012. 5: 5147-62. DOI: 10.1039/C1EE02497C Epub Nov. 23, 2011. Zhao et al., Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature. Apr. 17. 2014:508(7496):373-7, doi:10.1038/nature 13184. International Preliminary Report on Patentability for Application No. PCT/US2014/043047 mailed Dec. 30, 2015. International Search Report and Written Opinion for PCT/US2014/ 043047 mailed Mar. 13, 2015. Lee et al. An electrochemical system for efficiently harvesting low-grade heat energy. Nat Commun. May 21, 2014;5:3942. DOI: 10.1038/ncommS4942. Yang et al., Charging-free electrochemical system for harvesting low-grade thermal energy. Proc Natl Acad Sci U S A. Dec. 2, 2014:111(48): 1701 1-6. Chum et al. Review of thermally regenerative electrochemical systems. Solar Energy Research Institute, Golden, Colorado. Apr. 1981; vol. 2, 226 pages. Hammond et al., An electrochemical heat engine for direct Solar energy conversion. Solar Energy. 1979:23:443-9. * cited by examiner U.S. Patent Jan. 31, 2017 Sheet 1 of 32 US 9,559,388 B2

FIG. IA FIG. IB U.S. Patent Jan. 31, 2017 Sheet 2 of 32 US 9,559,388 B2

TR Temperature

T

Entropy

FIG. 2 U.S. Patent Jan. 31, 2017 Sheet 3 of 32 US 9,559,388 B2

Voltage Voltage

301

303 N Capacity Capacity

FIG. 3A U.S. Patent Jan. 31, 2017 Sheet 4 of 32 US 9,559,388 B2

FIG. 4 U.S. Patent Jan. 31, 2017 Sheet S of 32 US 9,559,388 B2

500

FIG. 5A U.S. Patent Jan. 31, 2017 Sheet 6 of 32 US 9,559,388 B2

550

FIG. 5B U.S. Patent Jan. 31, 2017 Sheet 7 of 32 US 9,559,388 B2

Temperature Spectrum

FIG. 6A

Heat Duty

FIG. 6B U.S. Patent Jan. 31, 2017 Sheet 8 of 32 US 9,559,388 B2

FIG. 7 U.S. Patent Jan. 31, 2017 Sheet 9 of 32 US 9,559,388 B2

Cierging Siep2 Charging tow W) s co .

. 9. . S. a 3.- i. Step4: Bischarging high W) Stepha Discia: gig Entropy, S

FIG. 8A FIG. 8B U.S. Patent Jan. 31, 2017 Sheet 10 of 32 US 9,559,388 B2

Charge (Oeit) FIG. 9 U.S. Patent Jan. 31, 2017 Sheet 11 of 32 US 9,559,388 B2

{eat Exchanger rix}

FIG. I.0 U.S. Patent Jan. 31, 2017 Sheet 12 of 32 US 9,559,388 B2

FIG. II U.S. Patent Jan. 31, 2017 Sheet 13 of 32 US 9,559,388 B2

FIG. I2A

FIG. I2B U.S. Patent Jan. 31, 2017 Sheet 14 of 32 US 9,559,388 B2

FIG. I2C U.S. Patent Jan. 31, 2017 Sheet 15 Of 32 US 9,559,388 B2

& x : x x Exxess 0 seat excitate FIG. I3A

FIG. I.3B U.S. Patent Jan. 31, 2017 Sheet 16 of 32 US 9,559,388 B2

six

esperature O

FIG. I.4B U.S. Patent Jan. 31, 2017 Sheet 17 Of 32 US 9,559,388 B2

(b)

Specific Capacity man FIG. I5B U.S. Patent Jan. 31, 2017 Sheet 18 of 32 US 9,559,388 B2

Specific capacity mang FIG. I.6A

(xxx FIG. I.6B U.S. Patent Jan. 31, 2017 Sheet 19 Of 32 US 9,559,388 B2

Charging-free Battery

FIG. I7B U.S. Patent Jan. 31, 2017 Sheet 20 of 32 US 9,559,388 B2

FIG. ISA

:::::::::::::::::::

six axy 88 &xxix: {{xy 88.8 °.

FIG. ISB U.S. Patent Jan. 31, 2017 Sheet 21 of 32 US 9,559,388 B2

::: it in FIG. ISC

Oaxcy (i. FIG. ISD U.S. Patent Jan. 31, 2017 Sheet 22 of 32 US 9,559,388 B2

FIG. I9A

FIG. IgE3 U.S. Patent Jan. 31, 2017 Sheet 23 of 32 US 9,559,388 B2

8.8 x 8. 8. & 3. 888.

FIG. OD U.S. Patent Jan. 31, 2017 Sheet 24 of 32 US 9,559,388 B2

C * : *Writief- :::::: mig FIG. 20A

(a)- no overpotential b)- 10 mV overpotential

eat Exchanger Electiveness (s FIG. 20B U.S. Patent Jan. 31, 2017 Sheet 25 Of 32 US 9,559,388 B2

X eral Paste

- C ye

hio Cei

Code

herocouple Fiberglass insuiation

FIG. 2I U.S. Patent Jan. 31, 2017 Sheet 26 of 32 US 9,559,388 B2

O War.So wasR to it (top) w Tim (middle) (s M \ - Tb (bottom)

20 4o so so too 12o. 14o 1so 1so Time (second)

FIG. 22 U.S. Patent Jan. 31, 2017 Sheet 27 Of 32 US 9,559,388 B2

A. Part 3: Coo::g the hot ce: s *art 2: Heating the cold get:

... 38

*io (the voice: is

a Citiet

FIG. 23 U.S. Patent Jan. 31, 2017 Sheet 28 of 32 US 9,559,388 B2

U.S. Patent Jan. 31, 2017 Sheet 29 of 32 US 9,559,388 B2

A SS 8

80 30 328 43 80 8283 220 340 288 20 4; 30 80 : O 23 130 0 180 200 Time (second) Time (second) FIG. 25 U.S. Patent Jan. 31, 2017 Sheet 30 of 32 US 9,559,388 B2

&

six:3: 3::ty

FIG. 26 U.S. Patent Jan. 31, 2017 Sheet 31 of 32 US 9,559,388 B2

789 8

50 A / •8• Effective&ss of . *&^ Effectiveness of O.85

- Number of Heat Exchangers

FIG. 27 U.S. Patent Jan. 31, 2017 Sheet 32 of 32 US 9,559,388 B2

*::::::