Y Isoph Nicole S

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Part I: Carbonyl-Olefin Metathesis of Norbornene

Part I: Carbonyl-Olefin Metathesis of Norbornene Part II: Cyclopropenimine-Catalyzed Asymmetric Michael Reactions Zara Maxine Seibel Submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy in the Graduate School of Arts and Sciences COLUMBIA UNIVERSITY 2016 1 © 2016 Zara Maxine Seibel All Rights Reserved 2 ABSTRACT Part I: Carbonyl-Olefin Metathesis of Norbornene Part II: Cyclopropenimine-Catalyzed Asymmetric Michael Reactions Zara Maxine Seibel This thesis details progress towards the development of an organocatalytic carbonyl- olefin metathesis of norbornene. This transformation has not previously been done catalytically and has not been done in practical manner with stepwise or stoichiometric processes. Building on the previous work of the Lambert lab on the metathesis of cyclopropene and an aldehyde using a hydrazine catalyst, this work discusses efforts to expand to the less stained norbornene. Computational and experimental studies on the catalytic cycle are discussed, including detailed experimental work on how various factors affect the difficult cycloreversion step. The second portion of this thesis details the use of chiral cyclopropenimine bases as catalysts for asymmetric Michael reactions. The Lambert lab has previously developed chiral cyclopropenimine bases for glycine imine nucleophiles. The scope of these catalysts was expanded to include glycine imine derivatives in which the nitrogen atom was replaced with a carbon atom, and to include imines derived from other amino acids. i Table of Contents List of Abbreviations…………………………………………………………………………..iv Part I: Carbonyl-Olefin Metathesis…………………………………………………………… 1 Chapter 1 – Metathesis Reactions of Double Bonds………………………………………….. 1 Introduction………………………………………………………………………………. 1 Olefin Metathesis………………………………………………………………………… 2 Wittig Reaction…………………………………………………………………………... 6 Tebbe Olefination………………………………………………………………………... 9 Carbonyl-Olefin Metathesis……………………………………………………………. -

Oxidative Chemistry of Phosphorothionate And

(i). OXIDATIVE CHEMISTRY OF PHOSPHOROTHIONATE AND RELATED COMPOUNDS A thesis submitted in fulfilment of the requirement for the degree of Doctor of Philosophy from Department of Organic Chemistry School of Chemistry University of New South Wales by Jeong Han Kim March 1992 (ii) DECLARATION This is to certify that the work described in this thesis was carried out by the author during the period March 1988 to March 1992, in Department of Organic Chemistry, University of New South Wales, Australia under the supervision of Dr. Robert F. Toia and Associate Professor Michael J. Gallagher. It is hereby declared that this thesis has not been submitted in part or in full to any other university or institution for the any degree or diploma. Date: .l.$:;.J.... ~.t't.~. (iii) ACKNOWLEDGEMENTS I would like to express my deepest gratitude and appreciation to my supervisors, Dr. Robert F. Toia and Associate Professor Michael J. Gallagher for their help, guidance and continuous encouragement throughout the study. My special thanks also go to Professor J. E. Casida for the valuable extensive study in Pesticide Chemistry and Toxicology Laboratory in U. C. Berkeley and to Professor C. K. Park in Seoul National University for his guidance and encouragement. Many thanks also to Dr. J. Hook for his great help with 3lp NMR, to the staff members of the Department of Organic Chemistry in University of New South Wales and to my fellow students for their help and friendship. Great acknowledgement is made to the Australian government for financial support in the form of a Commonwealth Postgraduates Research A wards. -

Organophosphorus Chemistry (Kanda, 2019)

Baran lab Group Meeting Yuzuru Kanda Organophosphorus Chemistry 09/20/19 bonding and non-bonding MOs of PH3 bonding and non-bonding MOs of PH5 # of R P(III) ← → P(V) O P P R R R R R R phosphine phosphine oxide D3h C3v C2v O O JACS. 1972, 3047. P P P P R NH R OH R OH R NH Chem. Rev. 1994, 1339. R 2 R R R 2 D C phosphineamine phosphinite phosphinate phosphinamide 3h 4v O O O R P R P R P R P R P R P NH2 NH2 OH OH NH2 NH2 H2N HO HO HO HO H2N phosphinediamine phosphonamidite phosphonite phosphonate phosphonamidate phosphonamide O O O O H N P P P P P P P P 2 NH HO HO HO HO HO HO H2N H N 2 NH2 NH2 OH OH NH2 NH2 NH2 2 H2N HO HO HO HO H2N H2N phosphinetriamine phosphorodiamidite phosphoramidite phosphite phosphate phosphoramidate phosphorodiamidate phosphoramide more N O more O Useful Resources more N P P P Corbridge, D. E. C. Phosphorus: Chemistry, Biochemistry and H OH H H H H H H H Technology, 6th ed.; CRC Press Majoral, J. P. New Aspects In Phosphorus Chemistry III.; Springer phosphinous phosphane phosphane Murphy, P. J. Organophosphorus Reagents.; Oxford acid oxide Hartley, F. R. The chemistry of organophosphorus compounds, O O volume 1-3.; Wiley P P P Cadogan. J. I. G. Organophosphorus Reagents in Organic H OH H OH H OH HO HO H Synthesis.; Academic Pr phosphonate phosphonus acid phosphinate Not Going to Cover ↔ (phosphite) Related GMs Metal complexes, FLP, OPV Highlights in Peptide and Protein NH S R • oxidation state +5, +4, +3, +2, +1, 0, -1, -2, -3 Synthesis (Malins, 2016) R P-Stereogenic Compounds P P R P • traditionally both +3 and -3 are written as (III) R • 13/25th most abundant element on the earth (Rosen, 2014) R • but extremely rare outside of our solar system Ligands in Transition Metal phosphine imide phosphine sulfide phosphorane Catalysis (Farmer, 2016) Baran lab Group Meeting Yuzuru Kanda Organophosphorus Chemistry 09/20/19 Me P Me Me Low-Coordinate Low Oxidation State P tBu tBu P P phosphaalkyne R N P PivCl 2 P Me Cl TMS OTMS NaOH R = tBu Nb N tBu PTMS3 P O H O P NR2 then Na/Hg tBu N -2 Nb tBu R2N Me Nb N tBu 5x10 mbar, 160 ºC NR2 95% R2N Me N O 1. -

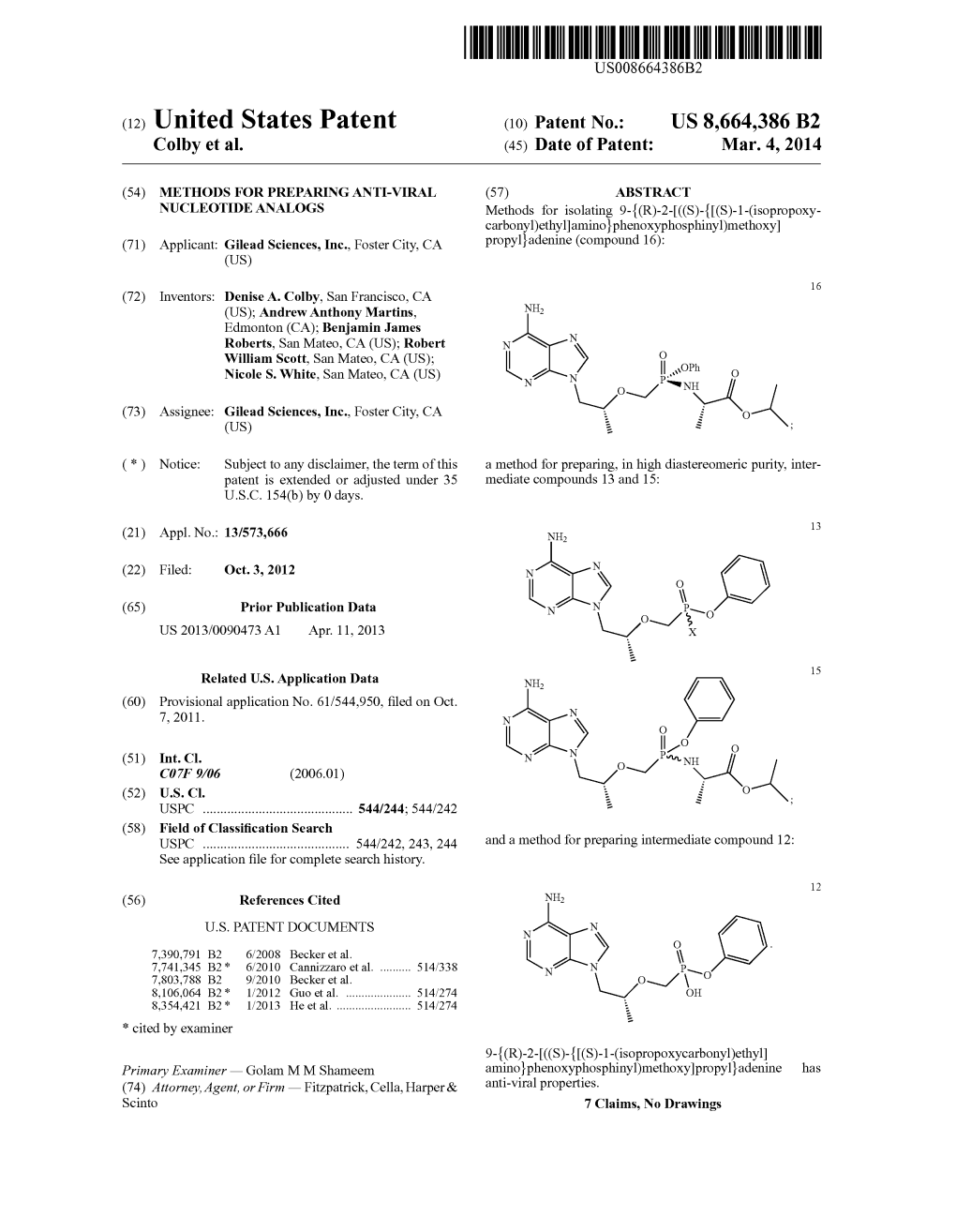

Methods for Preparing Anti-Viral Nucleotide Analogs

(19) TZZ¥¥¥¥_¥_T (11) EP 3 333 173 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention (51) Int Cl.: of the grant of the patent: C07F 9/6561 (2006.01) 26.06.2019 Bulletin 2019/26 (21) Application number: 18153951.1 (22) Date of filing: 03.10.2012 (54) METHODS FOR PREPARING ANTI-VIRAL NUCLEOTIDE ANALOGS VERFAHREN ZUR HERSTELLUNG ANTIVIRALER NUKLEOTIDANALOGA PROCÉDÉS DE PRÉPARATION D’ANALOGUES NUCLÉOTIDIQUES ANTIVIRAUX (84) Designated Contracting States: (72) Inventors: AL AT BE BG CH CY CZ DE DK EE ES FI FR GB • COLBY, Denise, A. GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO San Francisco, CA California 94127 (US) PL PT RO RS SE SI SK SM TR • MARTINS, Andrew, Anthony Designated Extension States: Edmonton, Alberta T6R 2J7 (CA) BA ME • ROBERTS, Benjamin, James San Mateo, CA California 94403 (US) (30) Priority: 07.10.2011 US 201161544950 P • SCOTT, Robert, William San Mateo, CA California 94401 (US) (43) Date of publication of application: • WHITE, Nicole, S. 13.06.2018 Bulletin 2018/24 San Mateo, CA California 94403 (US) (62) Document number(s) of the earlier application(s) in (74) Representative: Carpmaels & Ransford LLP accordance with Art. 76 EPC: One Southampton Row 12798029.0 / 2 764 002 London WC1B 5HA (GB) (73) Proprietor: Gilead Sciences, Inc. (56) References cited: Foster City, CA 94404 (US) US-B2- 7 390 791 US-B2- 7 803 788 Note: Within nine months of the publication of the mention of the grant of the European patent in the European Patent Bulletin, any person may give notice to the European Patent Office of opposition to that patent, in accordance with the Implementing Regulations. -

Page 1 of 37 Pleasepolymer Do Not Chemistryadjust Margins

Polymer Chemistry Accepted Manuscript This is an Accepted Manuscript, which has been through the Royal Society of Chemistry peer review process and has been accepted for publication. Accepted Manuscripts are published online shortly after acceptance, before technical editing, formatting and proof reading. Using this free service, authors can make their results available to the community, in citable form, before we publish the edited article. We will replace this Accepted Manuscript with the edited and formatted Advance Article as soon as it is available. You can find more information about Accepted Manuscripts in the Information for Authors. Please note that technical editing may introduce minor changes to the text and/or graphics, which may alter content. The journal’s standard Terms & Conditions and the Ethical guidelines still apply. In no event shall the Royal Society of Chemistry be held responsible for any errors or omissions in this Accepted Manuscript or any consequences arising from the use of any information it contains. www.rsc.org/polymers Page 1 of 37 PleasePolymer do not Chemistryadjust margins Polymer Chemistry Review Phosphorylation of bio-based compounds: state of the art Nicolas Illy,a,b,* Maxence Fache,c Raphaël Ménard,c Claire Negrell,c Sylvain Caillol,c and Ghislain Received 00th January 20xx, Davidc Accepted 00th January 20xx Over the last few years more and more papers have been devoted to phosphorus-containing DOI: 10.1039/x0xx00000x polymers, mainly due to their fire resistance, excellent chelating and metal-adhesion properties. www.rsc.org/ Nevertheless, sustainability, reduction of environmental impacts and green chemistry are increasingly guiding the development of the next generation of materials. -

Robert H. Morris

TSpace Research Repository tspace.library.utoronto.ca Brønsted-Lowry Acid Strength of Metal Hydride and Dihydrogen Complexes Robert H. Morris Version Post-print/accepted manuscript Citation Morris, R. H. Chemical Reviews 2016, 116, 8588–8654. (published version) http:/doi.org//10.1021/acs.chemrev.5b00695 Copyright / License Publisher’s Statement This document is the Accepted Manuscript version of a Published Work that appeared in final form in Chemical Reviews, copyright © American Chemical Society after peer review and technical editing by the publisher. To access the final edited and published work see http://pubs.acs.org/doi/abs/10.1021/acs.chemrev.5b00695. How to cite TSpace items Always cite the published version, so the author(s) will receive recognition through services that track citation counts, e.g. Scopus. If you need to cite the page number of the author manuscript from TSpace because you cannot access the published version, then cite the TSpace version in addition to the published version using the permanent URI (handle) found on the record page. This article was made openly accessible by U of T Faculty. Please tell us how this access benefits you. Your story matters. Brønsted‐Lowry Acid Strength of Metal Hydride and Dihydrogen Complexes Robert H. Morris* Department of Chemistry, University of Toronto, 80 Saint George St. Toronto, Ontario, M5S3H6, Canada Transition metal hydride complexes are usually amphoteric, not only acting as hydride donors, but also as Brønsted‐Lowry acids. A simple additive ligand acidity constant equation (LAC for short) allows the LAC estimation of the acid dissociation constant Ka of diamagnetic transition metal hydride and dihydrogen complexes. -

Structural Studies of Phosphorinanes John Alvin Mosbo Iowa State University

Iowa State University Capstones, Theses and Retrospective Theses and Dissertations Dissertations 1973 Structural studies of phosphorinanes John Alvin Mosbo Iowa State University Follow this and additional works at: https://lib.dr.iastate.edu/rtd Part of the Inorganic Chemistry Commons Recommended Citation Mosbo, John Alvin, "Structural studies of phosphorinanes " (1973). Retrospective Theses and Dissertations. 5037. https://lib.dr.iastate.edu/rtd/5037 This Dissertation is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for inclusion in Retrospective Theses and Dissertations by an authorized administrator of Iowa State University Digital Repository. For more information, please contact [email protected]. INFORMATION TO USERS This material was produced from a microfilm copy of the original document. While the most advanced technological means to photograph and reproduce this document have been used, the quality is heavily dependent upon the quality of the original submitted. The following explanation of techniques is provided to help you understand markings or patterns which may appear on this reproduction. 1.The sign or "target" for pages apparently lacking from the document photographed is "Missing Page(s)". If it was possible to obtain the missing page(s) or section, they are spliced into the film along with adjacent pages. This may have necessitated cutting thru an image and duplicating adjacent pages to insure you complete continuity. 2. When an image on the film is obliterated with a large round black mark, it is an indication that the photographer suspected that the copy may have moved during exposure and thus cause a blurred image. -

University of Groningen Alkaline Earth Organometallic Compounds In

University of Groningen Alkaline earth organometallic compounds in homogeneous catalysis Penafiel, Johanne IMPORTANT NOTE: You are advised to consult the publisher's version (publisher's PDF) if you wish to cite from it. Please check the document version below. Document Version Publisher's PDF, also known as Version of record Publication date: 2016 Link to publication in University of Groningen/UMCG research database Citation for published version (APA): Penafiel, J. (2016). Alkaline earth organometallic compounds in homogeneous catalysis: Synthesis, characterization and catalytic activity of calcium and magnesium complexes [Groningen]: Rijksuniversiteit Groningen Copyright Other than for strictly personal use, it is not permitted to download or to forward/distribute the text or part of it without the consent of the author(s) and/or copyright holder(s), unless the work is under an open content license (like Creative Commons). Take-down policy If you believe that this document breaches copyright please contact us providing details, and we will remove access to the work immediately and investigate your claim. Downloaded from the University of Groningen/UMCG research database (Pure): http://www.rug.nl/research/portal. For technical reasons the number of authors shown on this cover page is limited to 10 maximum. Download date: 11-02-2018 Alkaline earth organometallic compounds in homogeneous catalysis Synthesis, characterization and catalytic activity of calcium and magnesium complexes Proefschrift ter verkrijging van de graad van doctor aan de Rijksuniversiteit Groningen op gezag van de rector magnificus prof. dr. E. Sterken en volgens besluit van het College voor Promoties. De openbare verdediging zal plaatsvinden op maandag 22 februari 2016 om 11.00 uur door Johanne Penafiel geboren op 16 september 1985 te San Isidro, Lima, Peru Promotor Prof. -

University of Groningen Alkaline Earth Organometallic Compounds In

University of Groningen Alkaline earth organometallic compounds in homogeneous catalysis Penafiel, Johanne IMPORTANT NOTE: You are advised to consult the publisher's version (publisher's PDF) if you wish to cite from it. Please check the document version below. Document Version Publisher's PDF, also known as Version of record Publication date: 2016 Link to publication in University of Groningen/UMCG research database Citation for published version (APA): Penafiel, J. (2016). Alkaline earth organometallic compounds in homogeneous catalysis: Synthesis, characterization and catalytic activity of calcium and magnesium complexes. Rijksuniversiteit Groningen. Copyright Other than for strictly personal use, it is not permitted to download or to forward/distribute the text or part of it without the consent of the author(s) and/or copyright holder(s), unless the work is under an open content license (like Creative Commons). The publication may also be distributed here under the terms of Article 25fa of the Dutch Copyright Act, indicated by the “Taverne” license. More information can be found on the University of Groningen website: https://www.rug.nl/library/open-access/self-archiving-pure/taverne- amendment. Take-down policy If you believe that this document breaches copyright please contact us providing details, and we will remove access to the work immediately and investigate your claim. Downloaded from the University of Groningen/UMCG research database (Pure): http://www.rug.nl/research/portal. For technical reasons the number of authors shown on this cover page is limited to 10 maximum. Download date: 10-10-2021 Alkaline earth organometallic compounds in homogeneous catalysis Synthesis, characterization and catalytic activity of calcium and magnesium complexes Proefschrift ter verkrijging van de graad van doctor aan de Rijksuniversiteit Groningen op gezag van de rector magnificus prof. -

Superbases for Organic Synthesis : Guanidines, Amidines and Phosphazenes and Related Organocatalysts / Tsutomu Ishikawa

Superbases for Organic Synthesis Superbases for Organic Synthesis: Guanidines, Amidines, Phosphazenes and Related Organocatalysts Edited by Tsutomu Ishikawa © 2009 John Wiley & Sons, Ltd. ISBN: 978-0-470-51800-7 Superbases for Organic Synthesis: Guanidines, Amidines, Phosphazenes and Related Organocatalysts Editor PROFESSOR TSUTOMU ISHIKAWA Graduate School of Pharmaceutical Sciences, Chiba University, Japan This edition first published 2009 Ó 2009 John Wiley & Sons, Ltd Registered office John Wiley & Sons Ltd, The Atrium, Southern Gate, Chichester, West Sussex, PO19 8SQ, United Kingdom For details of our global editorial offices, for customer services and for information about how to apply for permission to reuse the copyright material in this book please see our website at www.wiley.com. The right of the author to be identified as the author of this work has been asserted in accordance with the Copyright, Designs and Patents Act 1988. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, except as permitted by the UK Copyright, Designs and Patents Act 1988, without the prior permission of the publisher. Wiley also publishes its books in a variety of electronic formats. Some content that appears in print may not be available in electronic books. Designations used by companies to distinguish their products are often claimed as trademarks. All brand names and product names used in this book are trade names, service marks, trademarks or registered trademarks of their respective owners. The publisher is not associated with any product or vendor mentioned in this book.