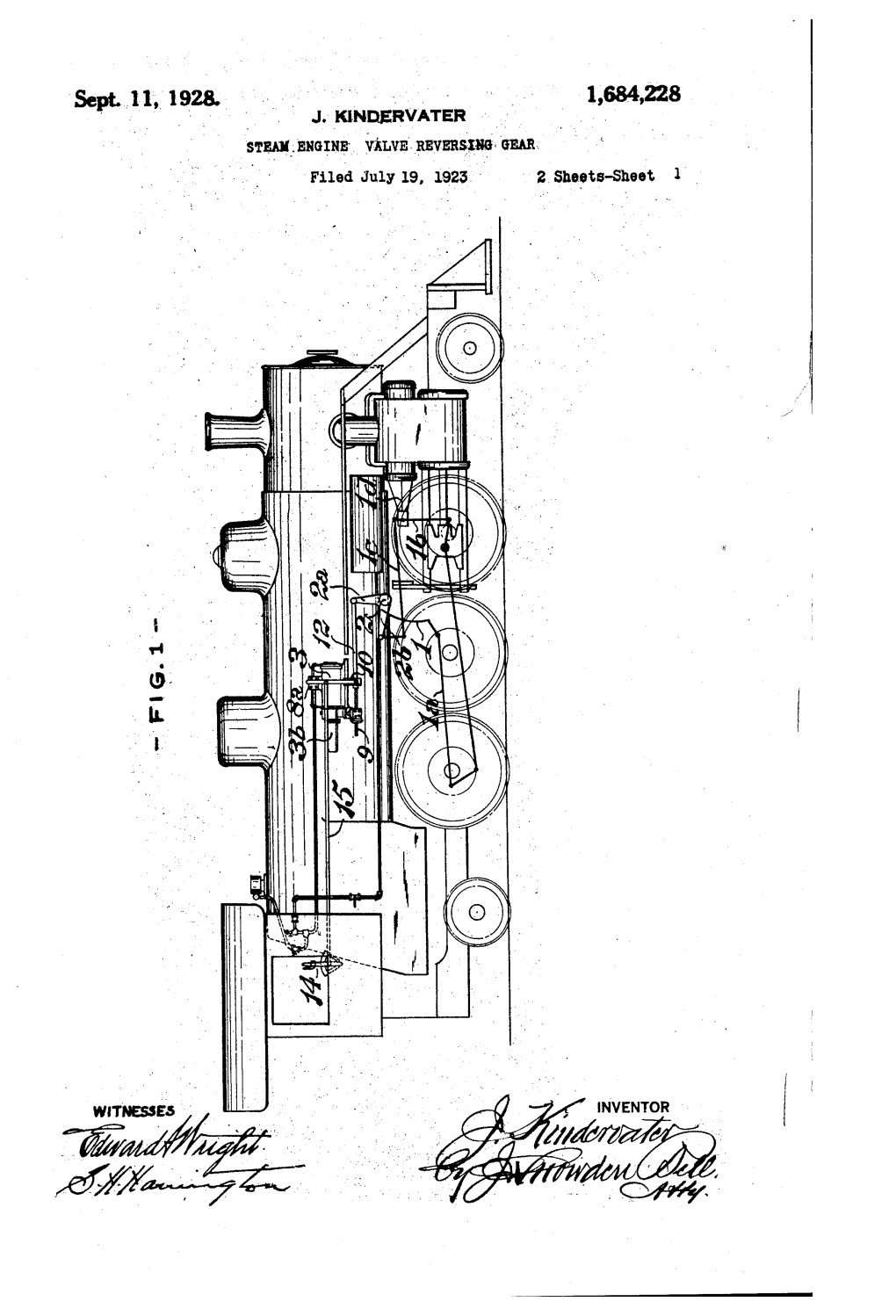

Steam. ENGINE VÁLVE REVERSENG, GEAR. 1,684,228

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Lima 2-8-0 “Consolidation”, Developed for TS2013, by Smokebox

Union Pacific 4000 Class 4884-1 "Big Boy" circa 1948-49 Developed by Smokebox TM for Dovetail Games' Train Simulator © Smokebox 2021, all rights reserved Issue 1 Union Pacific 4000 Class 4884-1 "Big Boy" Steam Locomotive Page 2 Contents Introduction ....................................................................................................................................................... 7 32- and 64-bit TS ................................................................................................................................................ 7 Expert or Simple Controls mode, HUD and Automatic Fireman ....................................................................... 7 "All-in-one" .................................................................................................................................................... 7 Standard TS Automatic Fireman .................................................................................................................... 8 F4 HUD ........................................................................................................................................................... 8 High Detail (HD) and Standard Detail (SD) ........................................................................................................ 8 Recommended Settings ..................................................................................................................................... 9 Cab Layout ...................................................................................................................................................... -

Cyclically Operating Valves for Machines Or Engines

CPC - F01L - 2021.01 F01L CYCLICALLY OPERATING VALVES FOR MACHINES OR ENGINES Definition statement This place covers: • Valve-gear or valve arrangements, e.g. lift-valve gear; • Lift-valve, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces; • Slide valve-gear or valve-arrangements; • Valve-gear or valve arrangements actuated non-mechanically; • Valve arrangements in working piston or piston-rod; • Modifications of valve-gear to facilitate reversing, braking, starting, changing compression ratio, or other specific operations; • Valve-gear or valve arrangements, e.g. with reciprocatory slide valves, other than provided for in groups; • Slide valve-gear or valve arrangements with cylindrical, sleeve, or part annularly-shaped valves surrounding working cylinder or piston; • Slide valve-gear or valve arrangements with reciprocatory and other movement of same valve, e.g. longitudinally of working cylinder and in cross direction • Use of working pistons or pistons-rods as fluid-distributing valves or a valve-supporting elements, e.g. in free-piston machines • Valves controlled by impact by piston, e.g. in free-piston machines; Drive, or adjustment during the operation, or distribution or expansion valves by non-mechanical means; • Distribution or expansion valve-gear peculiar to free-piston machines or engines; • Reversing gear Valve drive, valve adjustment during operation; • Rotary or oscillatory slide valve-gear or valve arrangements, specially adapted -

Engine Reversing When Running at Manoeuvring Speeds

09 REVERSING Part I - General Diesel engines intended for the propulsion of ship fitted with neither a controllable pitch propeller nor a reversing gearbox are made in direct reversing form. Astern running involves carrying out the events of the cycle in the reverse order, i.e. altering the timing of valves and fuel pumps to cause them to start the engine in the opposite direction and then continue its operating cycle in this direction. Fill in the missing word Part I - General Diesel engines intended for the propulsion of ship fitted with neither a ________________ nor a reversing gearbox are made in ________________ form. ________________ involves carrying out the events of the cycle in the reverse order, i.e. altering the _____________ and fuel pumps to cause them to start the engine in the opposite direction and then continue its ________________ in this direction. Using the diagram below describe the timing of a two-stroke diesel engine The propeller thrust must be reversible in order to do manoeuvring of a ship. Usually manoeuvring is done while entering a port or leaving a port. In case of a controllable pitch propeller an unidirectional engine is sufficient. In case of limited power systems like medium speed engines of high speed engines, clutches and reverse gears may be used. But in large diesel engines, the main engines must be reversible and should be able to produce thrust efficiently in both the directions ( ahead and astern ) To reverse an engine the engine cycle may require re-timing. Large diesel engines have scavenge ports which controls the scavenge timing. -

Full Page Photo

THE LIFE AND TIMES OF A DUKE Martyn J. McGinty AuthorHouse™ UK Ltd. 500 Avebury Boulevard Central Milton Keynes, MK9 2BE www.authorhouse.co.uk Phone: 08001974150 © 2011. Martyn J. McGinty. All rights reserved No part of this book may be reproduced, stored in a retrieval system, or transmitted by any means without the written permission of the author. First published by AuthorHouse 04/25/2011 ISBN: 978-1-4567-7794-4 (sc) ISBN: 978-1-4567-7795-1 (hc) ISBN: 978-1-4567-7796-8 (e) Front Cover Photo: Th e Duke at Didcot (Courtesy P. Treloar) Any people depicted in stock imagery provided by Th inkstock are models, and such images are being used for illustrative purposes only. Certain stock imagery © Th inkstock. Th is book is printed on acid-free paper. Because of the dynamic nature of the Internet, any web addresses or links contained in this book may have changed since publication and may no longer be valid. Th e views expressed in this work are solely those of the author and do not necessarily refl ect the views of the publisher, and the publisher hereby disclaims any responsibility for them. Born out of Tragedy and Riddles, his lineage traceable, unerasable, back through the great houses of Chapelon, Giffard, Stephenson, Belpaire and Watt, the Duke was laid to rust by the sea, a few meagre miles from the mills that shaped the steel that formed the frames that bore the machine that Crewe built. Time passed and the Duke was made well again by kindly strangers. -

3600 Marine Engine Application and Installation Guide

® 3600 Marine Engine Application and Installation Guide ● Ancillary Equipment LEKM8470 8-98 ® Ancillary Equipment Marine Gears Couplings Torsional Limits Propellers Fixed Pitch Controllable Pitch Marine Gears between the shafting, gearbox, and main engines. Collision chocks are normally Reversing marine gears are used: fitted at the corners of the gearbox mounting flange to maintain alignment • To match relatively small, economical in the event of an accident. medium speed engines to the low propeller rpm necessary for high Care should be taken in selecting the efficiency. capacity of the low speed output bearing. • To reverse the propeller rotation for It must be capable of carrying loads the non-reversing 3600 Family of imposed by the line shaft or tail shaft Engines. directly connected to the low speed coupling. Advise the gear manufacturer Marine gears are selected to transmit if a propeller blade actuating box is to be rated engine horsepower (plus overload mounted on the gearbox, or if auxiliary if required) at rated rpm. Design the equipment is to be driven from power gear to meet appropriate classification takeoffs on the gear housing. society rules. Inspection and Certification may be required. Advise Carefully review the final arrangement the gear manufacturer of expected of the gearbox in the engine room for the adverse conditions, such as operation in best overall installation. Space must be ice. available for service and maintenance. The following are examples of typical Main engine marine gears are normally arrangements used with the 3600 single or double reduction, with the ratio Family of Engines: of input and output speeds selected to meet the propeller design rpm. -

Owner's Manual

MODEL 49104 owner’s manual INTRODUCTION 3 BEFORE YOU Thank you for purchasing a Traxxas T-Maxx Nitro Monster Truck. PROCEED Traxxas engineers have loaded your T-Maxx with innovative features Traxxas Support and incredible “drive-over-anything” performance that you won’t find Traxxas support is with you every step of the 4 SAFETY way. Refer to the next page to find out how to PRECAUTIONS anywhere else! contact us and what your support options are. Your T-Maxx combines automatic, two-speed shifting in forward 5 TOOLS, SUPPLIES, and reverse, with powerful four-wheel disc braking. The patented AND REQUIRED Quick Start transmission design and TQ 2.4GHz system put these functions right at EQUIPMENT This manual is designed with a Quick your fingertips. Start path that outlines the necessary 6 ANATOMY OF The TRX 2.5 engine is one of the most powerful engines of its size procedures to get your model up THE T-MAXX ever available in a Ready-To-Race® truck. Two years of engineering and running in the shortest time possible. If you are an development and advanced design, along with thousands of hours of experienced R/C enthusiast, you will find it helpful and fast. 7 QUICK START: testing, puts the TRX 2.5 in a class by itself. Each part of the TRX 2.5, Be sure and read through the rest of the manual to learn GETTING UP TO from the air filter on the slide carburetor, to the tip on the dyno-tuned about important safety, maintenance, and adjustment SPEED exhaust system, has been carefully engineered to provide maximum procedures. -

US1811020.Pdf

June 23, 1931. B. V. NORDBERG 1,811,020 BEVERSIBLE ROLLING MILL ENGINE Filed May 21, 192s 8 Sheetg-Sheet l «m8S.,A \\\\ MEME.,„rk/ ivv l Glicine June 23, 1931. B. v. NORDBERG 1,811,020 REVERSIBLE ROLLING MILL ENGINE . Filed May 21, 1925 8 sheetsàsheet 2 QN NN WK O O 5amwxhä Nhä .mw NS , ä« MR .LähÈQ \o0onww ‘NNWN ww.,KK ‘sC mw@A L?@y `|I! QN wäí;_aä @làâ Q» â.. , mw1_Í atroz “WJ `lune 23, 1931. B..v; NORDBERG 1,811,020 REVERSIBLE ROLLING MILL ENGINE Filed May 21, 1925 8 Sheets-Sheet 5 Elibtoz/s m30, A June 23, 1931. B. v. NoRDBl-:RG 1,811,020 REVERSIBLE ROLLING MILL ENGINE Filed May 2-1, 1925 8 Sheets-Sheet 4 / fm. MÍ, r¿L ß„M ma@ ë@Wwavy„_ y ¿5% June 23, 1931. B. v. NORDBERG _ _1,811,020 REVERSIBLE ROLLING MILL ENGINE Filed May 21. 1925 ` 8 sheets-'sheet 5 « òA. Júne 23, 1931. B, v_ NORDBERG 1,811,020 REVERSIBLE ROLLING MILL ENGINE Filed May 2l, 1925 8 Sheets-Sheet 6 . OPERATING LEVER ~ NEUTRAL. ’/ l \ OPERATING I_EvERf» . \\ MAXIMUM ovER. 86”/ OPERATING LEVER 82, i , MAXIMUM IINIIER` "A yg /ag /. «LQUADRANTNEUTRAL. ¿_Q QIIADRANT :v MAX. UNDER June 23, 1931. B. v. NORDBERG 1,811,020 REVERSIBLE ROLLING MILL ENGINE Filed May 21, 1925 8’Sheets-Sheet- 7 30 l \ W. June 23, 1931. By. NORDBERG 1,811,020 REVERSIBLE ROLLING MILL ENGINE Filed May‘zl, 1925 BÀsheets-sneet _e 11 v (n / ` ` la@ l l. \\\\\\\\\\\\\\\\\\\\\ \\ . , Q ÄÑ o lill/11M 13TH/2.0 U /Vordßergjßececzsed- ' _ Helena Gl/ordbçzëßß'xeczzìrbg ' duck „gp Patented June 23, 193i A 1,811,020 UNITED STATES PATENT oFFlca BRUNO V. -

Derby Locomotive Drawings List.Xlsx

Derby Locomotive Drawing Lists Description: The collection consists of approximately 6000 drawings, plus 135 registers and lists. They cover the period from 1874 to 1961. The drawings relate to the construction, modification and rebuilding of locomotives of the Midland Railway, London Midland & Scottish Railway and British Railways, with occasional drawings from other railway companies and contractors. The drawings are mainly on linen with some blueprints, as well as Ozalid and paper copies. Each drawing has a number and/ or a letter code. These letter and number codes also relate to the registers, schedules and lists. The significance of these codes is explained in the ‘System of Arrangement’ section below. System of Arrangement: The drawings are arranged in the archive in five series and are listed as such in the catalogue. 1. Main Series. These are organised by drawing number in numerical sequence. Most drawings have a two number date prefix that usually relates to the year in which the drawing was produced, but may sometimes relate to the year the drawing was entered in the register. 2. D Numerical series. These are also organised by drawing number, but prefixed by the section reference, such as D1, D2, D3, D4 or D5. 3. Diagrams and Sketches. These are also organised by drawing number, but prefixed according to the section reference code, such as DS, DD, S, D or ED. 4. BR Standard Drawings from Derby. These drawings are proper to the main collection of British Rail Standard Drawings, but were found with the main Derby Works sequences. They are numerical with the prefix SL/DE. -

Driving Dynamics of Inland Vessels Vessel Behaviour on European Inland Waterways and Waterway Infrastructure with Special Respect to German Waterways

Book, Published Version Bundesanstalt für Wasserbau; Verein für europäische Binnenschifffahrt und Wasserstraßen e.V. (VBW) (Hg.) Driving Dynamics of Inland Vessels Vessel Behaviour on European Inland Waterways and Waterway Infrastructure with Special Respect to German Waterways Verfügbar unter/Available at: https://hdl.handle.net/20.500.11970/104201 Vorgeschlagene Zitierweise/Suggested citation: Bundesanstalt für Wasserbau; Verein für europäische Binnenschifffahrt und Wasserstraßen e.V. (VBW) (Hg.) (2016): Driving Dynamics of Inland Vessels. Karlsruhe: Bundesanstalt für Wasserbau. Standardnutzungsbedingungen/Terms of Use: Die Dokumente in HENRY stehen unter der Creative Commons Lizenz CC BY 4.0, sofern keine abweichenden Nutzungsbedingungen getroffen wurden. Damit ist sowohl die kommerzielle Nutzung als auch das Teilen, die Weiterbearbeitung und Speicherung erlaubt. Das Verwenden und das Bearbeiten stehen unter der Bedingung der Namensnennung. Im Einzelfall kann eine restriktivere Lizenz gelten; dann gelten abweichend von den obigen Nutzungsbedingungen die in der dort genannten Lizenz gewährten Nutzungsrechte. Documents in HENRY are made available under the Creative Commons License CC BY 4.0, if no other license is applicable. Under CC BY 4.0 commercial use and sharing, remixing, transforming, and building upon the material of the work is permitted. In some cases a different, more restrictive license may apply; if applicable the terms of the restrictive license will be binding. Driving Dynamics of Inland Vessels Vessel Behaviour on European -

The Development of Locomotive Power at Speed by E

404 The Development of Locomotive Power at Speed By E. L. Diamond, M.Sc. (Eng.), A.M.I.Mech.E.* The power developed per unit of cylinder volume of locomotives in the speed range from 250 to 400 r.p.m. has in recent years been doubled. Forty years ago it was often the case that the diminution of the mean effective pressure with increase of speed, rather than the evaporative capacity of the boiler, limited the power of the engine. The most advanced designs maintain the mean pressure at a high percentage of the calculated value to the highest speeds, and the effect of valve events and clearance volume on the calculated mean pressure thus becomes of practical importance, especially as designers are endeavouring to use considerably higher steam pressures in single-expansion cylinders. The first part of this paper sets out the effect of these factors over a wide range of steam pressures in the form of basic data graphs of mean pressure, relative efficiency, and steam consumption. It is shown that without the decrease of clearance volume and increase of expansion ratio which com- pound expansion affords, the improved thermal efficiency which higher steam pressure offers cannot be fully realized above about 250 lb. per sq. in. boiler pressure, though greater power can be obtained. The second part of the paper is devoted to an examination of the actual deviation of mean pressure with speed for a wide range of locomotives, including some of the most recent designs, and the reasons for the radical improvement are indicated. -

Power Trim and Tilt Systems

Chapter Eighteen Power Trim and Tilt Systems The MerCruiser power trim system permits Electrical Sub-system raising or lowering the stern drive unit for efficient operation under varying conditions. Early stern Single or dual solenoids may be used according drive units used a mechanical tilt system in the to system application. form of a series of holes in the gimbal ring. After Single Solenoid System the unit was set at the desired angle, an adjustment A 3-button power trim panel control operates the stud inserted through the appropriate hole held it single solenoid system shown in Figure 1. Battery in place. current reaches the solenoid through the red lead, a This chapter covers three MerCruiser power trim go-amp fuse, a 40-amp circuit breaker and the and tilt systems: the high-pressure pump system, red/purple lead. Depressing the IN button routes low-pressure pump system and auto trim system. current from the red/purple lead to the green/white wire, operating the pump in the down direction. Depressing the UP/OUT button sends current from the red/purple extension lead through the HIGH-PRESSURE PUMP SYSTEM purple/white lead to the trim limit switch. Current This MerCruiser power trim and tilt system is reaching the switch passes through the blue/white electro-hydraulically operated. Its electrical lead to the solenoid, where it travels to the trim sub-system consists of a power trim control panel motor through a larger blue/white lead. The trim or handle, a pump motor and a trim limit switch, motor can provide about 17” of trim before the with connecting wiring. -

Shay Live Steam

ACCUCRAFT TRAINS Large Scale Electric and Live Steam Models 2 Cylinder Shay Live Steam OWNER'S MANUAL Thank you for purchasing Accucraft Trains Live-steam Shay Like other fine models from Accucraft Trains, Live-steam Shay has been designed to provide a lifetime of model railroading pleasure. Live-steam Shay is handcrafted in brass and is a precision piece of equipment. Like all fine equipment it must be properly maintained and cared for. @ 2002 Accucraft Trains All Rights Reserved. ACCUCRAFT TRAINS 33268 Central Avenue Union City, CA 94587 USA TEL:510-324-3399 FAX:510-324-3366 www.accucraft.com Introduction Shay locomotives were developed by Ephraim Shay. His first successful engine that we would recognize today as a Shay locomotive was produced in 1880 by Lima Machine Works (later Lima Locomotive Works), who would go on to produce approximately 2,700 Shays up until 1945, when production ceased. Shay locomotives are unusual in that they are powered by a steam engine of either two or three cylinders mounted vertically near the cab on the right side of the locomotive (although there were a very few with the engine on the left). The boiler was offset on the frame to counterbalance the weight of the engine. The engine drove a drive shaft that, through flexible couplings, turned bevel gears that engaged the wheels. This type of engine is known as a geared engine, since the wheels turn at a different rate from the engine, due to the gear ratio. This arrangement made the engine very flexible and able to negotiate raggedy track without derailing.