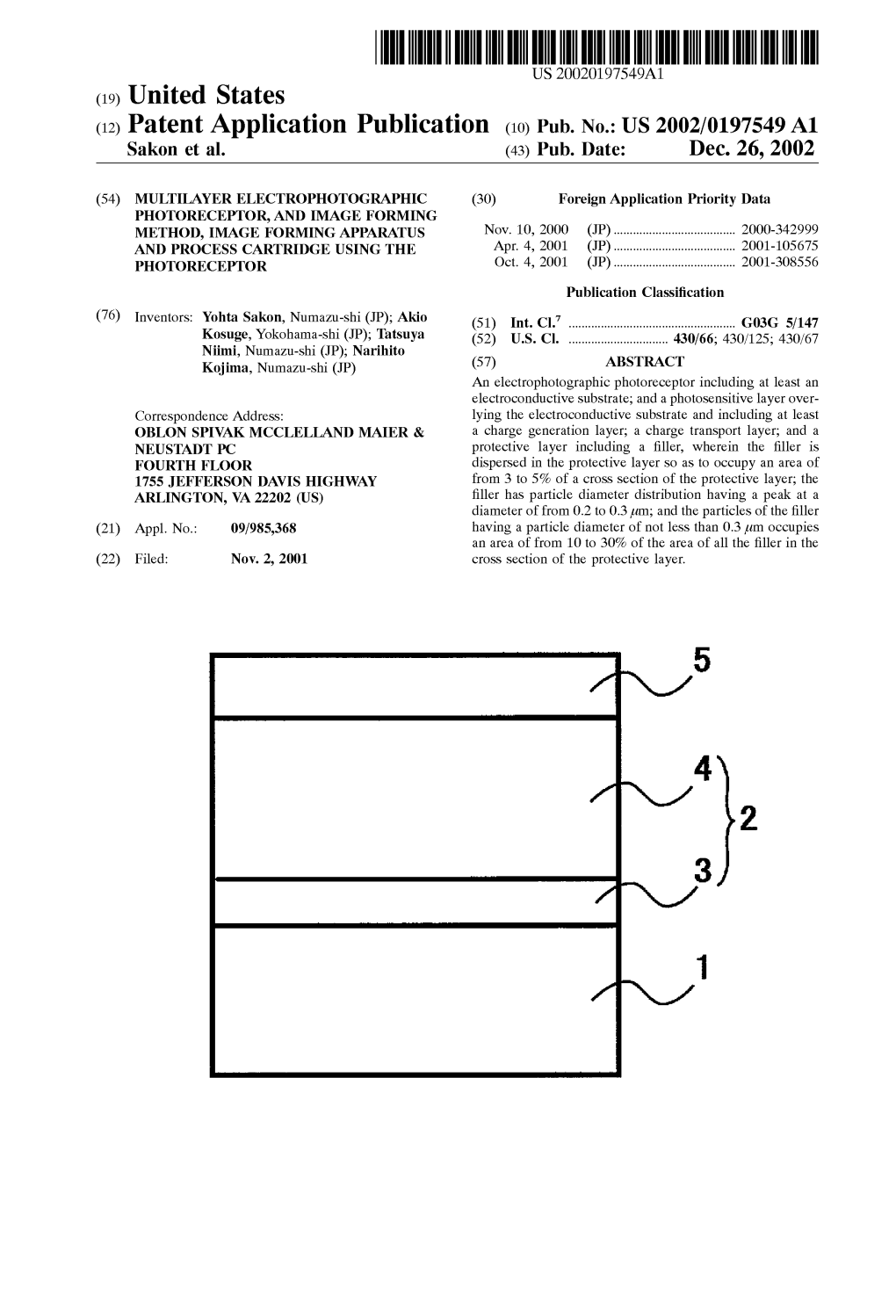

(12) Patent Application Publication (10) Pub. No.: US 2002/0197549 A1 Sakon Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Business Guidance on Phthalates

Business guidance on phthalates How to limit phthalates of concern in articles? November 2013 Danish branch of EPBA, Brussels This guidance has been prepared on the initiative of the Danish EPA and organisations, DI (the Confederation of Danish Industry), the Danish Chamber of Commerce, DI ITEK (the Danish ICT and electronics federation for it, telecommunications, electronics and communication enterprises), BFE (the Danish Consumer Electronics Association), Batteriforeningen (the Danish branch of the European battery association EPBA), ITB (the Danish IT Industry Association) and FEHA (the Danish Association for Suppliers of Electrical Domestic Appliances) in a collaboration between the Danish EPA and representatives from the organisations. The guidance applies to companies marketing articles to either private or industrial users in Denmark. The target group is buyers in Danish companies that import or act as commercial agents, intermediaries or retailers, as well as foreign companies that export to Denmark. 2 Content How to limit phthalates of concern in articles? ................................................................... 4 Key to identification of articles with phthalates .................................................................. 8 Facts on phthalates ............................................................................................................................. 10 What should you ask your supplier? .......................................................................................... 11 What are the -

Hazardous Substances in Plastic Materials

TA Hazardous substances in plastic 3017 materials 2013 Prepared by COWI in cooperation with Danish Technological Institute Preface This report is developed within the project of mapping of prioritized hazardous substances in plastic materials. The report presents key information on the most used plastic types and their characteristics and uses, as well as on hazardous substances used in plastics and present on the Norwegian Priority List of hazardous substances (“Prioritetslisten”) and/or the Candidate List under REACH, by August 2012. The aim of the report is to be a brief handbook on plastic types and hazardous substances in plastics providing knowledge on the characteristics and use of different plastic materials and the function, uses, concentration, release patterns, and alternatives of the hazardous substances, allowing the user to use the report as an introduction and overview on the most important hazardous substances in plastics and the plastic types, they primarily are used in. The development of the report has been supervised by a steering committee consisting of: Inger-Grethe England, Klima- og Forurensningsdirektoratet (chairman) Pia Linda Sørensen, Klima- og Forurensningsdirektoratet Erik Hansen, COWI, Denmark Nils H. Nilsson, Danish Technological Institute The report has been prepared by Erik Hansen, COWI-Denmark, Nils H. Nilsson, Danish Technological Institute, Delilah Lithner, COWI-Sweden and Carsten Lassen COWI- Denmark. Vejle, Denmark, 15. January 2013 Erik Hansen, COWI (project manager) 1 Content English Summary and -

Toxicity Review of Diisobutyl Phthalate (DIBP)

identification, that is, a review of the available toxicity data for the chemical under consideration and a determination of whether the chemical is considered “toxic”. Chronic toxicity data (including carcinogenicity, neurotoxicity, and reproductive and developmental toxicity) are assessed by the CPSC staff using guidelines issued by the Commission (CPSC, 1992). If it is concluded that a substance is “toxic” due to chronic toxicity, then a quantitative assessment of exposure and risk is performed to evaluate whether the chemical may be considered a “hazardous substance”. This memo represents the first step in the risk assessment process; that is, the hazard identification step. * This report was prepared for the Commission pursuant to contract CPSC-D-06-0006. It has not been reviewed or approved by, and may not necessarily reflect the views of, the Commission. Page 2 of 2 FINAL TOXICITY REVIEW FOR DIISOBUTYL PHTHALATE (DiBP, CASRN 84-69-5) Contract No. CPSC-D-06-0006 Task Order 012 Prepared by: Versar Inc. 6850 Versar Center Springfield, VA 22151 SRC, Inc. 7502 Round Pond Road North Syracuse, NY 13212 Prepared for: Kent R. Carlson, Ph.D. U.S. Consumer Product Safety Commission 4330 East West Highway Bethesda, MD 20814 July 14, 2011 * This report was prepared for the Commission pursuant to contract CPSC-D-06-0006. It has not been reviewed or approved by, and may not necessarily reflect the views of, the Commission. TABLE OF CONTENTS TOXICITY REVIEW FOR DIISOBUTYL PHTHALATE APPENDICES .............................................................................................................................. -

CAS 84-69-5 Diisobutyl Phthalate (DIBP)

CAS 84-69-5 Diisobutyl phthalate (DIBP) Toxicity The European Union classified DIBP as a reproductive Substance of Very High Concern (SVHC).1 A 2011 study observed decreased testicular testosterone in male rats fed DIBP for 4 days.2 Borch et al. 2006 found male offspring of female rats exposed to DIBP from gestation day 7 to gestation day 20 or 21 had significantly reduced anogenital distance.3 The Chronic Hazard Advisory Panel (CHAP) determined, due to toxicological profile similarities to Dibutyl phthalate (DBP), exposure to DIBP contributes to a cumulative antiandrogenic effect with other phthalates and should be permanently banned in children’s toys and child care articles at levels greater than 0.1 percent.4 In 2017 the CPSC permanently banned DIBP in children’s toys and childcare articles at levels greater than 0.1 percent.5 Exposure The 2015 National Health and Nutrition Examination Survey (NHANES) monitored a metabolite of DIBP in human urine, and the levels appear to be increasing.6 Metabolites of DIBP were detected in the urine of pregnant Danish women in a 2010-2012 study.7 A significant correlation was found between DIBP metabolite concentrations in the urine of Danish children and increased levels of DIBP in bedroom dust and day care centers.8 Other DIBP is used as a substitute ingredient to di-n-butyl phthalate (DBP) due to structural similarities, therefore, its’ presence in products may increase.3 References 1. European Commission, Endocrine disruptor priority list. Retrieved from: http://ec.europa.eu/environment/chemicals/endocrine/strategy/substances_en.htm 2. Hannas, B.R., Lambright, C.S., Furr, J., Howdeshell, K.L., Wilson, V.S., Gray, L.E., Jr. -

Chemical Resistance of Plastics

(c) Bürkle GmbH 2010 Important Important information The tables “Chemical resistance of plastics”, “Plastics and their properties” and “Viscosity of liquids" as well as the information about chemical resistance given in the particular product descriptions have been drawn up based on information provided by various raw material manufacturers. These values are based solely on laboratory tests with raw materials. Plastic components produced from these raw materials are frequently subject to influences that cannot be recognized in laboratory tests (temperature, pressure, material stress, effects of chemicals, construction features, etc.). For this reason the values given are only to be regarded as being guidelines. In critical cases it is essential that a test is carried out first. No legal claims can be derived from this information; nor do we accept any liability for it. A knowledge of the chemical and mechanical Copyright This table has been published and updated by Bürkle GmbH, D-79415 Bad Bellingen as a work of reference. This Copyright clause must not be removed. The table may be freely passed on and copied, provided that Extensions, additions and translations If your own experiences with materials and media could be used to extend this table then we would be pleased to receive any additional information. Please send an E-Mail to [email protected]. We would also like to receive translations into other languages. Please visit our website at http://www.buerkle.de from time to Thanks Our special thanks to Franz Kass ([email protected]), who has completed and extended these lists with great enthusiasm and his excellent specialist knowledge. -

Polymer Compositions

Europaisches Patentamt European Patent Office © Publication number: 0 434 067 A2 Office europeen des brevets © EUROPEAN PATENT APPLICATION © Application number: 90124972.272.2 © int. ci.s: C08K 5/13, C08L 37/00 © Date of filing: 20.12.90 © Priority: 21.12.89 JP 334449/89 © Applicant: KURARAY Co. LTD. 1621 Sakazu Kurashiki-shi @ Date of publication of application: Okayama 710(JP) 26.06.91 Bulletin 91/26 © Inventor: Matsumoto, Mitsuo © Designated Contracting States: 1505-9, Mitzue, Kurashiki-shi DE FR GB IT NL Okayama 710(JP) Inventor: Sanda, Fumio Sun-mall Tsukumi 101, 4-21-17, Chuorinkan, Yamato-shi Kanagawa 242(JP) © Representative: Vossius & Partner Siebertstrasse 4 P.O. Box 86 07 67 W-8000 Munchen 86(DE) © Polymer compositions. © Polymer compositions comprising a polymer (A) having a repeating structure unit of the formula (I) in the main chain r R5 R8 \ (I) CM < CO o wherein Ft1, R2, R3, R+, R5 and Rs are respectively a hydrogen atom or a lower alkyl, and at least one species selected from the group consisting of a phenol compound and a plasticizer. The polymer compositions of the contained therein in CO present invention disintegrate themselves due to decomposition of the polymer (A) ft atmosphere, soil or water and thus, they are useful as materials for disposable moldings. 111 Xerox Copy Centre EP 0 434 067 A2 POLYMER COMPOSITIONS The present invention relates to polymer compositions comprising a polymer having a tetrahydrofuran skeleton, and at least one species selected from the group of a plasticizer and a phenol compound of a specific structure. -

Image Forming Apparatus and Process Cartridge Therefor

Europäisches Patentamt *EP001271259A1* (19) European Patent Office Office européen des brevets (11) EP 1 271 259 A1 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: (51) Int Cl.7: G03G 15/01, G03G 21/18 02.01.2003 Bulletin 2003/01 (21) Application number: 02014163.6 (22) Date of filing: 25.06.2002 (84) Designated Contracting States: • Takahashi, Mitsuru, c/o Ricoh Co., Ltd. AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU Tokyo 143-8555 (JP) MC NL PT SE TR • Katoh, Kohki, c/o Ricoh Co., Ltd. Designated Extension States: Tokyo 143-8555 (JP) AL LT LV MK RO SI • Kawagoe, Katsuya, c/o Ricoh Co., Ltd. Tokyo 143-8555 (JP) (30) Priority: 26.06.2001 JP 2001192317 • Ogiyama, Hiromi, c/o Ricoh Co., Ltd. Tokyo 143-8555 (JP) (71) Applicant: Ricoh Company, Ltd. • Tamiya, Takahiro, c/o Ricoh Co., Ltd. Tokyo 143-8555 (JP) Tokyo 143-8555 (JP) (72) Inventors: (74) Representative: Barz, Peter, Dr. • Sugino, Akihiro, c/o Ricoh Co., Ltd. Patentanwalt Tokyo 143-8555 (JP) Kaiserplatz 2 • Sawai, Yuuji, c/o Ricoh Co., Ltd. 80803 München (DE) Tokyo 143-8555 (JP) (54) Image forming apparatus and process cartridge therefor (57) An image forming apparatus (100) comprises recording medium. A transport unit (10) transports the a latent image support (40) which supports an electro- recording medium so that the image support surface is static latent image. A charging unit (60) charges a sur- countered to a surface of the recording medium. The face of the image support. A latent image formation unit surface of the image support has a coefficient of friction forms an electrostatic latent image on the image support ranging from 0.1 to 0.7 according to Euler belt method, surface. -

Product Stewardship/Regulatory Summary for GPPS

Product Stewardship/Regulatory Summary for GPPS Americas Styrenics LLC has a fundamental concern for all who make, distribute, and use its products, and for the environment in which we live. This concern is the basis for our Product Stewardship philosophy by which we assess the safety, health, and environmental information on our products and then take appropriate steps to protect employees, public health and our environment. The success of our Product Stewardship program rests with every individual involved with Americas Styrenics LLC products - from the initial concept and research, to manufacture, use, sale, disposal, and recycle of each product. Product Overview Americas Styrenics manufactures General Purpose Polystyrene (GPPS) resins. These resins are available with various physical and mechanical properties and are formulated with additives to affect processability, color, or other characteristics. The resins are available as pellets or granules. Chemical Identity Common Name: General Purpose Polystyrene (GPPS) Also known as vinyl benzene, styrene polymer. CAS No. 9003-53-6 Exposure Potential Industrial Worker exposure Exposure can occur either in a resin manufacturing facility or in the various industrial or manufacturing facilities that use these resins. Each manufacturing facility should have a thorough training program for employees and appropriate work processes and safety equipment in place to limit unnecessary exposure. If there is a potential for exposure to dust particles that could cause eye discomfort, wear chemical goggles. Provide general and/or local exhaust ventilation to control airborne dust levels. No other precautions other than clean, body-covering clothing should be needed. Long sleeves and thermal gloves are necessary in areas where molten polymer is present. -

The Assessment of the Sewage and Sludge Contamination by Phthalate Acid Esters (Paes) in Eastern Europe Countries

sustainability Article The Assessment of the Sewage and Sludge Contamination by Phthalate Acid Esters (PAEs) in Eastern Europe Countries Olga Anne and Tatjana Paulauskiene * Department of Engineering, Faculty of Marine Technology and Natural Sciences, Klaipeda University, Klaipeda 92294, Lithuania; [email protected] * Correspondence: [email protected] Abstract: Phthalate acid esters (PAEs) are widely used as raw materials for industries that are well known for their environmental contamination and toxicological effects as “endocrine disruptors”. The determining of PAE contamination was based on analysis of dimethyl phthalate (DMP), diethyl phthalate (DEP), dipropyl phthalate (DPP), dibutyl phthalate (DBP), diisobutyl phthalate (DiBP), dicyclohexyl phthalate (DCHP) and di(2-ethylhexyl) phthalate (DEHP) in wastewater and sediment samples collected from city sewer systems of Lithuania and Poland, and Denmark for comparison. The potential PAE sources as well as their concentrations in the wastewater were analyzed and discussed. The intention of the study was to determine the level and key sources of pollution by phthalates in some Eastern European countries and to reveal the successful managerial actions to minimize PAEs taken by Denmark. Water and sludge samples were collected in 2019–2020 and analyzed by gas chromatography-mass spectrometry. The highest contamination with phthalates in Lithuania can be attributed to DEHP: up to 63% of total PAEs in water samples and up to 94% of total PAEs in sludge samples, which are primarily used as additive compounds to plastics but do not react with them and are gradually released into the environment. However, in water samples in Poland, the highest concentration belonged to DMP—up to 210 µg/L, while the share of DEHP reached 15 µg/L. -

Test Report. No

Test Report. No. SHAEC1800177705 Date: 11 Jan 2018. Page 1 of 6. SCHOTT AG, ADVANCED OPTICS . Hattenbergstrasse 10, 55122 Mainz, Germany . The following sample(s) was/were submitted and identified on behalf of the clients as : N-SF11 . SGS Job No. : SP18-000258 - SUZ . Date of Sample Received : . 04 Jan 2018. Testing Period :. 04 Jan 2018 - 09 Jan 2018 . Test Requested :. Selected test(s) as requested by client. Test Method :. Please refer to next page(s). Test Results :. Please refer to next page(s). Conclusion :. Based on the performed tests on submitted sample(s), the results of Cadmium, Lead, Mercury, Hexavalent chromium, Polybrominated biphenyls (PBBs), Polybrominated diphenyl ethers (PBDEs) and Phthalates such as Bis(2-ethylhexyl) phthalate (DEHP), Butyl benzyl phthalate (BBP), Dibutyl phthalate (DBP) and Diisobutyl phthalate (DIBP) comply with the limits as set by RoHS Directive (EU) 2015/863 amending Annex II to Directive 2011/65/EU. Signed for and on behalf of SGS-CSTC Standards Technical Services (Shanghai) Co., Ltd.. Marry Ma. Approved Signatory . Test Report. No. SHAEC1800177705 Date: 11 Jan 2018. Page 2 of 6. Test Results :. Test Part Description : . Specimen No.. SGS Sample ID. Description. SN1. SHA18-001777.005 Transparent glass. Remarks :. (1) 1 mg/kg = 0.0001% . (2) MDL = Method Detection Limit . (3) ND = Not Detected ( < MDL ) . (4) "-" = Not Regulated . RoHS Directive (EU) 2015/863 amending Annex II to Directive 2011/65/EU. Test Method :. With reference to IEC 62321-4:2013+AMD1:2017, IEC62321-5:2013, IEC62321-7-2:2017, IEC 62321-6:2015 and IEC62321-8:2017, analyzed by ICP-OES, AAS, UV-Vis and GC-MS. -

Polyvinyl Chloride in Health Care a Rationale for Choosing Alternatives

Safer Chemicals Polyvinyl chloride in health care A rationale for choosing alternatives Ted Schettler MD, MPH JANUARY 2020 INTRODUCTION Polyvinyl chloride (PVC) is a versatile, high-volume, mercury into the air, 742 kilograms of mercury into water, and synthetic material with many different formulations 23 tons of mercury into landfills. Mercury is a toxic metal that bioaccumulates in the food chain, particularly in fish, and can and configurations. Globally PVC is thefifth most damage the developing brain at fairly low levels of exposure. highly manufactured plastic at 61 million metric Mercury readily crosses the placenta, exposing the developing tons annually. Construction materials account for fetus in pregnant women. An estimated 6.5% of women of approximately 75% of all PVC use. The material reproductive age in the United States have blood mercury levels is commonly used in building materials, including higher than what is considered safe, although levels vary by region and ethnicity. Both the Food and Drug Administration and flooring, pipes, carpet backing, and wall coverings. the European Food Safety Authority recommend avoiding the Office furniture, supplies, and packaging can be consumption of some kinds of fish because of excessive mercury made of PVC. Health care-specific uses include levels. PVC-based IV bags, blood bags, urine bags, tubing, oxygen masks, catheters, and disposable gloves. Asbestos Another technology uses an asbestos diaphragm, which is then disposed of at the end of its useful life. Chlorine manufacturers Polyvinyl chloride is a particularly problematic plastic are the largest importers of asbestos in the United States. The because of the toxicity of chlorine production as well U.S. -

(10) Patent No.: US 8734772 B1

US00873.4772B1 (12) United States Patent (10) Patent No.: US 8,734,772 B1 Zhou et al. (45) Date of Patent: May 27, 2014 (54) PHOTO-CURABLE RESIN FOR COSMETIC 424/401, 486; 514/277, 357, 461, 473; APPLICATION 526/204, 213, 216 See application file for complete search history. (71) Applicant: L'Oreal, Paris (FR) (72) Inventors: XianZhi Zhou, Leonia, NJ (US); (56) References Cited Jean-Thierry Simonnet, Mamaroneck, U.S. PATENT DOCUMENTS NY (US); Hy Si Bui, Piscataway, NJ (US); Chunhua Li, Scotch Plains, NJ 2013/0167859 A1* 7, 2013 Buiet al. ...................... 132/2O2 US (US) OTHER PUBLICATIONS (73) Assignee: L'Oreal,9 Paris (FR) Wehrens et al., “Synthesis of a new photocrosslinkable prepolymer, (*) Notice: Subject to any disclaimer, the term of this based on poly(styrene-co-maleic anhydride). Reactive & Functional patent is extended or adjusted under 35 Polymers, vol. 29, 1996, (pp. 21-27). U.S.C. 154(b) by 0 days. * cited by examiner (21) Appl. No.: 13/729,326 Primary Examiner — Jane C Oswecki (22) Filed: Dec. 28, 2012 (74) Attorney, Agent, or Firm — The Marbury Law Group, PLLC (51) Int. Cl. A6 IK3I/765 (2006.01) (57) ABSTRACT A61 K 8/72 (2006.01) Disclosed herein are cosmetic compositions comprising (a) at A61 K 8/18 (2006.01) least one styrene-maleic anhydride copolymer bearing at A61 K 8/30 (2006.01) least one group chosen from Styrylpyridine and styrylpyri A61 K3 1/341 (2006.01) dinium groups and (b) at least one co-film forming agent A61 K31/435 (2006.01) and/or at least one plasticizer.