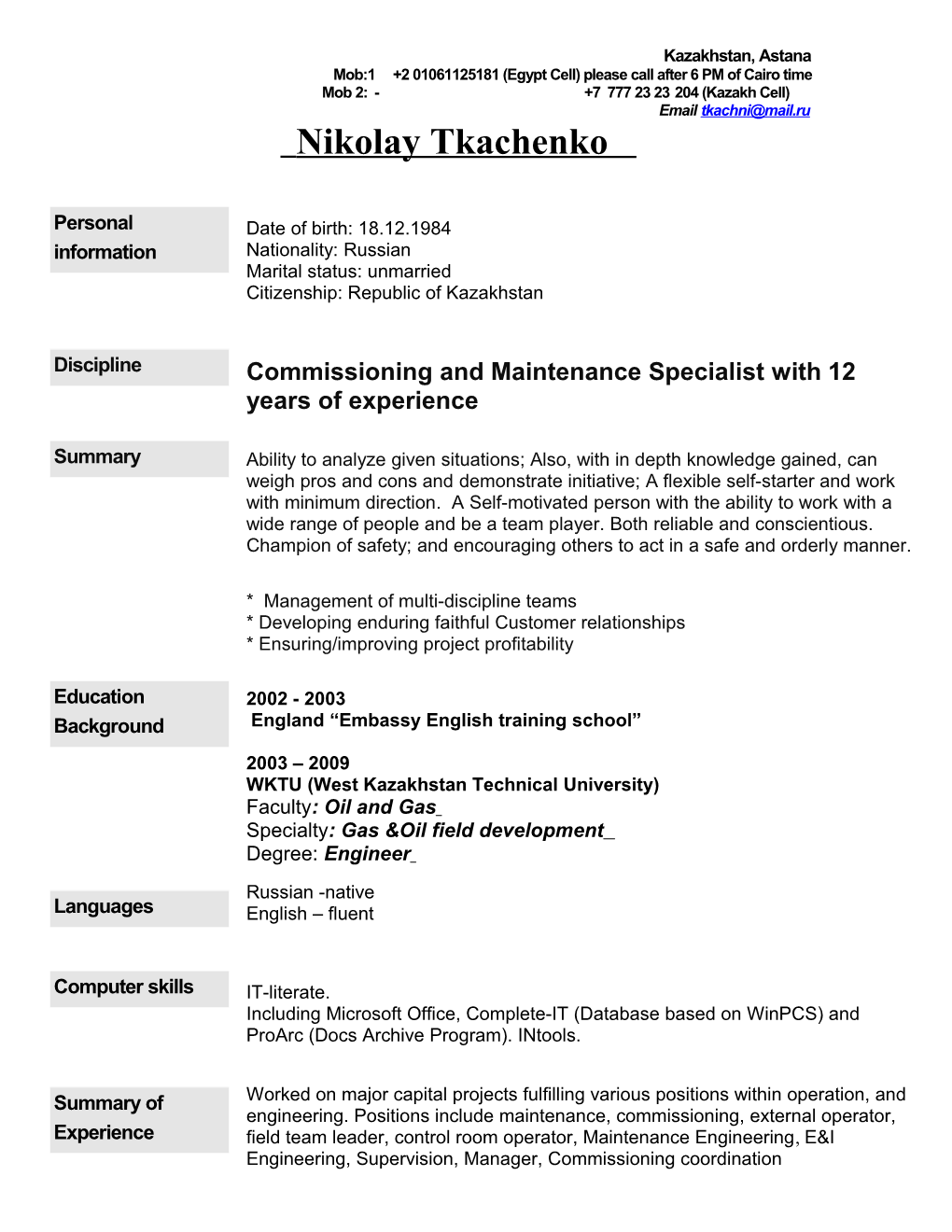

Kazakhstan, Astana Mob:1 +2 01061125181 (Egypt Cell) please call after 6 PM of Cairo time Mob 2: - +7 777 23 23 204 (Kazakh Cell) Email [email protected] Nikolay Tkachenko

Personal Date of birth: 18.12.1984 information Nationality: Russian Marital status: unmarried Citizenship: Republic of Kazakhstan

Discipline Commissioning and Maintenance Specialist with 12 years of experience

Summary Ability to analyze given situations; Also, with in depth knowledge gained, can weigh pros and cons and demonstrate initiative; A flexible self-starter and work with minimum direction. A Self-motivated person with the ability to work with a wide range of people and be a team player. Both reliable and conscientious. Champion of safety; and encouraging others to act in a safe and orderly manner.

* Management of multi-discipline teams * Developing enduring faithful Customer relationships * Ensuring/improving project profitability

Education 2002 - 2003 Background England “Embassy English training school” 2003 – 2009 WKTU (West Kazakhstan Technical University) Faculty: Oil and Gas Specialty: Gas &Oil field development Degree: Engineer

Russian -native Languages English – fluent

Computer skills IT-literate. Including Microsoft Office, Complete-IT (Database based on WinPCS) and ProArc (Docs Archive Program). INtools.

Summary of Worked on major capital projects fulfilling various positions within operation, and engineering. Positions include maintenance, commissioning, external operator, Experience field team leader, control room operator, Maintenance Engineering, E&I Engineering, Supervision, Manager, Commissioning coordination Familiar with the following control systems: Honeywell total plant solution, ICS trusted Safety system, Wormald Wellhead panels, Hima PLCs, Allen Bradley PLCs, Siemens, Bentley Nevada vibration monitoring systems and GE-Nuovo Pignone Mk V compressor control system. Familiar with most field instrumentation, such as flow, pressure, level and temperature transmitters including ultrasonic and radar 4-20 mA, and Profibus PA , Familiar with hazardous areas and explosion proof and intrinsically safe designs. Familiar with all project design deliverables and test procedures. Aware of site safety regulations and obtaining daily work permits.

From March 2014 - till present time DANIELI company Work experience Project : Egypt, EZZ Steel Direct Reduction Plant (DRI)

Project Commissioning Coordinator Position I was responsible for :

Track Changes and Queries against Systems, Areas, Work-packs and documents. Mechanical Completion of all systems Systems identification Preparation of Cold test certificates and submission to client Mechanical Completion data base tracking and updating Provide Overall status of Systems and Areas, including Outstanding Work and Punch lists. Report status of handover from Construction to Pre-/Commissioning and from Commissioning to Operations. Reporting of a "ready status" for loop/circuits testing and interlock matrix Priority settings to identify critical items or systems. Interface handling, between contractors, system and areas. Overview Installation, Commissioning and Maintenance Procedures. Submitting to client documentation via DDMS software Site surveys and meeting with client Punch List management and reporting

Work with following equipment - Natural Gas Reformer commissioning and startup - Process Gas Heater commissioning and startup - Compressors for cooling gas and process gas commissioning and startup - Reactor commissioning and startup - Quenching system - Conveyors - CO2 removal system commissioning and startup - Etc. From November 2013 – March 2014 DANIELI company Project : Abu Dhabi Emirates Steel Direct Reduction Plant (DRI) phase 2

Process Supervisor (Shut down activity and capacity enhancement ) Position Closing of Defect Reports and Nonconformity queries Supervise activity of - Reformer and Hydro -Desulphurizer units catalyst replacement Reactor painting and blasting Cold test of new Cooling gas and Pneumatic transport compressors Process Gas Separator chevron replacement Reformer burners change out JMS preparation Assistance to the client mechanical team for cold start up of the DRP plant Performance of Process Guaranty Test after plant revamping

Sep 2011 – till 2013 October DANIELI company .

Project- Sangan Iron Mine Project IRAN - Concentrator Plant

Commissioning & Startup Supervisor (Concentrator Plant) Position Commissioning and Start Up of following systems:

-2.6 Million Ton/Y iron ore beneficiation plant operation. -Natural iron ore crushing by Gyratory crusher and 1st 2nd 3rd grinding systems. -AG mill and Ball mill - 6750 kW (CEMTEC),Tower mill-1120kW X5 (EIRICH) etc operation to get optimum size of material. -Cluster Cyclones operation to separate the optimum size of fine material. -Cobber, Rougher, Scavenger, Finisher LIMS operation to separate Fe3O4. -Plaugh feeder and Reclaim conveyor operation. -Crusher, screener, de-duster, vi-bro feeder, diverter chut, conveyor belts operation. -2.1 Million Ton/Y tailing separation from Iron concentrate. -Rougher, conditioner,cleaner and scavager flotation cells using to separate sulfur. -Proper chemical such as SIPX, NaSH, MIBC, Na2Co3 dossing in flotation cells. -Thickener and under flow pumps operation.. -High capacity slurry pumps operation for product transport and de-watering. -Flow, pressure, density, level, PH, vibration etc. -Flocculant, coagulant, PAA etc adjustment for recovery water from tailings. -Pinion, bearing and hydraulic oil pump operation for big machines. -Ore transfer by different conveyor belts, plough feeder operation. -Crusher (Gyratory Pebble), screens, magnetic separator etc. operation. -Flotation cells operation to remove sulfur by proper chemicals dossing.. -Air compressor, cooling tower and high capacity slurry pumps etc operation. ALL PROCESS DRIVEN BY – Siemens and Allen Bradley PLCs Jan 2011 - Sep 2011 GRANITE SERVICE INTERNATIONAL [GE Energy affiliate]

Service Manager (Oil and Gas sector) Position Projects: Kazakhstan (Tengiz(TCO), Aksay(KPO), Karabotan(AGIP)) Russia Ekaterenbyrt (Ibedrolla))

Duties were to work with Clients to help facilitate their business needs and requests. Covering:- Providing support to all levels of management and personnel Manage field employees; including support to the HR and stressing safety requirements Employment contract reviews support and employee performance evaluation, Identifying training and job assignment and mobilization of field employees Addressing daily employee needs and requests Manage sales and financial responsibilities such as inventory analysis and accounts receivable, invoice review and Operating Plan targets oversee the mobilization/demobilization process for field employees Maintain positive employee relations and resolve employee performance issues in a timely manner Ensure accuracy of mobilization logistics and job data in all databases Obtain complete job mobilization data, employee feedback, and weekly reports, employee and site safety issues supporting the EHS department Time & Expense review/approval, company initiatives, other office related activities and any other duties which could be deemed suitable by company.

May 2009 - Jan 2011 General Electric Transportation

Field Service Engineer (Transportation Department)

Position Project: KTZ Kazakhstan Maintenance Service Agreement Coordination of Maintenance activities

Almaty depot. EVO locomotives I have commission and put in service new fleet of locomotives. I have work with assemble and disassemble of diesel engine 7FDL, EVO, Traction motors, GE locos control system. I Have pass USA Technical Director extension courses, Pennsylvania, Erie.

July 2008 – May 2009 J. Ray Mcdermott Caspian Contructors

Production Engineer (E&I Department)

Project for Dubai U.A.E: Pearl GTL (SHELL) Position The Pearl GTL Project consists of two offshore platforms, associated wells and two pipelines feeding a two-train Gas to Liquids (GTL) plant located within Ras Laffan City (RLC), which is located 75km north of the Qatar capital, Doha. The plant will produce approximately 140,000 bbl per day of liquid synthetic products from natural gas and will be constructed in two phases.

Job description: Assistance and co-ordination with the fabrication superintendent Co-ordination with other departments Review 4-week look ahead. o Participate in weekly meetings with senior production engineers for progress, 4WLA & job planning. Out of sequence activity planning Weekly fabrication progress reporting Visit the site on a daily basis. Check the work in progress. If a team is preparing work out of sequence or incorrect Review and provide input to secondary cable routing (branch cable trays, channel trays, single tubing) where detailing not done Advise fabrication crew location of small E&I equipment’s that are not sufficiently detailed in the AFC drawings

Issue materials to Yard as required. o Identify material shortages and raise requisitions as required. Monitor and follow up, of outstanding materials.

Raise revision order

Coordination of Hook & Commissioning activities

April 2008 – July 2008 Karabatan field, Facilities maintenance department, Eurest Support Service [ESS]

Utilities Maintenance Supervisor

Position Job overview: Operation and Maintenance of sewage and water treatment plants supplying water to residential camps Operation and maintenance of gas boilers Running of Irrigation project Supervision of personnel fulfilling maintenance and remedial activities Supervision and coordination of water/ sewage lines repairs. Water storage tanks cleaning and disinfection Effluent water storage tanks cleaning. Making sure all works are completed with high Safety standard and in accordance to Client requirements.

September 2006-2008(April) PFD (Parsons Fluor Daniel LLC.)

DCS Junior Engineer [Commissioning and Pre-Commissioning department] Tengiz Asset Development Project Kazakhstan Project: Second Generation Plant (SGP) Position Position involved leading a team of field technicians, vendors and subcontractors to provide project wide pre-commissioning and commissioning activities.

These activities include site acceptance tests, communications and bitmap verification, system integration, loop checking field IO, ESD and F&G cause & effect testing and facilitating system handover to the client.

Further general responsibilities include organizing vendors, managing subcontractors, interfacing with construction and various other disciplines, resolving problems with engineering, troubleshooting problems in the field and liaison with the client.

This required working independently without supervision, leading and directing multiple teams of technicians, communicating clearly both verbally and in writing with other project personnel from other nationalities

2003-2006 ECB ( Enel – Comerint – Bonatti )

From 2005-2006 -Control Room Operator DCS(with promotion to Supervisor) From 2003-2005 - Field Operator

Working with the following system: Position Steam generation system HP Boilers MACCHI 4x115 t/h,40 bar,400 t Fuel gas and diesel facility, scrubber and booster pumps Steam Turbine Generator MAN™10.5 Mw, back pressure, 40/5 bar, 400/170 t Let down station from HP/MP and HP/LP, MP 20 bar, LP 20 bar and correction of temperature (desuperheater) an according with parameters of customer

Water treatment Sand filters, Reverse osmosis, Mixed bed filters, two trains 60 m3/h each Regeneration and waste water treatment, chemical facility Condensate recovery system, flash drums, activated carbon filters, storage tanks Boiler feed water unit, Atmospheric deaeratoers, chemical facilities (Oxygen scavenger, Corrosion inhibitor) Boiler feed water pumps driven by electrical motor Ingersoll and steam turbine Dresser Rand ALL PROCESS DRIVEN BY DCS – Honyewell, Rock well, Turwin

Responsible, a quick learner with good observational skills. Hard working, capable, willing to learn, communicative and easy to travel. Able to work quickly and accurately within a team environmental, to plan work so that it is completed in the most efficient manner. Able to communicate with all levels of staff both within & external to the company. Additional EHS core matrix training attended: H2S & PTW courses, familiar with company HSE rules and always follow it. information Lockout/Tagout Authorized Hazardous Waste Awareness Confined Space Authorized Crisis Management and Security Fall Protection Awareness Lead Safety Awareness Customer Site Awareness Risk Assessment Travel, Health, Safety and Security Accident Prevention Signs and Tags Has driving license “B” “C”

To work creatively...

Reference available upon request