OHS & Risk Management Manual 8

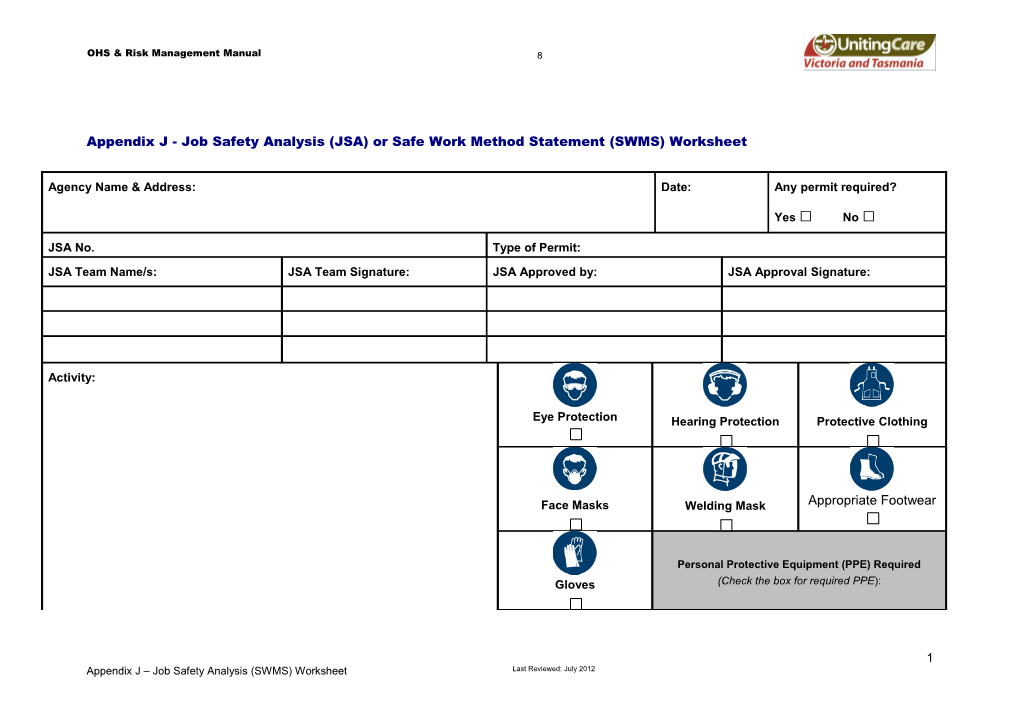

Appendix J - Job Safety Analysis (JSA) or Safe Work Method Statement (SWMS) Worksheet

Agency Name & Address: Date: Any permit required?

Yes □ No □

JSA No. Type of Permit:

JSA Team Name/s: JSA Team Signature: JSA Approved by: JSA Approval Signature:

Activity:

Eye Protection Hearing Protection Protective Clothing

Face Masks Welding Mask Appropriate Footwear

Personal Protective Equipment (PPE) Required Gloves (Check the box for required PPE):

1 Appendix J – Job Safety Analysis (SWMS) Worksheet Last Reviewed: July 2012 OHS & Risk Management Manual 2

Activity Hazards Risk control measures Who is responsible? Date List the tasks required to perform the activity in Against each task, list the hazards that List the control measures required to Write the name of the Expected date of the sequence they are carried out could cause injury when the task is eliminate or minimise the risk of injury person responsible to completion performed arising from the identified hazard implement the control measure identified

Each JSA (SWMS) must be task specific, including all workers (if applicable)

2 Appendix J – Job Safety Analysis (SWMS) Worksheet Last Reviewed: July 2012 OHS & Risk Management Manual 2

Appendix K - Workplace Inspection Checklist

General Details Name of Person Conducting Inspection: Date Conducted: / / UnitingCare Agency Name & Address: Reference:

Identify hazards below. Any item marked with a [N], is a hazard and must be risk assessed and controlled. This is to be documented in the later sections of this form. Prevention of Slips, Trips, Falls Y/N Comments

Cables and cords not in walk areas. Front reception area free of water, stored boxes, waste bins. Kitchen floors free of water, spills, stored boxes, waste bins. Back entrance free of water, stored boxes, waste bins.

Hallways free of water, stored boxes, waste bins.

Corridors and walkways free of clutter, boxes and water.

Toilets free of spills and stored boxes.

Are wet floors sign posted where required?

Are emergency exits free from clutter or boxes?

Is there any loose carpet, tiles etc? Stairways: Obstruction free, railings and toe boards fitted, non-slip surface, well maintained, no projecting fittings, nails etc. Are walkways and areas well lit? Emergency Procedures Y/N Comments

Are extinguishers attached to the wall?

Are hoses wound on the reel? Have extinguishers and reels been serviced in the last 6 months? Are evacuation plans clearly visible? Are workers trained in the use of the emergency equipment? Are emergency contact details displayed?

Are all exits clearly marked?

Electricity Y/N Comments

Are power points free of overloading (piggy backing)?

3 Appendix K – Workplace Inspection Checklist Last Reviewed: July 2012 OHS & Risk Management Manual 2

Are all cords, cables and extension cords free from visible wear and tear and damage? Are cables and sockets free of wet areas and heat sources? Are sockets free of splash areas?

Are all appliances currently tagged? Is portable electrical equipment such as extension leads, microphones and speakers protected by safety switches (RCDs)? Are all power leads and plugs in good condition? Is electrical equipment isolated from elements such as water, sharp edges and cutting devices that can cause shock? Ergonomics Y/N Comments Are work surfaces designed to suit the height and reach of all staff? Are work chairs well designed and adjustable? Is office based equipment selected and adjusted to take into account individual requirements (such as computers)? Are workers encouraged to take regular rest breaks? Vehicles and Equipment Y/N Comments

Are vehicle pre-operational checks being completed? Is staff aware of the requirements to report accidents / incidents to Workplace Manager and/or Synod Manager, and direct to the insurer and/or Synod OHS Team? Is equipment damaged including wear and tear? Chemical Management Y/N Comments Have all hazardous substances been identified, are they labelled and listed in a register? Are Material Safety Data Sheets (MSDS's) available for all chemicals? Have workers (i.e. employees, contractors and volunteers) been trained in reading a MSDS, safe handling, spillage, storage and disposal procedures for chemicals? Are records kept of this training? Is appropriate Personal Protective Equipment (PPE) available, maintained and used? Other hazards Y/N Comments

Are shelves and storage racks secured?

Are boxes and heavy objects stacked on lower shelves?

4 Appendix K – Workplace Inspection Checklist Last Reviewed: July 2012 OHS & Risk Management Manual 2

Are filing cabinets stable when the top drawer is open?

Do all work stations have good lighting?

Are all lights working throughout the office?

Is there good ventilation in all areas? Caution, information, danger signs appropriate, unobstructed, legible. Is the photocopier placed in a well ventilated area away from work stations? Are guillotines appropriately guarded?

Procedure available for tagging faulty equipment? Clothes lockers, washroom, showers, toilets, drinking fountains clean, tidy and hygienic? Cooling water system currently tested (if applicable). For each hazard identified above marked with a [N], document the risk assessment and control details below.

Risk Assessment and Control Date Date Hazard Risk Controls Implemented Reviewed

5 Appendix K – Workplace Inspection Checklist Last Reviewed: July 2012

Risk Assessment Information (please circle)

EXTREME HIGH MOD LOW

Notify Workplace Manager in the UnitingCare Portfolio Agency immediately; who will notify CEO, Insurance Services and Synod OHS Extreme Risk Team immediately. Temporary corrective actions should be taken immediately and permanent corrective actions within 24 hours of notification. Notify Workplace Manager in the UnitingCare Portfolio Agency immediately; who will notify CEO, Insurance Services and Synod OHS High Risk Team immediately. Temporary corrective actions should be taken immediately and permanent corrective actions should be taken within 48 hours of notification. Notify Workplace Manager who will follow up that corrective action is Moderate Risk taken within 7 days. Notify Workplace Manager who will follow up that corrective action is Low Risk taken within a reasonable time.

Review Controls Workplace Manager verifies controls are effective…….

Effective Not effective Name:

Date: / / Signature: