Agency Request State Building Commission Action August 2009

Agency: Department of Health Services

Institution: Winnebago Mental Health Institute, Winnebago, WI

Request: a) Authority to construct various maintenance and repair projects at an estimated total cost of $2,855,000 ($1,150,000 GFSB - Health, Safety and Environmental Protection [Z100] and $1,705,000 GFSB -Utilities Repair and Renovation [Z080]); b) Transfer all approved GFSB All Agency Allocations to the Department of Health Services (DHS) Infrastructure [Z480] appropriation; and c) Permit the Division of State Facilities to adjust individual project budgets.

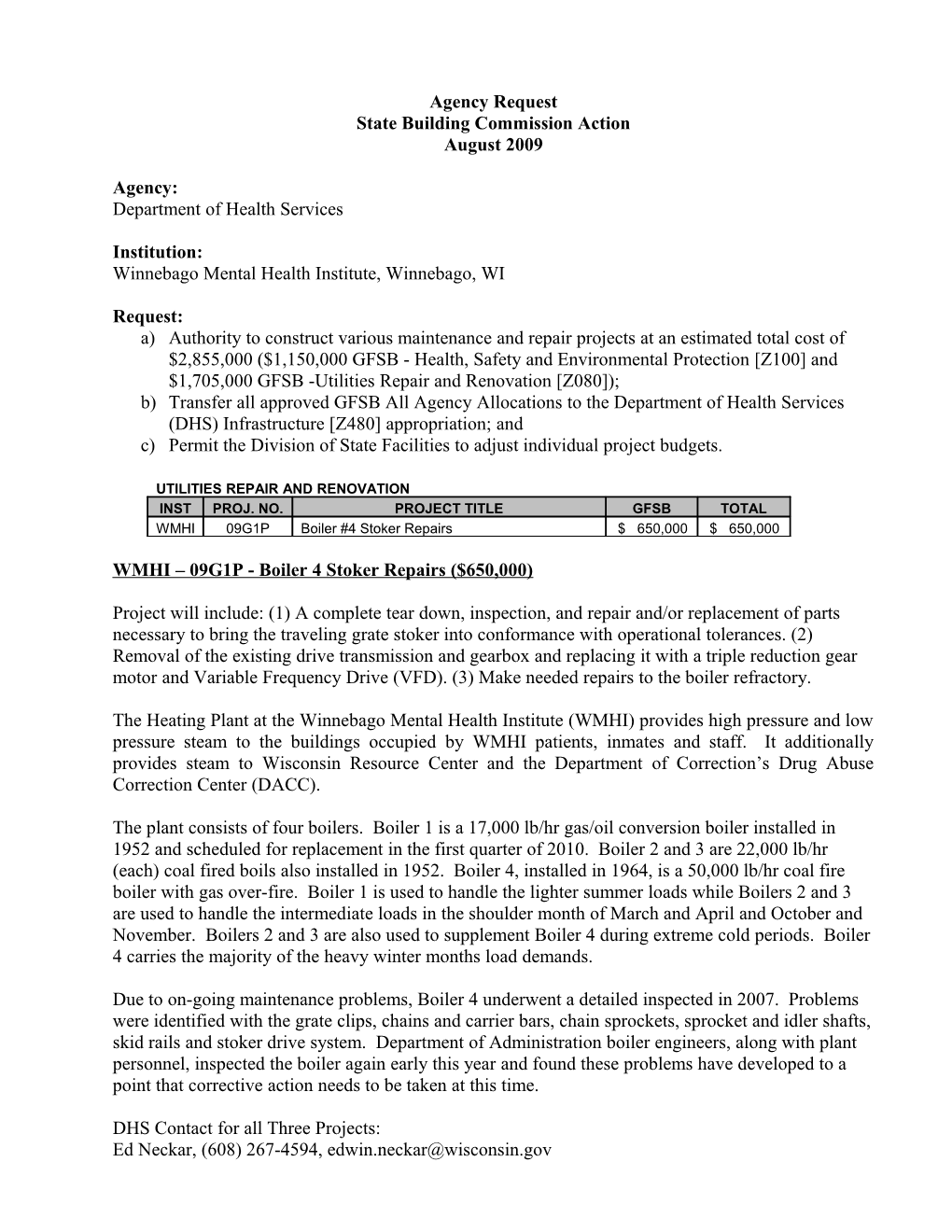

UTILITIES REPAIR AND RENOVATION INST PROJ. NO. PROJECT TITLE GFSB TOTAL WMHI 09G1P Boiler #4 Stoker Repairs $ 650,000 $ 650,000

WMHI – 09G1P - Boiler 4 Stoker Repairs ($650,000)

Project will include: (1) A complete tear down, inspection, and repair and/or replacement of parts necessary to bring the traveling grate stoker into conformance with operational tolerances. (2) Removal of the existing drive transmission and gearbox and replacing it with a triple reduction gear motor and Variable Frequency Drive (VFD). (3) Make needed repairs to the boiler refractory.

The Heating Plant at the Winnebago Mental Health Institute (WMHI) provides high pressure and low pressure steam to the buildings occupied by WMHI patients, inmates and staff. It additionally provides steam to Wisconsin Resource Center and the Department of Correction’s Drug Abuse Correction Center (DACC).

The plant consists of four boilers. Boiler 1 is a 17,000 lb/hr gas/oil conversion boiler installed in 1952 and scheduled for replacement in the first quarter of 2010. Boiler 2 and 3 are 22,000 lb/hr (each) coal fired boils also installed in 1952. Boiler 4, installed in 1964, is a 50,000 lb/hr coal fire boiler with gas over-fire. Boiler 1 is used to handle the lighter summer loads while Boilers 2 and 3 are used to handle the intermediate loads in the shoulder month of March and April and October and November. Boilers 2 and 3 are also used to supplement Boiler 4 during extreme cold periods. Boiler 4 carries the majority of the heavy winter months load demands.

Due to on-going maintenance problems, Boiler 4 underwent a detailed inspected in 2007. Problems were identified with the grate clips, chains and carrier bars, chain sprockets, sprocket and idler shafts, skid rails and stoker drive system. Department of Administration boiler engineers, along with plant personnel, inspected the boiler again early this year and found these problems have developed to a point that corrective action needs to be taken at this time.

DHS Contact for all Three Projects: Ed Neckar, (608) 267-4594, [email protected] Budgets: Boiler #4 (09G1Q) Construction $525,000 Contingency $55,000 A/E Design $46,000 DSF Mgt $24,000 TOTAL $650,000

Schedules:

Boiler #4 (09G1Q) BC Approval Aug 2009 A/E Selection Sep 2009 Bids Received Feb 2010 Start Construction Jun 2010 Project Completion Sep 2011

Previous Building Commission Action: None

DHS Contacts: Ed Neckar, (608) 267-4594, [email protected] Tom Westergard, [email protected], 920-235-4910 Ex. 2541