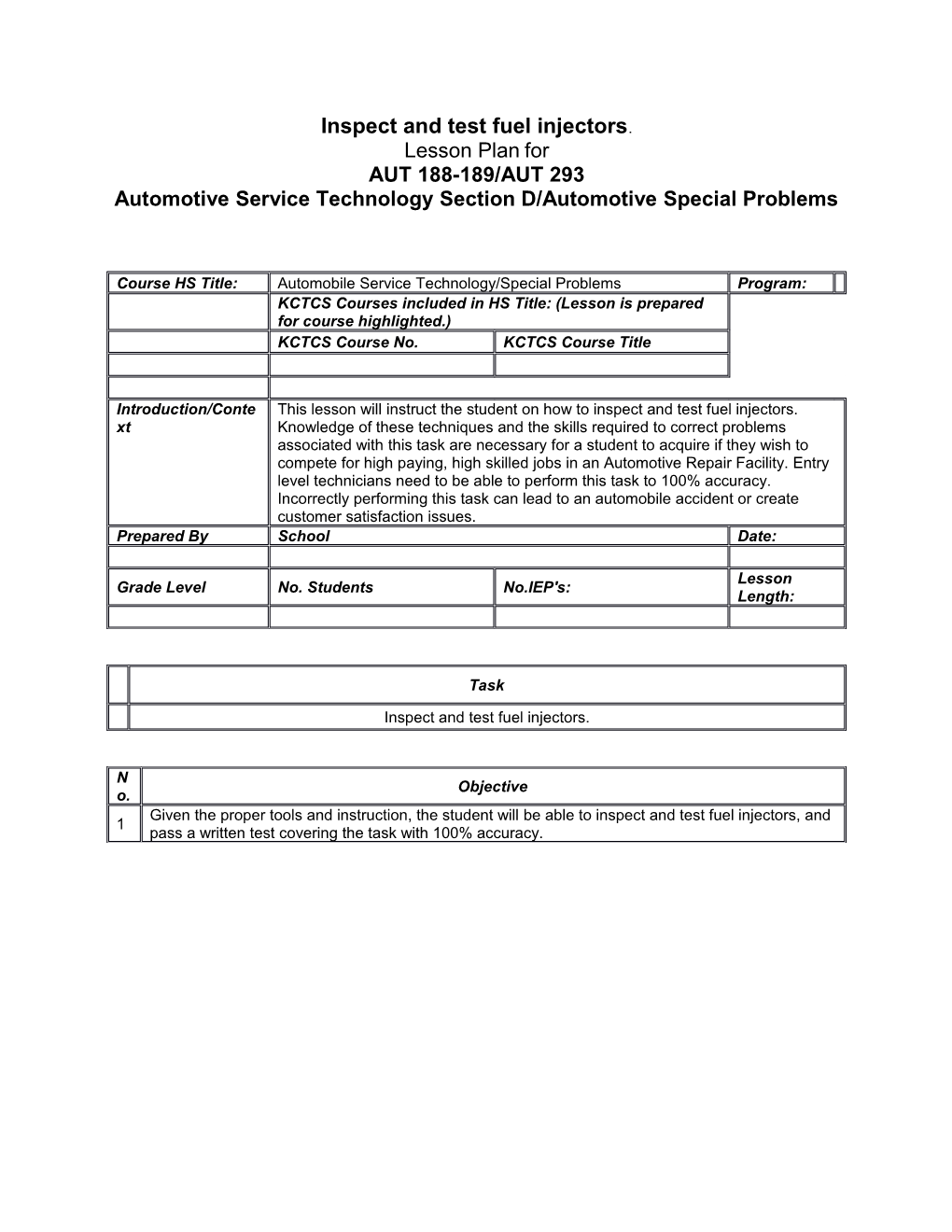

Inspect and test fuel injectors. Lesson Plan for AUT 188-189/AUT 293 Automotive Service Technology Section D/Automotive Special Problems

Course HS Title: Automobile Service Technology/Special Problems Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title

Introduction/Conte This lesson will instruct the student on how to inspect and test fuel injectors. xt Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in an Automotive Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an automobile accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task

Inspect and test fuel injectors.

N Objective o. Given the proper tools and instruction, the student will be able to inspect and test fuel injectors, and 1 pass a written test covering the task with 100% accuracy. Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-SYS-2 New Common Core Standards: RST 11-12.2 RST 11-12 3 A-CED-4 N-Q-1 New Generation Science Standards: HS-PS2-5. HS-PS3-3. HS-PS3-5.

INSTRUCTIONAL MATERIALS/TECHNOLOGY

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Thomson Ken Pickerill Automotive Engine Performance 4th 438-440 Delmar James Halderman/ Chase Automotive Technology, Principles, Second Prentice Hall 659 Mitchell Diagnosis and Service

Web Addresses Title Publisher URL Today's Class Melior www.todaysclass.com

Equipment Quantity Item Source As Needed NOID light Various An Needed System Scope/Ocsilloscope Various An Needed Test Light Various

Content/Presentation/Demonstration Outline Instruct students that a fuel injector is nothing more than a solenoid-actuated fuel valve. Its operation is quite basic in that as long as it is held open and the fuel pressure remains steady, it delivers fuel until it is told to stop. Inform students that because all fuel injectors operate in a similar manner, fuel injector problems tend to exhibit the same failure characteristics. The main difference is that in a TBI (Throttle Body Injection) design, generally all cylinders suffer if the injectors malfunction, whereas in port systems the loss of one injector is not as crucial. Teach students that an injector that does not open causes hard starts on port-type systems and an obvious no start on single-point TBI designs. Explain that an injector that is stuck partially open cause’s loss of fuel pressure (most noticeably after the engine is stopped and restarted within a short time period) and flooding due to raw fuel dribbling into the engine. In addition to a rich-running engine, a leaking injector also causes the engine to diesel or run on when the ignition is turned off. Instruct students that when an injector is suspected as the cause of a problem, the first step is to determine if the injector is receiving a signal from the control computer to fire. Explain that determining if the injector is receiving a voltage signal is easy and requires simple test equipment, but the location of the injector's electrical connector can make this simple voltage check somewhat difficult. Tell students that once the injector's electrical connector has been removed, be sure to check for voltage at the injector using an ordinary test light or a convenient NOID light that plugs into the connector. After making the test connections, have students crank the engine. Let students know that a series of rapidly flickering lights indicates the computer is doing its job and supplying voltage or a ground to open the injector. When performing this test, make sure to tell students to keep off the accelerator pedal. Students need to know that on some models fully depressing the accelerator pedal activates the clear flood mode in which the voltage signal to the injectors is automatically cut off. Techs that are unaware of this waste time tracing a problem that doesn’t exist. NOID LIGHT TEST RESULTS: * Instruct students that if the light is off and does not flash, the problem is an open in either the power side or ground side (or both) of the injector circuit. * A dim noid light indicates excessive resistance or low voltage available to the injector. Tell students that both the power and ground side must be checked. * If the noid light is on and does not flash, then both a power and a ground are present, but because the light does not flash (blink) when the engine is being cranked or started, then a short-to-ground fault exists either in the computer itself or in the wiring between the injector and the computer. If sufficient voltage is present after checking each injector, inform students to check the electrical integrity of the injectors themselves. They can use an ohmmeter to check each injector winding for shorts, opens, or excessive resistance. Tell them to compare resistance readings to the specifications found in the service manual. Instruct students that an ohmmeter can be used to test the electrical soundness of an injector. Have students connect the ohmmeter across the injector terminals after the wires to the injector have been disconnected. Explain that if the meter reading is infinity, the injector winding is open. If the meter shows more resistance than the specifications call for, there is high resistance in the winding. A reading that is lower than the specifications indicates that the winding is shorted. If the injector is even a little bit out of specifications, tell students it must be replaced. Inform students that if the injector's electrical leads are difficult to access, an injector test is hard to perform. As an alternative, tell students to start the engine and use a technician's stethoscope to listen for correct injector operation. Let students know that a good injector makes a rhythmic clicking sound as the solenoid is energized and de-energized several times each second. Tell students that if a clunk-clunk instead of a steady click-click is heard, chances are the problem injector has been found. Cleaning or replacement is in order. If a stethoscope is not handy, instruct students to use a thin steel rod, wooden dowel, or fingers to feel for a steady on/off pulsing of the injector solenoid. Explain to students that another way to isolate an offending cylinder when injector access is limited is to perform the more traditional cylinder power balance test by momentarily grounding each spark plug wire instead of disabling the injectors. Be sure to tell students to remember to bypass the idle air control. Tell students to watch the rpm drop and note any change in idle quality as each plug is shorted. If a lazy or dead cylinder is located, inform students to concentrate efforts on the portion of the fuel or ignition system pertaining to that cylinder, assuming no mechanical problems are present.

STUDENT AWARENESS: Inform students that any time cylinders are shorted during a power balance test, make the readings as quickly as possible. Prolonged operation of a shorted cylinder causes excessive amounts of unburned fuel to accumulate inside the catalytic converter and increase the risk of premature converter failure. Instruct students that an oscilloscope can be used to monitor the injector's pulse width and duty cycle when an injector-related problem is suspected. Explain that the pulse width is the time in milliseconds that the injector is energized. The duty cycle is the percentage of on time to total cycle time. To check the injector's firing voltage on the scope, tell students that a typical hookup involves connecting the scope's positive lead to the injector supply wire and the scope's negative lead to an engine ground. Let students know that even though these connections are considered typical, it is still a good idea to read the instruction manual provided with the test equipment before making connections. With the scope set on the low voltage scale and the pattern adjusted to fill the screen, inform students that a square-shaped voltage signal should be present with the engine running or cranking. Let students know that if the voltage pattern reads higher than normal, excessive resistance in the injector circuit is indicated. A low-voltage trace indicates low-circuit resistance. If the pattern forms a continuous straight line, tell students it means the injector is not functioning due to an open circuit somewhere in the injector's electrical circuit.

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)