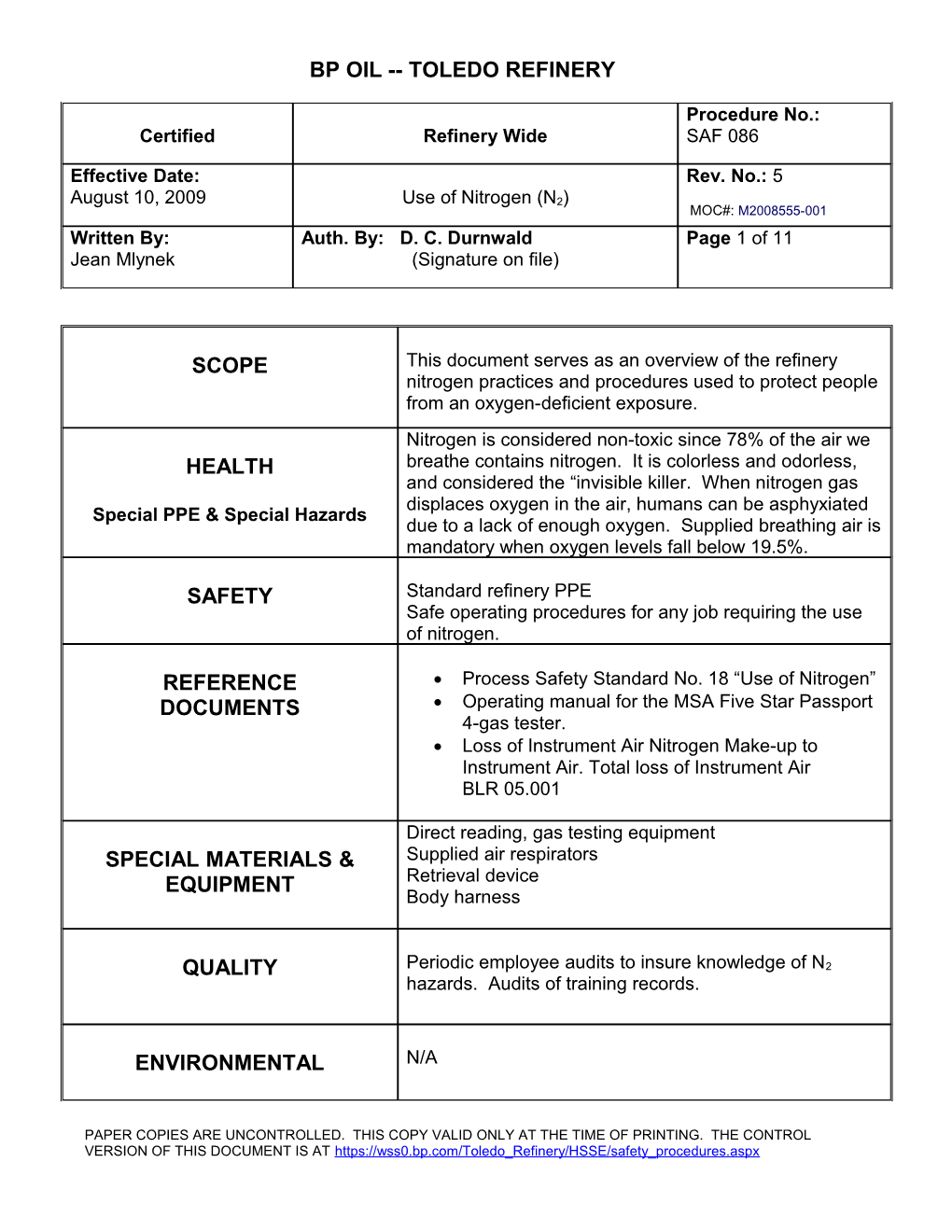

BP OIL -- TOLEDO REFINERY

Procedure No.: Certified Refinery Wide SAF 086

Effective Date: Rev. No.: 5 August 10, 2009 Use of Nitrogen (N2) MOC#: M2008555-001 Written By: Auth. By: D. C. Durnwald Page 1 of 11 Jean Mlynek (Signature on file)

SCOPE This document serves as an overview of the refinery nitrogen practices and procedures used to protect people from an oxygen-deficient exposure. Nitrogen is considered non-toxic since 78% of the air we HEALTH breathe contains nitrogen. It is colorless and odorless, and considered the “invisible killer. When nitrogen gas displaces oxygen in the air, humans can be asphyxiated Special PPE & Special Hazards due to a lack of enough oxygen. Supplied breathing air is mandatory when oxygen levels fall below 19.5%.

SAFETY Standard refinery PPE Safe operating procedures for any job requiring the use of nitrogen.

REFERENCE Process Safety Standard No. 18 “Use of Nitrogen” DOCUMENTS Operating manual for the MSA Five Star Passport 4-gas tester. Loss of Instrument Air Nitrogen Make-up to Instrument Air. Total loss of Instrument Air BLR 05.001

Direct reading, gas testing equipment SPECIAL MATERIALS & Supplied air respirators EQUIPMENT Retrieval device Body harness

QUALITY Periodic employee audits to insure knowledge of N2 hazards. Audits of training records.

ENVIRONMENTAL N/A

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 086 Rev. No. 5

OVERVIEW

Nitrogen (N2), as a gas, is colorless and odorless. When nitrogen concentration increases, the oxygen concentration decreases and the atmosphere may contain less than 19.5% oxygen. Breathing atmospheres of less than 19.5% oxygen can lead to progressively more adverse health effects, including rapid death (see Table 1). Nitrogen displaces carbon dioxide in the lungs, which tells the body to stop breathing. Nitrogen is typically used to displace air to create an oxygen deficient atmosphere, but other gases such as helium and argon, can create similar hazards.

Toledo Refinery uses nitrogen in several applications. As a gas, some uses include: 1.) inerting equipment to prevent flammable atmospheres; 2.) preparing equipment for maintenance by purging out hydrocarbons; 3.) removing air/oxygen in equipment before startup; 4.) blanketing tanks to prevent the ingress of air; 5.) certain welding operations; 6.) decommissioning equipment to prevent the “rusting” process; 7.) instrument air backup. Nitrogen is also used as a liquid for cooling purposes and is stored in large quantities in liquid form. The use of nitrogen can be harmful. Due to the hazards of working in nitrogen atmospheres, alternative processes not requiring entry into an inert atmosphere must be considered and, when appropriate, become the preferred alternative.

1.0 Routine Nitrogen Use __1.1 It is crucial that all nitrogen entering the refinery is of high quality. An assurance method must be in place to guarantee good nitrogen that is free from oxygen.

__1.2 All permanent connections into a nitrogen system must be disconnected, blanked, or blinded from the supply system. Permanent nitrogen connections REQUIRED for safety or process reasons must include a non-return device (e.g., check valve) to prevent potential contamination of the nitrogen system.

__1.3 Oxygen analyzers, alarms, and trips in nitrogen systems must be verified as operating correctly by testing and documenting on a periodic basis. The asset group will assure this is done.

__1.4 Utility stations on a nitrogen distribution system must have a non-return device (e.g., check valve), and must be clearly identified. Green signs with white lettering depict the nitrogen stations in the refinery. Special connectors and hoses that are not common to any other systems will be used.

__1.5 Where nitrogen is continuously in use, permanent warning signs (stating suitable precautions) must be located at all access points, such as manways, stairways, etc.

__1.6 Temporary warning signs must be located wherever potential personnel exposure to nitrogen exists due to the temporary use of nitrogen, i.e., during vessel or line venting or purging with nitrogen.

__1.7 A variety of applications for nitrogen use occur in the refinery quality laboratory. High-pressure nitrogen cylinders are used for several analyzing techniques.

Page 2 of 11

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 086 Rev. No. 5

__1.8 A management system must be in place to promptly alert all affected personnel whenever nitrogen is used to supplement the site instrument air or plant air systems. This includes temporary, short-term, backup connections. See Procedure BLR 05.001 Loss of Instrument Air

Nitrogen can be introduced to the instrument air system at the following two (2) locations:

· The SGP area just outside Sat 2 · The Alky 3 area.

The nitrogen block valves shall be car-sealed closed at these two locations and warning signs shall be posted that this nitrogen source is for emergency use only.

Refinery Coordinators will normally decide when to introduce nitrogen to the instrument air system. The person who decides to introduce the nitrogen to the instrument air system shall have the responsibility to notify the Refinery Coordinator. It is the Refinery Coordinator’s responsibility to notify all area Supervisors that nitrogen is being used to supplement the instrument air system. The area Supervisor will in turn notify all operators and maintenance personnel in their individual area.

__1.9 When alerted that nitrogen is being used to supplement the instrument air supply, operations personnel will continuously monitor their Satellites with a direct reading instrument (MSA Passport) to assure Oxygen levels in the building do not fall below 19.5%. If oxygen levels drop below 19.5%, the building must be ventilated with external air and evacuated until the oxygen level returns to normal levels (19.5 – 23.5)

__1.10 A traction report and a root-cause incident investigation must occur after each event that requires the use of nitrogen to supplement the instrument or plant air system.

WARNING Notify all area Supervisors that nitrogen is being used to supplement the instrument air system. They will in turn notify all operators in their area. Satellites and Analyzer buildings are not to be entered until tested for oxygen. The instrument air is used to purge analyzer buildings and could cause oxygen deficient atmospheres.

Page 3 of 11

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 086 Rev. No. 5

__2.1 All nitrogen utility stations throughout the plant will be controlled by 2.0 Lock-out / Tag-out using the following LOTO procedure. Exempted from this LOTO are (LOTO) of Nitrogen the two nitrogen to air connections described in Section 1.8 Each area, Utility Stations or unit, will number specific Nitrogen Stations. The Unit Name will be included. Here is an example:

NITROGEN NITROGEN STATION STATION # # 1 1 ADHTADHT

__2.2 At each Nitrogen Station, each Nitrogen Supply Valve will be assigned a Letter, from top to bottom for Vertical Manifolds and left to right for Horizontal Manifolds. NITROGEN HEADER 145 PSIG NITROGEN HEADER 145 PSIG NITROGEN STATION # 1 ADHT NITROGEN STATION # 1 ADHT A

B A B C D

C

D

Page 4 of 11

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 086 Rev. No. 5 ADHT __2.3 Each Nitrogen Supply Valve,1 C at each Nitrogen Station, will be tagged with the Unit Name, the Nitrogen Station Number, and the Nitrogen Valve Letter.

ADHT 1 C

Example of a tag

__2.4 All Lettered Valves will be closed and locked. All Lettered Valves will have two (2) Identifying Tags.

__2.5 One Identifying Tag will be fixed to the valve with a lock and chain and “S” hook or other secure method of attachment. The second Identifying Tag will be retained on the lock, with a split ring.

__2.6 A Nitrogen Lock Out Board will be located in the Control Room of each Unit. Keys for the locked Nitrogen valves will be fixed to the Nitrogen Lock Out Board with a Car Seal.

__2.7 When a Lettered Nitrogen Valve is unlocked for service, an Identifying Tag will be secured to the Nitrogen Lock Out Board.

__3.1 Working inside a vessel that contains an oxygen-deficient atmosphere 3.0 Entry into Oxygen- is considered Immediately Dangerous to Life and Health (IDLH). Deficient Reasonable alternatives to this option must be discussed before this Atmospheres option is selected. The alternatives and discussion must be documented before any work can proceed.

__3.2 No BP employee shall enter an oxygen-deficient vessel under any circumstances. Only trained and skilled personnel expert in inert entry and rescue will be allowed into the vessel.

__3.3 BP will submit bids and hire only trained and skilled specialty contractors for oxygen-deficient entry work.

__3.4 In addition to the training required in 3.2, all persons working in or Page 5 of 11

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 086 Rev. No. 5

around potentially oxygen deficient atmospheres must be trained regarding procedures, personal protective equipment, continuous monitoring, standby personnel responsibilities, emergency procedures, and rescue plan.

__3.5 BP and contractor personnel for all inert entry jobs will designate a BP employee as responsible for the assurance of the safe execution of activities.

__3.6 Procedures, including a job safety pre-plan, must be written to define how a vessel or other piece of equipment will be taken out of service, accessed by personnel, work scope and how to return to service. The designated BP responsible employee will review and sign off on the pre-plan. Additional points to include are:

Assurance (e.g. testing, analysis, QA/QC) of the quality and reliability of the nitrogen source. A diagram of the vessel with isolation points, nitrogen purging inlets, vents, and outlets, entry points, internal fittings. Methods to verify nitrogen flow, control, volume and venting. Methods to control personnel access to the equipment and the restricted area. Steps to eliminate or minimize other activities not associated with the use of nitrogen but are near the restricted area. Ways to manage other risks unique to the activities (e.g., skin absorption of contaminants in the equipment). Scheme on how to vent nitrogen from equipment to a location where the nitrogen does not create a hazard to unprotected personnel.

__3.7 Atmospheric (gas) testing must be performed to identify the parameters of the restricted area. Two trained and competent people from the specialty contractor group will conduct this. One will reside at a safe distance to perform rescue if needed.

__3.8 Both individuals will wear positive pressure, continuous flow, full face, supplied breathing air and rescue equipment (body harness).

__3.9 Proper gas testing equipment must be used which will accurately measure oxygen and combustibles in a potentially oxygen-deficient atmosphere. Refer to SAF 023, “Using Direct Reading Gas Testing Equipment” for additional guidance and explanation.

__3.10 Once the restricted area is determined, it will be cordoned off using barricade tape and warning signs placed at all access points, i.e., stairs, ladders, etc. The following verbiage will be used: Danger – Nitrogen in Use Life Threatening Hazard Present Oxygen-Deficient Hazard – Supplied Air Required Authorized and Trained Personnel Only

__3.11 The job safety pre-plan must be discussed, reviewed, and documented. Refer to Table 2 for a checklist to define the minimum requirements that will be met to allow inert entry into a vessel.

Page 6 of 11

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 086 Rev. No. 5

4.0 Training __4.1 All persons who may be exposed to the danger of nitrogen must be trained in the hazards of nitrogen.

__4.2 This training will include at least the following:

Where nitrogen is used and how its presence can result in an oxygen deficient atmosphere. Potential health effects due to low oxygen exposure.

Methods to detect and measure low oxygen concentration.

Requirements and authorization to work in and around an inerted vessel.

Emergency procedures and rescue plans.

Lessons learned involving nitrogen incidents.

__4.3 Refresher N2 training is provided before the start of a large turnaround project and/or catalyst change out.

__4.4 A written test is administered to insure a level of competency with the N2 training given and to provide for a training record.

Page 7 of 11

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 086 Rev. No. 5

Table 1

TYPICAL HUMAN PHYSIOLOGICAL RESPONSES TO OXYGEN DEFICIENCY

Oxygen (%vol) Effects & Symptoms

23.5 Maximum “Safe Level”

21 Typical O2 concentration in air

19.5 Minimum “Safe Level”

15-19 First signs of hypoxia. Decreased ability to work strenuously. May induce early symptoms in persons with coronary, pulmonary or circulatory problems.

12-14 Respiration increases with exertion, pulse up, impaired muscular coordination, perception and judgment.

10-12 Respiration further increases in rate and depth, poor judgment, lips blue.

8-10 Mental failure, fainting, unconsciousness, ashen face, blueness of lips, nausea, vomiting, inability to move freely.

6-8 6 minutes – 50% probability of death 8 minutes – 100% probability of death

4-6 Coma in 40 seconds, convulsions, respiration ceases, death

Page 8 of 11

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 086 Rev. No. 5

Table 2 Checklist of Minimum Requirements for Inert Entry

Unit Name: Date/Time :______/ / :

Equipment #: Equipment Description: s e e r l i b u a q c # y e i

r l R o p m t n e p c t o I i A a t

f t n s i o e t

t Item Description Comments N t a S A 1. Equipment isolation and entry permits are in accordance with HSE procedures. 2. Equipment isolation and entry permits have received the appropriate level of review and approval. 3. Procedures are in place to identify all persons authorized to enter the inert vessel. 4. Procedures are in place to prevent unauthorized persons from entering the vessel. 5. Provisions are in place to prevent unauthorized entry into the vessel when there is no activity in these areas (e.g., man way covers and entry control barriers). 6. Continuous atmospheric monitoring of the confined space with portable, personal and/or fixed monitoring equipment will be done to maintain the oxygen concentration below 5% to manage the risks of pyrophoric materials. 7. The vessel will be tested for other parameters, e.g., percent (%) Lower Explosive Limit (LEL) combustibles, concentration of other toxic gases, temperature, and/or pressure (as listed in with the work procedures or on the pre-job safety analysis). 8. The monitoring plan includes a method to detect any temperature change in excess of 20 oF/11oC. 9. Personal heat stress hazards have been evaluated in accordance with applicable guidelines.

Page 9 of 11

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 086 Rev. No. 5 s e e r l i b u a q c # y e i

r l R o p m t n e p c t o I i A a t

f t n s i o e t

t Item Description Comments N t a S A 10. All persons entering, or potentially entering (e.g., rescue

personnel), the vessel must wear appropriate equipment for working in an oxygen deficient vessel. This must at least include: two completely independent continuous air supplies and one secondary (e.g., emergency egress air supply of sufficient capacity for escape purposes) lock-on helmet mask type respiratory protection adequate air pressure monitoring devices; battery back-up power supplies for any critical electrical sources primary and secondary communication devices a full body harness with a retrieval line attached. 11. A safety stand-by hole watch is required and must: wear the same PPE as described in #10 above be in constant visual contact with those inside the vessel be trained in, and understand, the site vessel hole watch requirements never enter the oxygen deficient vessel 12. Rescue personnel and equipment must be assembled and ready for use, at the vessel entry points to vessels and tanks with an oxygen deficient atmosphere. 13. Rescue personnel must be available and trained in the proper use of the equipment, including resuscitation equipment. 14 Rescue equipment must be tested prior to the start of work. 15. All umbilicals, lighting cords and other lines must go through the manway in a neat manner so as not to interfere with ingress and egress 16. Fall arrest equipment is tested, secure, documented 17. Gas assessment equipment is tested and calibrated. 18. Sufficient low volt lighting is being used. 19. Ingress and egress ladder is in good condition and secured adequately. 20. Catalyst loading equipment is set up in way so as not to present any hazard or obstruction. 21. Utility rope is in good condition.

Page 10 of 11

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. SAF 086 Rev. No. 5 s e e r l i b u a q c # y e i

r l R o p m t n e p c t o I i A a t

f t n s i o e t

t Item Description Comments N t a S A 22. Internal safety attendants are in place and can maintain visual contact with personnel (generally required in multi-bed reactors - verifiable by video or communication check).

23. Video surveillance equipment is in good working. order, pan adjustments working and picture clear 24. Entrant and attendant system color code for umbilical use is set up and communicated. 25. Breathing air cylinders quality assurance has been provided (for CO and O2). 26. Breathing air cylinder manifold gauge readings will be monitored and logged. 27. Communications systems are tested regularly and Documented. 28. Harness inspections are completed regularly and Documented. 29. Rescue plan documented and is understood by all personnel. 30. Rescue plan distinguishes between different phases of the work such as unloading and loading of catalyst. 31. Module equipment checked out and is tested regularly. i.e. alarms, communications equipment, video equipment, gauges calibrated, etc.

Notes or other comments:

THIS IS THE LAST PAGE

Page 11 of 11

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx