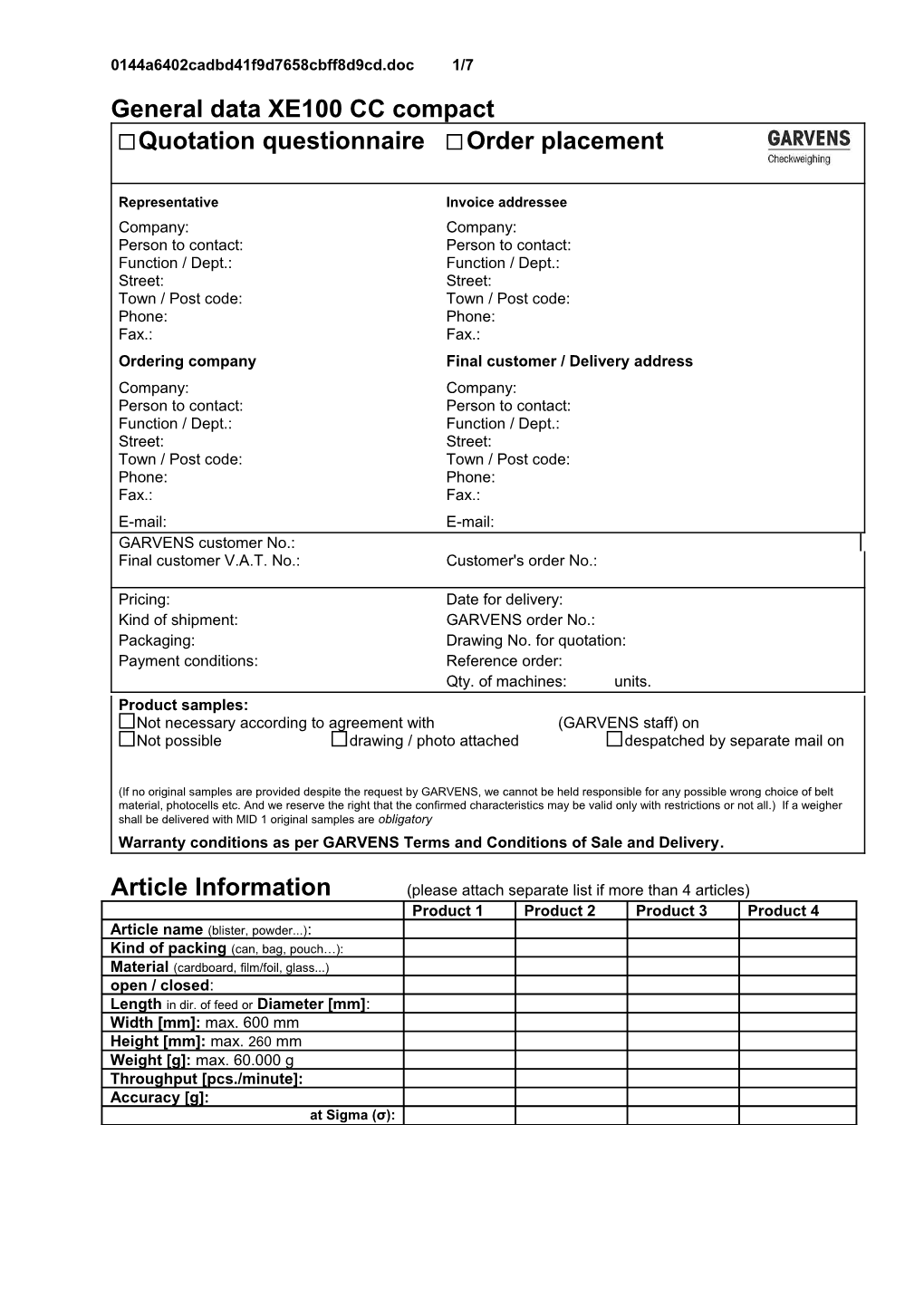

0144a6402cadbd41f9d7658cbff8d9cd.doc 1/7 General data XE100 CC compact Quotation questionnaire Order placement

Representative Invoice addressee Company: Company: Person to contact: Person to contact: Function / Dept.: Function / Dept.: Street: Street: Town / Post code: Town / Post code: Phone: Phone: Fax.: Fax.: Ordering company Final customer / Delivery address Company: Company: Person to contact: Person to contact: Function / Dept.: Function / Dept.: Street: Street: Town / Post code: Town / Post code: Phone: Phone: Fax.: Fax.: E-mail: E-mail: GARVENS customer No.: Final customer V.A.T. No.: Customer's order No.:

Pricing: Date for delivery: Kind of shipment: GARVENS order No.: Packaging: Drawing No. for quotation: Payment conditions: Reference order: Qty. of machines: units. Product samples: Not necessary according to agreement with (GARVENS staff) on Not possible drawing / photo attached despatched by separate mail on

(If no original samples are provided despite the request by GARVENS, we cannot be held responsible for any possible wrong choice of belt material, photocells etc. And we reserve the right that the confirmed characteristics may be valid only with restrictions or not all.) If a weigher shall be delivered with MID 1 original samples are obligatory Warranty conditions as per GARVENS Terms and Conditions of Sale and Delivery.

Article Information (please attach separate list if more than 4 articles) Product 1 Product 2 Product 3 Product 4 Article name (blister, powder...): Kind of packing (can, bag, pouch…): Material (cardboard, film/foil, glass...) open / closed: Length in dir. of feed or Diameter [mm]: Width [mm]: max. 600 mm Height [mm]: max. 260 mm Weight [g]: max. 60.000 g Throughput [pcs./minute]: Accuracy [g]: at Sigma (σ): 0144a6402cadbd41f9d7658cbff8d9cd.doc 2/7 General article information dry humid coarse slippery raw caustic/acid oily/greasy instable deep-frozen °C hot °C reflective miscellaneous: Given dist. between products’ centres: mm MID conformity assessment Required dist. between products’ centres: mm incl. MID Box Conveyor speed of customer’s systems: m/min. Suitable for official calibration: Required conveyor speed: m/min. Design approval in: Maximum load: g Direction of transport: leftright Definition (resolution): g rightleft Weighing range: g to g Line height (500-1000): mm (Observe whether checkweigher shall be officially calibrated!) (Separate cabinet) Product transport Speed of the existing infeed conveyor (customer): Roller diameter (infeed of customer’s conveyor): Speed of the existing outfeed conveyor (customer): Roller diameter (outfeed of customer’s conveyor): Product sequence: butt-to-butt regular gaps irregular gaps infeed in product groups gap between groups: gap between products: additional information: Product infeed: single article

Environmental conditions Placement: ground floor floor platform, stage, scaffold: height

Local Conditions: strong air draught by machines, ventilators, door or windows floor vibration dusty atmosphere extreme temperature from °C to °C high air humidity, approx. rel. % use in wet environment

Options and accessories, weighing terminal Remote display FAZ W 100 cable length: m

Metal detector selection (with display on MD) Frequency range (only one choice possible): 3 Frequencies: L(25+100+300 kHz) H(100+300+800 kHz)

MD case finish: painted silver Pass width MD [mm] 700 Pass Height MD [mm] 300 Usable height [mm] 260 0144a6402cadbd41f9d7658cbff8d9cd.doc 3/7 Conveyors Weighing conveyor [mm]: 1200x600 mm

Monitoring devices yes no Backup detection light barrier: Light barrier on infeed outfeed customer's conveyor with automatic conveyor shutdown with automatic conveyor shutdown + pot. free contact pot. free contact separate rejection rejection

Further electric / electronic options and accessories yes no Emergency stop: Transformer for special voltage: for V Hz em. stop input contact em. stop push-button increased "emergency stop" category (as per EN 60947-5-1-3)

Pressure monitoring device: Conveyor START/STOP, remote: automatic conveyor shutdown by customer's system activates potential-free output contact/conv. Shutdown housing w. push-buttons, cable m

Potential-free outputs (contacts): Classification outputs: stat. signal dyn. signal timer pfc 1 for signalling: Zone Good

pfc 2 for signalling: Zone T1+ pfc 3 for signalling: Zone T1- pfc 4 for signalling: Metal

Pot.-free input f. "final evaluation": Action input 1 Function: Pot.-free input f. "reset counters ": Action input 2 Function: Pot.-free input f. "finish batch": Action input 3 Function:

Signalling device: (standard: with 4 light elements) (available colours: red, green, amber, white, and blue) light element in colour for signalling: light element in colour for signalling: light element in colour for signalling: light element in colour for signalling: light element in colour for signalling: horn, for signalling: Kind of signal: dynamic signal static (permanent)

Motor controlled by customer using external guide voltage Checkweigher controls the customer's conveyor motor Checkweigher controls customers rejecting device (pfc) 0144a6402cadbd41f9d7658cbff8d9cd.doc 4/7

Programs / Interfaces (max. 1 interface port possible!) yes no Other interfaces: GARECO Weight data CL 20 active CL 20 passive RS232 RS422 RS485 Profibus (Miface Modul)

Weight zones 3 (Standard) 4 5

OPC Server PINYIN Chinese editor Fieldbus interface / system Binary article No. output to PLC Type of fieldbus: ProfiNet DeviceNet Ethernet IP ProdX Interface Driver

Interface FreeWeigh: Statistics program FW.Net Statistics only incl. Article download with attached ticket printer Ethernet with Printstick RS232 PrintStick-compl.kit/first installation PrintStick extension Add. PrintStick pcs.

Interface cable: 5m 10m length (in meter): m 0144a6402cadbd41f9d7658cbff8d9cd.doc 5/7 Miscellaneous Installation of the interface connection(s) by: GARVENS METTLER TOLEDO Customer, name: (It must be ensured, if the customer will do the installation himself, that he has sufficient expertise/know-how to do the interface configuration and connections himselfor Any service intervention necessary will be fully invoiced in cases where an after-sales service engineer is called to solve problems and where the engineer can demonstrate that the GARVENS interface port works correctly.) Initial operation by: GARVENS METTLER TOLEDO Customer, name:

On-screen dialogue language: trTR daDK deDE elGR enUS frFR svSE nnNO ruRU hrHR nlNL plPL itIT esE csCZ ptBR ptPT huHU roRO zhCN zhTW thTH slSI skSK srCS fiFI

Language of operating instructions: csCZ daDK deDE enGB esES frFR itIT nlNL plPL ruRU slSI skSK svSE Quantity: (additional charge for more than two copies)

Type/ratings plate: deDE enGB frFR plPL itIT nlNL trTr svSE hrHR esES daDK huHU fiFI

FAT (1 day): date:

Add. FAT day(s): days

EQ Pac: deDE enGB

Spare parts kit

Wear Part Kit Wear Part Kit plus motor Electronic Kit Complete Kit Customized Kit

Communication package: (not available in all countries) Silver Gold Platinum

Supplementary text / Comments

0144a6402cadbd41f9d7658cbff8d9cd.doc 6/7 0144a6402cadbd41f9d7658cbff8d9cd.doc 7/7 Pricing Option Gross list price Currency

Date: Name: Signature: