Hardware-in-the-Loop Testbed Douglas Pence, Ken Gobin, Aaron Eaddy, Advisor Sung Yeul Park ECE Team 186 Senior Design, University of Connecticut, Spring 2014

Abstract— In this document, a proof-of-concept design is developed same concept for the system that contained the energy storage and implemented to show the benefits of a hardware-in-the-loop device being tested. testbed for energy storage devices.

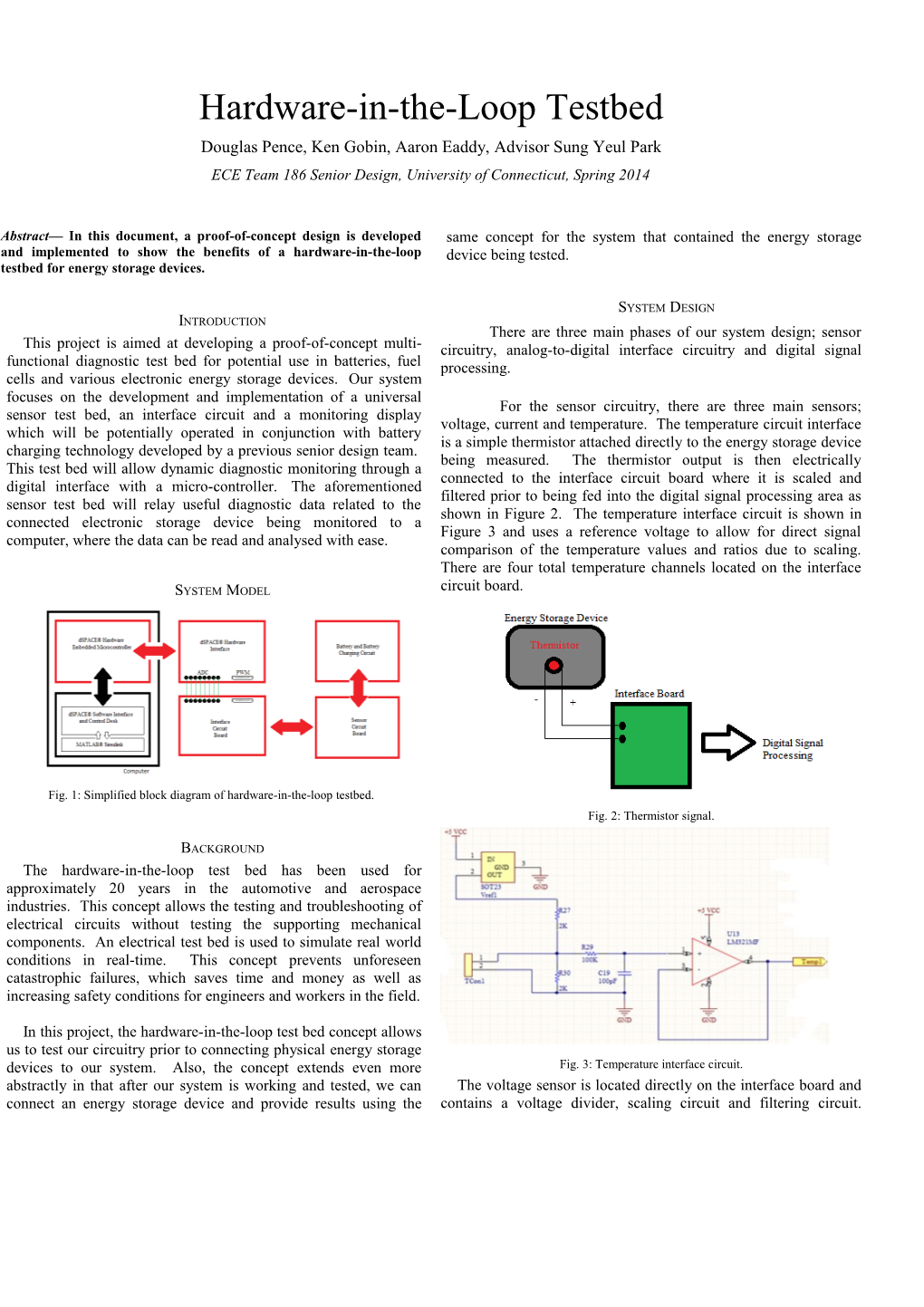

SYSTEM DESIGN INTRODUCTION There are three main phases of our system design; sensor This project is aimed at developing a proof-of-concept multi- circuitry, analog-to-digital interface circuitry and digital signal functional diagnostic test bed for potential use in batteries, fuel processing. cells and various electronic energy storage devices. Our system focuses on the development and implementation of a universal For the sensor circuitry, there are three main sensors; sensor test bed, an interface circuit and a monitoring display voltage, current and temperature. The temperature circuit interface which will be potentially operated in conjunction with battery is a simple thermistor attached directly to the energy storage device charging technology developed by a previous senior design team. being measured. The thermistor output is then electrically This test bed will allow dynamic diagnostic monitoring through a connected to the interface circuit board where it is scaled and digital interface with a micro-controller. The aforementioned filtered prior to being fed into the digital signal processing area as sensor test bed will relay useful diagnostic data related to the shown in Figure 2. The temperature interface circuit is shown in connected electronic storage device being monitored to a Figure 3 and uses a reference voltage to allow for direct signal computer, where the data can be read and analysed with ease. comparison of the temperature values and ratios due to scaling. There are four total temperature channels located on the interface SYSTEM MODEL circuit board.

Fig. 1: Simplified block diagram of hardware-in-the-loop testbed. Fig. 2: Thermistor signal.

BACKGROUND The hardware-in-the-loop test bed has been used for approximately 20 years in the automotive and aerospace industries. This concept allows the testing and troubleshooting of electrical circuits without testing the supporting mechanical components. An electrical test bed is used to simulate real world conditions in real-time. This concept prevents unforeseen catastrophic failures, which saves time and money as well as increasing safety conditions for engineers and workers in the field.

In this project, the hardware-in-the-loop test bed concept allows us to test our circuitry prior to connecting physical energy storage devices to our system. Also, the concept extends even more Fig. 3: Temperature interface circuit. abstractly in that after our system is working and tested, we can The voltage sensor is located directly on the interface board and connect an energy storage device and provide results using the contains a voltage divider, scaling circuit and filtering circuit. Capacitors were also placed across the operational amplifier The signal processing was done with the dSPACE® RTL 1104 (OPAMP) supply to eliminate any feedback noise which may be microcontroller. The interface contained 8 ADC inputs and along present. This circuit is shown in Figure 4. For a larger image, with the ability to generate PWM signals and digital inputs and please see Appendix A on Supplemental Materials. There are 4 outputs which were accessible and controllable with Simulink and component voltage channels as well as a total test bed voltage dSPACE® Controldesk. In order to accommodate the 12 sensor channel on the interface board. outputs to the 8 dSPACE® ADC inputs, the interface circuitry needed to utilize synchronized Time Division Multiplexing to be able to input alternating input signals on the same channel. The PWM generated from the dSPACE® controlled both the select bits from the multiplexors in the sensor circuit and the internal switches inside Simulink which allowed bussed alternating data to be channelled and accessed from their own respective variables on Simulink and dSPACE® Controldesk. The dSPACE® RTL contains its own custom blocksets that mirror the dSPACE® Fig. 4: Voltage interface circuit. microcontrollers’ functions and inputs. From within Simulink, the proper gains were added to the current and voltage in order to The four current sensors have their own circuit board separate correct their values. The temperature’s voltage reading was from the interface board to prevent any ground or power issues converted to Fahrenheit based on the expected voltage relative to between the analog and digital signal flow paths. These outputs the resistance value of the thermistor. from the current sensor is then fed into the current sensing circuit on the interface board where it is scaled and filtered prior to digital signal processing. The current sensor is shown in Figure 5 and the current sensing circuit on the interface board is shown in Figure 6. Both of these circuits are shown larger in Appendix A.

Fig. 5: Current sensor.

Fig. 7: Interface circuit.

Fig. 6: Current sensing circuit. EXPERIMENTAL SETUP To achieve the safe and efficient simulation environment The largest and most extensive piece of our design was the mentioned in the background, we used a microcontroller interface board which takes all of the analog sensor inputs and subsystem called dSPACE®. This hardware embedded conditions the signals and prepares them for use by the dSPACE® microcontroller system works directly with MATLAB® Simulink simulation tool. The interface circuit board contains all of the to build the C++ code and arrange the simulated environment sensor signal conditioning circuits, the dSPACE® input 37-pin d- within its system. Parameters can be changed and mathematical sub connector for pulse width modulation (PWM), and two manipulation of the input sensor data from the interface board can multiplexers (MUXs) for Time Division Multiplexing (TDM). be used to calculate useful data, such as State of Charge (SOC), Eight BNC connectors are also on the board and provide a path to State of Health (SOH), and Remaining Useful Life (RUL). transfer the conditioned signals through an Analog-to-Digital Conversion (ADC) interface into dSPACE® for manipulation. A Our experimental setup on senior design presentation day digital isolator separates the digital dSPACE® interface from the consisted of using a bench power supply to simulate voltage and analog and conditioned signals on the board. Separate polygon current changes similar to a battery. We chose the bench supply planes were poured to allow for ground and power isolation across over an actual battery for many reasons. Firstly, it is much safer the digital isolator during PCB manufacturing. This circuit is to have a completely controllable source, which helps predict shown in Figure 7 and the PCB Layout is displayed in Appendix A. circuit operation. Secondly, it was a safety concern with These three components allows us to get the information we need electrochemistry, current flow values, and predictability related to to in the future calculate state of charge, state of health, and the the potential for personal injury. An oscilloscope and digital remaining useful life of the battery. Potential future improvements multimeter were used in conjunction with our circuit to provide to the design include a more compact commercial design for our backup measurements and show signal flow through our circuit. sensor circuit, as well as the ability to expand the number of battery An adjustable potentiometer was used as the simulated load to cells that can be analysed at one time. Eventually preset dSPACE® allow current flow and the current sensing portion of our design to Control Desk layouts can be made so that the user can select from be tested safely and efficiently. Our general layout is shown in multiple layouts to monitor the different characteristics of the Figure 8. energy storage devices.

REFERENCES [1] R. A. Gayakwad, Op-Amps and Linear Integrated Circuits, Prentiss Hall, 2000. [2] dSPACE® Operating Mauals, RTI-1104.

Fig. 8: Experimental layout.

RESULTS Analysis The analysis of the voltage, current, and temperature readings currently contains a lot of ripple in the signal. When processed through dSPACE® and displayed on the computer the signals seem to be getting up to a maximum of 50% ripple. This may have been caused by the errors in the initial PCB design. In the PCB the poured polygons do not seem to transfer the power and ground signals throughout the entire board, which leads us to assume that there might be a break in the polygon at some point in the PCB. In order to get over this problem we had to supply our external current sensor and other ICs that needed the 5V supply using jumpers. Also for the voltage reading there is an isolated ground issue where the BNC for voltage is not grounded to the right reference, thus giving us the wrong value. To fix this problem we used the signal form the BNC and used wires external to the PCB to connect them to the right grounds. For the temperature sensor the scaling will need to be altered in the future to show more minimal changes in temperature. Also, the signal processing model did not incorporate a sample and hold block, so the sample and hold block will need to be utilized in order to hold the channels previous value in periods where the multiplexors are not switched to that specific channel. Appendix A: Supplemental Materials Conclusions The outcome of our Hardware-in-the-loop Testbed design gives us the functionality to diagnose and monitor any type of electronic energy storage device or fuel cell. Our design currently has the capabilities of diagnosing 4 different inputs’ voltage, current, and temperature along with the total voltage and current if these inputs were connected together. We achieve this through three main parts: the dSPACE® microcontroller, interfacing circuit, and sensors.

Printed Circuit Board Design for Interface Board