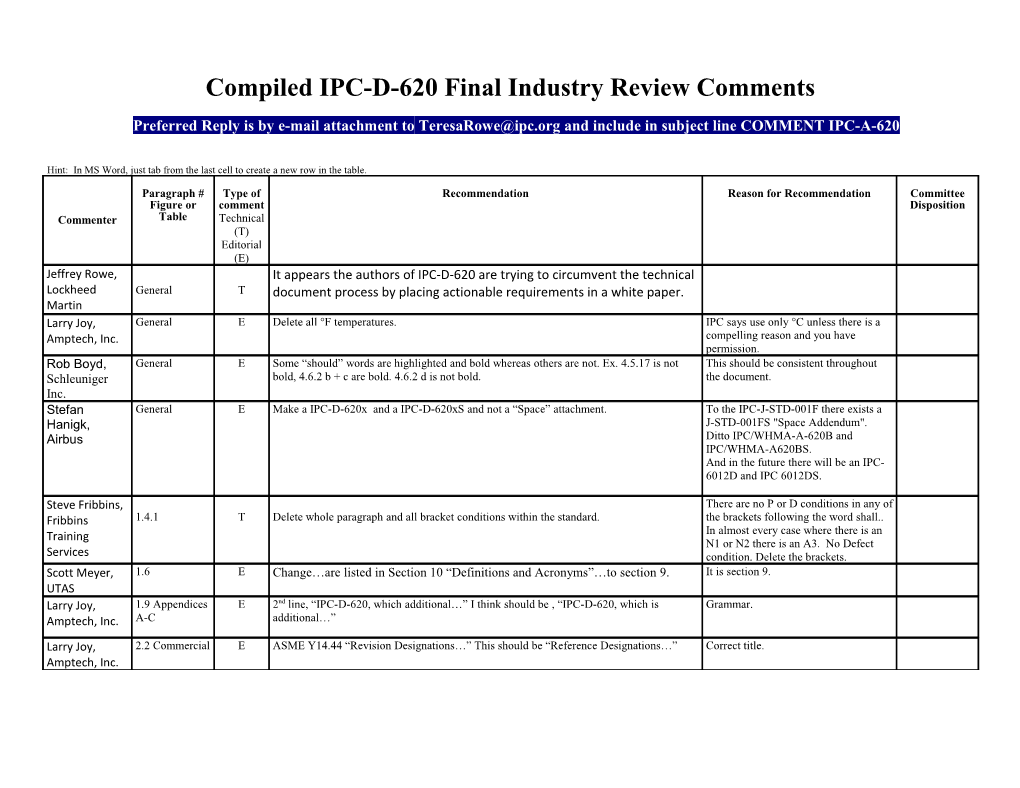

Compiled IPC-D-620 Final Industry Review Comments

Preferred Reply is by e-mail attachment to [email protected] and include in subject line COMMENT IPC-A-620

Hint: In MS Word, just tab from the last cell to create a new row in the table.

Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jeffrey Rowe, It appears the authors of IPC-D-620 are trying to circumvent the technical Lockheed General T document process by placing actionable requirements in a white paper. Martin Larry Joy, General E Delete all °F temperatures. IPC says use only °C unless there is a Amptech, Inc. compelling reason and you have permission. Rob Boyd, General E Some “should” words are highlighted and bold whereas others are not. Ex. 4.5.17 is not This should be consistent throughout Schleuniger bold, 4.6.2 b + c are bold. 4.6.2 d is not bold. the document. Inc. Stefan General E Make a IPC-D-620x and a IPC-D-620xS and not a “Space” attachment. To the IPC-J-STD-001F there exists a Hanigk, J-STD-001FS "Space Addendum". Airbus Ditto IPC/WHMA-A-620B and IPC/WHMA-A620BS. And in the future there will be an IPC- 6012D and IPC 6012DS.

Steve Fribbins, There are no P or D conditions in any of Fribbins 1.4.1 T Delete whole paragraph and all bracket conditions within the standard. the brackets following the word shall.. In almost every case where there is an Training N1 or N2 there is an A3. No Defect Services condition. Delete the brackets. Scott Meyer, 1.6 E Change…are listed in Section 10 “Definitions and Acronyms”…to section 9. It is section 9. UTAS Larry Joy, 1.9 Appendices E 2nd line, “IPC-D-620, which additional…” I think should be , “IPC-D-620, which is Grammar. Amptech, Inc. A-C additional…” Larry Joy, 2.2 Commercial E ASME Y14.44 “Revision Designations…” This should be “Reference Designations…” Correct title. Amptech, Inc. Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Larry Joy, 2.6 Reference E IACS (UR) E11, “E-11 Unified Requirements…1kV up to 15kV… Should be “1 kV” and Proper SI usage. Amptech, Inc. “15 kV”. Larry Joy, 2.6 Reference E Between IPC-2611 and IPC-OI-645 need a line space. To agree with rest of list. Amptech, Inc. Scott Meyer, 2.6 Reference E Between MIL-W-22759 and MIL-W-83575 need a line space. To agree with rest of list. UTAS Scott Meyer, 3.2.2 T Repeat of 3.1 Repeat UTAS Scott Meyer, 3.2.2.2 c E Delete "etc". Use of e.g and etc is redundant. UTAS Scott Meyer, 4.5.1 E Delete "etc". Redundant UTAS Scott Meyer, 4.5.3 E 'c.' Redundant with paragraph under 4.5.3. Redundant UTAS Larry Joy, 4.5.8 FN/HN E 4th line above the 4.5.9 heading, “potentials of +28 Vdc…” It should be “+28 V dc”. No Proper SI usage. Amptech, Inc. Grade… attachment is to be made to the SI unit symbol. Larry Joy, 4.5.9 Glass- E 3rd line, “…be used for in critical” should be “…be used in critical”. Grammar. Amptech, Inc. Like Materials Larry Joy, Figure 4-5 E The dimension of “8.0mm” should be “8.0 mm”. Proper SI usage. Amptech, Inc. Scott Meyer, 4.5.9 E Delete "etc." Redundant UTAS Exception: E/E components (e.g.: connectors, RF feed-through, diodes, components with glass-body seals, fiber optic, etc.) Jeffrey Rowe, IPC-D-620, T Change title from: Lead free tin is not a “technology”. Lockheed 4.5.10 “Lead-Free Tin (<3% Pb) Technology –Control Level 2C (Figure 4-5)” Any reference to it being a technology To “Lead-Free Tin (<3% Pb) (Figure 4-5)” must be removed. Control Level 2C is Martin a specific level based on a number of equipment and system factors. It should not be called out to the exclusion of the other Control Levels.

2 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jeffrey Rowe, IPC-D-620, T Replace all text with the following: GEIA-STD-0005-1 and GEIA-STD- Lockheed 4.5.10 “Lead-free tin materials can significantly impact the performance, reliability and service 0005-2 are the existing industry life of equipment and systems. See GEIA-STD-0005-1 and GEIA-STD-0005-2 for standards for lead-free risk management Martin technical guidance and requirements” and Lead-free Control Plans. They were developed and are maintained by recognized experts on the IPC PERM Council. Scott Meyer, 4.5.10 T Should tin (Sn) be removed throughout the section? Consideration is for any lead- UTAS free metallurgy with whisker concerns. Scott Meyer, 4.5.11 T Delete 'etc' Redundant UTAS Scott Meyer, 4.5.12 E Figure 4.6 should be placed with 4.5.11 (not 4.5.12) UTAS Barrie Dunn, 4.5.18 Splices T 4.5.18 Splices (Figure 4-7) No reason provided. Contact School of (Figure 4-7) information available. Engineering, f. Solder splices 3tilizing 'contained solder rings and flux' for space electronics or University of other hardware exposed to vacuum should be kept to a minimum. They shall not Portsmouth, be used in the vicinity of high voltage equipment or delicate optical systems UK designed to operate in space or vacuum chambers. Note: Flux entrapped within the sleeve and underneath wire insulation after soldering with heat guns, can outgas and give rise to corona discharge. Similarly, outgassed flux can condense onto optical surface as a contaminant, and become darkened under solar radiation. Preferred methods include the manual soldering of such splices using heat sinks to limit flux flow underneath wire insulation, followed by cleaning with lint-free cloth containing IPA , then cover with heat shrink tubing. Residual flux, after soldering is expected (from tests) have a weight loss, WL, of 34 - 63% and a volatile condensable material VCM of 3 - 12% when tested to ASTM E595 and ECSS Q-ST-70-02.

3 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Dave Kelly, Daniels Page 24, 4.7 (f) T Connectors that are not self-locking, and which are used in high vibration, Changes shown in red text… Manufacturing mechanical shock, or thermal-cycling environments, shall [A1A2A3] be Corp. (DMC) The referenced document for Safety capable of being safety wired, Safety Cabled, staked, or locked with thread Wire, Etc. is: adhesive. (1) Adhesives / doping / staking compounds shall [A1A2A3] be compliant NASM 33540 Safety Wiring, with flammability and outgassing requirements. Safety Cabling, Cotter Pinning, (2) Safety wire / lock wire, adhesives, and staking shall not [A1A2A3] be General Practices for used to secure the coupling mechanism in applications where the connector is frequently mated / demated during normal operations, but Which is listed on page 10 of this document. Safety Cable is an approved may be used to secure backshells and other components not loosened and preferable method of threaded during demating. fastener security in that document, and Note: Cutting the safety wire may create an unacceptable metallic FOD concern, should be so stated in the IPC-620 or present a sharp edge, puncture, snagging or injury concern to operating series documents. personnel. Safety Cable can minimize these conditions, and is a preferred retention system to safety wire.

Scott Meyer, 4.7.h E Delete 'etc' Redundant UTAS Scott Meyer, 4.7.1 a (1) E Delete 'etc' Redundant UTAS Scott Meyer, 4.7.1 a (2) E Delete 'etc' Redundant UTAS Larry Joy, 4.7.3 Pin E Why is d.(2) indented instead of at the left margin as in (1) and (3)? Correct indentation. Amptech, Inc. Assignment Scott Meyer, 4.7.4 E Delete 'etc' Redundant UTAS Scott Meyer, 5.1 d T All info in 'd' is contained in 'e'. UTAS Scott Meyer, 5.4.2 E Define EEDS Clarity UTAS Larry Joy, 5.5.2 E Paragraph after Figure 5-1, 4th line, “…(e.g..:…”. There are too many periods, should be Grammar/ Amptech, inc. Separation of “…(e.g.:…”. Redundant Systems

4 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Rob Boyd, 6.1 Wire T - Wire and connector combinations for crimped contact application shall [N1,A2,A3] be We have seen some applications where Schleuniger Terminations designed such that the combination when properly executed provides a gas-tight crimp. the terminal specified is not best suited Inc. - The designer shall [N1,A2,A3] ensure via microsections, etc. that a gas-tight crimp is for the wire size and does not result in a achieved with the specified wire/connector combination. gas-tight (e.g. good quality) crimp. Sometimes the wire size is within the technical specification of the terminal but a “properly executed” crimp does not provide a gas-tight connection. the designer should ensure via microsections, etc. that a gas-tight crimp is achieved Rob Boyd, Table 4 T - Ultrasonic splicing is a very common method for splicing (e.g. automotive) but it is not Schleuniger included in the table of acceptable splicing methods. Inc. Scott Meyer, 6.1 d E CMA to definitions. UTAS Scott Meyer, 6.4 E Use i.e. UTAS Rob Boyd, 6.9.3 Coaxial T - Change location of “Unless specified by the User,…” to include the entire statement. Many coaxial cables used outside the Schleuniger Cable “Unless specified by the User, Coaxial cable shall [N1A2A3] be identified by a military are black and continuous Inc. colored marker of 2.5 cm [1 in] nominal width, at intervals not greater than 61 labeling is not required. Most often a cm [24 in] of length and within 15 cm [6 in] of termination. The color of the white ink is used. marker shall [N1A2A3] be solid violet (VIO, 7) in accordance with ANSI/EIA- 359-A.” Scott Meyer, 6.9.4 c (1) E i.e. UTAS Scott Meyer, 6.9.4 c (2) E i.e. UTAS Larry Joy, 6.9.4 E a., 1st line at end, “…marker shall [N1A2A3] may be…” Delete the “may”. Grammar. Amptech, Inc. Connectors Rob Boyd, 7.1 E Unless otherwise specified in the contract, the Supplier shall [A1A2A3] be The word SUPPLIER is in all caps. Schleuniger responsible for the performance of all inspections and test requirements as Earlier references do not use all caps. Inc. specified in IPC/WHMA-A-620 and (if applicable) IPC/WHMA-A-620X-S. The Supplier may use their own facility, or any other facilities for the performance of the inspection and test requirements specified herein, unless disapproved by the User, or as otherwise specified in the contract. Larry Joy, 9.4 E ANSI American National Standards. The word “Institute” needs to be added. Correct title. Amptech, Inc.

5 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Larry Joy, 9.8 E Bend Radius. Add a line space above 9.8. Correct spacing. Amptech, Inc. Larry Joy, 9.15 E Cable, Coaxial, Flexable Flexable. The 2nd “Flexable” just needs to be capitilized, not Grammar. Amptech, Inc. bolded, as it begins the sentence. Larry Joy, 9.24 E 3rd line, at end, “5V and 25 V” should be “5 V and 25 V”. Proper SI usage. Amptech, Inc. Larry Joy, 9.24 E 1st line, “…from 5 to 25 V…” should be “…from 5 V to 25 V… Proper SI usage. Amptech, Inc. Larry Joy, 9.24 E 4th line at end, “…1V to 10V…” should be “…1 V to 10 V…” Proper SI usage. Amptech, Inc. Larry Joy, 9.24 E 6th line, “between 5V and 25V…” should be “between 5 V and 25 V…” Proper SI usage. Amptech, Inc. Larry Joy, 9.24 E Last line, “between 1V and 10V.” should be “between 1 V and 10 V.” Proper SI usage. Amptech, Inc. Larry Joy, 9.24 E In this clause and throughout the document the word “microsecond” or “microseconds” Proper SI usage. Amptech, Inc. should be replaced with “µs”. Larry Joy, 9.25 E 1st line, “…below 10V and less than 5A…” should be “…below 10 V and less than 5 A…”. Proper SI usage. Amptech, Inc. Larry Joy, 9.25 E 2nd line, “…less than 1V…” should be “…less than 1 V…” Proper SI usage. Amptech, Inc. Larry Joy, 9.25 E 3rd line, “…less than 5V…” and “…less than 1V…” should be “…less than 5 V…” and “… Proper SI usage. Amptech, Inc. less than 1 V…”. Larry Joy, 9.25 E 4th line, “…less than 5V…” should be “…less than 5 V…”. Proper SI usage. Amptech, Inc. Larry Joy, 9.27 E 2nd line, “10V” should be “10 V”. Proper SI usage Amptech, Inc. Larry Joy, 9.29 E 2nd line, “10V” should be “10 V” in two places. Proper SI usage. Amptech, Inc. Larry Joy, 9.29 E 3rd line, “25V” should be “25 V”. Proper SI usage. Amptech, Inc. Larry Joy, 9.30.1 E 1st line, “10V” and “5A” should be “10 V” and “5 A” respectively. Proper SI usage. Amptech, Inc. Larry Joy, 9.30.1 E 2nd line, “1V” should be “1 V”. Proper SI usage. Amptech, Inc. Larry Joy, 9.30.1 E 3rd line, “5V” should be “5 V” and “1V” should be “1 V”. Proper SI usage. Amptech, Inc.

6 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Larry Joy, 9.30.1 E 4th line, “5 V” should be “5 V”. Proper SI usage. Amptech, Inc. Larry Joy, 9.30.2 E 1st line, “5 to 25 V” should be “5 V to 25 V”. Proper SI usage. Amptech, Inc. Larry Joy, 9.43 E At the end, “Torr” should be “torr”. Units of measure are considered common nouns and Grammar. Amptech, Inc. are not capitilized. Larry Joy, 9.47 E Change “Association” to “Alliance”. Proper name title Amptech, Inc. Stefan Apendix A; T It was not defined what is a military application/product, and what is called a space In space applications, it may be that Hanigk, Reference application/product. extreme mechanical loads in the starting Airbus 4.5.20 (new) phase and thermal cyclic stresses occur It is not defined whether it is to use risk to the application or for the people who applied. during operation. In addition, an operation in vacuum. NEW: For military applications, there is a Parylene-C coatings shall not be used without user approval. long-term mechanical stress without vacuum. There is an unclear definition of military space applications (e.g. satellites).

Barrie Dunn, Appendix B T Cert. Processes No reason provided. Contact School of Storage shelf life: information available. Engineering, add: silver-coated copper wire that has passed the red-plague corrosion test (e.g University of ECSS Q-70-20), or wires that have full traceability that ensures they have been Portsmouth, stored in dry, nitrogen filled bags or other containers with activated desiccant UK (ref 3.6.1.d) should have unlimited storage life. Wire refers to cut lengths or long stranded wires and cables stored on reels.

7 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Barrie Dunn, WP-013 RED T This is a useful document, Good to see the ESA work is cited and ECSS Q-ST-70-20 See recommendation. School of PLAGUE is a Ref Doc. In Europe this standard is applied by all the wire and cable Engineering, CONTROL manufacturers supplying to ESA spacecraft. Years of experience with this University of PLAN standard and its requirement for routine Anthony and Brown testing has Portsmouth, prevented the red plague problems seen in earlier years. UK After the ref to my book

...... Wiley-Praxis; 1997; ISBN 0-471-96428-X you could indicate (the revised edition of this book will be published by Springer at end-2015).

Larry Joy, WP-013 RED E 4th line, “…often contain and outgas small amounts of sulfur.” Think this should be “… Grammar Amptech, Inc. PLAGUE often contain an outgas of small amounts of sulfur.” CONTROL PLAN Page 2, Chemical attack. Larry Joy, WP-013 RED E There are several pictures that overlap and block some text. Rearrange the pictures and text To make presentation clear. Amptech, Inc. PLAGUE as necessary. CONTROL PLAN Page 2, FIGURE 2. Jim Blanche WP-013 RED T Delete all “/cupric”. Red plague is cuprous oxide, not cupric and Garry PLAGUE oxide. McGuire, CONTROL MARSHALL Global FLIGHT SPACE CENTER Jim Blanche WP-013 RED E After the first paragraph, delete all “cuprous oxide corrosion” and just call it Red Plague in It is called a Red Plague Control Plan. st and Garry PLAGUE the document. Once it is defined in the 1 paragraph, there is no reason to constantly keep McGuire, CONTROL repeating it. MARSHALL Global FLIGHT SPACE CENTER

8 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-013 RED E Delete the paragraphs for “Inadequate Silver Coating Thickness”, “High Temperature”, and They are repeats of the three paragraphs and Garry PLAGUE “Chemical Attack”. in front of them. McGuire, CONTROL MARSHALL Page 2 FLIGHT SPACE CENTER Jim Blanche WP-013 RED T Top paragraph, last sentence - Exposure to atomic oxygen (AO) in spaceflight applications This condition should preclude red and Garry PLAGUE has been shown to tarnish and pit silver coatings. plague since being in space would eliminate the moisture necessary for the McGuire, CONTROL Clarify or delete galvanic couple? MARSHALL Page 2 FLIGHT SPACE CENTER Jim Blanche WP-013 RED T From: High Temperature, last sentence - This effect is typically experienced only in long If the wire is going to be operated and Garry PLAGUE duration operation at temperatures beyond the wire’s continuous rating, or in instances above its continuous rating for long where the wiring is exposed to excessive heat during test or highly accelerated burn-in. durations there may be bigger problems McGuire, CONTROL than Red Plague that does not rapidly Page 2 MARSHALL To: High Temperature - This effect is typically experienced in instances where the wiring cause failure. FLIGHT SPACE is exposed to excessive heat during test or highly accelerated burn-in. CENTER Jim Blanche WP-013 RED E Reword to: The documents cited should not be and Garry PLAGUE The authority for this document derives from the Red Plague Control requirements in the revision specific since this white paper space addendums (addenda?) to IPC/WHMA-A-620, Requirements and Acceptance for will probably exist in perpetuity. McGuire, CONTROL 1.4 Cable and Wire Harness Assemblies, and IPC J-STD-001, Requirements for Soldered For the same reason, there is no reason MARSHALL Electrical and Electronic Assemblies. to cite the specific clause numbers as FLIGHT SPACE they may change over time. CENTER Jim Blanche WP-013 RED T? 1st sentence: Delete “design”. The reason for taking this out of the and Garry PLAGUE design document was so that it can apply to storage and fabrication McGuire, CONTROL 1.5 processes as well. MARSHALL FLIGHT SPACE CENTER Jim Blanche WP-013 RED E Delete one of these. These are redundant. The “less and Garry PLAGUE stringent” plan allowed by “c” is still an alternate control plan. McGuire, CONTROL MARSHALL 1.9.b & .c FLIGHT SPACE CENTER 9 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-013 RED T Label the third column - Coating Thickness, or change the title of the table to Table B-1 Just “Thickness” is subject to and Garry PLAGUE Conductor Strand Material and Coating Thickness. misinterpretation as the strand thickness, even though 3.2 immediately McGuire, CONTROL following does clarify it. MARSHALL Table B-1 FLIGHT SPACE CENTER Larry Joy, WP-013 RED E 1st line, “…these documents fall in order…” Close up the space, should be, “…these Proper editing. Amptech, Inc. PLAGUE documents fall in order…” CONTROL PLAN 2.4 REFERENCE DOCUMENTS. Larry Joy, WP-013 RED E “1 Micrometer…” should be “1 µm…” Proper SI usage. Amptech, Inc. PLAGUE CONTROL PLAN 3.2.1. Jim Blanche 3.2.1 T Primary and shield conductors shall have a coating thickness of not less than 1 μm [~40 Average is made up of less than and and Garry μin] average, when measured in accordance with ASTM B 298-07. more than the average. “Not less than X average” is as meaningless as “average McGuire, minimum” thickness for copper plating MARSHALL on a through-hole wall. If ASTM B FLIGHT SPACE 298-07 takes an average then the 1µm CENTER is still ok.

Larry Joy, WP-013 RED E “2 Micrometer…” should be “2 µm…” Proper SI usage. Amptech, Inc. PLAGUE CONTROL PLAN 3.2.2. Jim Blanche WP-013 RED T See above comment to 3.2.1…Delete “average”. and Garry PLAGUE McGuire, CONTROL MARSHALL PLAN 3.2.2 FLIGHT SPACE CENTER

10 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-013 RED T Conflicts with 3.2.1 It doubles the thickness for the same and Garry PLAGUE thing. – Clarify the difference. McGuire, CONTROL MARSHALL PLAN 3.2.2 FLIGHT SPACE CENTER Jim Blanche WP-013 RED E Correct the list to a. b. and c. rather than a. a. c. Typo and Garry PLAGUE McGuire, CONTROL MARSHALL PLAN 3.2.3 FLIGHT SPACE CENTER Jim Blanche WP-013 RED T Second a. - Must samples of every roll of wire be microsectioned and analyzed by a lab and Garry PLAGUE certified to IPC-QL-653A or it that done by the wire manufacturer? McGuire, CONTROL MARSHALL PLAN 3.2.3 FLIGHT SPACE CENTER Jim Blanche WP-013 RED T/E ? White Plague – Reference WP-014 here. Or delete this clause because a white paper on Make sure the reader knows WP-014 . and Garry PLAGUE white plague exists. exists McGuire, CONTROL MARSHALL PLAN 3.4 FLIGHT SPACE CENTER Jim Blanche WP-013 RED T Limited Life Article - Document what action, if any, is called for with a cable incorporating Clarity and Garry PLAGUE silver-coated copper conductors that has been in use for more than ten years McGuire, CONTROL MARSHALL PLAN 3.5 FLIGHT SPACE CENTER Jim Blanche WP-013 RED E Add a space between the clause title and start of 1st sentence. and Garry PLAGUE McGuire, CONTROL MARSHALL PLAN 3.6 FLIGHT SPACE CENTER 11 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-013 RED T Delete “irreversible” in both sentences. Discussions during the 2014 Fall and Garry PLAGUE Meeting for 001FS resulted in the committee not using reversible or McGuire, CONTROL irreversible in the text, just requiring a MARSHALL PLAN 3.6.1 & humidity indicator card. Garry McGuire FLIGHT SPACE 3.6.1.e.(2) proposed during that meeting to allow CENTER only irreversible cards but was soundly rejected by the committee (I think availability in the real world was the issue but I’m not sure). The 620 space addendum will probably follow this lead when 620CS opens for revision. Jim Blanche WP-013 RED T Clarify how this humidity indicator (quality record) must be stored to assure it does not If it were to see higher or lower and Garry PLAGUE change over time. humidity in storage it would change its reading. Perhaps the reading at the time McGuire, CONTROL of receipt should be recorded and that MARSHALL PLAN 3.6.1.e. should become the quality record. FLIGHT SPACE (2) CENTER Larry Joy, WP-013 RED E 2nd line, “…for a period of 24 hours…” should be “…for a period of 24 h…” Proper SI usage. Amptech, Inc. PLAGUE CONTROL PLAN 3.6.1g. Larry Joy, WP-013 RED E 2nd line, “…relative humidity is less than 70%RH.” This should be, “…relative humidity is Grammar. Amptech, Inc. PLAGUE < 70 %.” It is redundant to say relative humidity and put RH. CONTROL PLAN 3.6.2. Jim Blanche WP-013 RED T 1st sentence: Change pointer from 4.1.c to 4. There are two methods for capping in and Garry PLAGUE section 4 so the pointer shouldn’t be so specific. McGuire, CONTROL MARSHALL PLAN 3.6.2.b FLIGHT SPACE CENTER

12 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-013 RED T 2nd sentence: Fix the pointer to 4.1. There is no storage discussed in Section and Garry PLAGUE 4….maybe a pointer back to 3.6.1? McGuire, CONTROL MARSHALL PLAN 3.6.2.b FLIGHT SPACE CENTER Larry Joy, WP-013 RED E Same as 3.6.2. Grammar. Amptech, Inc. PLAGUE CONTROL PLAN 3.6.2c. Jim Blanche WP-013 RED T 2nd sentence: Change “Material Review Board (MRB) to “authority”. This document will have broad and Garry PLAGUE applications. Not all contracts, organizations, or programs use MRBs. McGuire, CONTROL MARSHALL PLAN 3.7 FLIGHT SPACE CENTER Jim Blanche WP-013 RED T Deleted “[See 6, NONCONFORMANCE]”. There is no Section 6. An and Garry PLAGUE organization’s quality system will have a defined process for handling non- McGuire, CONTROL conformances. MARSHALL PLAN 3.7 FLIGHT SPACE CENTER Jim Blanche WP-013 RED Use increased magnification than the ranges listed in J-STD-001 or A-620. Recommend a The magnification ranges is the and Garry PLAGUE single magnification of least 10X or 20X. referenced standards are based on land size or wire gauge and range from 1.5X McGuire, CONTROL to 20X depending on feature sizes. Red MARSHALL PLAN 3.7.1.b plague, especially in the onset stages FLIGHT SPACE can be difficult to see and doesn’t care CENTER what wire size it is on. For instance – per A-620, wires larger than 14AWG require no magnification. Larry Joy, WP-013 RED E Note: “…from 3000 – 5000 K…” should be “…from 3000 K to 5000 K…” Proper SI usage. Amptech, Inc. PLAGUE CONTROL PLAN 3.7.1c.

13 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Larry Joy, WP-013 RED E Same as 3.6.2 Grammar. Amptech, Inc. PLAGUE CONTROL PLAN 3.7.2. Jim Blanche WP-013 RED E “cooper wire” should be “ copper wire”. Typo and Garry PLAGUE McGuire, CONTROL MARSHALL PLAN 3.8.2.b FLIGHT SPACE CENTER Jim Blanche WP-013 RED T Either delete “heavier plating thickness” from the parenthetical statement or delete It doesn’t matter how thick the plating and Garry PLAGUE everything after the parenthetical statement. I recommend the latter. is, it will not protect the cut end of the conductor. However, a heavier McGuire, CONTROL thickness will be less prone to exposing MARSHALL PLAN 3.8.2.b copper at the location the tool indenters FLIGHT SPACE form the crimp. CENTER Jim Blanche WP-013 RED T This is awfully specific. Recommend just saying something like “Nonconformances shall Any organization required to have this and Garry PLAGUE be processed in accordance with the Manufacturer’s Quality System.” plan will most likely be required to be If this is not accepted, “MRB” in “c” should be changed to “authority” if the similar compliant to ISO 9000 or AS9100. McGuire, CONTROL previous comment to 3.7 was accepted. They will have a very well defined MARSHALL PLAN 3.9 process for handling non-conforming FLIGHT SPACE products. We don’t need to tell them CENTER how to do it here. Larry Joy, WP-013 RED E 2nd line, “Hold pressure on the ‘tail’ for 20 to 40 seconds…” should be “Hold pressure on Proper SI usage. Amptech, Inc. PLAGUE the ‘tail’ for 20 s to 40 s…” CONTROL PLAN 4.1e. Larry Joy, WP-013 RED E 2nd line, “…+77 °F [+25 °C]…” should be “…+25 °C [+77 °F]…’ And “3 gm” should be Proper SI usage. Amptech, Inc. PLAGUE “3 g”. CONTROL PLAN 5.16. Larry Joy, WP-013 RED E 3rd line, “6 gm” should be “6 g”. Proper SI usage. Amptech, Inc. PLAGUE CONTROL PLAN 5.16.

14 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Dave Hillman, White Paper Technical The 620 committee should either: (1) needs to move these documents into the 620 Per the IPC Committee Chairman’s Rockwell WP-013 Handbook with significant reformatting or (2) make this document a true Appendix of the Handbook: And White 620 specification Collins WP-014 “7.3 Technical Reports, Technical Papers and White Papers There will be times when your committee feels there is a need for published data about a specific area of technology which is either not addressed or current with the times. These reports can fill a need found during the development of a standard or publication or may come from a request by someone or a group of people in the industry. Many technical reports and technical papers are a result of round robin testing programs. These reports and papers can follow a similar format to the IPC Standardization Procedures, but they do not have to meet the procedures. To assure relevance, these reports should go through some level of peer review by a committee or group of SMEs. The final report or paper will be submitted to the TAEC for review and approval. “

The current WP-013/014 is not a white paper per the CC Handbook definition. The WP-013/014 is written as a actionable specification addressing a technical topic germane to the 620 specification. If the committee intention is to have the industry utilize WP- 013/014 as a contractionable control plan addressing Red/White Plague then the technical descriptive information would be best suited in the 620 Handbook and the remaining material as an Appendix that could be selected and invoked as part of the overall 620 specification design protocols.

15 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-014 T The control requirements for White Plague appear to be identical to the control Does it need to be a separate white and Garry WHITE requirements for Red Plague other than specifying the allowable rate of fluorine paper? Have always heard the McGuire, PLAGUE outgassing. mitigation for white plague was to MARSHALL CONTROL not store in in a sealed environment, FLIGHT SPACE PLAN General allowing all the bad stuff to CENTER dissipate into the air. Recommend discussing this with the engineers at GSFC who first brought this to light. “Red” and “White” should be the same paper if the controls are the same. Barrie Dunn, WP-014 T A better Figure D1 with a cleaner cut insulation is preferred. Clarity School of WHITE Engineering, PLAGUE University of CONTROL Portsmouth, PLAN UK Jim Blanche WP-014 E Reword to: The document cited should not be and Garry WHITE The authority for this document derives from the White Plague Control revision specific since this white McGuire, PLAGUE requirements in the space addendum to IPC/WHMA-A-620, Requirements and paper will probably exist in MARSHALL CONTROL Acceptance for Cable and Wire Harness Assemblies. perpetuity. FLIGHT SPACE PLAN 1.4 For the same reason, there is no CENTER reason to cite the specific clause number as it may also change over time. Jim Blanche WP-014 T? 1st sentence: Delete “design”. The reason for taking this out of the and Garry WHITE design document was so that it can McGuire, PLAGUE apply to storage and fabrication MARSHALL CONTROL processes as well. FLIGHT SPACE PLAN 1.5 CENTER

16 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-014 E Second sentence – From: When this standard is contractually invoked, the This is a White Paper and not a and Garry WHITE applicable requirements of this standard shall be imposed on all applicable standard. If it is to be called a McGuire, PLAGUE subcontracts, assembly drawing(s), documentation and purchase orders standard its title should be changed. MARSHALL CONTROL FLIGHT SPACE PLAN 1.5.1 To: When the requirements of this document are contractually invoked, the CENTER applicable requirements of this document shall be imposed on all applicable subcontracts, assembly drawing(s), documentation and purchase orders. Jim Blanche WP-014 E Approval of Departures from this Document- delete a. thru d. The lead-in sentence covers all 4 of and Garry WHITE these items McGuire, PLAGUE MARSHALL CONTROL FLIGHT SPACE PLAN 1.9 CENTER Larry Joy, WP-014 E 1st line, “…of th insulation…” should be “…of the insulation…” Typographical error. Amptech, Inc. WHITE PLAGUE CONTROL PLAN 3.1a. Larry Joy, WP-014 E 2nd line, “24 hours” should be “24 h”. Proper SI usage. Amptech, Inc. WHITE PLAGUE CONTROL PLAN 3.1b. Jim Blanche WP-014 Delete “irreversible” in both sentences. Discussions during the 2014 Fall and Garry WHITE Meeting for 001FS resulted in the McGuire, PLAGUE committee not using reversible or MARSHALL CONTROL irreversible in the text, just FLIGHT SPACE PLAN 3.2.1 & requiring a humidity indicator card. CENTER 3.2.1.d Garry McGuire proposed during that meeting to allow only irreversible cards but was soundly rejected by the committee (I think availability in the real world was the issue but I’m not sure). The 620 space addendum will probably follow this lead when 620CS opens for revision. 17 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-014 T Clarify how must it be stored to assure it cannot change. It is a Quality Record (QR) that is and Garry WHITE subject to change if it sees higher McGuire, PLAGUE humidity in storage. MARSHALL CONTROL FLIGHT SPACE PLAN 3.2.1.d. CENTER (2) Jim Blanche WP-014 T 2nd sentence: Change “Material Review Board (MRB) to “authority”. This document will have broad and Garry WHITE applications. Not all contracts, McGuire, PLAGUE organizations, or programs use MARSHALL CONTROL MRBs. FLIGHT SPACE PLAN 3.3 CENTER Larry Joy, WP-014 E 2nd line, “…from 3000 – 5000°K…” should be “…from 3000 K to 5000 K…” Proper SI usage. Amptech, Inc. WHITE PLAGUE CONTROL PLAN 3.3.1c Note. Larry Joy, WP-014 E 3rd (last) line, “…and the relative humidity is less than 70% RH.” Should be, “…and the Grammar. Amptech, Inc. WHITE relative humidity is < 70%.” Or “…and < 70% RH.” PLAGUE CONTROL PLAN 3.3.1e. Larry Joy, WP-014 E 2nd line, “Maintain pressure on the ‘tail’ for 20 to 40 seconds…” Should be, “Maintain Proper SI usage. Amptech, Inc. WHITE pressure on the ‘tail’ for 20 s to 40 s…” PLAGUE CONTROL PLAN 4.1e. Jim Blanche WP-014 E The paragraph references are not correct. I think 5.1.d should be 3.3.1.d and 4.1 and Garry WHITE should be 3.2.1. McGuire, PLAGUE MARSHALL CONTROL FLIGHT SPACE PLAN 3.3.1.e CENTER

18 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-014 E Change reference to 5.1.d to [I think] 3.3.1.d. and Garry WHITE McGuire, PLAGUE MARSHALL CONTROL FLIGHT SPACE PLAN 3.4.a CENTER Jim Blanche WP-014 T Reword to: Nonconformances shall be processed in accordance with the Any organization required to have and Garry WHITE Manufacturer’s Quality System.” this plan will most likely be McGuire, PLAGUE If this is not accepted, “MRB” in “c” should be changed to “authority” if the required to be compliant to ISO MARSHALL CONTROL similar previous comment to 3.7 was accepted. 9000 or AS9100. They will have a FLIGHT SPACE PLAN 7 which very well defined process for CENTER is actually handling non-conforming products. after 3.4 and We don’t need to tell them how to before 4 do it here. Jim Blanche WP-014 T Delete the 2nd sentence. The requirement is to “seal by and Garry WHITE coating and saturating the exposed McGuire, PLAGUE end…”. User approval should not MARSHALL CONTROL be required for different ways to FLIGHT SPACE PLAN 4.2 accomplish it. CENTER Larry Joy, WP-014 E 2nd line, “air at +77 °F [+25 °C]…” should be “air at +25 °C [+77 °F]…” Proper SI usage. Amptech, Inc. WHITE PLAGUE CONTROL PLAN 5.10.

19 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Dave Hillman, White Paper Technical The 620 committee should either: (1) move this document into the 620 Handbook with Several significant issues with this Rockwell WP-015 significant reformatting or (2) refer this white paper to the IPC PERM Council for white paper: action/implementation and have it removed from inclusion in the 620 specification or (3) Collins include the white paper as an invokeable appendix with significant reformatting addressing (1) Per the IPC Committee Chairman’s the specific topic cable and wire harness assemblies in such a manner as to not conflict Handbook: with the existing IPC PERM Council LFCP specification. “7.3 Technical Reports, Technical Papers and White Papers There will be times when your committee feels there is a need for published data about a specific area of technology which is either not addressed or current with the times. These reports can fill a need found during the development of a standard or publication or may come from a request by someone or a group of people in the industry. Many technical reports and technical papers are a result of round robin testing programs. These reports and papers can follow a similar format to the IPC Standardization Procedures, but they do not have to meet the procedures. To assure relevance, these reports should go through some level of peer review by a committee or group of SMEs. The final report or paper will be submitted to the TAEC for review and approval. “

The current WP-015 is not a white paper per the CC Handbook definition and is written as a actionable specification. The white paper is written beyond the scope of the 620 specification for cable and wire harness assemblies as it addresses components, modules and assemblies in various sections. This white paper could be a 620 Handbook topic with considerable reformatting.

(2) Conflict with IPC PERM Council 20 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jeffrey Rowe, White Paper Technical Remove/delete this document in its entirety. Refer the document to the PERM Council for The document does not meet the Lockheed WP-015 a complete review and any subsequent action/implementation. definition or intent of a white paper. Martin There are numerous errors in the document that I will not go into detail as the document The document content conflicts in absolutely must not be released. numerous places with requirements in other released standards such as GEIA- STD-0005-1, GEIA-STD-0005-2 and GEIA-STD-0006.

The document defaults to Control Level 2C without consideration for the applicable equipment or system.

Barrie Dunn, WP-015 T No specific comments, looks good as it is. You may like to add some of the Clarity School of LEAD-FREE Figures from the ESA Guidelines for a LFCP (ESA STM-285 is attached). I Engineering, CONTROL personally like to include the "audit check list" in Appendix B. University of PLAN (LFCP) Portsmouth, UK Barrie Dunn, WP-015 T As a "living document" some of the: problems vs mitigation solutions contained See recommendation School of LEAD-FREE in the Table 1 vs Table 2 of Appendix A will in time, be modified based on newer Engineering, CONTROL tests and experience. These have proved useful during Material Review Boards University of PLAN (LFCP) when actual hardware is discussed and decisions are urgently needed. Portsmouth, UK Jim Blanche WP-015 E Insert “tin containing less than 3 percent lead (<3% Pb) by weight” after “high-tin Although defined later, it helps the and Garry LEAD-FREE content”. conversation by stating this right up McGuire, CONTROL front. MARSHALL PLAN (LFCP) FLIGHT SPACE 1st page, 1st CENTER sentence Jim Blanche WP-015 T Applicability - Delete 1.5.1, 1.5.2, 1.5.2 are all repeats of and Garry LEAD-FREE 1.3 and state it more clearly. McGuire, CONTROL MARSHALL PLAN (LFCP) FLIGHT SPACE 1.3 CENTER

21 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-015 E Reword to: The documents cited should not be and Garry LEAD-FREE The authority for this document derives from the lead free control requirements in revision specific since this white McGuire, CONTROL the space addendums to IPC/WHMA-A-620, Requirements and Acceptance for paper will probably exist in MARSHALL PLAN (LFCP) Cable and Wire Harness Assemblies, and IPC J-STD-001, Requirements for perpetuity. FLIGHT SPACE 1.4 Soldered Electrical and Electronic Assemblies. For the same reason, there is no CENTER reason to cite the specific clause numbers as they may change over time. Jim Blanche WP-015 T Delete. Verbal correspondence is never and Garry LEAD-FREE accepted in conflict resolutions. If it McGuire, CONTROL isn’t in writing, it didn’t happen. MARSHALL PLAN (LFCP) FLIGHT SPACE 1.6.f CENTER Jim Blanche WP-015 E Delete. Redundant to 1.9.a. “less stringent” and Garry LEAD-FREE is still an alternate. McGuire, CONTROL MARSHALL PLAN (LFCP) FLIGHT SPACE 1.9.b CENTER Jim Blanche WP-015 T 1st sentence, reword to: The Supplier shall establish a Lead Free Control Board Although implied by Table 1, the and Garry LEAD-FREE and document every incidence of use of lead-free tin technology in compliance document does not ascribe who is McGuire, CONTROL with the requirements of this document. responsible for establishing the MARSHALL PLAN (LFCP) Board. FLIGHT SPACE 1.10.a CENTER WP-015 E 2nd sentence: Insert “(see Section 5)” after “LFCP Report”. The addition lets the reader know LEAD-FREE this report will be discussed later. It CONTROL made me pause what this was PLAN (LFCP) because I read it as this white paper 1.10.a is the LFCP Report.

22 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-015 T Add a requirement to establish a lead free control board with the responsibilities As written it seems to presume that and Garry LEAD-FREE and authority as defined in the current 1.10.b, with a typical LFCB as shown in a Lead Free Control Board already McGuire, CONTROL Table 1. exists. MARSHALL PLAN (LFCP) FLIGHT SPACE 1.10.b CENTER WP-015 Lee Wilmot, LEAD-FREE TTM Reference should be J-STD-609A CONTROL E NOTE: J-STD-609B currently proposed Proposed reference has been superseced Technologies, PLAN (LFCP) Inc. 2.3 Jim Blanche WP-015 T The LFCP in this document is specified for Control Level 2C. Isn’t a control plan required for and Garry LEAD-FREE Control Level 2B? McGuire, CONTROL MARSHALL PLAN (LFCP) FLIGHT SPACE 3 CENTER Jim Blanche WP-015 E Correct the paragraph pointer to 3.2.5. and Garry LEAD-FREE McGuire, CONTROL MARSHALL PLAN (LFCP) FLIGHT SPACE 3.a CENTER Jim Blanche WP-015 T “at or below -30C” is a significantly lower temperature than the +13C mentioned +13C=+56F and it may be able to start and Garry LEAD-FREE in the introductory section. They should be consistent, or at least not so far apart there but really doesn’t or many of the tin cans in the pantry would McGuire, CONTROL without some explanation. occasionally disintegrate. MARSHALL PLAN (LFCP) FLIGHT SPACE 3.a CENTER Jim Blanche WP-015 T Lead-Free Tin (Sn) Fourth bullet. – add “printed wiring board (PWB)” to the list PWBs with immersion tin finish are and Garry LEAD-FREE Pb-free tin. McGuire, CONTROL MARSHALL PLAN (LFCP) FLIGHT SPACE 3.1 CENTER 23 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-015 T Delete the note at the end of the section. This is controlled by the governing and Garry LEAD-FREE assembly standards and has nothing McGuire, CONTROL to do with whisker control. MARSHALL PLAN (LFCP) FLIGHT SPACE 3.1 CENTER Jim Blanche WP-015 T Disagree with these requirements for anything less than 2C. These assume a control level of 2C. and Garry LEAD-FREE Is there any requirement for a McGuire, CONTROL control level less that 2C? Many of MARSHALL PLAN (LFCP) the lower levels are to specifically FLIGHT SPACE 3.2 build lead-free hardware and their CENTER control plan, if they have one, might be very different. Jim Blanche WP-015 T Insert “expected mission, including storage,” in front of “life”. “life of the hardware” is and Garry LEAD-FREE ambiguous. The actual life of most McGuire, CONTROL hardware could be in the tens of MARSHALL PLAN (LFCP) years when their expected useful FLIGHT SPACE 3.2.4.1.b life could be much shorter. CENTER Jim Blanche WP-015 E 1st sentence: delete the parenthetical J-STD reference. The sentence is clear without it and and Garry LEAD-FREE keeps the white paper from needing McGuire, CONTROL unnecessary updates as the MARSHALL PLAN (LFCP) referenced standards in the FLIGHT SPACE 3.2.4.2 Authority paragraph go through CENTER revisions. Consider this for the following paragraphs where there are multiple references to 001 and 620. Larry Joy, WP-015 E (1) “Not greater than +4 °C/sec. [+7.2 °F/sec.]” should be “≤+4 °C/s [+7.2 °F/s]”. Proper SI usage. Amptech, Inc. LEAD-FREE CONTROL PLAN (LFCP) 3.2.4.2c.

24 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Larry Joy, WP-015 E (2) “Not greater than –6 °C/sec. [-10.8 °F/sec.]” should be “≤-6 °C/s [-10.8 °F/s]”. Proper SI usage. Amptech, Inc. LEAD-FREE CONTROL PLAN (LFCP) 3.2.4.2c. Larry Joy, WP-015 E 1st line, “5 seconds” should be “5 s”. Proper SI usage. Amptech, Inc. LEAD-FREE CONTROL PLAN (LFCP) 3.2.4.2d Larry Joy, WP-015 E 4th line, “3 seconds” should be “3 s”. Proper SI usage. Amptech, Inc. LEAD-FREE CONTROL PLAN (LFCP) 3.2.4.2d Jim Blanche 3.2.4.2.e T Reword to: The current words would require and Garry All components shall be properly cleaned, visually inspected per J-STD-001ES organizations to unnecessarily McGuire, [4.2.3] and [11.2.2]. Moisture sensitive components shall be demoisturized per demoisturize a lot of components MARSHALL IPC-1601, J-STD-020, J-STD-033, or other demoisturization schedule approved (glass, ceramic, metal). FLIGHT by the User. SPACE CENTER Jim Blanche 3.2.4.2.1 E Fix Hsd to HSD in title and Garry McGuire, MARSHALL FLIGHT SPACE CENTER Larry Joy, WP-015 E “Embedment/Encapsulation (Figure C-5)”. I believe this should be “3.2.4.4” and “Figure Editing errors. Amptech, Inc. LEAD-FREE C-5” should be “Figure 4” CONTROL PLAN (LFCP) 3.244

25 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Larry Joy, WP-015 E 2nd line, “A FEMA is” should be “An FEMA is”. Grammar. Amptech, Inc. LEAD-FREE CONTROL PLAN (LFCP) 4.10 Lee Wilmot, WP-015 TTM LEAD-FREE Spell “Tin” correctly Technologies, CONTROL E Correct spelling of tin Inc. PLAN (LFCP) 4.15 Larry Joy, WP-015 E “Lead-Free Tim (Sn)” should be “Lead-Free Tin (Sn)”. Spelling/typographical error. Amptech, Inc. LEAD-FREE CONTROL PLAN (LFCP) 4.15 Stefan WP-015; T Add: More information Hanigk, "Lead-Free The risk of tin whiskers shall be mitigated. The method of mitigation is dependent on the It provides the reader with the Airbus Control Plan" component (i.e. lead materials and construction). Whiskers are not only observed on lead information, which is a whisker. The free tin but also on zinc, cadmium, Indium, silver, aluminum, tin silver copper alloys, gold whisker when using lead-containing Technical and on lead (Pb). materials is a rather unknown Background Tin (Sn) whiskers are highly conductive ‘‘hair-like’’ protrusions of tin that can grow from phenomenon. Practice in the use of the surface of pure tin plated parts (parts having <3% lead (Pb)) due in part to compressive lead-free materials, such as in the stress from the tin plating process or from other sources of compressive stress (e.g., industry for about 10 years, mitigation tightening of a fastener). Tin whiskers have been known to result in equipment operating measures to avoid whiskers are problems due to an electrical short-circuit resulting from a tin whisker bridging the gap necessary. between conductors or between conductors and ground. A LFCP provides recommendations to minimize but not completely eliminate risks pertaining to tin whisker growth.

Compressive stress by Coefficient of Thermal Expansion mismatch The maximum achievable compressive stress in the tin layer is the yield limit of tin (~ -15MPa). Cu base material (Coefficient of Thermal Expansion (CTE) ~ 16ppm) does show only a small interval where compressive stress can be achieved (20°C – 80°C). FeNi42 base material (CTE ~4ppm) does show a larger interval, where a compressive stress can be achieved (+10°C – 80°C). However: The texture of the plating is most relevant for whisker growth.

26 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Stefan WP-015; ongoing Depending on the texture of the tin a component is not prone to grow whisker or has a high Hanigk, "Lead-Free risk to show whisker after TC-testing. The texture is depending on the electrolyte and the Airbus Control Plan" process parameters. The texture can be optimized. Minimization by low mismatch of CTE is reducing whisker growth. CTE of Sn depending Technical on grain orientation: e.g. [101] with 36.6ppm, [220] with 13.4ppm. Grain orientation is Background depending from chemistry and process parameters.

Compressive stress by external force Whiskers are growing concentrated in an area around the location of the mechanical imprint. It is assumed, that the main whisker growth will take place in an area, where the yield limit is reached, but no plastic deformation took place. Every stress which is causing the necessary stress gradient and level (driving force) will cause whisker growth in all applications, e.g. molding, press-fit, connectors, etc., therefore no molding over bright tin shall take place. A pin shall never be pressed into a plated through hole as it is deforming the crystalline structure and causes a stress gradient which leads to whisker growth. Bending processes are not causing whisker growth if the layer system is not totally destroyed (e.g. cracks, welding of Al, etc.).

Stefan WP-015 E 1.3 a can be deleted 1.3.a is a copy from 1.5.2 Hanigk, 1.3a Airbus Stefan WP-015 E 1.3 b can be deleted 1.3.b is a copy from 1.5.3 Hanigk, 1.3.b Airbus Stefan WP-015 E Rewording from: Hanigk, 1.4 "Authority" Airbus To: "Responsibilities" in headline and text. IPC J-STD-001 is now version "F" and "FS".

Stefan WP-015 T Delete f Verbal correspondence or e-mails are Hanigk, 1.6.f not contractual Airbus Stefan WP-015 T Rewording from: According the IPC-J-STD-001FS is an Hanigk, 1.9 …with the User having waiver authority. approval by the USER required. Airbus To: …with the User having approval authority.

27 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Stefan WP-015 E Change from in headline and in graphical representation from "Table-1" to "Figure-1" It is a figure not a table Hanigk, 1.10 Airbus Stefan WP-015 E IPC J-STD-001 is now version "F" and "FS" Hanigk, 2.2 Airbus Stefan WP-015 E Delete … (see 3.2.6.) Chapter 3.2.6 does not existing Hanigk, 3.a Airbus Stefan WP-015 T Delete complete point a. The application of a LFCP at Hanigk, 3.a temperatures of about -30 ° is therefore Airbus unnecessarily. This is contrary to the requirements of IPC-J-STD-001FS and IPC/WHMA-A-620BS.

Stefan WP-015 T Add a second note: Add a link to J-STD-609, ref. to chapter Hanigk, 3.1 Many component manufacturers use J-STD-609 to classify their termination finishes. 3.2.2 Airbus Stefan WP-015 E Change from: Hanigk, 3.2.1 The default lead-free control level shall be 2C. Airbus To: The recommended default lead-free control level shall be 2C.

28 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Stefan WP-015 T LEAD-FREE TIN IDENTIFICATION AND REPORTING Add reference to J-STD-609 Hanigk, 3.2.2 The standard IPC-J-STD-609 describes the marking of components and the Marking of surface materials as a part Airbus labeling of their shipping containers to identify their 2nd level terminal finish or of the labeling from the components via material and applies to components that are intended to be attached to boards or the "e#" code. assemblies with solder or mechanical clamping or are press fit termination material and finish alloy compositions of piece parts. All components are checked in the incoming inspection for Lead Free of connections and external surfaces that appear similar to tin in color and texture (i.e. matte nickel, silver etc.). An X-ray fluorescence (XRF) or similar testing must be used. This standard uses codes e0 to e9 to classify termination finishes. See table below for an explanation of the codes:

Code - Explanation e1 - tin-silver-copper (SnAgCu) with silver content greater than 1.5% and no other intentionally added elements e2 - tin (Sn) alloys with no bismuth (Bi) nor zinc (Zn), excluding tin-silver-copper (SnAgCu) alloys in e1 and e8 e3 - tin (Sn) e4 - precious metal (e.g., silver (Ag), gold (Au), nickel-palladium (NiPd), nickel- palladium-gold (NiPdAu) (no tin (Sn)) e5 - tin-zinc (SnZn), tin-zinc-other (SnZnX) (all other alloys containing tin (Sn) and zinc (Zn) and not containing bismuth (Bi)) e6 - contains bismuth (Bi) e7 - low temperature solder (≤150 °C) containing indium (In) [no bismuth (Bi)] e8 - tin-silver-copper (SnAgCu) with silver content less than or equal to 1.5%, with or without intentionally added alloying elements. This category does not include any alloys described by e1 and e2 or containing bismuth or zinc in any quantity. e9 - symbol - unassigned.

Materials Ag Silver Bi Bismuth Cu Copper Pb Lead Ni Nickel Fe Iron Pd Palladium Au Gold Sn Tin short terms of materials

29 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Stefan WP-015 T APPROVAL TABLES Add this chapter Hanigk, 3.2.2.A The best method for preventing tin whiskers in a design is not to use any component with a Tables are from and IPC-AJ-820A Airbus tin plated finish whenever possible. However, if a tin plated component finish must be used "Assembly and Joining Handbook" because no other technically acceptable component finish is available, then there should be some form of tin whisker mitigation method employed by the component manufacturer, or The tables must be added in the new by others, as applicable. chapter 3.2.4.1.2 of this document.

The following table-a and table-b shows commonly available termination finishes on common base materials.

Table-a; Component Lead-Free Finishes

Table-b; Termination Finishes for Separable Connectors (and wires, cables, terminations, clamps, etc.)

Table-a and -b is in the annex to this document.

Stefan WP-015 T SOLDER ALLOYS ON PRINTED CIRCUIT BOARDS (BARE BOARDS) Add this chapter Hanigk, 3.2.2.B The manufacturer shall identify the solder alloys used on printed wiring boards in such a In general, we must take what the Airbus manner that users, maintainers, and repairers of the equipment have sufficient information market offers for EEE-Components etc. to perform their functions reliably. The alloy identification is documented in the drawing of In the case of PCBs we can free choose the bare board. Common PCB finishes are ENIG or SnPb-fused. Do not use immersion the plating. So here is an indication of silver or immersion tin. preferred PCB plating sense.

Stefan WP-015 T ASSISTANCE AND RECOMMENDATIONS FOR COMPONENT SELECTION Add this chapter Hanigk, 3.2.2.C In the following some recommendations to assist in the choice of some special platings and It is advisable for the user to provide Airbus component housings are presented. information to the hand around him dealing with lead-free surfaces / Avoid the use of Pure Tin Plated Components materials. The best strategy to prevent tin whisker induced failures is to avoid using pure tin plating altogether. Finishes such as tin lead (SnPb), nickel palladium (NiPd), nickel palladium gold (NiPdAu), nickel gold (NiAu) do not grow whiskers. Historically the predominant whisker mitigation strategy has been the addition of lead to the tin plating on the terminations (minimum of 3% Lead by weight). These parts can be used with no tin whisker mitigation. It is recognized that avoiding tin containing finishes is not always possible; it is however, the best choice.

30 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Stefan WP-015 T & W The best method for preventing tin whiskers in a design is not to use any component with a The mitigation strategies can be divided Hanigk, 3.2.4. tin plated finish whenever possible. However, if a tin plated component finish must be used into two groups. First in design and Airbus because no other technically acceptable component finish is available, then there should be second in technical/replating. some form of tin whisker mitigation method employed by the component manufacturer, or by others, as applicable. The HSD with SnPb Solder is the preferred mitigation strategy. This Lead-free Tin (Sn) technology shall be protected by at least two (2) design or process information clearly belong in the mitigation techniques to reduce or eliminate the risks created by metallic whisker formation chapter on HSD. and/or tin pest in the expected end-use application / environment. Point a. Design and Topography (no MITIGATION STRATEGIES modifications) 3.2.4.1) Design Selection of components acc. Table-a & 3.2.4.1.1) Design and Topography -b (new) 3.2.4.1.2) Selection of components acc. Table-a & -b Point b. Spacing/component 3.2.4.1.3) Spacing/component positioning positioning (with modifications) Point c. Finish-Adjacent Surfaces (no 3.2.4.2) Technical modifications) 3.2.4.2.1) HSD 3.2.4.2.2) Replating 3.2.4.2.3) Reflowed Tin 3.2.4.2.4) Conformal Coating 3.2.4.2.5) Encapsulation

31 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Stefan WP-015 T Electronic component lead and terminal finishes refer to the solderable finishes applied to new Hanigk, 3.2.4.1.2 electronic components. These include lead-frames for ICs, leads for other solderable Airbus components, terminations for discrete components and solderable finishes applied to plated covers on electronic components. Lead-frames are the metal tabs that electrically connect the chip die to the printed circuit board. The majority of current lead-frames are made of copper or a copper alloy. The options available are shown in the approval table-" short terms of materials". Electronic component lead and terminal finishes refer to the solderable finishes applied to electronic components. These include lead-frames for ICs, leads for other solderable components, terminations for discrete components, and solderable finishes applied to plated covers on electronic components. Lead-frames are the metal tabs that electrically connect the chip die to the printed circuit board. The majority of current lead-frames are made of copper or a copper alloy. In addition, some lead-frames are still made of an iron- nickel alloy (e.g., alloy 42). Typically, the lead-frames are purchased without a finish (or plating) and processed at the manufacturing site into a package. Tin lead-frame plating is done after the molding operation. Historically, the predominant lead-frame finish was a tin- lead alloy with typical nominal Pb content ranging from 7% to 37% Pb. However, this transitioned primarily to tinbased Pb-free alloys in the 2005/2006 timeframe. About 10% of the lead-frame finishes are NiPdAu, which is purchased in a pre-plated form by the component assembly manufacturer.

Replace figure-3 with this picture:

32 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Stefan WP-015 T Table-a lists all the lead-free finishes that the User Group has identified as offered or Hanigk, 3.2.4.1.2 ongoing proposed finishes for electronic components. For each finish, which includes under-layer Airbus plating if applicable, and associated base material, the finishes are placed in one of three categories. This table is specific to tin whiskers and does not directly address other possible issues and concerns with these finishes. Category 1 indicates that the proposed solderable finish will be accepted by the User Group without any tin whisker testing. Category 2 indicates that the finish will only be accepted if it passes the whisker test requirements given in JESD201, Environmental Acceptance Requirements for Tin Whisker Susceptibility of Tin and Tin Alloy Surface Finishes. Previous data generated according to the iNEMI Tin Whisker Acceptance Test Requirements may also be acceptable to users. A Category 3 rating indicates that User Group members consider this finish a high risk for tin whiskers and will not accept it in any case, regardless of tin whisker test data provided. The table summarizes what the majority of companies will accept for each finish. Suppliers should be aware that though this table represents the majority opinion, individual company requirements may vary.

Stefan WP-015 T Rewording from: Hanigk, 3.2.4.2.1 HSD HSD solder alloy shall be Sn60Pb40, Sn62Pb36Ag02 or Sn63Pb37. Other alloys may be Airbus used with prior approval from the User (See J-STD-001ES [3.1] / IPC/WHMA-A-620B-S [4.1.1.2]). To: HSD solder alloy shall be Sn60Pb40, Sn62Pb36Ag02 or Sn63Pb37. Other alloys may be used with prior approval from the User (See J-STD-001ES [3.1] / IPC/WHMA-A-620B-S [4.1.1.2]). The solder alloy used for the HSD shall be the same solder alloy as for further assembly/soldering operations.

33 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Stefan WP-015 T MITIGATION BY CONDUCTOR SPACING OR COMPONENT POSITIONING new Hanigk, 3.2.4.1.3 In certain exceptional cases it is acceptable to evaluate the tin whisker risk on an individual Airbus component basis. Perform a detailed analysis on the individual part considering the following issues. Consider the risks of component lead pitch and component positioning. Fine pitch components pre-sent a higher risk as the spacing between conductors is small. Whiskers infrequently grow longer then 3mm (growth rates 1mm/yr.) thus add a margin and consider a radius of 5mm around the conductor as the danger area. Analyze the circuit around the component, consider the voltages present. Tin whiskers are coated with an oxide layer, which has an average breakdown voltage of approximately 5 volts. If the circuitry around the part operates below this voltage, the risk of shorting is mitigated. Consider locally mitigating against whiskers by locally applying conformal coating by brush on the affected areas. All of the following can increase the propensity of a finish to grow whiskers; compressive stresses induced in the tin coating caused by trimming and forming the leads and scratches or nicks in the tin plating as a result of handling or test probe contact. If it can be justified that if whiskers do grow, the risk of shorting is absolutely minimal, it is possible to approve the use of individual components with non-compliant finishes.

Stefan WP-015 T STRIP AND RE-PLATE TERMINATIONS High risk, but why not. Hanigk, 3.2.4.2 If alternatives to tin plated parts cannot be obtained, it may be possible to remove the tin In special cases, an available Airbus finish. This is normally considered a high risk when performed on electronic components; alternative. the ability to remove the tin plating from the affected surfaces and refinish these surfaces must be made based on a risk and cost analysis. Such processes should be reviewed to determine the potential for affecting the reliability of the original product (e.g., chemical attack on component materials). This method is currently not approved and should be carefully reviewed prior to any use as it is perceived to be very high risk.

Stefan WP-015 T Possible damage to parts can include package cracking or loss of hermeticity resulting from At the end of the first paragraph add Hanigk, 3.2.4.2.1 thermal shock, popcorning of plastic packages, solder bridging between leads on fine pitch this sentence. Airbus packages, solder bridging between leads and component body and handling damage such as bent or non-coplanar leads, electrostatic discharge, etc.

34 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Stefan WP-015 T Reflowed /Fusing Tin Two available alternatives. Hanigk, 3.2.4.2.3 Reflowed tin is a stress relieving process applied to the component before it is soldered to Airbus the board. Fusing tin plating shortly after plating mitigates whisker formation. Fusing is a reflowing operation usually done by dipping the tin-plated surfaces into a hot oil bath.

Annealed Tin Annealing after plating has become a widely accepted whisker mitigation technique. Annealing at 150°C for 1 hour within 1 hr of plating is an acceptable mitigation technique as long as the part is also conformal coated after soldering to the board. Annealing has been proven to reduce the maximum whisker length and the growth rate by relieving plating stresses; causing grain growth increasing grain sizes and also forming a uniform intermetallic layer (IMC) of Cu6Sn5 over Cu3Sn which slows further intermetallic growth.

Stefan WP-015 T & E Conformal Coating Hanigk, 3.2.4.2.4 Conformal coating or foam encapsulation over the whisker prone surface can significantly Add this sentence in the beginning of Airbus reduce the risk of electrical short circuits caused by whiskers. The effectiveness of this the chapter. approach appears to be specific to the material types used and the environment. Publicly available data does not support conformal coating to be a cure for whisker growth. However, it does add an insulation barrier that may prevent shorting should long whisker growth occur. The finish thicknesses are specified in Delete: point d. (1) and (2). External surfaces, platings, metallization, etc., with a lead-free Tin (Sn) finish shall be fully coated with conformal coating with a total cured finish thickness of not less than 100 μm [0.004 in] for silicone (SR) and urethane (UR), and not less than 50 μm [0.002 in] for paraxylene coatings. Total cured finish thicknesses specified shall take precedence over requirements imposed by J-STD-001(SPACE) [Table 10-1], or other user-approved The LFCP overruled the IPC-J-STD- conformal coating / polymeric standard. 001x for lead-free surfaces.

New (3): Total cured finish thicknesses specified shall take precedence over requirements imposed For repair activities. by J-STD-001(SPACE) [Table 10-1], or other user-approved conformal coating / polymeric standard.

New (4) Using a combination of two different coatings parylene under either urethane or acrylic can be used, e.g. for repair.

35 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Stefan WP-015 T REPAIR, REWORK, MAINTENANCE AND SUPPORT A very important point that should Hanigk, 3.2.6 All data and information required to conduct repair and rework shall be made available to definitely be included. Airbus those responsible for repair, rework, maintenance and support. All repair or rework must conform to the requirements of the drawing, items list and any referenced manufacturing documents. At the time of writing there are no PCB assemblies containing lead free solder, the approved repair/rework process is to use a tin/lead solder to solder all components, irrespective of whether the components contain lead or not. Refer to the PCB assembly documentation (e.g. drawing, bill of material, etc.) to determine whether to apply conformal coating.

36 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Dave Hillman, WP-016 Technical The 620 committee should either: (1) needs to move this document into the 620 Handbook Per the IPC Committee Chairman’s Rockwell with significant reformatting or (2) refer this white paper to the IPC JSTD 001/610 Handbook: committees action/implementation and have it removed from inclusion in the 620 Collins specification “7.3 Technical Reports, Technical Papers and White Papers There will be times when your committee feels there is a need for published data about a specific area of technology which is either not addressed or current with the times. These reports can fill a need found during the development of a standard or publication or may come from a request by someone or a group of people in the industry. Many technical reports and technical papers are a result of round robin testing programs. These reports and papers can follow a similar format to the IPC Standardization Procedures, but they do not have to meet the procedures. To assure relevance, these reports should go through some level of peer review by a committee or group of SMEs. The final report or paper will be submitted to the TAEC for review and approval. “

The current WP-016 is not a white paper per the CC Handbook definition. The WP-016 is written as an actionable specification addressing a technical topic that is not exclusive to the 620 specification. The working paper could be tailored to reflect FOD topics specific to the 620 specification and included in the 620 specification as an actionable appendix. Alternatively, since the working paper does cover FOD at a high level, the working paper could be incorporated into the IPC JSTD 001/610 specifications either in the body of those documents or as an actionable appendix. 37 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Barrie Dunn, WP-016 No specific comments, but am undecided if it is more convenient to include all See recommendation School of FOREIGN these requirements into J-STD 001. Engineering, OBJECT University of DEBRIS (FOD) Portsmouth, CONTROL UK Jim Blanche WP-016 T 2nd paragraph - add to the end of the 2nd sentence: when a FOD Control Plan is Unlike the other three white papers and Garry FOREIGN required by the User. we are reviewing as part of this McGuire, OBJECT exercise, a FOD control plan is not MARSHALL DEBRIS (FOD) imposed as a requirement so we FLIGHT SPACE CONTROL 1.2 should not require prior User CENTER approval of a plan that isn’t contractually imposed. Jim Blanche WP-016 T Second sentence - From: When this standard is contractually invoked, the This is a White Paper and not a and Garry FOREIGN applicable requirements of this standard shall be imposed on all applicable standard. If it is to be called a McGuire, OBJECT subcontracts, assembly drawing(s), documentation and purchase orders standard its title should be changed. MARSHALL DEBRIS (FOD) FLIGHT SPACE CONTROL To: When the requirements of this document are contractually invoked, the CENTER 1.3.1 applicable requirements of this document shall be imposed on all applicable subcontracts, assembly drawing(s), documentation and purchase orders

Jim Blanche WP-016 T Delete. A white paper cannot be (or at least and Garry FOREIGN definitely should not) be McGuire, OBJECT contractually imposed. There are no MARSHALL DEBRIS (FOD) requirements in 001 or 620 to have FLIGHT SPACE CONTROL a FOD Control Plan. CENTER 1.3.1 Jim Blanche WP-016 T Delete. The references provided are not and Garry FOREIGN authority for a FOD control plan. McGuire, OBJECT Although they discuss FOD, they MARSHALL DEBRIS (FOD) do not invoke a requirement for a FLIGHT SPACE CONTROL plan. CENTER 1.3.2

38 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-016 T Delete f Verbal correspondence is never and Garry FOREIGN AND accepted in conflict resolutions. If it McGuire, OBJECT Switch c with d isn’t in writing, it didn’t happen. MARSHALL DEBRIS (FOD) AND FLIGHT SPACE CONTROL 1.4 As a white paper, it’s hard to CENTER defend that it would have precedence over a published IPC standard. Jim Blanche WP-016 T Delete a. thru d. The lead-in sentence covers all 4 of and Garry FOREIGN these items. McGuire, OBJECT MARSHALL DEBRIS (FOD) FLIGHT SPACE CONTROL 1.7 CENTER Jim Blanche WP-016 T 2nd paragraph: Delete. As mentioned previously, there is and Garry FOREIGN no requirement for a FOD Control McGuire, OBJECT Plan unless a User specifically MARSHALL DEBRIS (FOD) requires one. This paragraph reads FLIGHT SPACE CONTROL 3 as if it is using this white paper as CENTER justification for its existence. Alternatively, start the paragraph with “When required”. Jim Blanche WP-016 E Change Figure reference to 1-1. and Garry FOREIGN McGuire, OBJECT MARSHALL DEBRIS (FOD) FLIGHT SPACE CONTROL CENTER 3.1.d Larry Joy, WP-016 E The sentence refers to “Figure 2-1”. There is no Figure 2-1, the only figure in the document Editing error. Amptech, Inc. FOREIGN is “Figure F-1”. OBJECT DEBRIS (FOD) CONTROL 3.1d.

39 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Jim Blanche WP-016 T Delete d. Grounds and other facility areas / surfaces over which FOD-sensitive Grounds do not fit into 1.3 and Garry FOREIGN hardware are transported shall be maintained free of FOD. Applicability: “The requirements McGuire, OBJECT of this document apply to all work MARSHALL DEBRIS (FOD) areas where both critical and FLIGHT SPACE CONTROL 3.2 complex work is performed; and, to CENTER operations involved with designing, developing, manufacturing, assembling, testing, operating, repairing, modifying, refurbishing, and maintaining Class 3 (or higher) hardware.”

FOD sensitive hardware should be in protective packaging while being transported. Keeping the grounds clear of FOD would seem to be an impossible task.

Jim Blanche WP-016 T FOD Awareness and Prevention Training - delete b. and e. and if necessary The bullets that address what and Garry FOREIGN identify them in the second paragraph. training shall include mix who McGuire, OBJECT should be trained with what shall be MARSHALL DEBRIS (FOD) taught. The second paragraph FLIGHT SPACE CONTROL 3.5 identifies who should have the CENTER training Jim Blanche WP-016 T From: When FOD results in damage or suspected damage, the FOD Focal Point Recurrence control is as essential as and Garry FOREIGN shall lead an investigation into the incident and identify corrective action as part corrective action and is included in McGuire, OBJECT of the overall FOD trending and measurement assessment. the note but not in the requirements. MARSHALL DEBRIS (FOD) FLIGHT SPACE CONTROL 3.7 To: When FOD results in damage or suspected damage, the FOD Focal Point CENTER shall lead an investigation into the incident and identify corrective action and recurrence control as part of the overall FOD trending and measurement assessment.

40 Paragraph # Type of Recommendation Reason for Recommendation Committee Figure or comment Disposition Commenter Table Technical (T) Editorial (E) Larry Joy, WP-016 E Reference is made to “Figure 1” in two places. There is only a “Figure F-1” in the Editing error. Amptech, Inc. FOREIGN document. OBJECT DEBRIS (FOD) CONTROL 3.8a. Jim Blanche WP-016 T Cleanliness Level – Identify the cleanliness levels in this document somewhere. To avoid having to go to another and Garry FOREIGN document to identify them McGuire, OBJECT MARSHALL DEBRIS (FOD) FLIGHT SPACE CONTROL 4.1 CENTER

S Hanigk Comment - Annex: Component Lead-Free Finishes Base Material Thru Hole parts SMD Devices Low SMD Devices (Typically Cu 7025, expansion alloys (FeNi, Ceramics, no lead 194 etc. lead; Alloy 42, Kovar™ etc. frame (Resistors & Solderable Finish excluding brass) Typical CTE ±5ppm) Capacitors) NiPdAu NiPd NiAu Sn/Pb plating (>3% Pb) Gold Flash over Cu SnAgCu (SAC Alloy) Ag (over Ni) Ag (over Cu) see also WP-013; Red Plague Control Plan

Sn (fused), no barrier layer Hot dipped SnAgCu Hot dipped SnAg Matte SnCu 150°C anneal Plated SnAg (1.5 to 4% Ag) Sn over Brass 41 Component Lead-Free Finishes Base Material Thru Hole parts SMD Devices Low SMD Devices (Typically Cu 7025, expansion alloys (FeNi, Ceramics, no lead 194 etc. lead; Alloy 42, Kovar™ etc. frame (Resistors & Solderable Finish excluding brass) Typical CTE ±5ppm) Capacitors) Bright Sn with Ni barrier layer Sn over steel, Ag, Cu or Ni barrier

SnBi (2 to 4% Bi) Matte Sn with Ni barrier layer n/a Matte Sn with Ag barrier layer Sn, 150°C anneal

AgPd (over Ni) Ag (over Ni) Ag SnCu Bright Tin Matte SnCu, 150 anneal (2% Cu) Bright Tin with Ni barrier layer Matte Sn Semi Matte Sn Table-a

42 Termination Finishes for Separable Connectors Terminal finish use as Terminal finish use as a Termination finish use a separable interface separable interface for only as a solderable for fine spacing large spacing Finish finish applications. applications NiAu NiPd NiPdAu Ag (over Ni)

Hot dipped SnAgCu Reflowed Sn Hot Dipped Sn Hot Dipped SnCu Matte Sn w/Nickel underplate Matte Sn w/Silver underplate

Matte Sn - 150C anneal Matte SnBi (2-4% Bi) w/Nickel Underplate Matte SnAg (1.5 - 4% Ag) w/Nickel underplate SnCu w/Nickel underplate

Bright Tin w/nickel underplate Matte SNBi (2-4% Bi) Matte SnAg (1.5-4% Ag) Matte Sn (No underplate) Bright Tin SnCu Table-b

43