Multi-Cultivator MC 1000

Instruction Manual

Please read this guide before operating this product CONTENTS

Warnings and Safety Precautions...... 3

Device Description...... 4

General Description...... 4

Cultivation Control...... 4

Description of the Cultivation Vessel...... 5

Multi-Cultivator Front Panel Description...... 6

Accessories...... 7

Installation...... 8

Checking the Package...... 8

Device Installation...... 9

Connecting the Power Supply to the Multi-Cultivator...... 9

Vessel Assembly...... 10

Air Line Installation...... 11

PWM Pump Installation...... 13

Additional Cooling Unit AC-88 Installation...... 13

Operation...... 15

Cultivation Control...... 15

Menu...... 17

Cultivation Vessel Maintenance...... 26

Technical Specification...... 27

Warranty Terms and Conditions...... 29

Troubleshooting and Customer Support...... 29

2 WARNINGS AND SAFETY PRECAUTIONS

PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY BEFORE TURNING THE MULTI-CULTIVATOR ON:

Remove all packaging and transit protectors before connecting the Multi-Cultivator to the electricity supply.

Use only cables supplied by the manufacturer.

Keep the device dry outside and avoid working in high humidity environment!

The manufacturer is not responsible for any damage due to improper or incompetent operation!

Fill water and other liquids only into the compartments designed to it.

GENERAL ELECTRICAL SAFETY GUIDELINES:

Perform a routine check of the devices and their wiring.

Replace worn or damaged cords immediately.

Use electrical extension cords wisely and do not overload them.

Place the devices on a flat and firm surface. Keep them away from wet floors and counters.

Avoid touching the devices, socket outlets or switches if your hands are wet.

Do not perform any alterations to the electrical part of the devices or their components.

WARNING:

The Multi-Cultivator MC 1000 is considered Class 1M* LED Product. LED radiation may be harmful to eye. Avoid direct and strongly reflected exposure. Use protective glasses.

*Class 1M: Laser and LED equipment that is safe for the naked eye under foreseeable conditions of operation. Looking directly into the source of radiation by employing optics within the beam, such as magnifying glass, telescope or microscope, can be potentially hazardous.

3 DEVICE DESCRIPTION

GENERAL DESCRIPTION

Multi-Cultivator MC 1000 serves for small scale cultivation of algae, bacteria or cyanobacteria. It consists of 8 test tubes, each holding up to ca. 85 ml of cultivated suspension. The test tubes are immersed in a thermostated waterbath. Each tube is illuminated by an array of warm white LEDs that can generate incident irradiance, which is independently adjustable up to 500 µmol(photon)/m2.s. Each test tube can be bubbled with gas. The gas may be humidified and distributed to each test tube through a manually adjustable valve manifold.

Multi-Cultivator MC 1000 is supplied with a light controlling unit that supports user-defined dynamic illumination protocols, such as, flashing light or diurnal regime.

The instrument function can by enhanced by two optional accessories: Cooling Unit AC-88, which serves for the thermostated waterbath cooling, and the PWM Pump for automatic waterbath refilling. In an extended instrument version, MC-1000-OD, the suspension growth is estimated by measuring its transmission optical density.

CULTIVATION CONTROL

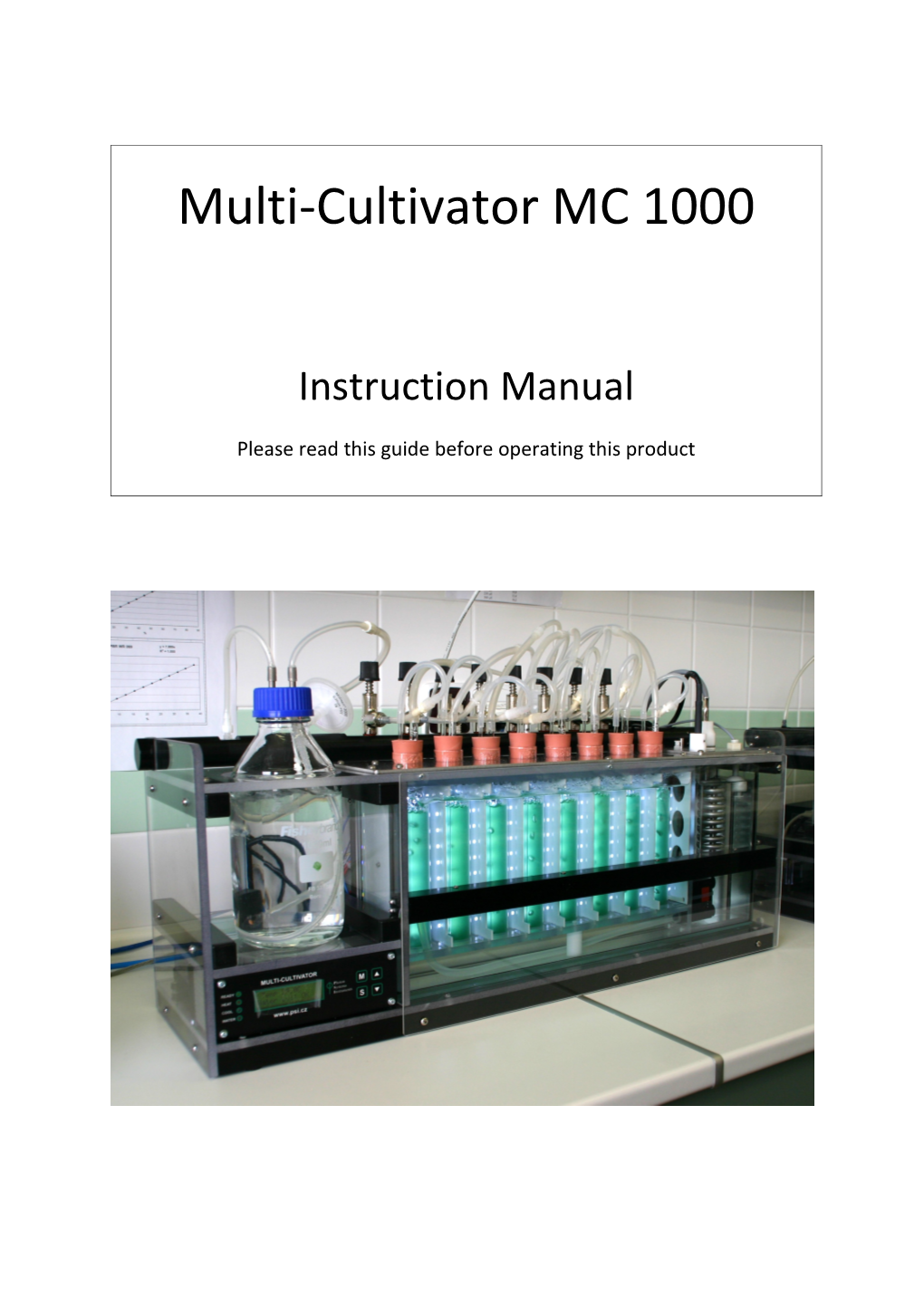

Control unit, air-pump and bubble humidifier are positioned on the left side of the device. On the right side, there are heating and cooling units, water level monitoring system, temperature sensor, and water pump. In the rear, serial connectors and a fan can be found. On the top, air dispenser tubes are positioned (Fig. 1).

Light emitting diodes in the cultivation vessel generate a highly uniform irradiance flux that can be controlled in the range of 0-500 µmol (photons).m-2.s-1 PAR. The Multi-Cultivator MC 1000 enables to set day/night regime of light conditions for each test-tube individually.

Fig. 1: Multi-Cultivator with standard equipment – front view

DESCRIPTION OF THE CULTIVATION VESSEL

4 The Multi-Cultivator MC 1000 cultivation vessel is a flat, rectangular glass container with the capacity of 5 liters.

The vessel includes 8 slots for cultivation test-tubes, water pump and an additional system of supported functions and settings. Water in cultivation vessel is circulated by a water pump and provides the environment for test-tubes. The cultivation itself is realized in test-tubes. Plastic dividers in cultivation vessel separate light environment of the individual tubes.

Each test-tube slot is constructed for a tube 3 cm in diameter and at least 20 cm high. The maximum culture volume which can be cultivated in one test-tube is 100 ml, but to fill the test-tube over 85 ml is not recommended due to risk of overflow.

IMPORTANT NOTICE:

If the test-tube is filled over 85 ml the excessive fluid may overflow.

MULTI-CULTIVATOR FRONT PANEL DESCRIPTION

5 The device is controlled via front panel with 4 LED lights on the left and 4 main keys for settings on the right (Fig. 4).

Fig. 4: Multi-Cultivator front panel

LED LIGHTS

Green LED indicator READY is lighting when the current temperature is equal to target temperature.

Orange LED indicator HEAT is lighting when heating stick is warming up water in the cultivation vessel.

Blue LED indicator COOL is lighting when the cooling spiral is cooling water in the cultivation vessel.

Red LED indicator WATER is lighting when the water level in the cultivation vessel drops under required level.

MAIN KEYS

[M]: Used to move back in the menu tree or to exit the menu.

[S]: Used to move forward in the menu tree, to save the selection, or to turn ON/OFF.

[ ]: Used to move up in the menu or to add value.

[ ]: Used to move down in the menu or to subtract value.

ACCESSORIES

The function of the Multi-Cultivator MC 1000 may be enhanced by adding two optional accessories – additional Cooling Unit AC-88 (Fig. 2) and PWM Pump (Fig. 3).

6 Additional Cooling Unit AC-88 chills water in the cultivation vessel. At laboratory temperature of 22°C, the vessel temperature can be lowered to 15 °C.

PWM Pump automatically fills water into the cultivation vessel when water level drops under the required level.

For more information, see chapter Device Installation.

Fig. 3: PWM Pump

Fig. 2: Cooling Unit AC-88

INSTALLATION

CHECKING THE PACKAGE

7 Check the contents of the package and compare it to the enclosed package list. Make sure that the serial number of the Multi-Cultivator is the same as the serial number on the label of the power supply (Fig. 5).

Fig. 5: Label from the Multi-Cultivator MC 1000 and the Power Supply of the Multi-Cultivator MC 1000. Red arrows show the serial numbers.

WARNING:

Damage can be caused when the power supply is incompatible with the Multi-Cultivator. Be aware that both devices should have the same serial number.

STANDARD EQUIPMENT

Water pump with voltage changer

Heating and cooling units

Water level sensor

Temperature sensor

Air pump

Humidifier including air filter, plastic tubes and plastic connectors

8 test-tubes including plugs, glass tubes , plastic tubes and plastic connectors

Power supply & power cord of the power supply

OPTIONAL ACCESSORIES

PWM Pump including plastic tubes and plastic connectors

Cooling Unit AC-88 including plastic tubes, power cord and control cable

Spare Part Kit including 8 culture tubes, 8 short glass straws, 8 long glass straws, and 8 stoppers.

DEVICE INSTALLATION

To install the device properly, it is necessary to follow the proper sequence of steps as described below.

CONNECTING THE POWER SUPPLY TO THE MULTI-CULTIVATOR

8 Make sure that the power supply is switched off.

Plug the power cord of the power supply (the thickest cable) into the round connector, labeled POWER, on the rear of the Multi-Cultivator (Fig. 6).

Fig. 6: Connection of the device and the power supply (red arrow) on the rear of the Multi-Cultivator. The service connector is crossed out

WARNING:

Do not use the service connector (red cross in fig.2) without prior consultation with the manufacturer.

VESSEL ASSEMBLY

Insert test-tubes into slots on the top of the Multi-Cultivator. Be sure that all test-tubes are positioned the same in the cultivation vessel.

9 Fill the cultivation vessel with water through one of the test-tube slots with 4.55 liter of tap water. The water level should be about 5 cm bellow the top of the vessel (Fig. 7). Insert the test-tubes; the water level should now be about 1 - 3 centimeters above the water level control (Fig. 8).

Unused or empty slots should be closed to prevent water evaporation from the vessel (Fig. 9).

IMPORTANT NOTICE

All the test-tubes, stoppers and glass straws must be positioned the same; otherwise the cultivation conditions cannot be well comparable.

All aeration glass straws (long ones) and outlet glass straws (short ones) must be of the same length in each test-tube.

Make sure that flexible tubing is not squeezed anywhere.

It is important to use the same type of connectors for each test-tube.

The aeration glass straw should be positioned so as its end is about 0.5 cm from the test-tube bottom. In this way, more small bubbles are formed. The higher is the position of the aeration tubing end in the test-tube the larger bubbles are formed.

The lower part of the outlet glass straw should end about 0.5 cm below the stopper.

Be sure that the aeration glass straws do not block the OD readers. The aeration glass straws should be positioned to the side of each test-tube.

WARNING:

Damage can be caused or the device might not work properly if the water level in the tank gets below the water level sensor. Lights will turn off and running protocol will be terminated automatically.

Fig 7: Filling water into the cultivation vessel Fig. 8: Water level control in front of a cooling spiral

10 Fig 9: Closed slots of the cultivation vessel

AIR LINE INSTALLATION

The bubble humidifier consists of four main parts – air pump, bubble humidifier, air dispenser tubes and air valves.

Put the bubble humidifier on the top of the display unit (Fig. 10).

Connect the air pump and bubble humidifier with the tube and make sure that the connection is tight. Insert tube into the slot near the bubble humidifier (Fig. 11)

If necessary, install air filter between the air pump and the bubble humidifier (Fig. 12)

Connect the bubble humidifier and the main dispenser tube (Fig. 13).

Connect each test-tube to a valve as shown in Fig. 14. The valves must be set manually. Free end of the second tube leading from the test-tube plug (taking away excessive liquid) must be put into an empty jar. Make sure that the tubing is not squeezed at any part.

IMPORTANT NOTICE

Make sure that bubbles in all test-tubes are of the same size and that the ends of glass straws bringing air into test-tubes are of the same distance from the bottoms of the test-tubes during an experiment.

11 Fig. 10: Properly positioned bubble humidifier Fig. 11: Bubble humidifier tubing connection

Fig. 12: Microbial filter Fig.13: Bubble humidifier tube in the main dispenser tube

Fig. 14: Connection of a test-tube to a valve

12 PWM PUMP INSTALLATION

Connect PWM Pump (OUT) and the connector for refilling water via tube and make sure that the connection is tight (Fig. 15).

Connect PWM Pump (IN) and a water reservoir via tube and make sure that the connection is tight.

Insert the PWM Pump cable into the plug labeled AUX2 on the back panel of the Multi-Cultivator (Fig. 16).

Fig. 15: PWM Pump tube connected to Fig. 16: Plugged PWM Pump cable

water level checking system

ADDITIONAL COOLING UNIT AC-88 INSTALLATION

Connect the Multi-Cultivator cooling spiral and the Cooling Unit AC-88 (Fig.17) with tubes and make sure that the connection is tight.

Fill the Cooling Unit with the cooling liquid (distilled water) 1 cm below the black edge (Fig.18).

Insert the Cooling Unit cable to the AUX1 connector on the back panel of the Multi-Cultivator.

Set ON the temperature control in the Multi-Cultivator Control Unit (in menu Sensors – Temp. Control).

Connect the Cooling Unit cable to the round connector on the left side of the Unit and set switch to position II = Remote Control (Fig. 19).

Circulation of cooling liquid in the system indicates the green the LED diode at the bottom on front side of the Cooling Unit AC-88 and the blue LED light COOL in the Multi-Cultivator control panel.

13 IMPORTANT NOTICE:

Please allow the unit to stand for 24 hours before use as a coolant because it may become unsettled during transit. Must be treated the same way as a domestic refrigerator.

It is recommended to use distilled water as a cooling liquid for the AC-88.

In some cases, when lights are planned to be set on maximum, the distilled water may be replaced by non-freezing coolant (used in cars) so as to avoid cooling liquid freezing.

Fig. 17: Additional Cooling Unit AC-88

Fig. 18: Cooling Unit filled with distilled water Fig.19: Remote control of the Cooling Unit

OPERATION

14 Plug the voltage changer of the water pump into the electric outlet.

Plug the power cord into the electric outlet.

Switch on the power supply (Fig.20).

Plug the Cooling Unit AC-88 power cord into an electrical outlet.

Fig. 20: Power supply

CULTIVATION CONTROL

The following pages bring the graphical presentation of the operation scheme of the Multi-Cultivator. This scheme is structured into five levels:

Main menu (blue)

First-level nested sub-menu (yellow)

Second-level nested sub-menu (green)

Third -level nested sub-menu (orange)

Fourth-level nested sub-menu (grey)

See pages 15 - 23 of this Manual for the graphical presentation of single menus and for explanations of their particular options.

EXPLANATION OF SYMBOLS AND COLOR DIFFERENTIATION* USED IN THE GRAPHICAL PRESENTATION:

[M] key: Used to move back in the menu tree or to exit the menu.

15 [S] key: Used to move forward in the menu tree or to save your selection.

[↑] key: Used to move up in the menu or to add value.

[↓]key: Used to move down in the menu or to subtract value.

Full-line arrows are used for the [S] key.

Dashed-line arrows are used for the [M] key.

Dotted-line arrows are used for the [UP/DOWN] keys.

Blue colour represents the Main Menu.

Yellow colour represents the first-level nested sub-menu.

Green colour corresponds to the second-level nested sub-menu.

Orange colour corresponds to the third-level nested sub-menu.

Grey colour corresponds to the fourth-level nested sub-menu.

* The Multi-Cultivator screen does not reflect this color differentiation.

NOTE:

After 10 seconds of no action, an idle screen appears; displayed is the actual temperature inside the Multi- Cultivator.

MENU

16 17 18 19 20 21 22 23 24 25 CULTIVATION VESSEL MAINTENANCE

Use only distilled water in the cultivation vessel to avoid boiler incrustation.

Use a tube to pump over polluted fluid from the cultivation vessel.

To clean the vessel, unscrew 4 screws on the top of the small square metal cover with inlets for heater, cooler, water level sensor and remove it. Then unscrew 6 screws on the top of the cultivation vessel with slots for test-tubes and remove it. Pull out the stand for test-tubes and water pump.

Wash inside of the cultivation vessel and its content with detergent or vinegar water.

To remove rough pollution on the walls of the cultivation vessel, use brush.

When assembling the cultivation vessel, please, do not tighten the screws too much to avoid damaging screw threads.

Plastic tubing, plastic connectors and glass components of the Multi-Cultivator can be autoclaved at temperatures not exceeding 120°C.

WARNING:

Avoid spilling water to all parts of the Multi-Cultivator except the cultivation vessel.

TECHNICAL SPECIFICATION

26 Online Measured Parameters: Optical density (OD) – optional

Optical Density Measurement: Real time measurement of OD by two IR LEDs (720 nm, 680 nm)

Number of Test-Tube Slots: 8

Volume of each test-tube: R100 ml (maximum recommended cultivation volume of each test-tube is 85 ml)

Precision Controlled Temperature: 20 °C - 60 °C (standard) 15 °C – 60 °C (optional)

Heating System: One 150W cartridge heater

LED Lighting: Light intensity adjustable from 0 to 100 % Maximum light intensity up to 500 µmol(photon)/m2.s

Light Regime: Static or dynamic (sinus, daylight, pulse form)

Display: System control + actual readings

Controlled Flow of Bubbled Air: Manual

Controlled Composition of Bubbled air: Optional

Volume of Water Bath: 5 liters

Detector Wavelength Range: PIN photodiode with 665 nm-750 nm bandpass filters

Bios: Upgradeable firmware

Communication Port: Serial - RS232

Material: Glass, stainless steel, silicon gasket, polycarbonate

Dimension: 71 x 20,5 x 33 cm

27 Weight: 13.0 kg

Electrical: 110-240 V

WARRANTY TERMS AND CONDITIONS

This Limited Warranty applies only to the Multi-Cultivator MC 1000. It is valid one year from the date of shipment.

28 If at any time within this warranty period the instrument does not function as warranted, return it and the manufacturer will repair or replace it at no charge. The customer is responsible for shipping and insurance charges (for the full product value) to PSI. The manufacturer is responsible for shipping and insurance on return of the instrument to the customer.

No warranty will apply to any instrument that has been (i) modified, altered, or repaired by persons unauthorized by the manufacturer; (ii) subjected to misuse, negligence, or accident; (iii) connected, installed, adjusted, or used otherwise than in accordance with the instructions supplied by the manufacturer.

The warranty is return-to-base only, and does not include on-site repair charges such as labor, travel, or other expenses associated with the repair or installation of replacement parts at the customer's site.

The manufacturer repairs or replaces faulty instruments as quickly as possible; the maximum time is one month.

The manufacturer will keep spare parts or their adequate substitutes for a period of at least five years.

Returned instruments must be packaged sufficiently so as not to assume any transit damage. If damage is caused due to insufficient packaging, the instrument will be treated as an out-of-warranty repair and charged as such.

PSI also offers out-of-warranty repairs. These are usually returned to the customer on a cash-on- delivery basis.

WEAR & TEAR ITEMS (such as sealing, tubing, padding, etc.) are excluded from this warranty. The term WEAR & TEAR denotes the damage that naturally and inevitably occurs as a result of normal use or aging even when an item is used competently and with care and proper maintenance.

TROUBLESHOOTING AND CUSTOMER SUPPORT

In case of troubles and for customer support, please, write to [email protected] or contact your local distributor.

Manual Version: 2011/10

© PSI (Photon Systems Instruments), spol. s r.o.

29