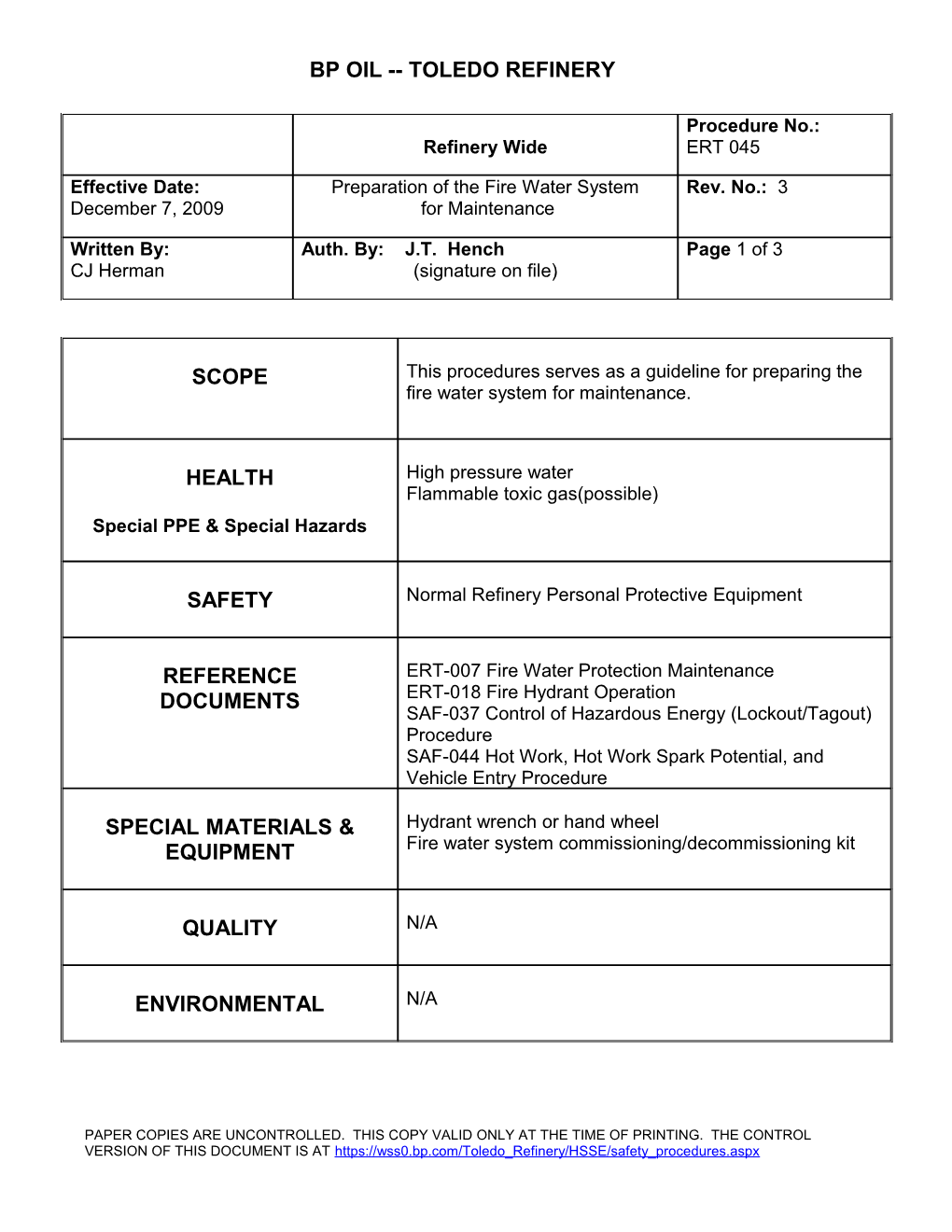

BP OIL -- TOLEDO REFINERY

Procedure No.: Refinery Wide ERT 045

Effective Date: Preparation of the Fire Water System Rev. No.: 3 December 7, 2009 for Maintenance

Written By: Auth. By: J.T. Hench Page 1 of 3 CJ Herman (signature on file)

SCOPE This procedures serves as a guideline for preparing the fire water system for maintenance.

HEALTH High pressure water Flammable toxic gas(possible) Special PPE & Special Hazards

SAFETY Normal Refinery Personal Protective Equipment

REFERENCE ERT-007 Fire Water Protection Maintenance DOCUMENTS ERT-018 Fire Hydrant Operation SAF-037 Control of Hazardous Energy (Lockout/Tagout) Procedure SAF-044 Hot Work, Hot Work Spark Potential, and Vehicle Entry Procedure

SPECIAL MATERIALS & Hydrant wrench or hand wheel EQUIPMENT Fire water system commissioning/decommissioning kit

QUALITY N/A

ENVIRONMENTAL N/A

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. ERT 045 Rev. No. 3

1.0 Blocking in the NOTE: Any knowledgeable individual can block the system if System for Hydrant assigned to the job. (As directed by Operations or HSSE Repair personnel)

1.1 Start water flowing from the hydrant that is to be blocked in. (This will flush dirt from the valve seats.)

__1.2 Close the “watch” block valve(s) next to the hydrant on the Ringmain side of the hydrant to be repaired.

__1.3 Allow hydrant to bleed prevent a pressure build up in the system.

__1.4 Close main valve and Cover hydrant with black bag and tag it out of service.

__1.5 Notify Maintenance that the hydrant is ready

__1.6 Disassemble hydrant and repair. (Consult manufacture manual)

2.0 Blocking in the NOTE: Any Knowledgeable individual can block in the system if System for a valve or assigned to the job. (As directed by Operations or HSSE pipeline Repair personnel)

2.1 Start a large flow (500 gpm) from a hydrant on the pipeline to be blocked in . (This will flush dirt from the valve seats.)

2.2 Close the block vavle(s) on either side of the leak or valve to be repaired. (Lock and Tag Both - DO NOT OPEN!)

2.3 Leave a hydrant open between the isolation valves to keep pressure from building up in the system. (Tag Hydrant - DO NOT CLOSE!) CAUTION Failure to notify owners and the refinery fire chief of affected equipment could compromise response effectiveness. __2.3.1 Cover all hydrants and water spray activation valves with black bags and tag each that are within the blocked in portion of the pipeline and are out of service.

__2.4 Inform the Refinery fire chief and or the Refinery Coordinator which valves are closed and which units are affected.

NOTE: Mark up the firewater maps at the nerve center or sat #7 for reference when put ing the system back in service

Page 2 of 3

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx Procedure No. ERT 045 Rev. No. 3

WARNING Fire water mains have been contaminated, from time to time with Toxic and flammable hydrocarbons.

__2.5 Make the necessary repairs

__2.6 If cutting of the pipe is required, follow SAF-044 Hot Work, Hot Work Spark Potential, and Vehicle Entry Procedure.

3.0 Re-pressurizing the 3.1 Assure that the bleed hydrant that was left open. Fire Water System after Repair --- 3.2 Start opening the block valve(s) slowly at the opposite end of the loop until flow can be felt through the valve. Allow water to the repair section of the main unit water is seen running from the bleed hydrant

__3.3 Close bleed hydrant, allow the sytem to pressure up. Then open the block valves completely.

---3.4 Re open the bleed hydrant that was just closed to vent air from system .

NOTE: Should it be impossible to open valves on system, back pressure the system to equalize pressure on either side of the valves. Do this by attaching a 1 1/2 hose between a “Live” hydrant and a hydrant on the out of service line and pressure up, until water flows from the second hydrant. Close the outlet valve on the second hydrant, then open the system block valves

3.5 Continue the slow flow of water until all air is forced from the system. (This prevents water hammer.)

THIS IS THE LAST PAGE

Page 3 of 3

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_procedures.aspx