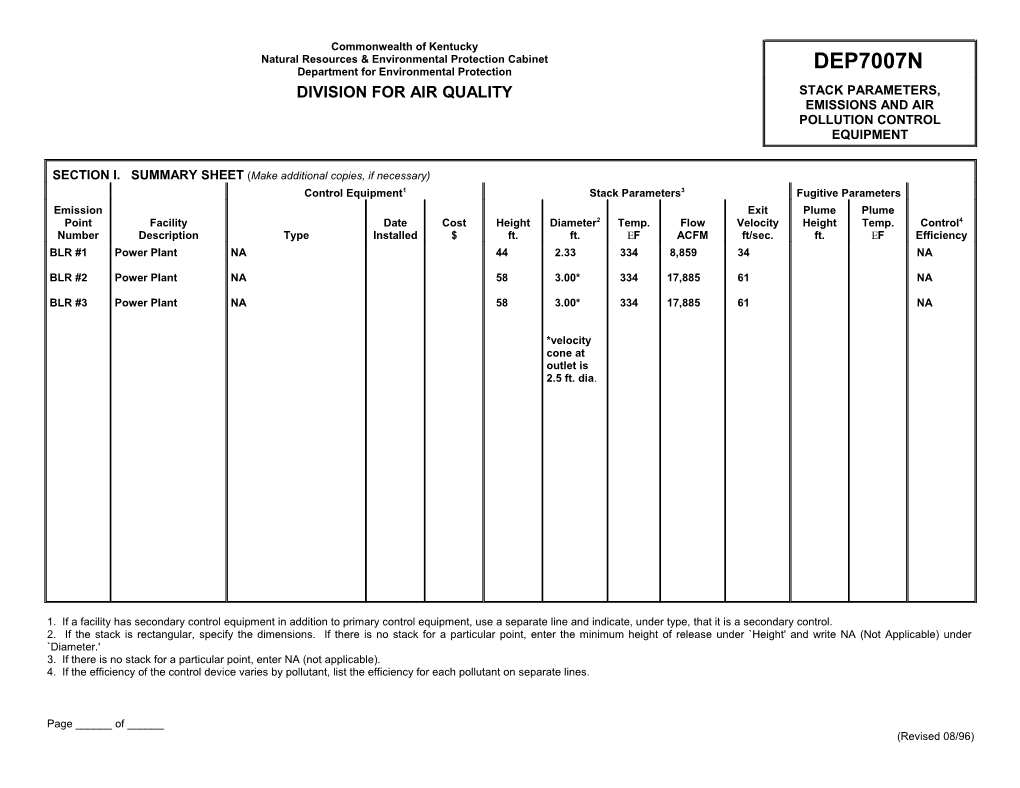

Commonwealth of Kentucky Natural Resources & Environmental Protection Cabinet Department for Environmental Protection DEP7007N DIVISION FOR AIR QUALITY STACK PARAMETERS, EMISSIONS AND AIR POLLUTION CONTROL EQUIPMENT

SECTION I. SUMMARY SHEET (Make additional copies, if necessary) Control Equipment1 Stack Parameters3 Fugitive Parameters Emission Exit Plume Plume Point Facility Date Cost Height Diameter2 Temp. Flow Velocity Height Temp. Control4 Number Description Type Installed $ ft. ft. F ACFM ft/sec. ft. F Efficiency BLR #1 Power Plant NA 44 2.33 334 8,859 34 NA

BLR #2 Power Plant NA 58 3.00* 334 17,885 61 NA

BLR #3 Power Plant NA 58 3.00* 334 17,885 61 NA

*velocity cone at outlet is 2.5 ft. dia.

1. If a facility has secondary control equipment in addition to primary control equipment, use a separate line and indicate, under type, that it is a secondary control. 2. If the stack is rectangular, specify the dimensions. If there is no stack for a particular point, enter the minimum height of release under `Height' and write NA (Not Applicable) under `Diameter.' 3. If there is no stack for a particular point, enter NA (not applicable). 4. If the efficiency of the control device varies by pollutant, list the efficiency for each pollutant on separate lines.

Page ______of ______(Revised 08/96) DEP7007N (continued) Grain Loading (Grains/SCF at Amount Emitted 68F) Capture1 or Emission Collection Basis of Name and Chemical Composition Maximum Maximum Basis of Estimate Point No. Efficiency % Estimate of Pollutants Inlet Outlet Lb/Hr. Tons/Yr. (Attach copies of calculations)

BLR #1 NA Nat=l gas Nitrogen oxides - NOx NA NA 2.2 9.9 Burner performance data

Carbon monoxide - CO NA NA 0.9 4.0 Burner performance data

NA No. 2 fuel Nitrogen oxides - NOx NA NA 5.1 22.2 Burner performance data oil Carbon monoxide - CO NA NA 0.9 4.0 Burner performance data

Sulfur dioxide - SO2 NA NA 12.6 55.2 Burner performance data

BLR #2 NA Nat=l gas Nitrogen oxides - NOx NA NA 6.1 26.7 AP-42 emission factors

Carbon monoxide - CO NA NA 5.1 22.3 AP-42 emission factors

No. 2 fuel Nitrogen oxides - NOx NA NA 8.7 38.0 AP-42 emission factors oil Carbon monoxide - CO NA NA 2.2 9.5 AP-42 emission factors

Sulfur dioxide - SO2 NA NA 31.0 136.0 AP-42 emission factors

BLR #3 NA Nat=l gas Nitrogen oxides - NOx NA NA 6.1 26.7 AP-42 emission factors

Carbon monoxide - CO NA NA 5.1 22.3 AP-42 emission factors No. 2 fuel oil Nitrogen oxides - NOx NA NA 8.7 38.0 AP-42 emission factors

Carbon monoxide - CO NA NA 2.2 9.5 AP-42 emission factors

Sulfur dioxide - SO2 NA NA 31.0 136.0 AP-42 emission factors

1. Capture or collection efficiency is the efficiency with which the pollutants are collected at the emission source before being sent to the control device.

Page ______of ______(Revised 08/96) DEP7007N (continued

SECTION I. (Continued)

The basis for all efficiency estimates should be given and supported with documentation and a detailed explanation of the method of calculation and/or the source of information. Submit all pertinent drawings. Describe briefly the disposal of particulates collected, scrubbing liquid, and/or wastes generated at the plant site:

N.A.

SECTION II. Specific Control Equipment ADSORPTION UNIT 1. EMISSION POINT NUMBER OF ADSORPTION UNIT:

2. MANUFACTURER: 3. MODEL NAME & NUMBER:

4. ADSORBENT:

Activated Charcoal: Type Other (specify):

5. ADSORBATE(S):

6. NUMBER OF BEDS: 7. WEIGHT OF ADSORBENT PER BED:

lb.

8. DIMENSIONS OF BED:

Thickness in direction of gas flow inches Cross-section area sq. inches

9. INLET GAS TEMPERATURE 10. PRESSURE DROP ACROSS UNIT:

F or C inches water gauge

11. TYPE OF REGENERATION:

Replacement Steam Other (specify):

12. METHOD OF REGENERATION:

Alternate use of beds Source shut down Other (specify):

13. TIME ON LINE BEFORE REGENERATION: 14. EFFICIENCY OF ADSORBER:

minutes %

Page ______of ______(Revised 08/96) DEP7007N (continued) AFTERBURNER (Incinerator for Air Pollution Control) 1. EMISSION POINT NUMBER OF AFTERBURNER:

2. MANUFACTURER: 3. MODEL NAME AND NUMBER:

4. COMBUSTION CHAMBER DIMENSIONS:

Length inches; Cross-sectional area sq. inches

5. INLET GAS TEMPERATURE: 6. OPERATING TEMPERATURE OF CHAMBER:

F or C F or C

7. TYPE OF AUXILIARY FUEL: Higher Heating Value

% Sulfur Maximum Average

% Ash Maximum Average

Maximum Auxiliary Fuel Usage (specify units):

Hourly Annually

8. BURNERS PER AFTERBURNER: @ BTU/hr. each

9. CATALYST USED: No Yes

Describe Catalyst

10. HEAT EXCHANGER USED: No Yes

Describe Heat Exchanger

11. GAS FLOW RATE: 12. EFFICIENCY OF AFTERBURNER:

scfm %

13. COMPOSITION OF WASTE COMBUSTED:

14. MAXIMUM QUANTITY OF WASTE COMBUSTED (specify units):

Per hour Per year

15. INCINERATOR RESIDENCE TIME: 16. MOISTURE CONTENT OF EXHAUST GAS:

sec. %

DEP7007N

Page ______of ______(Revised 08/96) (continued) CONDENSER 1. EMISSION POINT NUMBER OF THE CONDENSER:

2. MANUFACTURER: 3. MODEL NAME AND NUMBER:

4. HEAT EXCHANGER AREA: 5. COOLANT FLOW RATE:

SQ. FT. Water GPM

Air scfm (at 68F)

Other: Type

Flow Rate

6. GAS FLOW RATE: 7. COOLANT TEMPERATURE:

scfm (AT 68F) In F; Out F

8. GAS TEMPERATURE: 9. EFFICIENCY OF CONDENSER:

In F; Out F %

10. COMPOSITION OF THE GAS AT THE:

A. Inlet:

b. Outlet:

ELECTROSTATIC PRECIPITATOR 1. EMISSION POINT NUMBER OF PRECIPITATOR:

2. MANUFACTURER: 3. MODEL NAME AND NUMBER:

4. COLLECTING ELECTRODE AREA: sq. ft.

5. GAS FLOW RATE: 6. EFFICIENCY:

scfm(@ 68F) acfm %

7. VOLTAGE ACROSS THE PRECIPITATOR PLATES: 8. RESISTIVITY OF POLLUTANTS:

9. NUMBER OF STAGES IN THE PRECIPITATOR:

Page ______of ______(Revised 08/96) DEP7007N (continued) CYCLONE 1 EMISSION POINT NUMBER OF CYCLONE:

2. MANUFACTURER: 3. MODEL:

4. TYPE OF CYCLONE: 5. NUMBER OF CYCLONES IN MULTIPLE CYCLONE:

Single Multiple

6. GAS FLOW RATE: 7. EFFICIENCY:

scfm (AT 68F) %

8. DIMENSION THE APPROPRIATE SKETCH BELOW (in inches)) OR PROVIDE A DRAWING WITH EQUIVALENT INFORMATION:

Page ______of ______(Revised 08/96) DEP7007N (continued) FILTER UNIT 1. EMISSION POINT NUMBER OF FILTER UNIT:

2. MANUFACTURER: 3. MODEL NAME AND NUMBER:

4. FILTERING MATERIAL: 5. FILTERING AREA:

6. CLEANING METHOD: Shaker Reverse Air

Pulse Air Pulse Jet Other (specify)

7. GAS COOLING METHOD: Ductwork: Length ft.; Diameter inches

Heat Exchanger Bleed-in Air Water Spray Other (specify)

8. GAS FLOW RATE (from source) 9. COOLING GAS FLOW RATE:

scfm (at 68F) Bleed-in Air scfm (at 68F);

Pressure Drop PSIA Water Spray GPM

10. INLET GAS CONDITION: 11. EFFICIENCY OF FILTER UNIT:

Temperature F Dew point F %

SCRUBBER 1. EMISSION POINT NUMBER OF SCRUBBER:

2. MANUFACTURER: 3. MODEL NAME AND NUMBER:

4a. TYPE OF SCRUBBER: Venturi Wet Fan

Packed; Packing Type Size Packed Height inches

Spray; Number of Nozzles Nozzle Pressure psig

Other (specify) (Attach description and sketch with dimensions)

4b. Pressure Drop Across the Scrubber inches H 2O

5. TYPE OF FLOW: Concurrent Countercurrent Crossflow

6. SCRUBBER GEOMETRY: Length in direction of Gas Flow ft. Cross-sectional area sq. ft.

7. CHEMICAL COMPOSITION OF SCRUBBING LIQUID: Ph Range 8. SCRUBBING LIQUID FLOW RATE: ______GPM 9. GAS FLOW RATE: scfm (at 68F) FRESH LIQUID MAKE UP RATE: ______GPM 10. INLET GAS TEMPERATURE: ______F 11. EFFICIENCY OF SCRUBBER: ______%

Page ______of ______(Revised 08/96) DEP7007N (continued)

OTHER TYPE OF CONTROL EQUIPMENT

1. EMISSION POINT NUMBER OF "OTHER TYPE" OF CONTROL EQUIPMENT:

2. GENERIC NAME OF "OTHER" EQUIPMENT:

3. MANUFACTURER: 4. MODEL NAME AND NUMBER:

5. DESCRIPTION AND SKETCH, WITH DIMENSIONS, FLOW RATES AND EFFICIENCY OF "OTHER" EQUIPMENT.

Page ______of ______(Revised 08/96)