Master thesis work CFD in Gas Turbine Swirl Generator The secondary air system of a gas turbine has the main purpose to supply cooling air to components in and near the hot gas channel. Additionally, it prevents hot gas from leaving the gas channel and flow into other more sensitive parts. Lack of cooling air or sealing air will lead to elevated component temperatures and in the worst case to machine failure. Therefore, it is essential to have a well designed secondary air system. On the other hand, extracting air from the compressor and discharge it into the gas channel will reduce the gas turbine performance, and it is therefore important to keep the secondary air flow at a minimum. Hence, there is a trade off between component lifetime and performance.

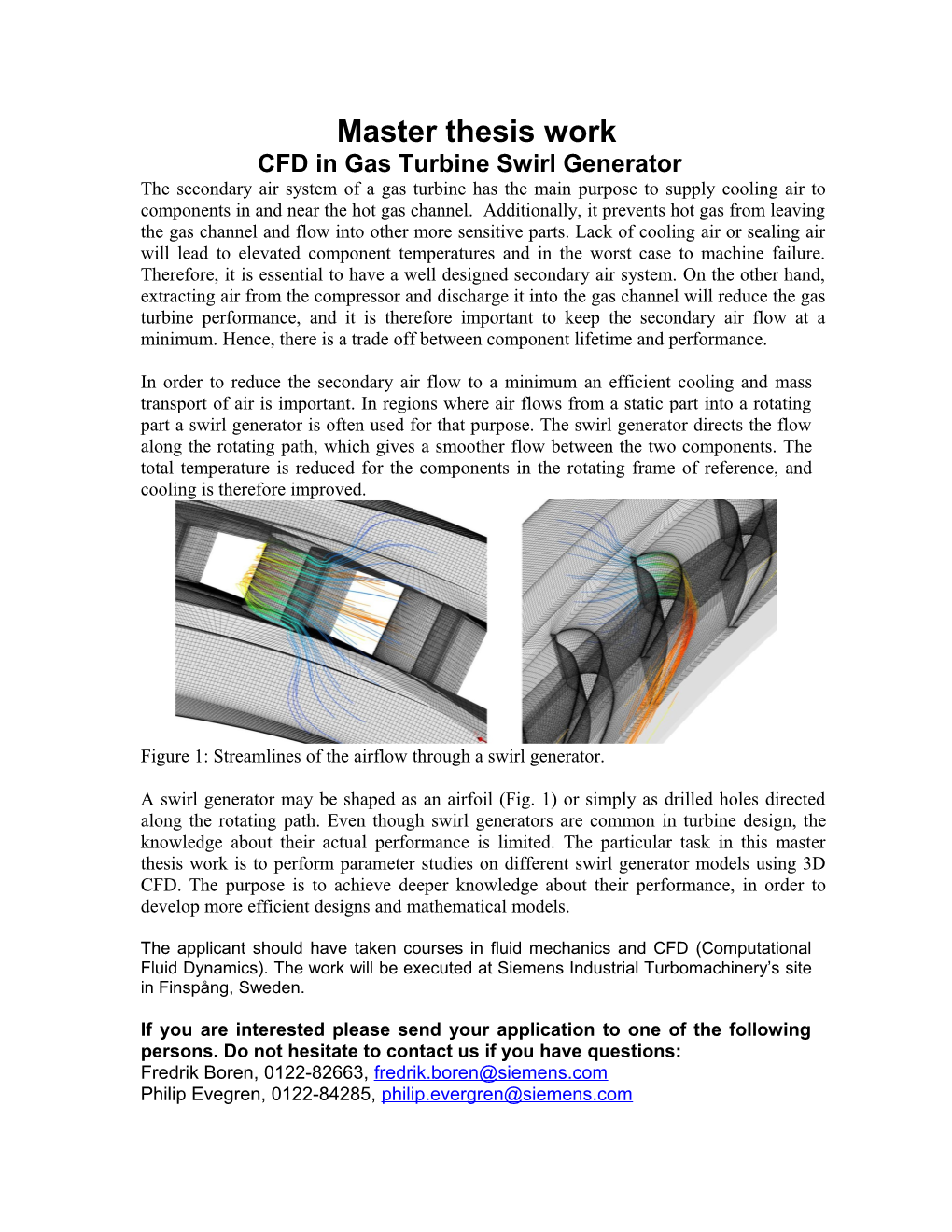

In order to reduce the secondary air flow to a minimum an efficient cooling and mass transport of air is important. In regions where air flows from a static part into a rotating part a swirl generator is often used for that purpose. The swirl generator directs the flow along the rotating path, which gives a smoother flow between the two components. The total temperature is reduced for the components in the rotating frame of reference, and cooling is therefore improved.

Figure 1: Streamlines of the airflow through a swirl generator.

A swirl generator may be shaped as an airfoil (Fig. 1) or simply as drilled holes directed along the rotating path. Even though swirl generators are common in turbine design, the knowledge about their actual performance is limited. The particular task in this master thesis work is to perform parameter studies on different swirl generator models using 3D CFD. The purpose is to achieve deeper knowledge about their performance, in order to develop more efficient designs and mathematical models.

The applicant should have taken courses in fluid mechanics and CFD (Computational Fluid Dynamics). The work will be executed at Siemens Industrial Turbomachinery’s site in Finspång, Sweden.

If you are interested please send your application to one of the following persons. Do not hesitate to contact us if you have questions: Fredrik Boren, 0122-82663, [email protected] Philip Evegren, 0122-84285, [email protected]