650:349 MECHANICAL MEASUREMENTS GROUP 4B APRIL 23, 2018

Strain Gage Measurements of has one clamped end and one free end, on Constant Stress and Cantilever which the load is applied. Beams

Your Name Here1, Norwood Fisher, Lisa Grant, Walter Kibby, Kendall Jones, Chris Dowd, Angelo Moore Department of Mechanical and Aerospace Engineering Rutgers University, Piscataway, New Jersey 08854

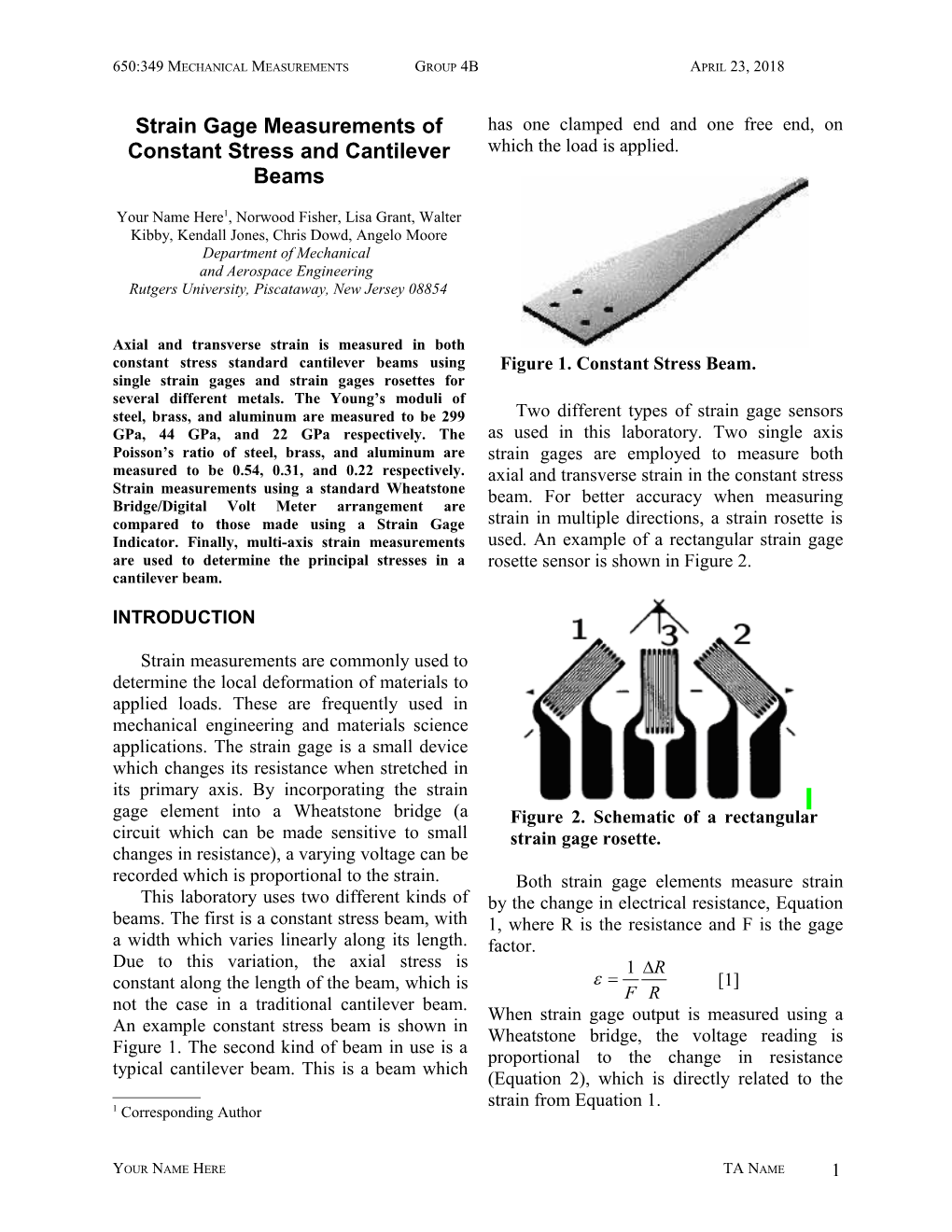

Axial and transverse strain is measured in both constant stress standard cantilever beams using Figure 1. Constant Stress Beam. single strain gages and strain gages rosettes for several different metals. The Young’s moduli of steel, brass, and aluminum are measured to be 299 Two different types of strain gage sensors GPa, 44 GPa, and 22 GPa respectively. The as used in this laboratory. Two single axis Poisson’s ratio of steel, brass, and aluminum are strain gages are employed to measure both measured to be 0.54, 0.31, and 0.22 respectively. axial and transverse strain in the constant stress Strain measurements using a standard Wheatstone beam. For better accuracy when measuring Bridge/Digital Volt Meter arrangement are compared to those made using a Strain Gage strain in multiple directions, a strain rosette is Indicator. Finally, multi-axis strain measurements used. An example of a rectangular strain gage are used to determine the principal stresses in a rosette sensor is shown in Figure 2. cantilever beam.

INTRODUCTION

Strain measurements are commonly used to determine the local deformation of materials to applied loads. These are frequently used in mechanical engineering and materials science applications. The strain gage is a small device which changes its resistance when stretched in its primary axis. By incorporating the strain gage element into a Wheatstone bridge (a Figure 2. Schematic of a rectangular circuit which can be made sensitive to small strain gage rosette. changes in resistance), a varying voltage can be recorded which is proportional to the strain. Both strain gage elements measure strain This laboratory uses two different kinds of by the change in electrical resistance, Equation beams. The first is a constant stress beam, with 1, where R is the resistance and F is the gage a width which varies linearly along its length. factor. Due to this variation, the axial stress is 1 R constant along the length of the beam, which is [1] F R not the case in a traditional cantilever beam. When strain gage output is measured using a An example constant stress beam is shown in Wheatstone bridge, the voltage reading is Figure 1. The second kind of beam in use is a proportional to the change in resistance typical cantilever beam. This is a beam which (Equation 2), which is directly related to the strain from Equation 1. 1 Corresponding Author

YOUR NAME HERE TA NAME 1 650:349 MECHANICAL MEASUREMENTS GROUP 4B APRIL 23, 2018

R V R [2] V 4 2R R

Using this rosette, one can determine the principal strains using geometry and the strain transformation equations. Thus strains recorded by the three gages can give the principle strains of the material, using Equation 1.

2 1 1 2 2 A,B 2 3 3 1 [3] 2 2 Figure 3. Axial and transverse strain for a Once the principal strains are known, using the constant stress aluminum beam. material properties, one can also calculate the stresses using Equation 2 a and b, where E is Comparison of the axial and transverse the Young’s modulus and is the Poisson’s strains from the constant stress beams gives the ratio for the material. Then, using equations material’s Poisson ratio. These strains are from the theory of cantilever beams, we can plotted in Figure 4 and the negative slope of compare the measured stresses to those the line is equal to the Poisson ratio. For mild calculated using standard formulas. steel, the Poisson ratio is 0.28. For brass and E aluminum, the Poisson ratios are 0.27 and 0.33 A 1 2 A B respectively. These values agree fairly well [4a,b] E with the theoretical ratios of 0.27-0.3 for steel, B 1 2 B A 0.33 for aluminum, and 0.34 for brass [1]

RESULTS AND DISCUSSION

Axial and transverse strain measurements were recorded from constant stress beams made of steel, brass, and aluminum. Strain is recorded using a zeroed Wheatstone bridge/digital volt meter as well as a strain gage indicator (SGI). Example data are shown in Figure 3 for the aluminum constant stress beam. There is good agreement between the two measurement methods for the transverse strain, Figure 4. Comparison of axial strain to but there is significant difference between the transverse strain to determine Poisson’s ratio of two methods for the axial strain. This could be several materials. due to drift in the Wheatstone bridge or in the strain gage. However, the strain recorded Using cantilever beam theory, we can increases linearly with applied load as expected calculate the stress in the constant stress beam from materials theory. No significant and compare that to the axial strain. The slope hysteresis is present between loading and of the line from this plot gives the Young’s unloading the beam. modulus of elasticity (E), Figure 5. For mild steel, E is found to be 155 GPa. For brass and

YOUR NAME HERE TA NAME 2 650:349 MECHANICAL MEASUREMENTS GROUP 4B APRIL 23, 2018 aluminum, it is found to be 62.5 and 45.6 GPa, Table 1. Measured and calculated stresses and respectively. The values are about 30% lower strains of a cantilever beam. than the accepted values (200 GPa for steel, A A B Cantilever 100 GPa for brass, and 70 GPa for brass). The mm mm/mm MPa mm/mm MPa source of this error could be the position of the meas. calc meas calc clamp holding the beam to the table during the 0 2.41E-06 0.2 -4.14E-07 0 experiment. The clamp should have been as 2.5 1.61E-04 11.9 -4.22E-05 11.8 5 3.23E-04 23.7 -8.68E-05 23.6 close to the edge of the table as well as to the 7.5 4.85E-04 35.6 -1.31E-04 35.4 point of the beam where the rectangular base 10 6.47E-04 47.4 -1.76E-04 47.2 meets the triangular shaped section of the beam. This idealized setup what not achieved CONCLUSIONS in the lab and probably led to the discrepancies between the calculated and theoretical values. Strain gages were used to measure axial and transverse strains in constant stress and standard cantilever beams. Measured values for Young’s modulus and Poisson’s ratio were close to accepted values; however, errors in the way the beam was clamped may have caused these differences. Strain measurements were made with a Wheatstone bridge/Digital Voltmeter system as well as a strain gage indicator. Generally, the SGI was more accurate. For the cantilever beam, measured principal stains were in excellent agreement with theoretical values.

REFERENCES

[1] Gere, J.M., Mechanics of Materials, 5th ed, Figure 5. Calculated axial stress versus Chapman and Hall, London, 2000. measured axial strain to determine Young’s Modulus for several constant stress beams.

The second part of this study looked at the stress in a simple cantilever beam. A strain rosette (as pictured in Figure 2) is used to measure three strain values at 45 degrees from each other for a beam of aluminum with dimension (9 x 1 x 0.1 inches) that is deflected a known amount () using a micrometer. Principal strains and stresses are then computed using Equation 3 and 4a,b and are shown in Table 1. Very good agreement is seen between the calculated principal stress and the calculated stress in the cantilever beam.

YOUR NAME HERE TA NAME 3