Introduction & Figures of Merit

Suggested Reading Skoog/Holler/Crouch 6th Edition: Chapter 1A, 1B, 1E, Appendix 1

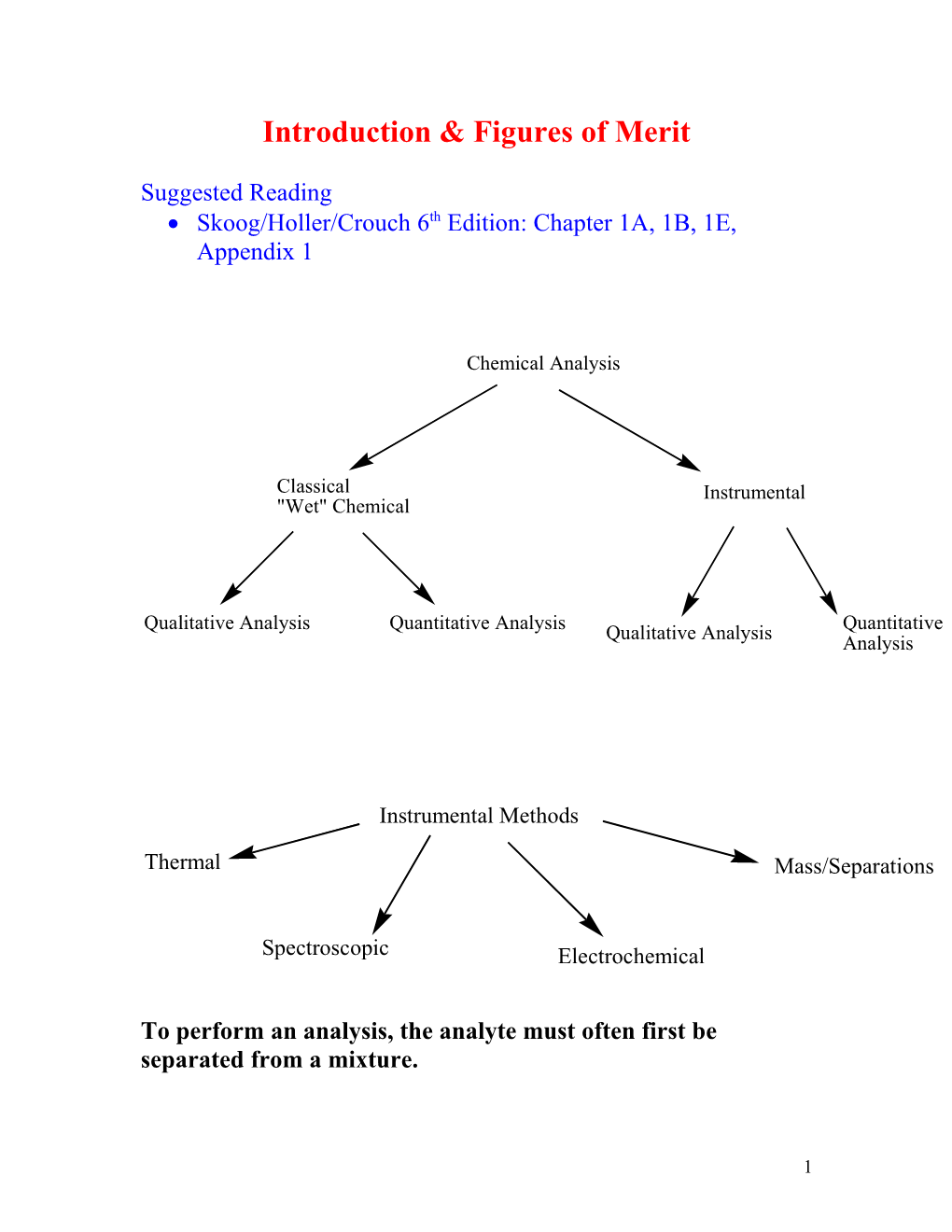

Chemical Analysis

Classical Instrumental "Wet" Chemical

Qualitative Analysis Quantitative Analysis Qualitative Analysis Quantitative Analysis

Instrumental Methods

Thermal Mass/Separations

Spectroscopic Electrochemical

To perform an analysis, the analyte must often first be separated from a mixture.

1 Analytical Separations

Chromatography Mass Spectrometry GC, LC, SFC Capillary Electrophoresis

After separation chemical analysis often performed on analyte.

Preparatory Separations – analysis often performed off-line. (Synthesis, large scale separations) Analytical Separations – analysis often performed on-line with separation method. This course is concerned with analytical, or very small scale separations.

Fundamentals are the same for analytical and preparatory separations, technique specifics differ.

Outline for this section 1. Fundamentals A. Instrument performance characteristics (Figures of Merit) and statistical background review.

B. Instrument Calibrations a. Traditional (Review) b. Standard Additions c. Internal Standards C. Signals, Noise, S/N a. Definitions/Sources

2 b. Methods for S/N enhancement

General Instrument Performance Characteristics First define the problem: What accuracy is required? What is the analyte concentration range? What components of the sample might interfere with the analysis? Etc.

Statistics Review in Appendix 1 Appendix 1 (answers on p. 1008)

You should be able to do the following questions and problems. Some are trivial, others not so much. 1-7, 10, 12-13, 16, 21, 24

3 1. Precision = Measurement Reproducibility Review statistics:

4 2. Bias = systematic measurement error

3. Sensitivity = Ability to distinguish between small differences in analyte concentration

Sensitivity Illustration

12

S = mC + SBl

10

8 l a n g i S

t

n 6 e m u r t s n I

4

2

0 0 1 2 3 4 5 6 Analyte Concentration

5 4. Detection Limit = minimum analyte concentration that can be detected with a given confidence level.

Find the detection limit for a fluorescence analysis given the following calibration data. Analyte Conc. (pg/mL) Fluorescence Intensity 0 2.1 2 5.0 4 9.0 6 12.6 8 17.3 10 21 12 24.7

30

l y = 1.9304x + 1.5179 a 25 n g i

S 20

e c

n 15 e c s

e 10 r o u

l 5 F 0 0 2 4 6 8 10 12 14 pg/mL

6 SUMMARY OUTPUT Standard Coefficients Error Regression Statistics Intercept 1.517857143 0.294936001 X Variable Multiple R 0.998879565 1 1.930357143 0.040900264 R Square 0.997760386 Adjusted R Square 0.997312463 Standard Error 0.432847713 Observations 7

5. Linear Dynamic Range = Analyte concentration range from the Limit of Quantification concentration at which there is a non- linear instrument response.

7 6. Selectivity = A method’s ability to selectively analyze an analyte in the presence of other chemical species (the sample “matrix”). Signal = maCa + mbCb + Sbl m = analytical sensitivity, c = concentration

Instrument Calibrations External Standards (Traditional) Standard Additions Internal Standards

Section 1D pp. 11-17 Appendix 1 Section a1D.

External standards – prepared separate from the sample (what you are familiar with).

1) Prepare standards of “exactly” known concentrations covering the linear dynamic range 2) Prepare a blank containing everything in the sample except the analyte 3) Obtain instrument response for standards and blank 4) Plot instrument response versus standard concentrations

8 Plot is linear over the dynamic range Use linear least squares within the dynamic range to fit the data For non-linear calibrations fit to appropriate function (not ideal).

Signal from unknown must be within range of standards (no extrapolation)

9 What if you have a complicated sample with many species – and a method that is not completely selective?

If you know the matrix…

If you don’t know the matrix… Standard Additions –

This is the most common “spiking” procedure: 1. Equal volumes of unknown are pipetted into several volumetric flasks 2. Increasing volumes of standard are added to each flask (the standard is the same as the analyte) 3. Each flask is diluted to the same final volume

10 4. For each flask a measurement of analytical signal is obtained (containing both unknown analyte + known amount of additional added analyte)

To treat the data – can think about it graphically or algebraically.

11 Algebraically

What if … You have an instrument whose response fluctuates, or You have a sample preparation procedure that results in irreproducible loss of analyte, or You have no way to reproducibly input a constant volume of sample into an instrument

Internal standards calibration procedure

12 K with Li Internal Standard Calibration

4.5

o 4 i y = 0.00721x + 0.474 t

a 3.5 2

R R = 0.995 3 y t i 2.5 s

n 2 e t n

I 1.5

i

L 1 /

K 0.5 0 0 100 200 300 400 500 600 ppm K

Chapter 1 Problems 9, 11

13 Signals and Noise Sections 5A Signal-to-Noise Ratio √ 5B Noise sources in instruments requires knowledge of electronics (Skip) 5C Signal-to-Noise Enhancement 5C-1 Hardware requires knowledge of electronics (Skip) 5C-2 Software methods √

5A Signal-to-Noise Ratio Remember – every measurement has inherent uncertainty (random error) “Noise” is the electronic manifestation of this random error. It degrades measurement accuracy/precision Determines the detection limit

Every measurement contains 2 components: 1. Signal = response from analyte 2. Noise

Since noise is mostly independent of signal strength, the effect of noise on the analysis depends on the signal. A most useful figure of merit: Signal-to-Noise Ratio (S/N)

14 Noise – standard deviation of numerous measurements of signal strength Signal – average (mean) of numerous measurements of signal strength

S/N =

This is nothing new. Calculate the S/N ratio for the following titrimetric data. Five titrations of the same amount of material required the following volumes: 24.38 mL, 24.21 mL, 24.46 mL, 24.30 mL, 24.40 mL.

Why is S/N important? For one thing, it tells whether or not a signal is detectable.

General Rule: A signal cannot be detected if S/N < 3.

15 To calculate S/N for 2 absorbance spectra: S/N =

Malachite Green Absorbance Spectra

0.45 Signal = 0.39 0.4

0.35

0.3 Concentrated solution 0.25 e c n a b

r 0.2 o

s Signal = 0.079 b A 0.15

0.1

0.05 S

0 Dilute solution

-0.05 400 450 500 550 600 650 700 750 800 Wavelength (nm)

Clearly a high S/N is desirable. Hardware devices to increase S/N (5C-1, electronics/instrument design) Software methods to enhance S/N. Routinely done (5C-2)

16 5C-2 Software methods to enhance S/N 1. Ensemble or signal averaging. Make n repetitive measurements and average the result. (No different from replicate titrimetric analyses)

In the absence of systematic error…

Find means of replicate measurements, less scatter.

Below is data from an absorbance spectrum of malachite green in a region where there is no absorbance (i.e. noise or random error).

0.12 1. Find the mean and standard deviation for this set of 20 0.12 0.09 measurements. 0.08 0.07 0.08 2. Find the mean and standard deviation from the means 0.07 of sets of 5 measurements. 0.07 0.08 0.08 3. Compare the mean and standard deviations. 0.07 0.06 0.08 0.09 0.08 0.07 0.05 0.07 0.07 0.08

The standard deviation of the means is inversely proportional to n , where n = number of measurements averaged to generate the mean. (Note confidence interval equation)

Noise = random error of measurement, measured by standard deviation.

17 There is a n dependence on S/N for ensemble or signal averaging.

Vertical scale increases as the number of scans increases.

Random signal fluctuations (noise) increases with n .

Signal increases with n.

S/N increases

Summary:

18 2. Boxcar Averaging The average of a small number of adjacent data points is a better measure of signal than all of the individual data points. (Signal varies more slowly than noise)

2 pt 3 pt x-axis Signal boxcar boxcar x-axis Signal x-axis Signal 1 0.2 2 0.9 1.5 0.55 2 0.733 3 1.1 4 2.2 3.5 1.65 5 3.5 5 3.233 6 4 5.5 3.75 7 3.6 8 3.8 7.5 3.7 8 3.567 9 3.3 10 3.1 9.5 3.2 11 2.9 11 2.8 12 2.4 11.5 2.65 13 1.8 14 1.2 13.5 1.5 14 1.267 15 0.8

unprocessed

4.5

4

3.5

3

2.5 l a n g i S 2

1.5

1

0.5

0 0 2 4 6 x-axis8 10 12 14 16

2 pt boxcar

4

3.5

3

2.5 l a

n 2 g i S Summary: 1.5

1

0.5

0 0 2 4 6 8 10 12 14 16 19 x-axis 3. Digital Filtering A moving boxcar average – must include an odd number of data points. 3 pt moving 5 pt moving x-axis Signal boxcar boxcar x-axis Signal x-axis Signal 1 0.2 2 0.9 2 0.733 3 1.1 3 1.4 3 1.58 4 2.2 4 2.267 4 2.34 5 3.5 5 3.233 5 2.88 6 4 6 3.7 6 3.42 7 3.6 7 3.8 7 3.64 8 3.8 8 3.567 8 3.56 9 3.3 9 3.4 9 3.34 10 3.1 10 3.1 10 3.1 11 2.9 11 2.8 11 2.7 12 2.4 12 2.367 12 2.28 13 1.8 13 1.8 13 1.82 14 1.2 14 1.267 15 0.8 Shown below are the results of moving boxcar averages from real spectra of many hundreds of data points.

Malachite Green Absorbance Spectra

0.09

0.08

0.07

0.06

0.05 e c n a b

r 0.04 o s b A 0.03

0.02

0.01

0

-0.01 400 450 500 550 600 650 700 750 800 Wavelength (nm)

20 y t i s n e t n I l a n g i S m a e

B -1 0.5 cm resolution e l 19 pt. Boxcar averaged g n i S e v i t a l e R

2390.00 2370.00 2350.00 2330.00 2310.00 2290.00 2270.00 2250.00 Wavenumber

21 Summary:

Polynomial least squares data smoothing: similar to moving boxcar averaging but with weighted data points.

Rather than simply averaging (an odd number) of data points, a least squares fit of x data points to a polynomial is done. The central point of the fitted polynomial is the new data point. This “Savitzky-Golay” smoothing is available in most data analysis software.

Original ref: Anal. Chem. 1964, 36, 1627.

The best solution is to eliminate, or reduce as much as possible, noise in the first place.

There are various sources of noise (Section 5B), much of it resulting from electronics in the instrumentation: Thermal Shot (from junctions) Flicker (1/f) Environmental*

It is good to be aware of sources of environmental noise.

22 Often low frequency signals are modulated to frequency regions which have minimal environmental noise.

In spectroscopy the signal can be modulated by a chopper which interrupts the light beam periodically blocking the beam. The resulting square wave output has a frequency of the chopper.

23 End of Chapter 5 problems: 1-3, 6-8, 11-12, 13a,e (Problem 13 data exists on the website: www.thomsonedu.com/chemistry/skoog)

24