Flow Computer - Operation Manual

Contents

Introduction 1 Front Panel Description 3 Technical Specification 4 Installation 4 Terminal Arrangement 5 Programming Flow Chart 6 Operation 7 Panel Cutout 10 Error Message And Troubleshooting 12

Introduction:

ASFC-1209 represents Flow indicator/totalizer/transmitter for flow applications related to any GAS flow. The instrument is designed to accept 3 inputs of FLOW, PRESSURE and TEMPERATURE at a time. Based on these inputs instrument have in-built automatic computations of Density of the gas and other fed in parameters, the instrument calculates the instantaneous flow rate. This Calculation totally compile with AGA3, Nx19. This flow computer can be easily interfaced to PLC, SCADA or DCS systems as various options like analog retransmission and RS232/485-MODBUS or GPRS/GSM connectivity And SCADA OFFERS more flexibility and enables remote monitoring. Display models are available with weatherproof &flame proof endosome as an optional feature.

These computing units having Different parameter FED facility like: DP Transmitter range in mm WC Pressure range in Kg/cm2 Flow rate for retransmission output Orifice diameter in mm Pipe inside diameter in mm Specific gravity Mole % CO2 gas Mole % N2 gas FB/NB Communication parameter with automatic unit range ability.

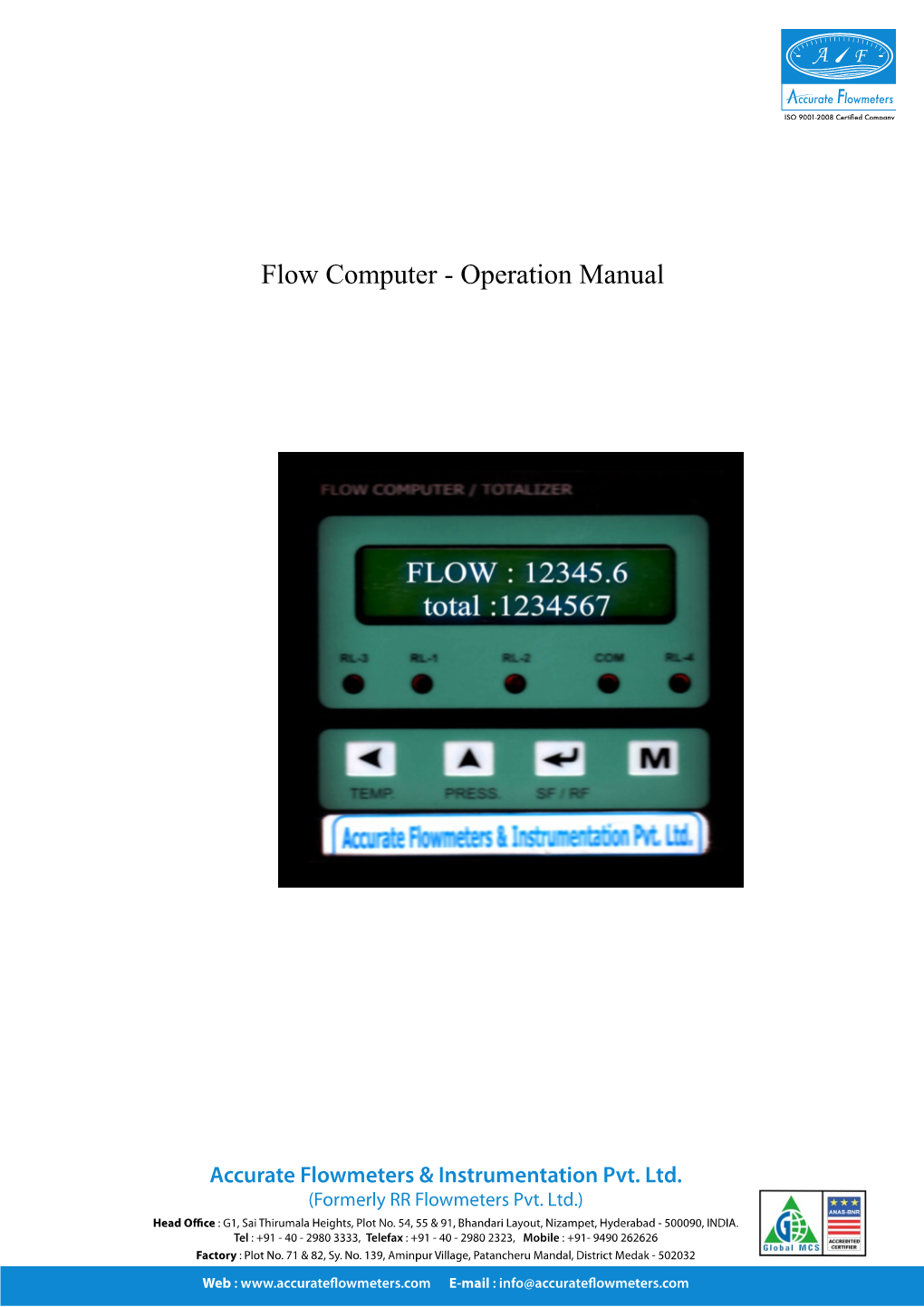

Front Panel Description:

Sl. No. Display Description 1 Flow Actual Flow Rate Value 2 Tot. Total Flow Value 3 R1 Not Applicable 4 R2 Not Applicable 5 COM. Red LED will blink when active communication

Sl. No. Key Particular Description 8 M Function (M) Press to access the programmable Parameter 9 Up Press to increase selected digit or value in Programming mode. 10 Pass Press to change digit selection or selected value in Programming mode. 11 Enter Press to accept modified digit or value in Programming ↵ mode.

Features:

Multi parameter auto scroll display like Gas Pressure, Temperature, Normal Cubic Meters and Standard Cubic Meters and Total. The instrument can be configured to work on Natural gas or any gas, Steam, etc. Accepts up to three inputs; Flow (mA), Pressure (mA), Temperature (Ma / RTD Pt-100) Non-volatile memory to retain Totalized Flow. No battery to change or fail. Gives efficient Pressure and Temperature Compensations for Mass Flow Calculations. Calculates Flow rates in NCMH or SCMH, as selected. Linear or square root input selections, with 0.1% accuracy. Isolated 0/4-20mA retransmission output Proposal to standard Flow Rate. Field operated user-friendly menu for device Configuration & Calibration. 8/10 digit Flow Totalizer with password protected resetting. Fully password protected for tamper free operation. Isolated highly communicative serial interface facility (RS 232 / 485) 2 numbers 24V loop power supply for Flow & Pressure Transmitters. Optional GSM mobile connectivity for wireless remote reading purpose (SMS) Flow metering computer software available. Weather proof or flame proof housing.

Technical Specifications:

Installation:

Terminal Arrangement:

Setup Mode:

Parameter Description Range Default Value Password: 0000 Password for Parameter Setting Values between 0000 Enter Password Scroll the digit by key, increase by key. 0000 to 9999

Password for Configuration Parameter DP. Dp Loc: 000.0 DP Decimal Point 0000. 000.0 Setup mode Scroll the digit by key, increase by key. 000.0 00.00 Decimal point for DP value 0.000 Pressure - kg/cm2: Pressure Transmitter Range Values between 7.000 7.000 Scroll the digit by key, increase by key. 0.000 to 9.999 Setup mode Pressure transmitter range in Kg/cm2 DP – mmWC: 550.0 Diff. pressure Transmitter Range Values between 550.0 Setup mode Scroll the digit by key, increase by key. 000.0 to 999.9 Diff. pressure Transmitter Range in mm WC. Pipe dia.: 52.50 Pipe Diameter Values between 52.50 Setup mode Scroll the digit by key, increase by key. 00.00 to 99.99 Flow pipe diameter in mm

Orifice dia.: 26.95 Orifice Diameter Values between 26.95 Setup mode Scroll the digit by key, increase by key. 00.00 to 99.99 Orifice diameter in mm

Base pressure: 14.73 Base Pressure Values between 14.73 Setup mode Scroll the digit by key, increase by key. 00.00 to 99.99 Base pressure condition factory set value Base temperature: Base Temperature Values between 0060. 0060 Scroll the digit by key, increase by key. 0000. To 9999. Setup mode Base Temp. Condition Factory set value

%CO2 Mol.: 01.20 %CO2 Mole. Values between 01.20 Setup mode Scroll the digit by key, increase by key. 00.00 to 99.99 Mole percentage of Carbon Dioxide. Factory set value

%N2 mol.: 01.00 %N2 Mole. Values between 01.00 Setup mode Scroll the digit by key, increase by key. 00.00 to 99.99 Mole percentage of nitrogen. Factory Set Value. Sp. Gravity: 0.650 Specific Gravity. Values between 0.650 Setup mode Scroll the digit by key, increase by key. 0.000 to 9.999 Specific Gravity of Gas. Factory set Value. Nb: 4322 NB Factory Set Value. 4322 Setup mode Scroll the digit by key, increase by key. Fb: 1615 Fb factory set value. 1615 Setup mode Scroll the digit by key, increase by key. MUL: 0000 MUL factory set value. 0000 Setup mode Scroll the digit by key, increase by key.

Parameter Description Range Default Value Cal Total: 1681 Cal total factory set value. 1681. Setup mode Scroll the digit by key, increase by key. O/P flow: 2000 Output flow Values between 2000. Setup mode Scroll the digit by key, increase by key. 0000 to 9999 Output flow O/P flow: 2000 Output flow Values between 2000. Setup mode Scroll the digit by key, increase by key. 0000 to 9999 Output flow Node address: Node Address. Values between 0001 0001. Scroll the digit by key, increase by key. 0000to 0255 Setup mode Device address for communication. Baud Rate Baud rate. 4800 9600 9600 Change the type by key. 9600 Setup mode Baud rate for communication. 19200 Parity: none Parity. None: none None Setup mode Change the type by key. Odd: even parity Baud rate for communication. Even: odd parity

Calibration Mode:

Parameter Description Range Default Value Password: 0000 Password for Parameter Setting. Scroll the digit Values between 0000 Enter Password by key, increase by key. 0000 to 9999 Temp Low:_ Calibration Temperature Low According to input ----- Calibration Mode Apply the low Temperature signal & press ↵ type key According to input type Temp High:_ Calibration Temperature High According to input Calibration Mode Apply the high Temp. signal & press ↵ key type ----- According to input type Press Low:_ Calibration Pressure Low According to input Calibration Mode Apply the low Temp. signal & press ↵ key type ----- According to input type Press Low:_ Calibration Pressure High According to input Calibration Mode Apply the High Temp. signal & press ↵ key type ----- According to input type

Parameter Description Range Default Value Press High:_ Calibration DP Low Calibration Mode Apply the High Temperature signal & press According to input ----- ↵ key type DP High:_ Calibration DP High ----- Calibration Mode Apply the High Temp. signal & press ↵ key According to input type Out Lo:_ Calibration Output Low Calibration Mode Set the out put by and key Press ↵ According to input ----- key to fix the desired low output type

Out Hi:_ Calibration Mode ⏎⏎⏎ Calibration Output High Set the output by and key Press ↵ key According to input ----- to fix the desired High output type

Reset Mode:

Parameter Description Range Default Value Password: 0000 Password of Parameters Setting Value between 0000 Enter Scroll the digit by key increase by 0000to 9999 password key

Password for Setup Parameters Reset total: No Reset Total Value Reset Mode Change the Type by key No: No to Reset No Yes: Reset Value To Reset Total Flow value

Panel Cut Out:

A

PANEL CUTOUT

Model A B C D E a b c d

AA- 96 96 10 80 92 92+0.5 92+0.5 120 96 96*96

ERROR MESSAGE AND TROUBLE SHOOTING:

Parameter Description Range Default Value Temp Low:_ Calibration Temperature Low According to input type ----- Calibration According to input type Mode Apply the low Temp. signal & press key Temp High:_ Calibration Temperature High According to input type Calibration According to input type ----- Mode Apply the high Temp. signal & press key Press Low:_ Calibration Pressure Low According to input type Calibration According to input type ----- Mode Apply the low Temp. signal & press key Press Low:_ Calibration Pressure High According to input type Calibration According to input type ----- Mode Apply the High Temp. signal & press key Press High:_ Calibration DP Low Calibration According to input type ----- Mode Apply the High Temp. signal & press key DP High:_ Calibration DP High ----- Calibration According to input type Mode Apply the High Temp. signal & press key Out Lo:_ Calibration Output Low Calibration According to input type ----- Mode Set the output by and key Press key to fix the desired low output Out Hi:_ Calibration Calibration Output High Mode According to input type ----- Set the output by and key Press key to fix the desired High output

5. RESET MODE

Parameter Password of Parameters Setting Range Default Value Password: Scroll the digit by key increase by key Value between 0000to 9999 0000 0000 Password for Setup Parameters password

Reset total Reset Total Value No: Change the Type by key No: No to Reset No Reset Mode To Reset Total Flow value Yes: Reset Value

ERROR MESSAGE AND TROUBLE SHOOTING:

Symptom Probable Solution 0000 -Sensor break error -Replace senor Value -Sensor not connected -Check the sensor is connected correctly

Keypad no function - Keypads are locked -Check Keypad -Keypads defective continuity? -Replace Keypads No proper -Input connection incorrect -Check out input wiring Flow value -Check all Sensor All LED’s and display -No power to controller Connected Properly not light -Controller circuit failure

Process Value changed -Electromagnetic -Check power lines abnormally Interference(EMI)or connection Radio Frequency Interference(RFI) -Check Control Supply Voltage -Suppress arcing contacts in system to eliminate high voltage spike sources. Separate sensor and controller wiring from – dirty line OR Ground heaters Entered data lost -Fail to data to EEPROM -EEPROM Error, Replace EEPROM