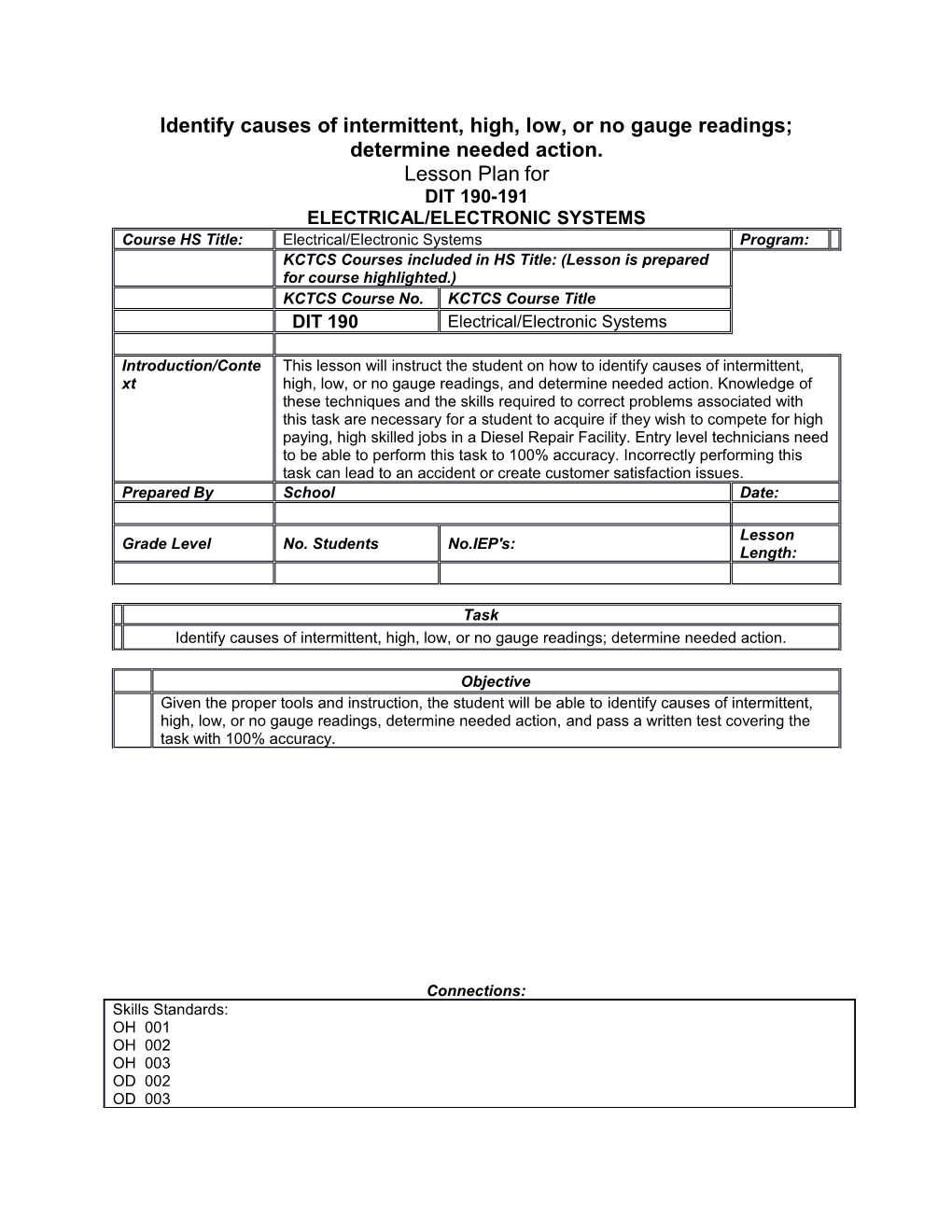

Identify causes of intermittent, high, low, or no gauge readings; determine needed action. Lesson Plan for DIT 190-191 ELECTRICAL/ELECTRONIC SYSTEMS Course HS Title: Electrical/Electronic Systems Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title DIT 190 Electrical/Electronic Systems

Introduction/Conte This lesson will instruct the student on how to identify causes of intermittent, xt high, low, or no gauge readings, and determine needed action. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in a Diesel Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Identify causes of intermittent, high, low, or no gauge readings; determine needed action.

Objective Given the proper tools and instruction, the student will be able to identify causes of intermittent, high, low, or no gauge readings, determine needed action, and pass a written test covering the task with 100% accuracy.

Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 New Common Core Standards: RST 11-12 3 Common Core Technical Standards: TD-OPS 2 TD-SYS 2

INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Various Electrical/Electronic Systems ASE Test Prep T6 Fifth Delmar 32-33

Equipment Quantity Item Source

Content/Presentation/Demonstration Outline Tell students that when troubleshooting gauge systems, it is important to determine whether the problem exists with all the gauges or just one gauge. For example, older style bi-metal gauges are sensitive to voltage fluctuations. If they find that they all read too high or too low, let them know that it is possible that the instrument voltage regulator is malfunctioning. Explain that the purpose of the instrument voltage regulator is to maintain a steady voltage supply to the gauges, regardless of battery voltage. Inform them that a number factors, including high resistance, a defective sending unit, or a malfunctioning gauge, may cause individual gauges to read erratically. Instruct students to follow the manufacturer’s instructions for out-of-dash gauge testing. Tell them that a good place to begin diagnosis on a single gauge problem is to disconnect the sending unit. Explain that doing this should cause the gauge to react either by moving to the top or bottom of the scale. Next, tell them to try connecting the sending unit wire to a good ground. This action should cause the cause to move to the opposite end of the range as before. Let them know that some technicians will use a variable resistor at the sending unit to make the gauge move throughout its range. If the gauge reacts to the above actions, then the gauge and related wiring is good and the sending unit should be replaced. Tell them that late-model instrumentation systems primarily use magnetic-style gauges. Most are not affected by changes in system voltage and therefore do use a separate instrument voltage regulator. Remind them to follow OEM instructions when diagnosing electronic dash displays. Let them know that not all gauges in an instrument panel are electrically operated. Some gauges, such as air application gauges, are mechanically actuated and not affected by electrical problems. Tell them that air application gauges must test within 4 psi of an accurate master gauge. Inform them to never rely only on the accuracy of dash gauges to make major decisions, such as determining the need for an engine rebuild. For example, if vehicle instrumentation indicates low engine oil pressure, tell them to confirm the problem with a known, accurate, mechanical gauge to verify the condition. Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)