End-cap Electromagnetic Calorimeter

Introduction The EEMCs are made of lead and scintillating fibers, at the two ends of BESⅢ, 115cm apart from the colliding point, giving an angular coverage range: 0.80<|cosθ| <0.94. The main purpose of the EEMC is to measure the energies and hit positions of electrons and photons in the EEMC coverage range. The EEMC has a rapid time response and can give fast trigger, and charged particle identification. Same as the Barrel EMC, to keep energy resolution in an enough wide range will be necessary.

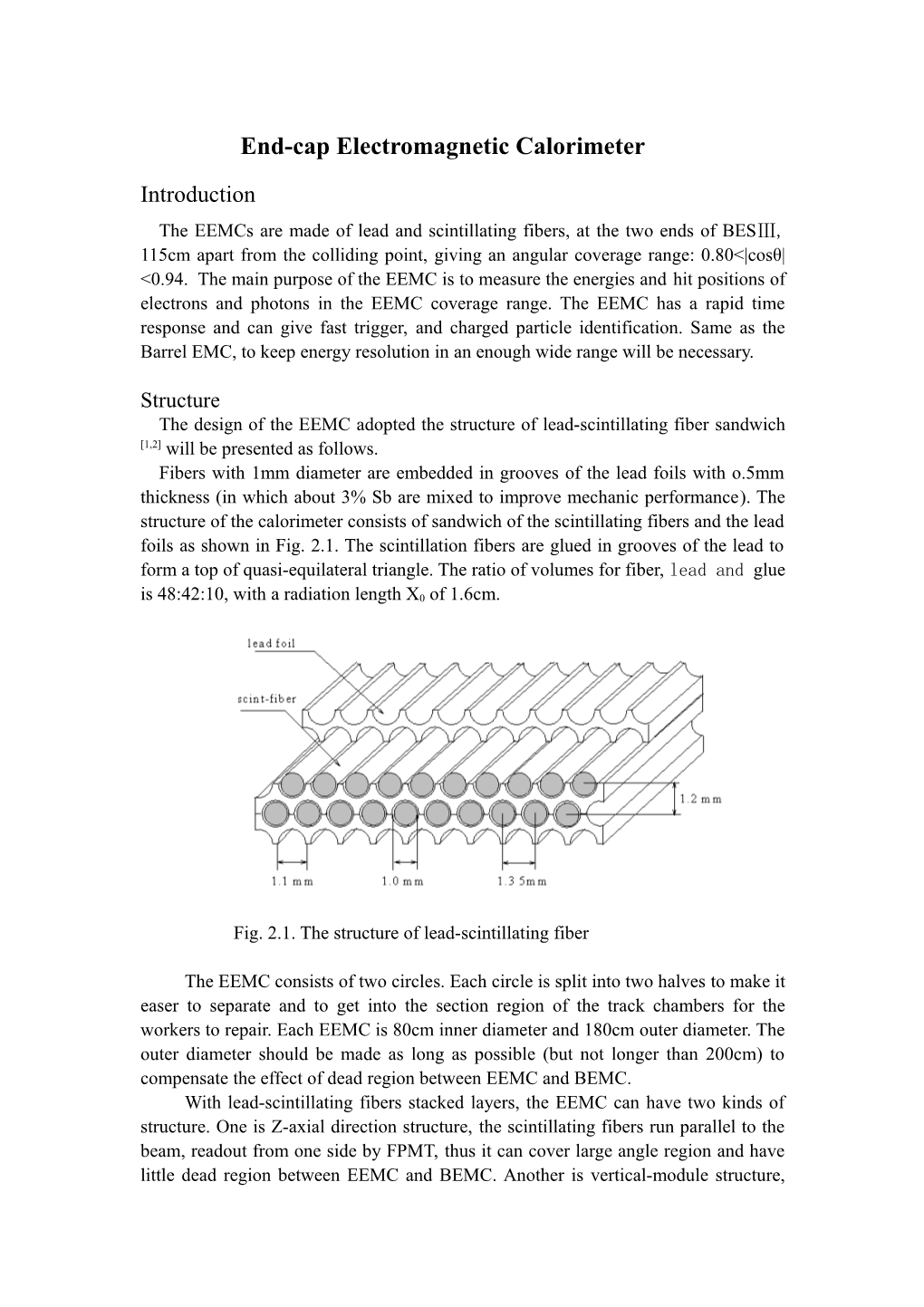

Structure The design of the EEMC adopted the structure of lead-scintillating fiber sandwich [1,2] will be presented as follows. Fibers with 1mm diameter are embedded in grooves of the lead foils with o.5mm thickness (in which about 3% Sb are mixed to improve mechanic performance). The structure of the calorimeter consists of sandwich of the scintillating fibers and the lead foils as shown in Fig. 2.1. The scintillation fibers are glued in grooves of the lead to form a top of quasi-equilateral triangle. The ratio of volumes for fiber, lead and glue is 48:42:10, with a radiation length X0 of 1.6cm.

Fig. 2.1. The structure of lead-scintillating fiber

The EEMC consists of two circles. Each circle is split into two halves to make it easer to separate and to get into the section region of the track chambers for the workers to repair. Each EEMC is 80cm inner diameter and 180cm outer diameter. The outer diameter should be made as long as possible (but not longer than 200cm) to compensate the effect of dead region between EEMC and BEMC. With lead-scintillating fibers stacked layers, the EEMC can have two kinds of structure. One is Z-axial direction structure, the scintillating fibers run parallel to the beam, readout from one side by FPMT, thus it can cover large angle region and have little dead region between EEMC and BEMC. Another is vertical-module structure, the scintillating fibers are vertically placed, readout from two ends by FPMT, as shown in Fig .2.2. In this structure several advantages can be acquired, which are listed below.

Fig. 2.2. The structure of the EEMC

1) The cross section is 4.5cmx4.5cm. There are 5 units along Z-axial direction,

which are 22.5cm in thickness (about 14X0) in total. Information of charge and time are read out by FPMTs at both ends of each unit. The readout number needed here are only half of the Z-axial direction structure with same cross section of the unit. 2) The hit point can determine by analyzing the information of the time difference from both ends for each unit. The spatial resolution of the hitting center of shower is less than 1cm/ E(GeV ) , thus the developing direction of the shower can be determined. 3) For the hadrons penetrating through the EMC, we will get time information of 5 layers, from 10 FPMTs, which can provide a time resolution of 120ps. Also we can get good identification of K/πat a 2σlevel, covering the energy region up to 1.1GeV. 4) Because of hitting location determination in every layer, the energy resolution of γ radiation can be improved up to about 6%/ E(GeV ) by doing correction to the attenuation length of scintillating fibers. While for the Z-axial structure, the attenuation in the area more close to the export point is much larger, which makes the energy non-linear due to the light readout of different shower location, and this cannot be corrected. 5) This structure occupies a Z-space about 25cm, as thick as the absorbent material, less than the structure of the Z-axial direction, which is thicker than 45cm and makes the iron to expand outward and the solenoid of the magic field correspondingly longer. However, in the vertical-module structure, the outer diameter of the EEMC will be cut down 20cm in order to place the FPMTs. Thus it can only cover a polar angle of cosθ~0.83, while the BGO-EMC covers cosθ~0.77, so there is a dead region here. The light collection 1. As shown in Fig.2, there are 30 units in the outer region of the EEMC circle and 10 up, 10 down units in the inner region. Each EEMC needs 500 FPMT, and totally amounts to 1000. 2. Adopting a special structure to couple the FPMTs to the end of the units. First, the scintillating fibers are about 15cm longer than the lead plates, and the scintillating fibers of each unit are bended about 45 degrees angle and bundled into a cylinder of 3.6cm diameter. In order to distribute the light over the photo-cathode area of the FPMT, the fibers are coupled to the FPMT through a piece of cone light guide (8cm length, with diameter from 2.8cm to 3.8 cm) by gluing (in between the fibers and light guide). The light guide is made of the plexiglas, the light transmits via several reflections at the interface of plexiglas- air, with a trapping efficiency of 100% (not including absorption). The readout of the PMT The type of the FPMT to be used is R5946 produced by HAMAMATSU, with outer diameter of 40cm, cathode window diameter of 27mm, transit time of 7.2ns, fluctuation of single photoelectron transit time of 150ps and photoelectric efficiency of 22% to 439nm wave-length light. The gain of PMT with diameter of 40mm is only 1x106, which will be reduced to 1/50 in a magnetic field of 1T. In order to keep a good time information and high detecting efficiency, a 50-time fast multiplier will be added to the end of voltage distributor. The type of Scintillating Fiber is BCF-12, 1mm diameter, emitting light’s wavelength of 435nm, attenuation length of 2.7m and decay time of emission of 3.2ns.

Cost Item amount cost FPMTs: 1200 ~10 million Scintillating Fibers: 800km 3.5 million Light guide: 1000 0.3 million Divider : 1200(not including pre-multiplier) 0.4 million Unit production:(including lead, glue, etc.) 2.0 million Mechanical equipment: 0.8 million High voltage equipment: 1.4 million Testing equipment & monitoring equipment: 1.6 million Total 20 million Project schedule 2001.6—2002.12 R&D and searching for international co-operations

order of PMTs 2003.1—2004.12 order of light guide and fiber mechanical design & machining

light guide machining 2004.1—2004.12 voltage distributor production detector production measurement of PMTs & voltage distributor

2005.1—2005.6 measurement of detector 2005.6— completing installation and adjustment together Reference: 1. Nuclear Instrument and methods in physics Research A354(1995)352-363 2. Nuclear Instrument and methods in physics Research A360(1995)201-205