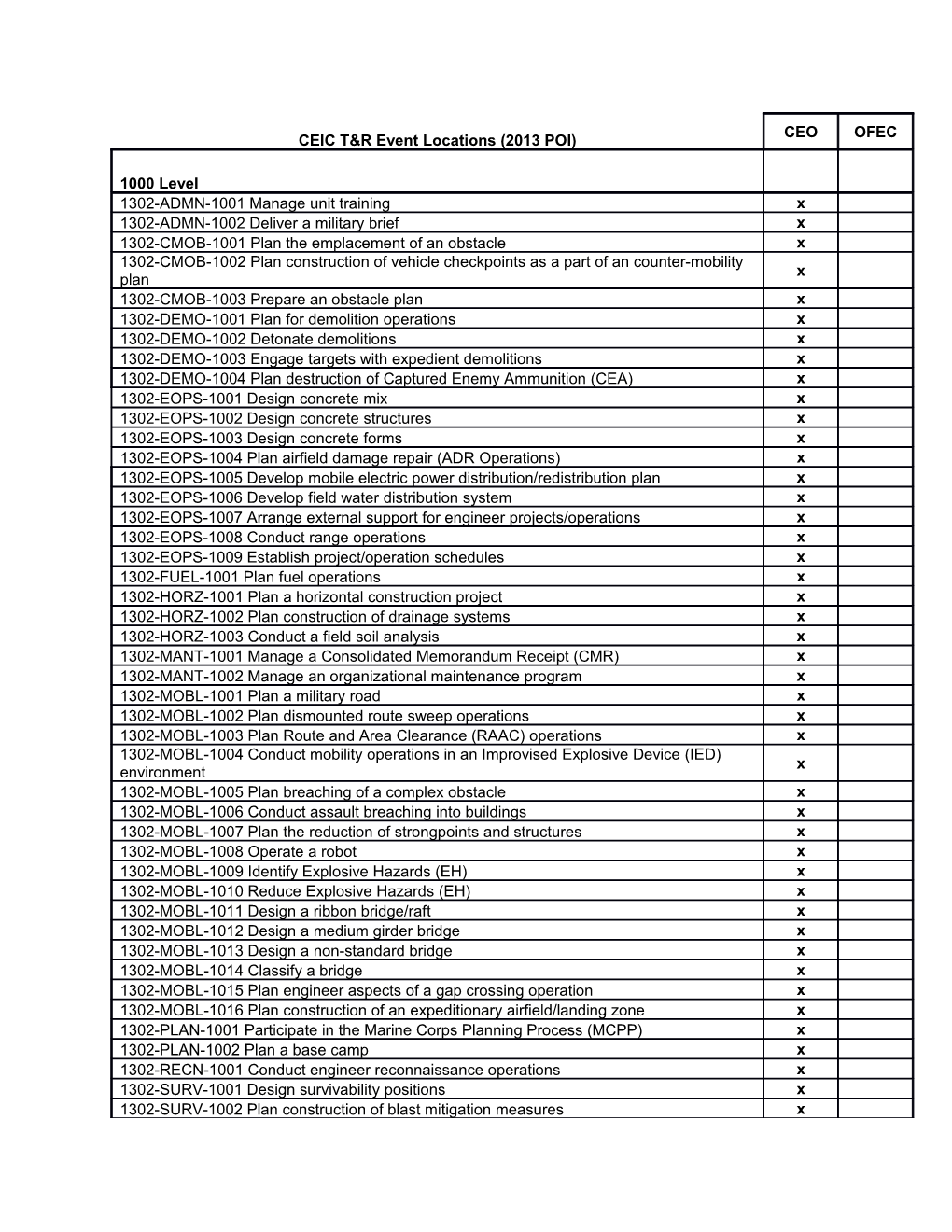

CEO OFEC CEIC T&R Event Locations (2013 POI)

1000 Level 1302-ADMN-1001 Manage unit training x 1302-ADMN-1002 Deliver a military brief x 1302-CMOB-1001 Plan the emplacement of an obstacle x 1302-CMOB-1002 Plan construction of vehicle checkpoints as a part of an counter-mobility x plan 1302-CMOB-1003 Prepare an obstacle plan x 1302-DEMO-1001 Plan for demolition operations x 1302-DEMO-1002 Detonate demolitions x 1302-DEMO-1003 Engage targets with expedient demolitions x 1302-DEMO-1004 Plan destruction of Captured Enemy Ammunition (CEA) x 1302-EOPS-1001 Design concrete mix x 1302-EOPS-1002 Design concrete structures x 1302-EOPS-1003 Design concrete forms x 1302-EOPS-1004 Plan airfield damage repair (ADR Operations) x 1302-EOPS-1005 Develop mobile electric power distribution/redistribution plan x 1302-EOPS-1006 Develop field water distribution system x 1302-EOPS-1007 Arrange external support for engineer projects/operations x 1302-EOPS-1008 Conduct range operations x 1302-EOPS-1009 Establish project/operation schedules x 1302-FUEL-1001 Plan fuel operations x 1302-HORZ-1001 Plan a horizontal construction project x 1302-HORZ-1002 Plan construction of drainage systems x 1302-HORZ-1003 Conduct a field soil analysis x 1302-MANT-1001 Manage a Consolidated Memorandum Receipt (CMR) x 1302-MANT-1002 Manage an organizational maintenance program x 1302-MOBL-1001 Plan a military road x 1302-MOBL-1002 Plan dismounted route sweep operations x 1302-MOBL-1003 Plan Route and Area Clearance (RAAC) operations x 1302-MOBL-1004 Conduct mobility operations in an Improvised Explosive Device (IED) x environment 1302-MOBL-1005 Plan breaching of a complex obstacle x 1302-MOBL-1006 Conduct assault breaching into buildings x 1302-MOBL-1007 Plan the reduction of strongpoints and structures x 1302-MOBL-1008 Operate a robot x 1302-MOBL-1009 Identify Explosive Hazards (EH) x 1302-MOBL-1010 Reduce Explosive Hazards (EH) x 1302-MOBL-1011 Design a ribbon bridge/raft x 1302-MOBL-1012 Design a medium girder bridge x 1302-MOBL-1013 Design a non-standard bridge x 1302-MOBL-1014 Classify a bridge x 1302-MOBL-1015 Plan engineer aspects of a gap crossing operation x 1302-MOBL-1016 Plan construction of an expeditionary airfield/landing zone x 1302-PLAN-1001 Participate in the Marine Corps Planning Process (MCPP) x 1302-PLAN-1002 Plan a base camp x 1302-RECN-1001 Conduct engineer reconnaissance operations x 1302-SURV-1001 Design survivability positions x 1302-SURV-1002 Plan construction of blast mitigation measures x 1302-SURV-1003 Prepare a survivability plan x 1302-SURV-1004 Plan construction of an entry access control point as part of a protective x barrier plan 1302-SURV-1005 Plan building hardening x 1302-VERT-1001 Plan a vertical construction project x

_

1000 LEVEL EVENTS (MOS:1302)

1302-ADMN-1001: Manage unit training

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a unit training plan, time restraints, commander's intent, personnel, and equipment access to automated systems and commander’s training guidance.

STANDARD: To meet requirements of the training plan and the commander's intent To meet training requirements, sustaining engineer operations per NAVMC 3500.12_ Marine Corps Engineer and Utilities Training and Readiness Manual.

PERFORMANCE STEPS: 1. Determine Employ information management systems to mission requirements based on unit missions, Mission Essential Task Lists, Mission Performance Standards, Collective Training Events and Individual Training Events. 2. Determine current unit capabilities, both individual and unit proficiency. 3. Identify training shortfalls and strengths of unit. 4. Determine specific training objectives to correct shortfalls in accordance with T&R manual and METs. 5. Develop logical sequence for training individual skills and collective task events. 6. Brief commander on training plan, as required. 7. Prepare a training schedule utilizing backwards planning. 8. Issue the order for training. 9. Coordinate logistical support. 10. Conduct a after action (hotwash) as required Supervise the development of electronic training jackets via training management systems.

11. Provide input for development of readiness reports via the readiness reporting system.

. PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCO 3500.27_ Operational Risk Management (ORM) 2. MCO 3501.1_ Marine Corps Combat Readiness Evaluation (MCCRE) 3. MCRP 3-0A Unit Training Management Guide 4. MCRP 3-0B How to Conduct Training 5. NAVMC 3500.12_ Marine Corps Engineer and Utilities Training and Readiness Manual 6. MCTIMS User’s Guide

_ 1302-ADMN-1002: Deliver a military brief

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a mission, commander's intent, and references.

STANDARD: To provide an oral description of the current engineer situation, proposed execution, and logistical support capabilities and limitations. in accordance with MCWP 3-40.1 MAGTF Command and Control.

PERFORMANCE STEPS: 1. Review the operations order and commander's intent. 2. Review the engineer situation. 3. Develop a briefing outline for the engineer situation. 4. Brief engineer situation to the commander.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCWP 3-17 Engineering Operations 2. MCWP 3-40.1 MAGTF Command and Control _ 1302-CMOB-1001: Plan the emplacement of an obstacle Conduct obstacle emplacement

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, an operations order, an obstacle plan overlay, and references.

STANDARD: To meet the requirements of the obstacle plan in accordance with MCWP 3-17.5 Combined Arms Obstacle Integration.

PERFORMANCE STEPS: 1. Analyze requirements outlined in the obstacle plan. 2. Conduct a site recon. 3. Task organize personnel and equipment. 4. Identify logistical requirements. 5. Coordinate security with supported maneuver elements as required. 6. Coordinate obstacle overwatch and coverage by fires with supported unit. 7. Verify the obstacle is effective based on the principles of obstacle employment. 8. Monitor construction/installation of the obstacle. 9. Submit required engineer reports.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. GTA 90-01-011 Joint Forward Operations Base (JFOB) Protection Handbook 2. GTA 90-01-018 Joint Entry Control Point & Escalation of Force Procedures 3. MCRP 2-3A Intelligence Preparation of the Battlefield/Battlespace 4. MCRP 3-17.2D Explosive Hazards Operations 5. MCWP 3-1 Ground Combat Operations 6. MCWP 3-17.4 Engineer Reconnaissance 7. MCWP 3-17.5 Combined Arms Obstacle IntegrationCountermobility Operations

_ 1302-CMOB-1002: Plan construction of vehicle checkpoints as a part of an counter-mobility plan EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, an operations order, a map, required personnel, equipment, and references.

STANDARD: To meet supported unit requirements outlined in the concept of operations of the operations order in accordance with MCWP 3-17.5 Combined Arms Obstacle Integration.

PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Conduct a site reconnaissance. 3. Develop obstacle/barrier plan as required to prevent bypass of the checkpoint. 4. Design vehicle checkpoint to provide holding areas, personnel holding areas, search areas, active vehicle barriers, and overwatch positions. 5. Develop bill of materials. 6. Identify logistical requirements. 7. Task organize personnel and equipment. 8. Coordinate security with supported maneuver elements as required. 9. Estimate construction time. 10. Generate sketches as required.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. GTA 90-01-011 Joint Forward Operations Base (JFOB) Protection Handbook 2. GTA 90-01-018 Joint Entry Control Point & Escalation of Force Procedures 3. MCRP 3-17A Engineer Field Data 4. MCWP 3-17.5 Combined Arms Obstacle Integration 5. MCWP 3-17.6 Survivability Operations 6. MCWP 3-35.3 Military Operations on Urbanized Terrain (MOUT)

_ 1302-CMOB-1003: Prepare an obstacle plan

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION: MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, an operations order, a map, and references.

STANDARD: That recommends types of obstacles; obstacle placement; the resources required to construct the obstacles; and an obstacle overlay, which support the scheme of maneuver by fixing, turning, blocking or disrupting enemy movement.

PERFORMANCE STEPS: 1. Conduct mission analysis problem framing. 2. Conduct fires analysisDetermine obstacle intent. 36. Determine obstacle intent integration with firesCoordinate fire integration. 43. Determine obstacle priorities. 54. Determine mobility requirements. 65. Determine obstacle design and resourcing. 7. Prepare an overlay and obstacle plan appendix to operations order.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. GTA 90-01-011 Joint Forward Operations Base (JFOB) Protection Handbook 2. GTA 90-01-018 Joint Entry Control Point & Escalation of Force Procedures 3. MCDP 1 Warfighting 4. MCDP 1-3 Tactics 53. MCRP 2-3A Intelligence Preparation of the Battlefield/Battlespace 64. MCRP 3-17B Engineer Forms and Reports 75. MCWP 3-1 Ground Combat Operations 86. MCWP 3-17 Engineering Operations 97. MCWP 3-17.5 Combined Arms Obstacle IntegrationCountermobility Operations 10. MCWP 3-40.1 MAGTF Command and Control 8. MCRP 3-17.7L Explosives and Demolitions 9. MCRP 3-17.2D Explosive Hazards Operations

_ 1302-DEMO-1001: Plan for demolition operations

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 3 months

DESCRIPTION: MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, a map, an operations order, equipment, personnel, and references.

STANDARD: To execute a demolition mission in support of the commander's intent and concept of operations in accordance with MCRP 3-17.7L Explosives and Demolitions.

PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Conduct target analysis. 36. Determine the amount of explosives required to achieve the desired effect. 43. Direct demo recon, as required. 54. Analyze required information from the DA Form 2203-R. 6. Complete the demolition target folder. 75. Estimate the logistics required based on the demolition reconnaissance. 87. Determine task organization of personnel and equipment. 98. Prioritize targets based on commander's intent. 109. Complete Directed and/or Situational Obstacle matrices and overlays, as requiredthe appropriate orders/appendixes, as required.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7L Explosives and Demolitions 2. MCRP 3-17A Engineer Field Data 3. MCRP 3-17B Engineer Forms and Reports 4. MCWP 3-17 Engineering Operations 5. STANAG 2123 Obstacle Folder

SUPPORT REQUIREMENTS:

EQUIPMENT: MAP, DA Form 2203-R, NOTE TAKING GEAR

MATERIAL:

UNITS/PERSONNEL:

OTHER SUPPORT REQUIREMENTS:

_ 1302-DEMO-1002: Detonate Employ demolitions EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, appropriate Class V material, a demolition kit, target material, personal protective equipment (PPE) and references.

STANDARD: To ensure all charges are constructed according to the method of use and ensuring detonation while observing all safety procedures in accordance with MCRP 3-17.7L Explosives and Demolitionsdesired effect on target(s) is achieved.

PERFORMANCE STEPS: 1. Review target folder. 2. Conduct target reconnaissance (to obtain critical dimensions necessary for charge calculations and firing point location). 3. Determine type of explosive to use. 4. Select formula calculation for single charge. 5. Determine number of charges/total amount of explosives and minimum safe distance. 6. Construct the charge. 67. Place the charge(s) on the target. 78. Prime the charge. 89. Tamp explosive(s) as required. 910. Detonate the explosive(s). 1011. Conduct battle damage assessment. 1112. Submit required engineer reports.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.2D Explosive Hazards Operations 2. MCRP 3-17.7L Explosives and Demolitions 3. MCRP 3-17A Engineer Field Data 4. MCRP 3-17B Engineer Forms and Reports

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity M023 Chg, Demo Block M112 11/4 pound C4 1 charges per Marine M028 Demo Kit, Bangalore Torpedo M1A2 1 cases per Team M030 Chg, Demo Block TNT 1/4Pound 1 charges per Marine M032 Chg, Demo Block TNT 1Pound 1 charges per Marine M039 Chg, Demo Cratering 40Pound 1 charges per Team M130 Cap, Blasting Electric M6 3 blasting caps per Marine M131 Cap, Blasting Non-Electric M7 5 blasting caps per Marine M420 Chg, Demo Shaped M2 Series 15Pound 1 charges per Team M421 Chg, Demo Shaped M3 Series 40Pound 1 charges per Team M456 Cord, Detonating PETN Type I Class E 85 FT per Marine M591 Dynamite, Military M1 2 charges per Marine M670 Fuse, Blasting Time M700 40 FT per Marine M757 Chg, Assembly Demo M183 Comp C4 1 cases per Team M982 Chg, Demo Sheet 0.166 Inch Thick 1 FT per Marine MM30 Chg, Flexible 20 Gram PETN MK140 Mod 4 charges per Team MM44 Chg, Demo FLSC 75 Gr/Ft 1 charges per Team MM45 Chg, Demo FLSC 125 Gr/Ft 1 charges per Team MM47 Chg, Demo FLSC 400 Gr/Ft 1 charges per Team MM48 Chg, Demo FLSC 600 Gr/Ft 1 charges per Team MN08 Igniter, Time Blasting Fuse with Sho 5 igniters per Marine MN52 Detonator, Percussion, NonElectric M 1 detonators per Marine

RANGE/TRAINING AREA: Facility Code 17830 Light Demolition Range

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT: Squad Demolition Kit, PPE.

MATERIAL:

UNITS/PERSONNEL: Range OIC, Range Safety Officer, Corpsman

OTHER SUPPORT REQUIREMENTS: Safety vehicle, Ammunition vehicle, Communications (radio).

MISCELLANEOUS:

ADMINISTRATIVE INSTRUCTIONS: ORM

ROAD MILES:

EQUIPMENT HOURS:

SPECIAL PERSONNEL CERTS:

SIMULATION:

ORDNANCE ADDITIONAL INSTRUCTIONS:

_ 1302-DEMO-1003: Engage targets with expedient demolitions

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 3 months

DESCRIPTION: MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Provided a mission, a designated area, personnel, demolition tools, explosives, improvised materials, and references.

STANDARD: To produce the desired effect on the target per the mission requirements in accordance with MCRP 3-17.7L Explosives and Demolitions.

PERFORMANCE STEPS: 1. Review the mission. 2. Construct a platter charge. 3. Construct an expedient claymore charge. 4. Construct a grape shot directional charge. 5. Construct an omni (360 degree) charge. 6. Construct expedient shaped charge. 7. Construct expedient flame charge. 8. Construct a purpose built charge (based on mission requirements). 9. Engage the target. 10. Confirm target reduction. 2. Identify the target 3. Gather necessary material 4. Construct the charge 5. Construct initiating system 6. Position the charge 7. Prime the charge 8. Detonate the charge 9. Confirm desired effects.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. GTA 05-10-033 Demolition Card 2. MCRP 3-17.2D Explosive Hazards Operations 3. MCRP 3-17.7L Explosives and Demolitions 4. MCRP 3-17A Engineering Field Data 5. SWO60-AA-MMA-010 Demolition Materials

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity M023 Chg, Demo Block M112 11/4 pound C4 10 charges per Team M032 Chg, Demo Block TNT 1Pound 10 charges per Team M130 Cap, Blasting Electric M6 14 blasting caps per Team M131 Cap, Blasting Non-Electric M7 14 blasting caps per Team M456 Cord, Detonating PETN Type I Class E 500 FT per Team M670 Fuse, Blasting Time M700 50 FT per Team M757 Chg, Assembly Demo M183 Comp C4 1 charges per Team ML03 Firing Device, Demo MultiPurpose M14 2 detonators per Team ML47 Cap, Blasting Non-Electric M11 with 3 blasting caps per Team MN08 Igniter, Time Blasting Fuse with Sho 10 igniters per Team MN52 Detonator, Percussion, NonElectric M 5 detonators per Team MN88 Cap, Blasting, Non-Electric, M21 w/ 3 blasting caps per Team

RANGE/TRAINING AREA: Facility Code 17830 Light Demolition Range

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT: Squad Demolition Kit, PPE.

MATERIAL: Ammonium Nitrate (33% Nitrogen), JP-8 fuel.

UNITS/PERSONNEL: Range OIC, Range Safety Officer, Corpsman

OTHER SUPPORT REQUIREMENTS: Safety vehicle, Ammunition vehicle, Communications (radio).

MISCELLANEOUS:

ADMINISTRATIVE INSTRUCTIONS: ORM

ROAD MILES:

EQUIPMENT HOURS:

SPECIAL PERSONNEL CERTS:

SIMULATION:

ORDNANCE ADDITIONAL INSTRUCTIONS:

_ 1302-DEMO-1004: Plan destruction ofDestroy Captured Enemy Ammunition (CEA)

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT

INITIAL TRAINING SETTING: FORMAL CONDITION: Without Explosive Ordnance Disposal (EOD) support readily available, given a tactical scenario, commander's intent, map, explosives, captured enemy ammunition (CEA), and references.

STANDARD: To successfully destroy the CEA in accordance with the commander's intent, mission requirements and MCRP 3-17.2D Explosive Hazard Operations.

PERFORMANCE STEPS: 1. Positively identify captured enemy ammunition (CEA). 2. Calculate minimum standoff distance to detonate CEA. 3. Coordinate with higher headquarters. 4. Destroy CEA. 5. Confirm target destruction. 6. Report results to higher headquarters.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. CHB Country Handbooks 2. GTA 05-10-033 Demolition Card 3. MCRP 3-17.2D Explosive Hazards Operations 4. MCRP 3-17.7L Explosives and Demolitions 5. MCWP 3-17 Engineering Operations 6. ORD ORDATA II (Software)

_ 1302-EOPS-1001: Design concrete mix

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Provided construction drawings, blueprints, specifications, writing materials, a calculator, and the reference.

STANDARD: To meet strength specifications described in the concrete structure design and the construction standards achieve proper compressive strength per the specification in accordance with MCRP 3-17.7D Concrete and Masonry.

PERFORMANCE STEPS: 1. Determine the type of cement to be used. 2. Identify water and aggregate for suitabilitysuitable water source. 3. Identify suitable aggregate. 34. Determine desired slump. 45. Determine percentage of air entrainment, as required. 56. Determine amount of water. 67. Determine a water/cement ratio. 78. Determine amount of cement. 89. Determine loose volume of gravel. 910. Convert weights to absolute volumes. 1011. Determine weight of sand. 1112. Determine loose volume of sand. 1213. List final proportions for a one cubic yard batch. 1314. Perform field moisture test on the aggregates. 1415. Adjust mix design to account for aggregate moisture, as required.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7D Concrete and Masonry

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA: Facility Code 17413 Field Training Area

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT: Concrete and Masonry kit, Concrete Mixer, Pioneer kit.

MATERIAL: Portland cement, fine and coarse aggregates.

UNITS/PERSONNEL:

OTHER SUPPORT REQUIREMENTS: Fuel requirement.

_ 1302-EOPS-1002: Design Plan concrete structures

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS: GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given construction standards, commander's intent, concept of operations, task organized personnel and equipment,a requirement, construction standards and references.

STANDARD: To specify type of materials to be used, proper spacing of all components, and quantity and type of material required for finished structures capable of supporting all loads considered in accordance with the specifications and MCRP 3-17.7D Concrete and Masonry.

PERFORMANCE STEPS: 1. Review mission. 2. Conduct site survey. 3. Identify requirements. 1. Review the specifications. 24. Design a concrete footing, if required. 35. Design a concrete wall, if required. 46. Design a reinforced concrete structure, if required. 58. Design a concrete block structure, if required. 67. Prepare construction drawingDesign forms to meet specification. 79. Generate a Bill bill of Materials materials for each type of design. 10. Determine resources. 11. Determine project schedule. 12. Plan inspections of structure for proper building techniques. 13. Submit required documents. 8. Obtain design approval, (if required).

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7D Concrete and Masonry 2. MCRP 3-17A Engineering Field Data 3. NAVPERS 0-486-20242-9 Basic Construction Techniques for Houses and Small Buildings 2. MCRP 3-17.7M Construction Estimating

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA:

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT: MATERIAL: Blueprints/drawings/specifications, calculation worksheets, calculator

UNITS/PERSONNEL:

OTHER SUPPORT REQUIREMENTS:

_ 1302-EOPS-1003: Design concrete forms

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given construction standards and speicifcations, concrete structure design, commander's intent, concept of operations, task organized personnel and equipment, and references.

STANDARD: To support all dead loads and live loads and meet standards in accordance with MCRP 3-17.7D Concrete and Masonry.

PERFORMANCE STEPS: 1. Analyze the concrete structure design to determine the type of form. 2. Determine bill of materials. 3. Determine the proper spacing for all components of the form. 4. Illustrate final design.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7C Carpentry 2. MCRP 3-17.7D Concrete and Masonry 3. MCRP 3-17.7M Construction Estimating 4. NAVPERS 0-486-20242-9 Basic Construction Techniques for Houses and Small Buildings

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA: AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT:

MATERIAL: Blue Prints/drawings/specifications, calculation worksheet, calculator

UNITS/PERSONNEL:

OTHER SUPPORT REQUIREMENTS:

_ 1302-EOPS-1004: Plan Conduct airfield damage repair (ADR) Operations)operations

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, an operations order, an airfield/landing zone requiring repair, and references.

STANDARD: To ensure the airfield is operationally capable in compliance with the concept of operations in accordance with MCRP 3-17.7B Design of Theater of Operations - Airfields and Helipads.

PERFORMANCE STEPS: 1. Provide recommendations to the Survival Recovery Staff for the task organization of personnel and equipment. 2. Determine the appropriate Foreign Object Debris (FOD) cover requirements. 3. Calculate the material requirements for crater repair. 4. Calculate the material requirements for spall repair. 5. Identify appropriate dispersal areas for equipment, materials, and personnel in the event of follow-on attacks. 6. Submit appropriate engineer reports. 7. Coordinate with supported commander, as required. 8. Coordinate logistical support, as required. 9. Incorporate safety measures. 10. Receive reports from damage assessment teams and damage assessment response teams. 11. Repair critical facilities. 12. Establish a sustainable facility/ site maintenance and repair plan. 1. Review requirement. 2. Task organize resources. 3. Conduct assessment. 4. Recommend minimum operating strip (MOS) location. 5. Coordinate external support, if required. 6. Repair spalls, if required. 7. Repair craters, if required. 8. Install FOD cover on repaired craters, as required.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7B Planning and Design of Roads, Airfields, and Heliports in the Theater of Operations - Airfield and Heliport Design 2. MCRP 3-17A Engineering Field Data 3. NAVAIR 00-80T-115 Expeditionary Airfield NATOPS Manual 4. NAVAIR 51-60A-1(_) AM2 Airfield Mat and Accessories 5. UFC 3-270-07 Airfield Damage Repair

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA: Facility Code 17918 Road/Airfield Construction Training Site

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT: Airfield Damage Repair (ADR) kit, 260 CFM, engineer equipment (420 backhoe, multi-terrain loader).

MATERIAL: Fine/coarse aggregate, sand grid, pavemend.

UNITS/PERSONNEL:

OTHER SUPPORT REQUIREMENTS:

_ 1302-EOPS-1005: Develop Plan mobile electric power distribution/redistribution- system plan

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS: GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, a map, an operations order, specific number of personnel, equipment, and facilitiesrequirement, list of equipment, and references.

STANDARD: To meet or exceed requirements outlined in the concept of operations in accordance with MCRP 3-17.7K Theater of Operations Electrical SystemsSo electrical power generation and distribution resources are allocated and safely support the mission.

PERFORMANCE STEPS: 1. Conduct mission analysisReview the requirement. 2. Integrate utilities SME(s) into planning process. 3. Conduct site reconnaissance, if required. 4. Identify existing electrical power sources. 5. Determine electrical power requirements based on personnel, equipment, and facilities. 6. Determine priorities for electric power. 7. Determine task organization of personnel and equipment. 8. Develop a Integrate distribution diagram into overall plan.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7K Theater of Operations Electrical Systems 2. MCRP 3-17A Engineering Field Data 3. MCRP 3-17B Engineer Forms and Reports 4. MCWP 3-17 Engineering Operations

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA:

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT:

MATERIAL:

UNITS/PERSONNEL: Utility Officer (1120) or Utilities Chief (1169) will assist.

OTHER SUPPORT REQUIREMENTS: _ 1302-EOPS-1006: Develop field water distribution system Plan water support operations

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, a map, an operations order, specific number of personnel, equipment, and facilities requirement, list of equipment, and references.

STANDARD: To meet or exceed requirements outlined in the concept of operations and in accordance with MCRP 4-11.6A Water Supply in Theaters of Operations So water production, storage and distribution resources are allocated to support the mission.

PERFORMANCE STEPS: 1. Conduct mission analysis Review the requirement. 2. Integrate utilities SME(s) into planning process. 3. Conduct site reconnaissance Determine water site, if required. 4. Identify existing water sources through water point reconnaissance. 5. Determine Identify water consumption requirement (i.e., based on numbers of personnel, equipment, facilities, and climate conditions. 6. Develop plan for production, purification, storage, and distribution of water. 7. Plan drainage system to prevent contamination of water source from storm runoff. 8. Plan construction or improvement main supply routes (MSR) from water point and/or well sites. 97. Determine task organization of equipment and personnel. 108. Develop a distribution diagram Integrate distribution diagram into overall plan. 11. Coordinate with supported commander, as required. 12. Coordinate logistical support, as required.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. FM 10-52 Water Supply in Theaters of Operation MCRP 3-17.7Q Water Support Operations 2. MCWP 4-11.5 SeaBee Operations in the MAGTF 32. MCWP 4-11.6 Petroleum and Water Logistics Operations Bulk Liquid Operations

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA:

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT:

MATERIAL:

UNITS/PERSONNEL: Utility Officer (1120) or Utilities Chief (1169) will assist

OTHER SUPPORT REQUIREMENTS:

_ 1302-EOPS-1007: Arrange external support for engineer projects/operations

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Provided an operations order.

STANDARD: To provide all required support for a project or operation per the concept of operations and the commander's intent.

PERFORMANCE STEPS: 1. Review the operations order. 2. Identify tasks/missions beyond organic capabilities. 3. Determine sources of support. 4. Coordinate with supporting elements to provide required support.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS: REFERENCES: 1. JP 3-34 Joint Engineer Operations 2. MCWP 3-17 Engineering Operations 3. MCWP 3-21.1 Aviation Ground Support 4. MCWP 3-40.1 MAGTF Command and Control 5. MCWP 4-1 Logistics Operations 6. MCWP 4-11.5 SeaBee Operations in the MAGTF

_ 1302-EOPS-1008: Conduct range operations

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given the requirement to conduct live fire training, approved range, valid RSO card, Class V, target material, personal protective equipment (PPE), and references.

STANDARD: To complete required training without injury to personnel and equipment and in accordance with AR 385-63/DA PAM 385-63/MCO 3570.1B Range Safety.

PERFORMANCE STEPS: 1. Plan for training. 2. Conduct site reconnaissance, if required. 3. Build target folder(s), if required. 4. Submit logistical support requirements. 5. Calculate Class V requirements. 6. Review SDZs/range regulations, if required. 7. Conduct training. 8. Submit required reports. 9. Conduct accountability of personnel, weapons, and equipment. 10. Repair/restore range, as required. 11. Direct lineout.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. AR 385-63/ DA PAM 385-63 / MCO 3570.1B Range Safety 2. AR 385-64 / DA PAM 385-64 Army Explosives Safety 3. MCO 3500.27_ Operational Risk Management (ORM) 4. MCRP 3-17.7L Explosives and Demolitions

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA: Facility Code 17502 Non-Standard Small Arms Range Facility Code 17581 Machine Gun Field Fire Range Facility Code 17830 Light Demolition Range

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT: M4, M16A4, M9, M249, M240G, M2, MK19, MK153, Squad demolitions kit, Shotgun, PPE.

MATERIAL:

UNITS/PERSONNEL: Range OIC, Range Safety Officer, Corpsman w/medical supplies, Ammo Tech, Armorer.

OTHER SUPPORT REQUIREMENTS: SAfety Safety vehicle, Ammunition vehicle, Communications (radio).

MISCELLANEOUS:

ADMINISTRATIVE INSTRUCTIONS:

ROAD MILES:

EQUIPMENT HOURS:

SPECIAL PERSONNEL CERTS: Approved RSO/OIC card, Special permits (if applicable)

SIMULATION:

ORDNANCE ADDITIONAL INSTRUCTIONS:

_ 1302-EOPS-1009: Establish project/operation schedules Manage engineer projects

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS: GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Provided a mission, construction drawings/blueprints, specifications, a calculator, writing materials, activity estimate sheets, and the reference construction directive, resources and references.

STANDARD: To detail all personnel, equipment, and materials necessary to accomplish the mission, while establishing a defined duration for each subtask and the overall project/operation, and graphically depict the schedule in accordance with MCRP 3-17.7F Project Management To successfully plan, schedule and execute engineering and contingency construction projects.

PERFORMANCE STEPS: 1. Review the mission. 2. Determine activities/tasks necessary to complete the project. 3. Arrange activities/tasks in logical sequence. 4. Complete activity estimate sheets. 5. Identify critical tasks. 6. Graphically depict schedule. 7. Update schedule throughout duration of project/operation. 1. Conduct preliminary planning. 2. Employ management scheduling tools. 3. Conduct detailed project planning. 4. Develop QC plan. 5. Conduct final planning. 6. Execute project. 7. Monitor project activities. 8. Perform project transfer.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7F Construction Project Management 2. MCRP 3-17.7I Earthmoving Operations 3. MCRP 3-17.7M Construction Estimating 4. NAVFAC P-405 Seabee Planner's and Estimator's Handbook

_ 1302-FUEL-1001: Plan fuel operations

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS: GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, a map, operations order, task organization of equipment and personnelthe requirement, list of personnel and equipment, and references.

STANDARD: To meet requirements as outlined in the concept of operations in accordance with MCWP 4-11.6 Petroleum and Water Logistics Operation So resources are allocated to meet or exceed the mission.

PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Integrate Bulk Fuel SME(s) into planning process. 3. Plan reconnaissance of selected sites. 4. Determine the fuel shortage requirements. 5. Determine distribution requirements. 6. Identify existing fuel sources and host nation support availability. 7. Coordinate with appropriate services with for the delivery of fuel. 8. Select sites for fuel farms. 9. Plan horizontal construction operations. 10. Determine task organization of equipment and personnel. 11. Illustrate the layout of the fuel farm. 12. Illustrate fuel distribution plan. 13. Develop record(s) for fuel distribution. 14. Plan/coordinate firefighting support. 15. Develop spill contingency plan. 1. Review the requirement. 2. Integrate bulk fuel SME(s) into planning process. 3. Conduct fuel site reconnaissance. 4. Develop plan for storage of fuel 5. Develop plan for distribution of fuel. 6. Plan for the construction of bulk fuel site.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCWP 3-17 Engineering Operations 2. MCWP 4-1 Logistics Operations 3. MCWP 4-11.6 Petroleum and Water Logistics Operations

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA:

AIRCRAFT:

ROOMS/BUILDINGS: EQUIPMENT:

MATERIAL:

UNITS/PERSONNEL: Bulk Fuel Officer (1390) or Bulk Fuel Specialist (1391) and Engineer Equipment Officer (1310) or Engineer Equipment Chief (1349) will assist.

OTHER SUPPORT REQUIREMENTS:

_ 1302-HORZ-1001: Plan a horizontal construction project Estimate equipment production rates

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Provided a horizontal construction mission, a map, construction standards, operations order mission, specifications, calculator, writing materials, appropriate form(s), and references.

STANDARD: To meet requirements as outlined in the concept of operations and in accordance with MCRP 3-17.7(A&B) Design of Theater of Operations-Roads, Airfields and Helipads determine resources, equipment, and production time tomeet mission requirements.

PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Conduct site reconnaissance. 3. Perform hasty field identification of soils. 4. Determine drainage requirements. 5. Select appropriate configuration. 6. Determine matting requirements, if applicable. 7. Calculate earthwork production estimations. 8. Determine logistical requirements. 9. Employ construction management tool. 10. Establish quality control plan. 11. Develop maintenance/repair plan. 12. Issue the order. 13. Coordinate as required with supported commander. 14. Coordinate logistical support, as required. 15. Coordinate security, as required. 1. Review the requirement. 2. Determine equipment required. 3. Determine work rate. 4. Estimate production time required. 5. Complete equipment worksheet(s). 6. Incorporate estimates in overall project schedule.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 2-3A Intelligence Preparation of the Battlefield/Battlespace 2. MCRP 3-17.7A Planning and Design of Roads, Airfields, and Heliports in the Theater of Operations - Road Design 3. MCRP 3-17.7B Planning and Design of Roads, Airfields, and Heliports in the Theater of Operations - Airfield and Heliport Design 41. MCRP 3-17.7F Construction Project Management 5. MCRP 3-17.7G Military Soils Engineering 6. MCRP 3-17.7H Materials Testing 72. MCRP 3-17.7I Earthmoving Operations 83. MCRP 3-17.7M Construction Estimating 9. MCWP 3-17 Engineering Operations 10. MCWP 3-17.7 General Engineering 11. MCWP 3-17.8 Combined Arms Mobility Operations 12. MCWP 3-21.1 Aviation Ground Support 13. MCWP 4-11.5 SeaBee Operations in the MAGTF

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA:

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT:

MATERIAL:

UNITS/PERSONNEL: Engineer Equipment Officer (1310) or Engineer Equipment Chief (1369) will assist.

OTHER SUPPORT REQUIREMENTS:

_ 1302-HORZ-1002: Plan construction of drainage systems

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION: MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a mission, commander's intent, tactical situation, a map, task organized equipment and personnel, design specifications, requirement, list of construction materials, and references.

STANDARD: To intercept, collect, and remove surface water flowing toward a designated area from adjacent areas in accordance with MCRP 3-17.7A Design of Theater of Operations - Road Design accomodate the peak flow generated by runoff from contributing watersheds, prevent excessive rosion, and minimize impact to operations.

PERFORMANCE STEPS: 1. Analyze the mission reports (i.e. recon, trafficability, etc.). 2. Review drainage specifications. 3. Review the terrain Conduct terrain analysis. 4. Calculate area of waterway/peak run off. 5. Determine type of drainage structure(s) required. 6. Calculate size/amount of Design culvert as required, (if applicable). 7. Design a drainage ditch, as required. 8. Determine logistical requirements needed. 9. Complete a bill of materials, (if required). 10. Submit required reports Complete the construction directive.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7A Planning and Design of Roads, Airfields, and Heliports in the Theater of Operations - Road Design 2. MCRP 3-17.7F Construction Project Management 3. MCRP 3-17A Engineering Field Data 4. MCRP 3-17.7G Military Soils Engineering

_ 1302-HORZ-1003: Conduct a field soil analysis

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING: BILLETS:

GRADES: 2NDLT, 1STLT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given an unidentified soil sample, an SL-3 completearea to be tested, soil test kit, and references.

STANDARD: To obtain a two-letter USCS classification, CBR, and moisture content in accordance with MCRP 3-17.7G Military Soils Engineeringto identifiy the type of soil and properties for construction operations.

PERFORMANCE STEPS: 1. Obtain a soil sample. 2. Perform a visual examination of the soil. 3. Separate gravel. 4. Conduct field identification tests on the -40 material 5. Determine the USCS classification. 6. Determine the CBR. 7. Determine the moisture content. 8. Record and report analyze results.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7G Military Soils Engineering 2. MCRP 3-17.7H Materials Testing 3. MCRP 3-17A Engineering Field Data

_ 1302-MANT-1001: Manage a Consolidated Memorandum Receipt (CMR)

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 3 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMALMOJT

CONDITION: Given itemized equipmentGiven a responsible officer appointment letter, itemized equipment, and references. STANDARD: To maintain accountability of assigned itemized equipment and associated documentation in accordance with MCO 4400.150_, Consumer-Level Supply Policy Manual.

PERFORMANCE STEPS: 1. Receive assignment letter from Commanding Officer as Responsible Officer for CMR account. 2. Receive CMR from Supply Officer. 31. Inventory gear/materiel annotated on the CMR. 42. Compile discrepancies and submit a request for investigation/discrepancy letter, if applicable. 53. Subcustody Sub-sign gear/material to responsible individual(s), if applicable. 64. Conduct quarterly reconciliation with Supply Officer; Initial, sign and date CMR. 75. Provide delegation of authority to receive/turn-in gear to Supply. 86. Maintain documentation of reconciliation and sub-custody for personal reference. 97. Maintain records of receipt and disposal.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. Current GCSS-MC Procedural Notices (GPN) 21. MCO 4400.150_ Consumer-Level Supply Policy Manual 32. TM 4700-15/1_ Ground Equipment Record Procedures 3. UM 4400-124 SASSY Using Unit Procedures SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA:

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT:

MATERIAL:

UNITS/PERSONNEL:

OTHER SUPPORT REQUIREMENTS: Administrative Note: Training an be received through…..

_ 1302-MANT-1002: Manage an organizational maintenance program EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMALMOJT

CONDITION: Given an engineer task organization of engineer equipment and personnel, technical manuals, appropriate maintenance reports, and references.

STANDARD: To identify discrepancies and processing errors within the maintenance cycle; account for gear/materiel on CMR; track deadlined or readiness reportable ground equipment.

PERFORMANCE STEPS: 1. Ensure proper manuals and forms are available. 2. Ensure required maintenance is performed and documented. 3. Review reports for discrepancies within the maintenance and supply cycle. 4. Review reports transaction for processing errors. 5. Inspect reports for compliance with references. 6. Review supply parts requisitions to identify any discrepancies. 7. Conduct reconciliation with MMO and supplySupply.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. Current GCSS-MC Procedural Notices (GPN) 21. MCBUL 3000 Marine Corps Automated Readiness Evaluation System (MARES) Equipment 32. MCO 4400.150_ DON'T DELETE-OTHER SCHOOLS USE THIS-BESIDES, read the cover- the other .150 is wrong Consumer-Level Supply Policy 4. MCRP 3-0B How to Conduct Training 53. TM 4700-15/1_ Ground Equipment Record Procedures 4. UM 40000-125 Retail Supply and Maintenance Execution Procedures

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA:

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT: MATERIAL:

UNITS/PERSONNEL:

OTHER SUPPORT REQUIREMENTS: Will be required to complete the following GCSS-MC modules: Module CS 101 - Getting Started in GCSS-MC Module CS 102 - iSupport Requestors Module CS 103 - Requestors (Field Service Request) Module RPTS 101 - Reports Users (Discoverer & Standard) Module RPTS 102 - Daily Business Intelligence

Optional: Module AO 101 - Accountable Officers Module RO 101 - Responsible Officers

To enroll in GCSS-MC online modules us the following link (https://gcssmc.csd.disa.mil) Administrative Note: Training can be received through……

_ 1302-MOBL-1001: Plan a military road

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situationrequirement, a map, an operations order, task organizationa list of equipment and personnel, and references.

STANDARD: To meet or exceed traffic support requirements in the concept of operations.for the given load class and allow safe and efficient traffic movement.

PERFORMANCE STEPS: 1. Conduct Review reconnaissance information of proposed road. 2. Integrate SMEs into the planning process. 23. Determine number and type of vehicles that will use the road. 4. Design road. 36. Recommend road design and requirements to commander. 45. Determine logistics support requirements to support construction. 5. Prepare operations order to construct pioneer road. 6. Coordinate with supported unit. 7. Coordinate logistical support, as required. 8. Coordinate security, as required. 9. Ensure safety measures are observed.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7A Planning and Design of Roads, Airfields, and Heliports in the Theater of Operations - Road Design 2. MCRP 3-17.7H Materials Testing 3. MCRP 3-17.7I Earthmoving Operations 4. MCRP 3-17A Engineering Field Data 5. MCWP 3-17 Engineering Operations

_ 1302-MOBL-1002: Plan dismounted route sweep operations

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, a route to be swept, map, task organized personnel and equipment, an operations order, and references.

STANDARD: To ensure sufficient mobility is planned to support the concept of operations and the commander's intent in accordance with MCRP 3-17.2D Explosive Hazards Operations.

PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Determine the most likely areas to be mined, booby-trapped or have improvised explosive devices. 3. Identify common signs and markings that may be associated with the location of mines, IEDs, and booby traps. 4. Determine type and extent of mines/obstacles/IEDs. 5. Determine task organization of personnel and equipment. 6. Determine material requirements. 7. Determine Explosive Ordnance Disposal (EOD) support. 8. Develop route sweep order. 9. Plan mission rehearsals.

PREREQUISITE EVENTS: CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.2D Explosive Hazards Operations 2. MCRP 3-17A Engineering Field Data 3. MCRP 3-17B Engineer Forms and Reports 4. MCWP 3-17 Engineering Operations 5. MCWP 3-17.4 Engineer Reconnaissance

_ 1302-MOBL-1003: Plan Route and Area Clearance (RAAC)Conduct clearing operations

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, a route/area to be cleared, task organized personnel and clearance equipment, a map, an operation order, and references. Given a tactical situation with an explosive hazard threat, a Higher Headquarters operations order, supported commander’s intent and planning guidance, a map, specified route/area, and references.

STANDARD: To assure mobility in support of the concept of operations in accordance with MCRP 3-17.2D Explosive Hazards Operations. To ensure clearance plan is supportable and consistent with the commander's intent and to ensure route/area is cleared from EHs?

PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Develope a RAAC operation order. 3. Ensure employment concept is consistent with the tactical situation and scheme of maneuver. 4. Plan rehearsals and Immediate Action (IA) drills. 5. Ensure all obstacles are detected, identified, and marked. 6. Plan for the reduction or bypass of obstacle. 7. Issue order. 1. Review mission. 2. Review IPB. 3. Develop CONOPS. 4. Conduct coordination with higher/adjacent. 5. Request EOD support, if required. 6. Task organize personnel. 7. Task organize equipment. 8. Prepare appendix to the operations order. 9. Conduct rehearsals 10. Execute mission 11. Record/report, as required

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. GTA 05-10-033 Demolition Card 2. GTA 5-2-5 Engineer Reconnaissance 3. MCO 3500.27_ Operational Risk Management (ORM) 41. MCRP 3-17.2D Explosive Hazards Operations 52. MCRP 3-17.7L Explosives and Demolitions 6. MCRP 3-17A Engineering Field Data 7. MCRP 3-17B Engineer Forms and Reports 8. MCRP 5-12A Operational Terms and Graphics 9. MCWP 3-17 Engineer Operations 10. MCWP 3-17.2 MAGTF Explosive Ordnance Disposal 11. MCWP 3-17.3 MAGTF Breaching Operations 12. MCWP 3-17.4 Engineer Reconnaissance 133. MCWP 3-17.8 Combined Arms Mobility Operations 14. MCWP 3-35.3 Military Operations on Urbanized Terrain (MOUT) 4. MCWP 3-17 MAGTF Engineer Operations 5. MCIP 3-17.02 MAGTF Counter-Improvised Explosive Device Operations

_ 1302-MOBL-1004: Conduct mobility operations in an Improvised Explosive Device (IED) environmentLead a convoy

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, with Explosive Ordnance Disposal (EOD) support unavailable within mission parameters, given relevant combat engineer T/E, appropriate Class V items, and referencesGiven a requirement, personnel and equipment.

STANDARD: To ensure mobility by reducing 100% of IEDs located with no injuries to personnel or equipment in accordance with MCIP 3-17.01 Combined Arms IED Defeat Operationsunit movement is completed to support the mission. PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Plan immediate actions for mobility operation. 3. Conduct immediate actions. 4. Conduct breaching actions. 5. Submit required reports. 1. Review intelligence reports. 2. Determine lift requirements. 3. Coordinate route reconnaissance. 4. Develop a movement plan. 5. Plan for enabler support. 6. Direct loading operations. 7. Conduct a convoy commander’s brief. 8. Conduct rehearsals 9. Conduct pre-combat checks/inspections. 10. Execute convoy. 11. Conduct mission debrief. 12. Prepare after action reports.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. GTA 90-01-001 Improvised Explosive Device and Vehicular Borne Improvised Explosive Device Smart Card 2. MCIP 3-17.01 Combined Arms Improvised Explosive Device Defeat Operations 3. MCRP 2-3A Intelligence Preparation of the Battlefield/Battlespace 41. MCRP 3-17.2D Explosive Hazard Operations 5. MCRP 3-17.7L Explosives and Demolitions 6. MCRP 3-17B Engineer Forms and Reports 72. MCWP 3-17 Engineering Operations 83. MCWP 3-17.4 Engineer Reconnaissance 94. MCWP 3-17.8 Combined Arms Mobility Operations 10. MCWP 3-35.3 Military Operations on Urbanized Terrain (MOUT) 5. GTA 90-001-004 Logistics Convoy Operations 6. MCWP 3-17.02 MAGTF Counter-IED Operations 7. MCRP 4-11.3F Convoy Operations Handbook

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA: Facility Code 17410 Maneuver/Training Area, Light Forces Facility Code 17413 Field Training Area Facility Code 17420 Maneuver/Training Area, Heavy Forces Facility Code 17961 Combat In Cities Facility

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT: MATERIAL: Inert Explosive Hazards.

UNITS/PERSONNEL: Range Safety Officer, Corpsman.

OTHER SUPPORT REQUIREMENTS: Safety vehicle, Communications (radio).

_ 1302-MOBL-1005: Plan breaching of a complex obstacle

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, an Higher Headquarter’s operations order, supported commander’s intent and planning guidance, a map, task organized personnel and equipment, and references.

STANDARD: To establish a sufficient number of cleared lanes for assured mobility in accordance with the commander's intent and MCWP 3-17.3 MAGTF Breaching Operations.

To ensure the breach is supportable and consistent with the commander's intent, while accounting for all tactical control measures.

PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Identify available bypasses. 3. Identify the type(s) of breaching operation required. 4. Identify number of lanes required. 5. Identify potential breach sites. 6. Determine number/type of explosive/nonexplosive breaching assets available. 7. Task organize engineer personnel and equipment within the breach force. 8. Determine proper sequencing of the breach force based on tactical situation. 9. Develop battle drills (individual/unit) to rehearse the breach of a complex obstacle. 10. Determine support requirements. 11. Plan, prioritize, and recommend fire support requirement. 12. Prepare appendix of the operations order. 13. Coordinate actions of support force and assault force before, during, and after, planned breaches. 14. Coordinate rehearsals with breach, support, and assault forces. 1. Analyze the mission. 2. Identify available reduction assets. 3. Template enemy obstacles. 4. Understand supported units SOM. 5. Identify the number of required breach lanes. 6. Identify assets required to reduce, proof, and mark lanes. 7. Task organize assets within the breach force. 8. Assist in developing the appendix for the operation order.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 2-3A Intelligence Preparation of the Battlefield/Battlespace 2. MCWP 3-1 Ground Combat Operations 3. MCWP 3-17 MAGTF Engineering Operations 4. MCWP 3-17.3 MAGTF Breaching Operations 5. MCWP 3-17.4 Engineer Reconnaissance 6. MCWP 3-17.8 Combined Arms Mobility Operations

_ 1302-MOBL-1006: Conduct assault breaching into buildings urban mobility breaching EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Provided a mission, a designated area, personnel, demolitions tools, explosives, improvised materials, and references.

STANDARD: To secure passage through the target while limiting the amount of collateral damage and ensuring that the assault force gains access.

PERFORMANCE STEPS: 1. Review the mission and reconnaissance reports. 2. Organize the breaching team. 3. Identify the location of the target. 4. Evaluate the target and surrounding areas. 5. Determine breaching method. 68. Select and construct appropriate explosivescharges. 79. Determine possible effects of detonation on the target and surrounding structures. 810. Determine possible effects on the assault team. 911. Identify safety precautions required during detonation. 106. Compute Net Explosive Weight (NEW). 117. Determine standoff distance. 1213. Brief team members on explosive effects and safe locations. 1314. Position yourself and your team in a safe location during detonation. 1412. Suppress enemy fire and set up securityApply breaching fundamentals. 15. Obscure target from enemy observation. 1615. Emplace the charge. 1716. Detonate the charge. 1817. Employ mechanical breaching, as required. 18. Employ ballistic breaching, as required. 19. Proof breach site. 20. Ensure adequacy of breach. 21. Pass assault force through the breach site.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7L Explosives and Demolitions 2. MCRP 3-17A Engineer Field Data 3. MCWP 3-17.3 MAGTF Breaching Operations 42. MCWP 3-17.4 Engineer Reconnaissance 53. MCWP 3-17.8 Combined Arms Mobility Operations 64. MCWP 3-35.3 Military Operations on Urbanized Terrain (MOUT) 75. NSWC DL TR-3714 Urban Building Characteristics 86. NSWC TR 79-224 Characteristics of Urban Terrain 97. SWO60-AA-MMA-010 Demolition Materials 108. SWO60-AA-MMA-020 DEMOLITION MATERIALSDemolition Materials (Vol II) 119. TM 1003A/07172A/09081A-13P Operator and Maintenance Manual, Model 500, Mossberg 12-gauge shotgun 1210. TM 1005A-303-14 SHOTGUN M1200 WINCHESTER 13. VOLUME I Guidebook for Assault Entry Techniques, Volume I 14. VOLUME II Guidebook for Assault Entry Techniques Volume II

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity A011 Ctg, 12 Gauge #00 Buckshot M162 10 rounds per Marine A023 Ctg, 12 Gauge 1 Ounce Slug Commercia 8 rounds per Marine AA54- Cartridge, 12 Gauge, Breaching, M103 12 rounds per Marine AX14 Primer, Percussion 12 Gauge W209 12 primers per Marine M023 Chg, Demo Block M112 11/4 pound C4 10 charges per Marine M130 Cap, Blasting Electric M6 8 blasting caps per Marine M131 Cap, Blasting Non-Electric M7 6 blasting caps per Marine M456 Cord, Detonating PETN Type I Class E 200 FT per Marine M670 Fuse, Blasting Time M700 24 FT per Marine ML03 Firing Device, Demo MultiPurpose M14 1 detonators per Team MN08 Igniter, Time Blasting Fuse with Sho 4 igniters per Marine MN14 Firing Device, Dual Mode MK54 2 detonators per Team MN52 Detonator, Percussion, NonElectric M 6 detonators per Marine

RANGE/TRAINING AREA: Facility Code 17961 Combat In Cities Facility AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT: Assault Breacher's kit, Squad demolitions kit, Shotgun, PPE.

MATERIAL: Double sided tape, waterproof tape, duct tape, grease, prop stick, appropriate medium, B-mod target, backing material, 550 parachute cord, IV bags, electrical tape, rigger's tape, rubber conveyor belt, treble hook.

UNITS/PERSONNEL: Range OIC, Range Safety Officer, Corpsman.

OTHER SUPPORT REQUIREMENTS: Safety vehicle, Ammunition vehicle, Communications (radio).

_ 1302-MOBL-1007: Plan the reduction of strongpoints and structures

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Provided a mission, a designated area, demolitions tools, explosives, improvised materials, heavy equipment, and references.

STANDARD: So that the strongpoint or structure is reduced with minimal/no damage to friendly equipment or personnel. in accordance with MCWP 3-17.3 MAGTF Breaching Operations.

PERFORMANCE STEPS: 1. Review the mission and reconnaissance reports. 2. Organize demolition team, if required. 3 Organize heavy equipment teams, if required. 3. Identify location of target. 4. Evaluate the target and surrounding areas. 5. Select and/or construct appropriate means of reduction. 6. Determine possible effects of reduction on target and surrounding structures.Plan mitigation of collateral damage. 7. Determine possible effects on the assault team and friendly forces. 87. Identify safety precautions required during reduction. 9. Brief team members on safe locations. 10. Position yourself and your team in a safe location during reduction. 118. Suppress enemy fire and sSetup site security. 129. Obscure target from enemy observationCoordinate enabler support, if required. 1310. Mark Identify areas for safe transit/ occupation by friendly forces. 1411. Reduce strongpoint/structureCoordinate logistical support. 1512. Coordinate transfer of control of reduction site to follow-on/ designated force. 1613. Submit required reports.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7I Earthmoving Operations 2. MCRP 3-17.7L Explosives and Demolitions 3. MCRP 3-17A Engineer Field Data 4. MCWP 3-17.3 MAGTF Breaching Operations 5. MCWP 3-17.4 Engineer Reconnaissance 6. MCWP 3-17.8 Combined Arms Mobility Operations 7. MCWP 3-35.3 Military Operations on Urbanized Terrain (MOUT)

_ 1302-MOBL-1008: Operate a robot

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given an operating environment, suspected explosive hazards, combat engineer equipment, personal protective equipment and references.

STANDARD: To locate, confirm, and mark the explosive hazard(s) per the operator's manual.

PERFORMANCE STEPS: 1. Visually assess the terrain. 2. Prepare the robot for operation. 3. Operate the robot and components. 4. Conduct robotic reconnaissance. 5. Retrieve the robot. 6. Conduct post-op preventive maintenance checks and services (PMCS).

PREREQUISITE EVENTS:

CHAINED EVENTS: RELATED EVENTS:

REFERENCES: 1. Appropriate Manufacturer's Assembly Manual/Instructions 2. Appropriate Technical Manuals 3. MCRP 3-17.2D Explosive Hazards Operations 4. MCRP 3-17.7L Explosives and Demolitions 5. MCWP 3-17 Engineering Operations 6. MCWP 3-17.8 Combined Arms Mobility Operations 7. MCWP 3-35.3 Military Operations on Urbanized Terrain (MOUT)

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity

RANGE/TRAINING AREA: Facility Code 17413 Field Training Area Facility Code 17961 Combat In Cities Facility

AIRCRAFT:

ROOMS/BUILDINGS:

EQUIPMENT: PackBot 510 w/FASTAC kit, SUGV 310, SUGV 320.

MATERIAL:

UNITS/PERSONNEL: Range OIC, Range Safety Officer.

OTHER SUPPORT REQUIREMENTS: Obstacles to represent urban and rural conditonsconditions. Inert explosive hazards and mock-ups.

_ 1302-MOBL-1009: Identify Explosive Hazards (EH)

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 3 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given an operating environment, suspected explosive hazards, combat engineer equipment, field protective equipment, and country handbooks/ORDATA II.

STANDARD: To identifyBy category, country of origin, type of function, safeties, and conditions.

PERFORMANCE STEPS: 1. Visually identify explosive hazard markers and indicators. 2. Identify components of Improvised Explosive Devices (IEDs). 3. Identify booby traps. 4. Identify thrown munitions. 5. Identify projected munitions. 6. Identify dropped munitions. 7. Identify placed munitions. 8. Record and report results. 1. Confirm existence of EH 2. Classify EH based on category 3. Identify characteristics of EH. 4. Identify sub-components of EH 5. Identify fuses of EH. 6. Identify safeties of EH. 7. Validate identification IAW reference(s).

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. Appropriate Reference Materials 21. CHB Country Handbooks 32. FM 3-34.210 Explosive Hazard Operations 43. MCIP 3-17.012 Combined Arms Improvised Explosive Device Defeat OperationsMAGTF Counter-Improvised Explosive Device Operations 54. MCRP 3-17.2D Explosive Hazards Operations 65. MCRP 3-17A Engineering Field Data 76. CORD ORDATA II (Software)Collaborative Ordnance Data Tool 8. SWO 60-AA-MMA-010 Demolition Materials

_ 1302-MOBL-1010: Reduce Explosive Hazards (EH)

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given an operating environmenta requirement, a positively identified explosive hazard, combat engineer equipment, Class V, personal protective equipment, commander's decision authorization and references. STANDARD: By calculating, placing and detonating an explosive charge that will result in the reduction of the explosive hazard and allow for assured mobility.To eliminate threat to friendly personnel and equipment

PERFORMANCE STEPS: 1. Evaluate go/no go criteria per the explosive hazard decision matrixleader’s decision consideration diagram. 2. Employ protective measures. 3. Build a charge appropriate to reduce the explosive hazard. 4. Remotely pPlace the charge(s). 5. Detonate the charge(s). 6. Conduct Coordinate post-blast analysis (PBA), if required. 7. Report results.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. Appropriate Technical Manuals 21. MCIP 3-17.012 Combined Arms Improvised Explosive Device Defeat OperationsMAGTF Counter-Improvised Explosive Device Operations 32. MCRP 3-17.2D Explosive Hazards Operations 43. MCRP 3-17.7L Explosives and Demolitions 54. MCRP 3-17A Engineering Field Data 6. MCRP 5-12.1C Risk Management - Cancelled w/o replacement 7. MCWP 3-1 Ground Combat Operations 8. MCWP 3-17 Engineer Operations 95. MCWP 3-17.2 MAGTF Explosive Ordnance Disposal 10. MCWP 3-17.3 MAGTF Breaching Operations 116. MCWP 3-17.4 Engineer Reconnaissance 127. MCWP 3-17.8 Combined Arms Mobility Operations 138. MCWP 3-35.3 Military Operations on Urbanized Terrain (MOUT)

SUPPORT REQUIREMENTS:

ORDNANCE: DODIC Quantity M023 Chg, Demo Block M112 11/4 pound C4 2 charges per Marine M131 Cap, Blasting Non-Electric M7 4 blasting caps per Team M456 Cord, Detonating PETN Type I Class E 10 FT per Marine M670 Fuse, Blasting Time M700 500 FT per Team M757 Chg, Assembly Demo M183 Comp C4 2 charges per Team MN08 Igniter, Time Blasting Fuse with Sho 2 igniters per Team MN88 Cap, Blasting, Non-Electric, M21 w/ 1 detonators per Team MN90 Cap, Blasting, Non-Electric, M23 w/ 1 detonators per Marine

RANGE/TRAINING AREA: Facility Code 17830 Light Demolition Range

AIRCRAFT:

ROOMS/BUILDINGS: EQUIPMENT: Squad demolitions kit, robot, Pioneer kit, PPE.

MATERIAL: Electrical tape, duct tape, prop stick.

UNITS/PERSONNEL: Range OIC, Range Safety Officer, Corpsman.

OTHER SUPPORT REQUIREMENTS: Safety vehicle, Ammunition vehicle, Communications (radio).

_ 1302-MOBL-1011: Design a ribbon bridge/raft

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situationrequirement, a map, an operations order, task organization of, completed reconnaissance forms, equipment, and personnel, and references.

STANDARD: To ensure design standards are met to support the concept of operations in accordance with TM 11518A-OR Improved Ribbon Bridge (IRB) Operators Manual.mobility operations.

PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Conduct reconnaissance of ribbon bridge/raft site. 3. Determine site condition and layout. 4. Determine logistical support requirements. 5. Determine engineer estimate of supportability. 6. Determine configuration of the ribbon bridge/raft. 7. Review the ribbon bridge/raft design. 8. Coordinate suppression of enemy force overwatching the crossing area. 9. Establish safety plan. 10. Coordinate obscuration of the crossing site. 1. Coordinate with supported unit commander, if required. 2. Review site reconnaissance information. 3. Determine bridge requirement, if applicable. 4. Determine rafting requirements, if applicable. 5. Determine logistical support requirements.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS: REFERENCES: 1. MCRP 3-17A Engineer Field Data 2. MCWP 3-17 Engineering Operations 3. MCWP 3-17.8 Combined Arms Mobility Operations 4. TM 10020C-OI Bridge Erection Boat (MKIII) Operator's Manual 5. TM 11518A-OR Improved Ribbon Bridge (IRB) Operators Manual

_ 1302-MOBL-1012: Design a Medium Girder Bridge (MGB)

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situationrequirement, a map, an operations order, military load classification requirements, completed reconnaissance forms, equipment, personnel, and references.

STANDARD: To meet or exceed the military load classification required supporting the concept of operation's traffic in accordance with TM 5-5420- 212-12 Medium Girder Bridgeensure design standards are met to support mobility operations.

PERFORMANCE STEPS: 1. Conduct mission analysisReview reconnaissance forms. 2. Conduct a reconnaissance of the bridge site.Determine gap requirements. 3. Determine configuration of Medium Girder Bridge (MGB) to be utilized. 4. Complete design Pro Forma. 45. Determine site condition and layout.logistical support requirements. 5. Develop engineer estimate of supportability.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17A Engineering Field Data 2. TM 5-5420-212-12MCRP 3-17.1A Medium Girder Bridge 3. TM 5-5420-212-12-1 Link Reinforcement Set

_ 1302-MOBL-1013: Design a non-standard bridge

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situationrequirement, a map, an operations order, a wet or dry gap, completed engineer reconnaissance forms, military load requirements, and references.

STANDARD: To meet or exceed the military load classification required to support the concept of operations/traffic in accordance with MCRP 3-17.1B Military Non-Standard Bridgingmobility operations.

PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Conduct site reconnaissance. 3. Determine bridge type. 4. Determine superstructure type. 5. Determine substructure type. 6. Determine bill of materials (BOM). 7. Coordinate support requirements. 8. Illustrate final design. 9. Submit design. 1. Review engineer reconnaissance reports. 2. Conduct site reconnaissance. 3. Determine the bridge type based on gap size and MLC. 4. Determine the number of stringers. 5. Design the deck. 6. Design the stringers. 7. Check the vertical deflection. 8. Design the lateral bracing. 9. Check the dead load. 10. Check the shear forces. 11. Design the end-bearing components. 12. Design the connections. 13. Design the substructure, if required. 14. Design the abutments, if required. 15. Calculate the bill of materials. 16. Determine logistical support requirements. 17. Illustrate final design.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.1B Military Non-Standard Fixed Bridging 2. MCRP 3-17A Engineering Field Data

_ 1302-MOBL-1014: Classify a bridge

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situationrequirement, a map, a bridgecompleted reconnaissance form(s), and references.

STANDARD: To determine the military load classification with consideration to width and overhead clearance restrictions in accordance with MCRP 3-17.1B Military Non-Standard Fixed Bridging..

PERFORMANCE STEPS: 1. Conduct mission analysisReview reconnaissance form(s). 2. Coordinate support/security requirements with supported units. 3. Prepare bridge reconnaissance team. (include all applicable forms and reports). 4. Conduct bridge reconnaissance. 52. Make appropriate calculations.Determine moment classification. 63. Determine bridge classification/restrictionsDetermine shear classification, if required. 74. Submit reportsDetermine width classification. 5. Determine deck classification, if required. 6. Determine final bridge classification.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. GTA 05-07-013 Rapid Field Classification Booklet 2. MCRP 3-17.1B Military Non-Standard Fixed Bridging 3. MCRP 3-17A Engineering Field Data 4. MCRP 3-17B Engineer Forms and Reports 5. MCWP 3-17.4 Engineer Reconnaissance

_ 1302-MOBL-1015: Plan engineer aspects of a gap crossing operation

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, operations order with river crossing annexpersonnel, equipment, and references.

STANDARD: To maintain maneuver forcemeet the mobility requirements in support of maneuver in accordance with the concept of operations and MCWP 3- 17.8 Combined Arms Mobility Operations.

PERFORMANCE STEPS: 1. Conduct mission analysis. 2. Task organize personnel and equipment. 3. Coordinate with supported unit commander. 4. Issue orders to engineer personnel. 5. Establish tactical control measures. 6. Coordinate required logistics support. 7. Coordinate with supported unit. 8. Submit required engineer reports. 9. Coordinate with bridge force, support force, and assault force, as required. 10. Plan for follow-on actions. 1. Analyze the mission. 2. Determine crossing means. 3. Select crossing sites. 4. Task organize personnel and equipment. 5. Estimate crossing rates. 6. Establish crossing area control measures. 7. Coordinate logistical support requirements. 8. Integrate crossing plan with supported unit’s operation order.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.1B Military Non-Standard Fixed Bridging 21. MCRP 3-17A Engineering Field Data 32. MCRP 3-17B Engineer Forms and Reports 4. MCWP 3-1 Ground Combat Operations 53. MCWP 3-17.8 Combined Arms Mobility Operations _ 1302-MOBL-1016: Plan construction of an expeditionary airfield/landing zoneforward aviation combat engineering

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given a tactical situation, a map, operations orderrequirement, airfield configuration (if required), aircraft type and density, and references.

STANDARD: To meet requirements of the concept of operations in accordance with MCRP 3-17.7B Design of Theater of Operations-Airfields and Helipads (Volume 2). support the air movement, personnel, and supplies.

PERFORMANCE STEPS: 1. Conduct mission analysisReview requirements. 2. Conduct Review airfield/landing zone site reconnaissance information. 3. Evaluate available resources. 3. Advise commander on site selection, if required. 4. Develop construction plan. 5. Determine task organization of equipment and personnel.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MCRP 3-17.7A Planning and Design of Roads, Airfields, and Heliports in the Theater of Operations - Road Design 21. MCRP 3-17.7B Planning and Design of Roads, Airfields, and Heliports in the Theater of Operations - Airfield and Heliport Design 32. MCRP 3-17.7I Earthmoving Operations 43. NAVAIR 00-80T-115 Expeditionary Airfield NATOPS Manual 4. MCWP 3-21.1 Aviation Ground Support 5. MCWP 3-17.8 Combined Arms Mobility Operations

_ 1302-PLAN-1001: Participate in the Marine Corps Planning Process (MCPP)

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 6 months

DESCRIPTION: MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT

INITIAL TRAINING SETTING: FORMAL

CONDITION: Given an operating environment, higher headquarters' order, commander's guidance and the reference, while implementing the orders process.

STANDARD: Produce plans and orders products which support the accomplishment of the mission and commander's intent and in accordance with MCWP 5-1 Marine Corps Planning Process.

PERFORMANCE STEPS: 1. Assist in problem framing. 2. Assist in the development of courses of action. 3. Assist in wargaming of courses of action. 4. Assist in comparison and recommendation of courses of action. 5. Assist in development of appropriate staff products, operations plans, orders, annexes, and appendices. 6. Assist in transition by compiling the components of an operations order for distribution to subordinate units.

PREREQUISITE EVENTS:

CHAINED EVENTS:

RELATED EVENTS:

REFERENCES: 1. MSTP PAM 5-0.2 Operational Planning Team Guide 2. MSTP PAM 5-0.3 MAGTF Planner's Reference Manual

_ 1302-PLAN-1002: Plan a base camp

EVALUATION-CODED: NO SUSTAINMENT INTERVAL: 12 months

DESCRIPTION:

MOS PERFORMING:

BILLETS:

GRADES: 2NDLT, 1STLT, CAPT, MAJ

INITIAL TRAINING SETTING: FORMAL