Superconducting Undulator (SCU) R&D for Free-Electron Laser (FEL) Systems (Argonne)

Highlights – September 01-30, 2014

The LCLS-SCU design meeting was held; design concepts for an integrated SCU-based undulator system for LCLS-II were presented.

SCU and Test Cryostat - Undulator Fabrication:

1. A $109,530 order for three 1.5-meter magnet core assemblies plus full dimensional inspection has been placed with Hi-Tech Mfg., Inc. Delivery is scheduled for 11 January 2015. o Delivery of the cores will be later than planned. Core procurement was delayed pending test results of the APS’s SCU1 – a 1.0-m-long magnet scheduled for installation in the storage ring in the winter shutdown. Testing of APS-SCU1 has thus far shown excellent performance, however several improvements were implemented in LCLS-SCU as a result of APS-SCU1 experience: o . Material change: The steel was changed from 10-18 to 10-06 after SCU1’s vertical field mapping results were known. . Correction coils: coils will now be wound and powered separately. . Dimensional tolerances: more rigorous inspection was implemented.

2. A drawing package for the cold mass support frame is complete and under review. A price quote of $12,282 each for a quantity of two was received in late June 2014 and will need to be reconfirmed with a delivery estimate prior to order placement. Procurement of two frames is planned to enable independent cold-mass assembly to take place at Argonne and Berkeley.

3. Current lead assembly components for the test cryostat that are common to the APS-SCU1 design have been received. Additional components have yet to be ordered pending final design completion.

Drawings and Models:

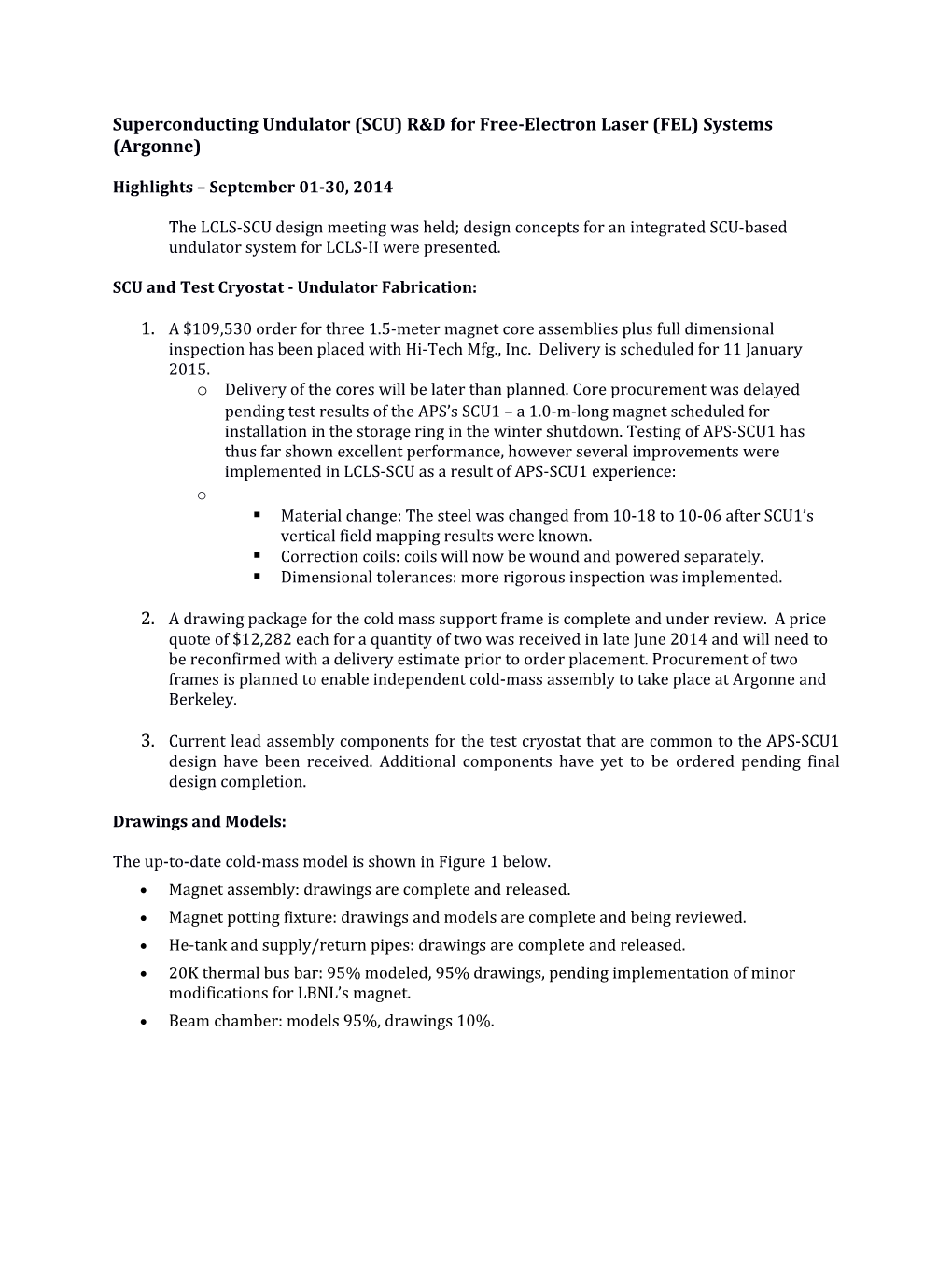

The up-to-date cold-mass model is shown in Figure 1 below. Magnet assembly: drawings are complete and released. Magnet potting fixture: drawings and models are complete and being reviewed. He-tank and supply/return pipes: drawings are complete and released. 20K thermal bus bar: 95% modeled, 95% drawings, pending implementation of minor modifications for LBNL’s magnet. Beam chamber: models 95%, drawings 10%. Figure 1: LCLS-SCU cold-mass model.

Measurement System Fabrication:

1. A quote of 6k$ was received for a linear stage with 2.13-m range. The stage will be used for vertical cryostat measurements. 2. The modification to the 2.5-m vertical cryostat top plate is complete. 3. Drawings for small fixtures for the interface from the cryostat top-plate to the linear stage are almost complete. 4. The small ceramic Hall probe holders that will be mounted inside carbon-fiber tubes are in- house, and will soon be sent to Arepoc for installation of the Hall sensors. After we receive the mounted Hall sensors we will begin to build two 2.8-m-long carbon-fiber Hall probe assemblies. 5. A 5-mm OD titanium guide tube for the horizontal cryostat system and other minor parts still need be ordered. 6. Estimated completion of the measurement system is now around March 2015, later than the scheduled December 2014 date. The measurement system is not on the critical path.

Test Cryostat Fabrication:

Helium Reservoir: The following highlights are extracted from Meyer Tool’s September monthly report: There was much more shrinkage than anticipated of the outside full-penetration welds on both the 7.5” OD and 6.0” OD port flanges on the LHe Reservoir. Weld repairs were completed, and Meyer has moved on to final machining and brazing, with planned completion of those activities by Friday 10/3. A flange is shown in Figure 2 below, during one step in the weld repair process.

The ASME pressure test and leak test are planned for the morning of Thursday 10/9 with shipping to Argonne occurring shortly thereafter.

Figure 2: Successful weld repairs were accomplished by adding material to the flange face and then remachining.

Cryostat: The following highlights are extracted from PHPK’s September monthly report:

• Cryostat delivery has been delayed from 13 October to 21 November due to longer than expected machining time. PHPK is aware of the impact to our schedule and is doing their best to speed up their schedule.

1. The 20K shield is complete and in storage in its shipping crate for protection prior to trial fit up with the remaining components of the cryostat assembly. 2. The 60K shield is at 80% complete, and should be finished by 10-October. 3. The stainless steel vacuum tank legs are complete and installed on the tank cylinder. The tank cylinder has been pre-machined for nozzle installation. The vacuum tank and nozzles are en route to the machine shop for precision nozzle fit up and final welding. 4. The cover dished heads were welded to the pre-machined flange rings and are ready for machining of the hole in the dished head for the magnet mount nozzle. The covers are en route to the machine shop for machining of the nozzle hole. 5. It was expected that the tank final machining would be completed by this date. However, due to our large machining center work load, this has been delayed approximately 3 weeks with an expected completion of final machining of the vacuum tank by mid to late October. 6. Final machining of the covers will occur immediately after the vacuum tank final machining. This is expected to be completed by 01-November. 7. The vacuum tank turret tubes will be completed during the final machining of the vacuum tank and covers. 8. It is expected that the vacuum tank, covers and turret tube assemblies will be shipped to the electroplater during the first week of November. PHPK is currently coordinating with the electroplater to expedite the process. 9. Final reaming of fiduciary holes, trial fit up and preliminary mass spec leak testing will occur at PHPK on 17 and 18-November. The required ANL witness of trial fit up and mass spec leak testing can occur on 19-November. 10. This places shipping from PHPK of the completed cryostat on 20-November with an arrival date of 21-November at ANL. Figure 3: The vacuum tank assembly, pre-machined for nozzle installation, is shown.

Issues and Actions

• Working to recover schedule where possible.

Schedule Status The magnet core order was delayed due to waiting on performance data for APS-SCU1. This likely puts delivery of the wound and tested cores about two months late. Cryostat delivery is about 5 weeks later than the contractual date. 90-day Forecast

• Cryocoolers will be delivered from Sumitomo. • 8 Km of 0.7-mm NbTi conductor will be ordered • 4K cold mass models and drawings will be complete. • PHPK will deliver the cryostat. • Meyer Tool will deliver the helium vessel.