For Micro Surfacing, attach an additional strike off to the spreader box after the adjustable rear seal that provides a smooth finished surface. Do not use a burlap drag.

SECTION 421 MICRO SURFACING

421.01 GENERAL. This work consists of applying a thin overlay material composed of modified emulsified asphalt, aggregate, water, and additives over a prepared surface.

421.02 EQUIPMENT. Equipment Section Micro Surfacing Equipment 156.02 D

Calibrate each mixing unit in the presence of the Engineer before starting work. Perform calibration according to ISSA-MA 1. The Engineer may accept previous calibration documentation if the calibration was done within the calendar year. Include the individual calibration of each material at various settings in the documentation.

421.03 MATERIALS. Item Section Water 812 Aggregate 816.04 Bitumen 818.03

Obtain and submit a certificate of compliance from the emulsion manufacturer stating that the aggregate and emulsion are compatible.

If necessary, introduce a liquid field control additive and blend it with water to provide effective control of the required quick-set properties. Certify that the additive is compatible with the mixture.

421.04 CONSTRUCTION REQUIREMENTS.

A. Mix Design. Submit a mix design prepared by a qualified testing laboratory. Use the same materials in the mix design as on the project. Obtain a new approved mix design from the same testing laboratory before changing any materials in the mix design.

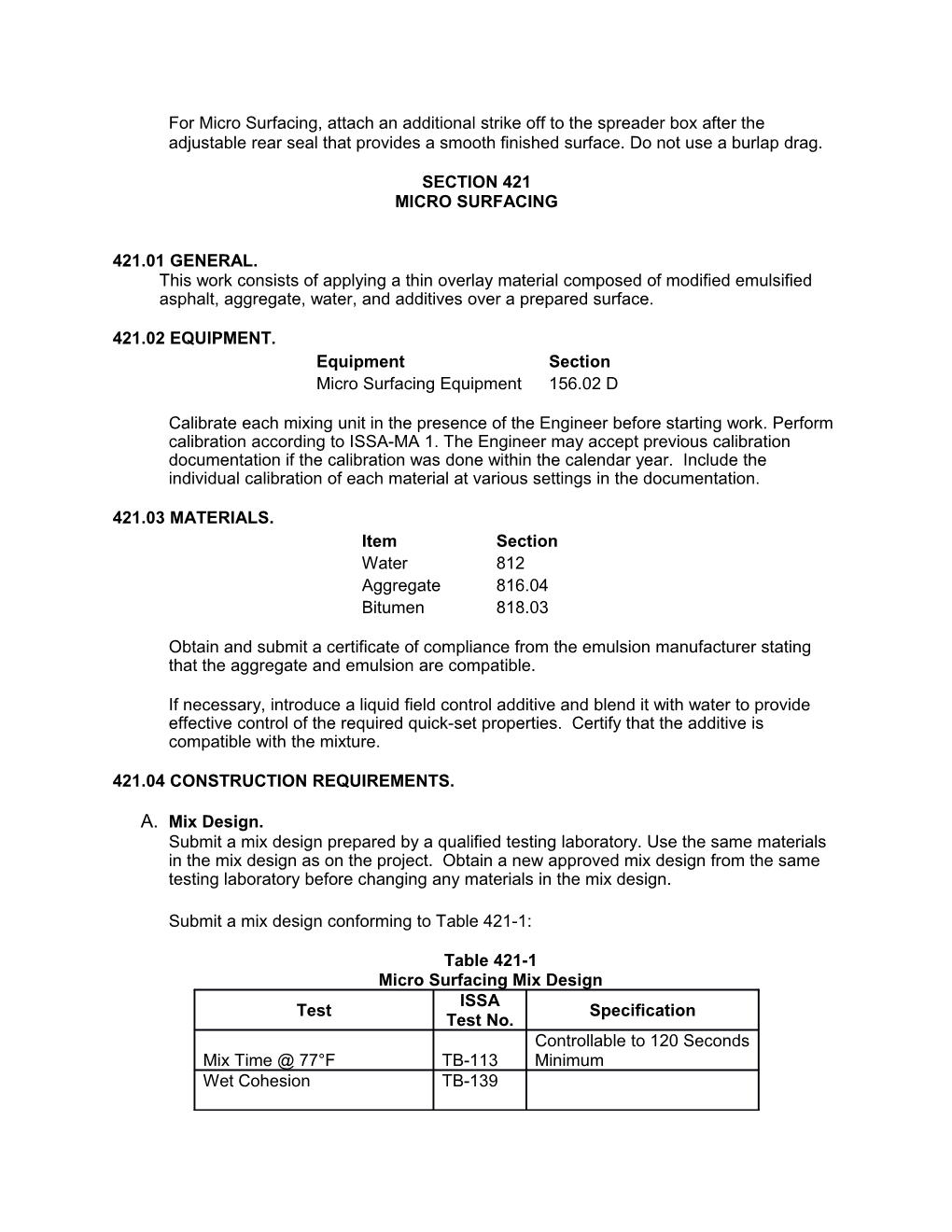

Submit a mix design conforming to Table 421-1:

Table 421-1 Micro Surfacing Mix Design ISSA Test Specification Test No. Controllable to 120 Seconds Mix Time @ 77°F TB-113 Minimum Wet Cohesion TB-139 Table 421-1 Micro Surfacing Mix Design ISSA Test Specification Test No. @ 30 Minutes Minimum (Set) 12 kg-cm Minimum

@ 60 Minutes Minimum 20 kg-cm or Near Spin (Traffic) Minimum Wet Stripping TB-114 Pass (90% Minimum) Wet-Track Abrasion Loss

One-hour Soak TB-100 50 g/ft2 Maximum

Six-day Soak 75 g/ft2 Maximum Lateral Displacement 5% Maximum TB-147 Specific Gravity after 1,000 Cycles of 125 lb 2.10 Maximum Excess Asphalt by LWT TB-109 50 g/ft2 Maximum Sand Adhesion 11 Grade Points Minimum Classification Compatibility TB-144 (AAA, BAA)

Use component materials that meet requirements in Table 421-2

Table 421-2 Micro Surfacing Component Material Requirements Component Quantity Residual Asphalt 5.5% to 10.5% by dry weight of aggregate Mineral Filler 0.0% to 3.0% by dry weight of aggregate Polymer Content Minimum 3.0% solids based on bitumen weight content Additives As required to provide specified properties Water As required to produce consistency

B. Test Strip. Construct a one lane, 1,000 foot test strip for each machine used on the project at an approved location. Construct the test strip at sunrise. Postpone the construction of the test strip until the emulsion temperature is below 122° F. The Engineer will compare the machines for variances in surface texture and appearance. Correct variations before beginning production application.

Open the test strip to traffic within 90 minutes. The Engineer will inspect the test strip for damage immediately after it begins carrying traffic and again after 12 hours. The Engineer will accept the test strip If no damage to test strip after inspections. The Engineer will allow full production to begin after accepting the test strip.

In place of construction of a test strip, submit evidence of successful construction of a test strip on another Department project using the same mix designs. The project must have been constructed in the same construction season. The material, material source, and equipment used for the test strip must be identical to all parts of the proposed material, material source, and equipment.

Construct a new test strip if the material or equipment changes. The Engineer may direct the construction of a new test strip during production application.

C. Weather Limitations. Place material if the surface and ambient temperatures are at least 45° F and the forecast is greater than 32° F for 24 hours after placement. Do not place the material if the pavement or ambient temperatures is below 50° F and falling.

Do not place the material if it is raining.

D. Flagging and Pilot Car. Furnish flagging and pilot cars as specified in Section 704. Include the cost of flagging and pilot cars in the price bid for other items. On two-lane, two-way traffic highways, place additional flaggers and signs at each end of the surfacing operation and at major intersections within the operation area. Provide flaggers on the project during the surfacing application operation when using a pilot car.

E. Surface Preparation. 1. General. Remove deleterious material. Protect manholes, valve boxes and other service entrances from the surfacing material.

2. Tack Coat. Allow tack coat to cure before the applying the micro surfacing.

F. Application. Fog the surface with water if necessary. Adjust the rate of application of the fog spray to suit the pavement surface and atmospheric conditions.

Uniformly spread the material using the spreader. Ensure the material does not prematurely break in the spreader box and is homogeneous during mixing and spreading.

Use hand methods to spread the mixture in areas inaccessible by mechanical spreaders. Complete handwork at the time of the machine applied application. Finish hand-worked areas to resemble the mechanical spreader finish.

Do not leave streaks in the finished surface. If excessive streaking develops, stop production and fix the situation. Streaking is excessive if in any 30 square yard area there are more than four drag marks greater than: 0.5 inches wide and 4.0 inches long 1.0 inches wide and 3.0 inches long Construct joints with no excessive buildup or uncovered areas. Place longitudinal joints on lane lines. Construct straight edges along curbs and shoulders and through intersections, with no runoff.

421.05 METHOD OF MEASUREMENT. The Engineer will measure, completed and in place as specified in Section 109.01 and as follows.

The Engineer will measure the dry aggregate weight. The Engineer will subtract the weight of moisture determined from moisture tests.

421.06 BASIS OF PAYMENT.

Pay Item Pay Unit Aggregate for Microsurfacing Type_ Ton Asphalt Emulsion for Microsurfacing Gallon

Such payment is full compensation for furnishing all materials, equipment, labor, and incidentals to complete the work as specified.