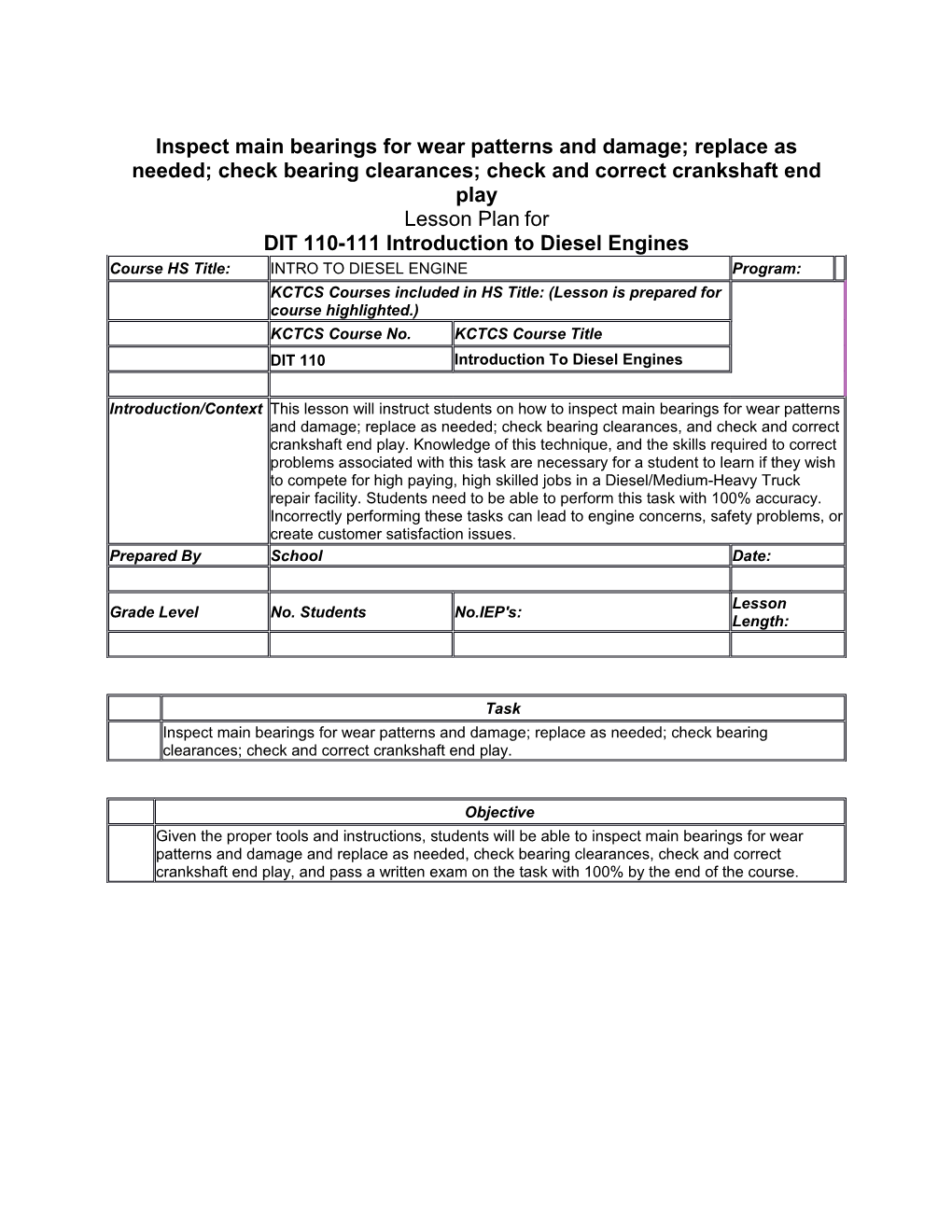

Inspect main bearings for wear patterns and damage; replace as needed; check bearing clearances; check and correct crankshaft end play Lesson Plan for DIT 110-111 Introduction to Diesel Engines Course HS Title: INTRO TO DIESEL ENGINE Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title DIT 110 Introduction To Diesel Engines

Introduction/Context This lesson will instruct students on how to inspect main bearings for wear patterns and damage; replace as needed; check bearing clearances, and check and correct crankshaft end play. Knowledge of this technique, and the skills required to correct problems associated with this task are necessary for a student to learn if they wish to compete for high paying, high skilled jobs in a Diesel/Medium-Heavy Truck repair facility. Students need to be able to perform this task with 100% accuracy. Incorrectly performing these tasks can lead to engine concerns, safety problems, or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Inspect main bearings for wear patterns and damage; replace as needed; check bearing clearances; check and correct crankshaft end play.

Objective Given the proper tools and instructions, students will be able to inspect main bearings for wear patterns and damage and replace as needed, check bearing clearances, check and correct crankshaft end play, and pass a written exam on the task with 100% by the end of the course. Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 New Common Core Standards: RST 11-12 3 A-CED-4 N-Q.1 Common Core Technical Standards: TD-OPS 2 TD-SYS 2 New Generation Science Standards: HS-PS2-1

INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts Instructor may use the content section of this plan to create a handout for the students.

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Sean Medium/Heavy Duty Truck Engines, Fuel and Computerized Second Delmar 104 Bennett Management Systems Various Diesel Engines Test T2 Fourth Delmar 33-34

Supplies Quantity Item Source As Needed Plastigage Various

Equipment Quantity Item Source As Needed Dial Indicator Various

Content/Presentation/Demonstration Outline Explain to students that inspection of the main bearing bore alignment and out-of-roundness can prevent possible damage to the crankshaft or premature bearing failure. Let them know that if the bearing bore is out of alignment, uneven pressure is applied to each of the bearings, causing the crank to flex as it is rotated. Also, this flexing and its effects can also be created by an operator who “hot rods” or when the engine becomes lugged down. Inform students that in this case, the engine will heat unevenly, resulting in uneven expansion of the journal. Tell students that verifying the alignment by using a master bar may prove the latter. Instruct students that this flexing can cause the crank to fracture and will result in bearings with unusual wear patterns. Tell students to use an inside micrometer to check the bearing bore for correct diameter and an out-of-round condition. If the bearing bore is too large, explain that bearing shells will not seat properly against the bore. Tell students that this may cause inadequate heat transfer from the shells to the bore, turning or movement of shells in the bore, and misalignment of the crank when load is applied. Inform students that an out-of-round bore will cause uneven torque on the crank, which could lead to fatigue, fracturing, and failure or breakage of the crank. Let them know that the bearing shells will not be lubricated evenly and will wear more on one side, while the distorted shell will create fractures in the bearing surface. Instruct students that the correct installation of bearing shells is essential to any successful overhaul. Let them know that about 13 percent of premature bearing failures are caused by improper assembly of bearings. Inform them that after reconditioning the block and selecting proper-sized bearings, they should carefully install the top half of each bearing into the cylinder block. Tell them to be sure the locating lugs (indented notch in each shell) are fitted into the matching slot in the cylinder block bore. Explain that this type of error can cause movement of bearings leading to metal in oil and finally a spun bearing, causing oil starvation and seizing of the crank. Tell students to sight through the oil passage in the shell to ensure that it is aligned to the oil passage in the bore. Remind them that failure to align the oil passages will result in oil starvation, bearing fatigue, scoring, metal in oil, and finally, other bearing failure. Instruct students to carefully install the rear main seal (split type), crank in the block, and align marks on the crank timing gear and cam gears. Instruct them to use a Plastigage® to check all main bearing clearances. Tell students that if clearances are not within specification, check for improperly sized bearings, dirt, metal under shells, or misalignment of shells. If clearances are correct, instruct students to remove the Plastigage, lubricate bearings, reinstall bearing caps, and torque to specifications. Have them rotate the crank by hand to check for binding. If binding occurs, tell them they should loosen all caps and tighten individually to determine which bearing is at fault. Tell them to check and adjust crankshaft end play. Instruct students that one of the main bearings is usually flanged to define crank endplay. Explain that this is known as the thrust bearing and it is available in several sizes to accommodate some thrust surface wear as well as some thrust face dressing in the crankshaft. Let students know that alternatively, split rings known as thrust washers may be used to control crank endplay. Tell students that endplay specifications would typically be in the 0.2 to 0.3 mm (0.008—0.012”) range. Inform students to use a dial indicator to measure, and have them force the shaft fore and aft for measurement. Explain to students the causes of Spun Bearing(s) and Bearing Seizure: Instruct students that a lubrication-related failure is caused by insufficient or complete absence of oil in one or all the crank journals. Let students know that the bearing is subjected to high friction loads and surface welds itself to the affected crank journal. Tell them that this may result in a spun bearing in which the bearing friction welds itself to the journal and rotates with the journal in the bore or alternatively continues to scuff the journal to destruction. Inform students that when a crankshaft fractures as a result of bearing seizure, the surface of the journal is destroyed by excessive heat and it fails because it is unable to sustain the torsional loading. Inform students that the causes of spun bearings and bearing seizure include the following: *Misaligned bearing shell oil hole, *Improper bearing to journal clearance. Explain that excessive clearance will result in excessive bearing oil throw-off, which starves journals farthest from the supply of oil, and that insufficient bearing clearance can be caused by overtorquing, use of oversize bearing shells where a standard specification is required, and cylinder block line bore irregularities. *Sludged lubricating oil causing restrictions in oil passages. *Contaminated engine oil. Fuel or coolant in lube oil will destroy its lubricity.

Teach students that etched main bearings are caused by the chemical action of contaminated engine lubricant. Explain that chemical contamination of engine oil by fuel, coolant, or sulfur compounds can result in high acidity levels, which can corrode all metals. Let students know that the condition is usually first noticed in engine main bearings. Explain that it may result from extending oil change intervals beyond that recommended. Tell them that etching appears initially as uneven, erosion pock marks, or channels. Applications/Practice 1 Refer to Content

Evaluation and feedback Prior to Testing or Lab Work Objective 1/ Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist should be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1/ Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required.

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)