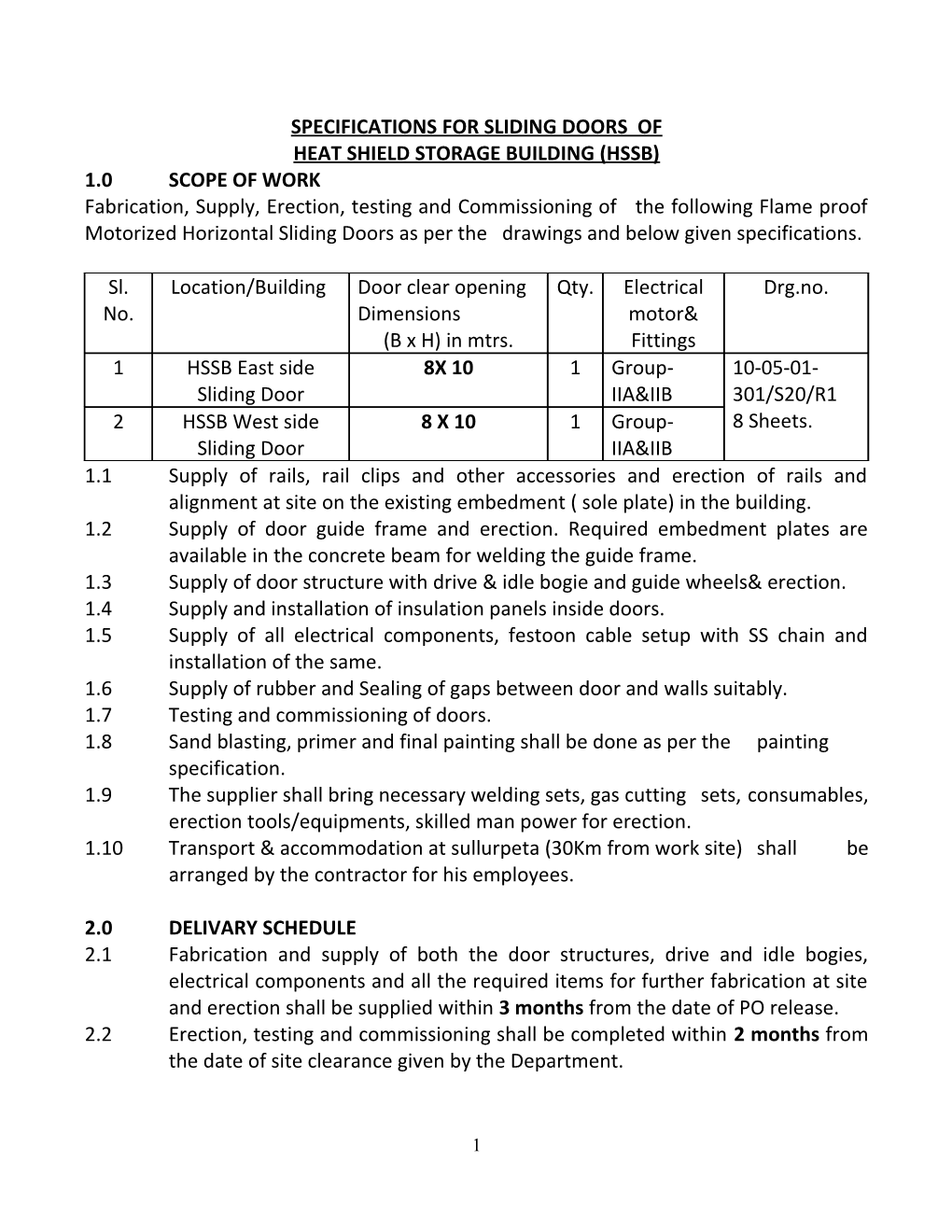

SPECIFICATIONS FOR SLIDING DOORS OF HEAT SHIELD STORAGE BUILDING (HSSB) 1.0 SCOPE OF WORK Fabrication, Supply, Erection, testing and Commissioning of the following Flame proof Motorized Horizontal Sliding Doors as per the drawings and below given specifications.

Sl. Location/Building Door clear opening Qty. Electrical Drg.no. No. Dimensions motor& (B x H) in mtrs. Fittings 1 HSSB East side 8X 10 1 Group- 10-05-01- Sliding Door IIA&IIB 301/S20/R1 2 HSSB West side 8 X 10 1 Group- 8 Sheets. Sliding Door IIA&IIB 1.1 Supply of rails, rail clips and other accessories and erection of rails and alignment at site on the existing embedment ( sole plate) in the building. 1.2 Supply of door guide frame and erection. Required embedment plates are available in the concrete beam for welding the guide frame. 1.3 Supply of door structure with drive & idle bogie and guide wheels& erection. 1.4 Supply and installation of insulation panels inside doors. 1.5 Supply of all electrical components, festoon cable setup with SS chain and installation of the same. 1.6 Supply of rubber and Sealing of gaps between door and walls suitably. 1.7 Testing and commissioning of doors. 1.8 Sand blasting, primer and final painting shall be done as per the painting specification. 1.9 The supplier shall bring necessary welding sets, gas cutting sets, consumables, erection tools/equipments, skilled man power for erection. 1.10 Transport & accommodation at sullurpeta (30Km from work site) shall be arranged by the contractor for his employees.

2.0 DELIVARY SCHEDULE 2.1 Fabrication and supply of both the door structures, drive and idle bogies, electrical components and all the required items for further fabrication at site and erection shall be supplied within 3 months from the date of PO release. 2.2 Erection, testing and commissioning shall be completed within 2 months from the date of site clearance given by the Department.

1 3.0 FABRICATION & MATERIALS: 3.2.1 Fabrication should be carried out only as per the dimensions and tolerances indicated in the enclosed drawings. 3.2.2 Unless otherwise specified general tolerances as per IS have to be followed 3.2.3 Test certificates from Govt. approved test houses for chemical and mechanical properties should be produced for all the materials used in the fabrication. 3.2.4 All bolts, nuts, washers etc., should be as per the relevant IS unless otherwise specified in the drawings. Wherever not mentioned, only coarse pitch is to be provided for these threads 3.2.5 All fasteners, nuts, washers etc., shall be hot dip galvanized as per relevant IS wherever not indicated in the drawings. 3.2.6 All the steel materials shall confirm to IS:2062 grade A, unless otherwise specified in the drawings. 3.2.7 All the sharp edges shall be chamfered to 1mmX45deg.unless otherwise specified 3.2.8 The doors are to be sealed with rubber sheet all around between the walls and door to avoid the entry of rain water, birds, insects Rats and snakes etc and also to avoid heat in leak. 3.2.9 Door drive and idle wheel bogie shall be closed fully by metallic enclosure with bolt and nuts. 3.2.10 Insulation: Phenotherm insulation in panel form ( 700mmx700mmx40thick, density;35+/-2kg/cu.mtrs, thermal conductivity:0.020kca/h m deg.C, BS 32047) shall be wrapped in 0.2mm thick aluminium sheet and fixed inside the door over the area 10150mmx8200mm before closing the top plate for each door.Test certificates shall be supplied for physical,thermal and mechanical properties of phenotherm material.

4.0 ELECTRICAL SYTEMS: 4.1 All elements like Electrical motors, limit switches, Junction boxes, starter/ Local control panel, Forward/reverse Switches, ON/OFF switches, emergency stop switches, indication lamps shall be Flame proof type suitable for Group IIA& IIB hazardous area as per IS: 2148. 4.2 All Electrical systems shall be rated for 3 phase, 415 V±10% and 50Hz power supply.

2 4.3 ELECTRIC MOTORS: All Electric motors shall be of squirrel cage, induction, crane duty motors with S5 duty, 60% CDF, 300 starts per hour and motors shall be flame proof type confirming to Group IIA/IIB as per IS 2148/IS325/IS4691.The motor rating shall be selected such a way that the motor will draw less than 80% rated current at standard operating conditions. 4.4 LOCAL CONTROL PANELS: Local Control Panel shall be Flame proof type confirming to Group IIA& IIB hazardous area as per IS: 2148. The control panel shall have Forward & Reversing power contactors with overload relay having forward and rev. Limit switches interlocks, safety interlocks, control power MCB, 3 Phase power ON indicating lamps, Emergency stop PB, Forward & Reverse PBs with Indication lamps & O/L Trip lamp. The contactor rating shall be selected one rating higher than the design requirement. 4.5 LIMIT SWITCHES:The drive system for HSDs shall be provided with limit switches for end limit and stop and it shall be of Flame proof type confirming to Group IIA& IIB hazardous area as per IS: 2148. All flame proof limit switches shall be of lever type. 4.6 CABLES: LT power cables are 1100 V grade, multi core, stranded Copper conductor of grade H4 and class 2, XLPE insulated, extruded PVC inner sheathed of type St-2, galvanised single round steel wire armoured and with outer sheath made of FRLS PVC compounded of type ST-2. 4.7 Control cables are 1100V grade, multi core, 2.5 sq.mm cross section, stranded copper conductor having 7 strands, PVC insulated inner PVC sheathed of type St-1, galvanised steel wire armoured and outer sheath made of FRLS PVC compound of type St-1, Control cable shall be provided. 4.8 Power has to be tapped from the existing ISRO Power socket (16A,5pin female) available at 1mtrs below the LCP (to be provided by the supplier). 4.9 All power and control cables between Incoming power socket to LCP, LCP to motor and limit switches shall be in the bidder scope. 4.10 Incoming power cable from 16A power socket to the LCP, power cable from LCP to junction box on the wall above door, from junction box on the door to Motor shall be minimum of 4CX6Sqmm. copper conductor of XLPE insulated armoured PVC overall sheathed. About 30mtrs cable is required for each door. 4.11 Festoon Cable System: From Junction box on wall to junction box on door is through by EPR/FRLS cable or suitable cable as approved by SDSC for flexible portion of the wiring. Only S.S steel chain shall be used for Pestoon cable arrangement. About 20mtrs FRLS/EPR cable is required for each door for festoon system.

3 4.12 Control cables of minimum size 3CX2.5 Sqmm. Copper conductor PVC insulated with overall shielded with PVC outer sheathed cable (3.6.2) has to run for limit switches. 4.13 Cable terminations shall be either through standard Crimping type copper lugs for power cables and pin type or spliced lugs for electrical control cables. 4.14 Double compression nickel-plated brass cables glands are to be used at both (Emanating and terminating) the ends of the cable. 4.15 Cable laying : The power and control cables shall be laid on suitable GI cable trays-50X50 mm /50mm dia. GI conduit and shall be fixed on the walls/Door with metallic clamps. 4.16 EARTHING: The motors, LCP, all metal enclosures of all electrical equipment, cable trays shall be effectively grounded with double earthing and shall be connected to building earth. SDSC-SHAR will only provide ground rise at suitable location for grounding. Further connection from this riser to HSDs system for earthing shall be in tenderer scope.

5.0 WELDING: 5.1 All welding shall be carried out as per standard ASME-section 9 welding procedures by qualified welders 5.2 The inside surfaces of all the closed steel box sections shall be inspected and cleared by the purchaser before closing them 5.3 All the weldments root run and final weld shall be DP tested. All the welds shall be free from cracks or any other defects.

6.0 PAINTING: 6.1 All the steel parts shall be painted as per the painting scheme mentioned below: 6.2 Sand/Steel grit blasting confirming to SA2.5 shall be done for cleaning the surfaces. 6.3 After Sand/Steel grit blasting all the surfaces have to be cleaned free from dust, moisture , oil etc. 6.4 Zinc rich epoxy primer (Two component) shall be applied to a dry film thickness of 60 microns minimum. 6.5 An intermediate coat of epoxy/polyurethane enamel paint shall be applied to a dry film thickness of 100 microns 6.6 A final coat of Chlorinated rubber/polyurethane enamel paint shall be applied to a dry film thickness of 40 microns minimum

4 6.7 Only light grey colour shall be used for painting the doors. 6.8 The inside surface of all the closed steel box sections shall be cleaned by sand blasting and two component Zinc rich epoxy primer shall be painted to a dry film thickness of 60 microns minimum before closing them. 6.9 The thickness of the paint shall be measured by the contractor in the presence of a representative of the department and shall meet the specifications.

7.0 BOUGHTOUT ITEMS: The approved brands of bought out items are given below. No other make is acceptable. However for the items which are not listed, the supplier shall take the approval of department, before procurement. 1. Paints : Asian/Bombay paints/ Berger/ Grand polycoats 2. High tensile fasteners : TVS/Unbrako/GKW/PFL. 3. LT power cables :Incab/Universal/Nicco/Delton/ Finolex/Polycab/APAR

4. Motors : Siemens/ CG/Bharat bijlee 5. Bearings : SKF/ FAG 6. Geared motor : PBL /Elecon/ Shanthigear/ New Allenbarry/Radicon 7 Electrical forward/ reverse switches : Siemens/ BHC/L&T 8 Limit switches : Siemens/ Sterling control/ Speed-O control 9. Junction boxes & LCP : FCG/ Baliga 10. Steel (IS 2062) : SAIL/TATA /Jindal/ESSAR/RINL

8.0 INSPECTION: 8.1 The representative of the department shall have access and right to inspect the work , at all times during the progress of the work. Any work which is proved faulty shall be corrected by the supplier without delay. The fact that faulty work or work which is not in accordance with plans and specifications are not pointed out by the representative of the Department, shall not relieve the supplier of his responsibility for correcting such work. 8.2 The Department has no obligation to discover defects in the work performed and it shall be the sole responsibility of the supplier to ensure such completed work is defect free and meets the technical specifications/ requirement. Inspection and clearance for dispatch by Department’s inspectors shall not relieve the supplier of any of his obligations& duties.

5 9.0 TESTING AND COMMISSIONING: 9.1 At Supplier site: Functional testing of drive system, electrical systems, idle wheel drive and any other tests as demanded by purchaser shall be carried out by the contractors. Relevant test certificates shall be furnished. 9.2 At SDSC-Sriharikota Satisfactory functioning of doors shall be checked after erection as a complete assembly in actual position as per the following checklist. 9.2.1. Checking the sealing of door by water sprayings between doors and between wall & doors. 9.2.2. Smooth movement with power drive without jerk and smooth opening and closing of doors. 9.2.3. Speed of operation of doors. 9.2.4 Functioning of limit switches. 9.2.5. Sealing arrangements of door. 9.2.6. Checking of current drawn by motor and IR values. 9.2.7. Undulation of the surface of door shall not be more than 2mm for any 1mx1m area and +/-3mm for the entire area. Parallelism between 2 edges shall be within 10mm 9.3 DEPARTMENT SUPPLY DURING ERECTION 9.3.1 As part of erection for Guide frame assembly, positioning of Doors on rail, required crane/fork lift will be provided by Dept. on chargeable basis. Department will provide the following at free of cost at site during receipt, erection & testing: 9.3.2 Free power supply & water supply. 9.3.3 Material handling equipments for handling doors during receipt at our site. 9.3.4 For Guide frame assembly, embedment plates will be available in wall. 9.3.5 For rail erection, embedment plate(soleplate) will be available on the floor. 9.3.6 For motor current &IR measurements, relevant meters will be provided.

10.0 DISPATCH: 10.1 The items are to be dispatched to SDSC-SHAR, Sriharikota only after inspection and clearance for dispatch by the representatives of the department. 10.2 Any damage during transportation are to be rectified by the supplier at free of cost. No transit insurance charges will be borne by the Department. Final inspection and acceptance of the systems will be at site in Sriharikota.

6 11.0 PAYMENT: 11.1 90% payment will be made against the supply of all the fabricated items and required materials (for final fabrication at site and erection) within 30days from the date of certification by Department inspection team. 11.2 Remaining 10% payment of supply price and 100% payment of erection price will be made within 30days from the date of completion of erection and certification by Department inspection team.

12.0 LD, SD, PBG & GUARANTEE 12.1 Late delivery (LD), Security Deposit(SD)& Performance Bank Guarantee(PBG) are applicable as given in the indent form. 12.2 Supplier shall furnish Guarantee for a period of 1 year from the date of Department certification after erection and commissioning. During the above guarantee period, any rectification work need to be attended by the supplier at free of cost.

13.0 HOW TO QUOTE? 13.1 Supplier shall quote the price in lump sum for fabrication and supply of doors and related components including their transportation to SDSC-SHAR. CST shall be mentioned over the above price separately. 13.2 Supplier shall quote the price of erection, testing and commissioning in lump sum mentioning service tax over it separately.

7