STANDARD OPERATING PROCEDURE (SOP) Department: Pressroom

Stitcher Operations

1. Tools Needed: None 2. Prep Work: None

3. Issues: 3.1. Power Up: 3.1.1. Turn on Red Power Switch (screen 1 main menu) 3.1.2. Do not use the wire feed on screen to manually feed wire. 3.1.3. Feed wire through by hand, without press walking. 3.1.4. Pull out 150mm of wire and insert into feeder tube. 3.1.5. If running one stitcher with both stitchers in, the electrical plug to the stitcher not running, must be unplugged.

3.2. Changing the Position of the Stitch: 3.2.1. Push the button below the word “Position”, then use the number keys, the numbers are placed in from right to left. 3.2.2. Push the “OK” button. 3.2.3. Adding numbers will lower the stitch or come to the head. 3.2.4. Stitcher number will vary on each run. 3.2.5. To change the screens on the Control Panel use the “?” key. To return to the main menu press the “Exit” key in any of the screens.

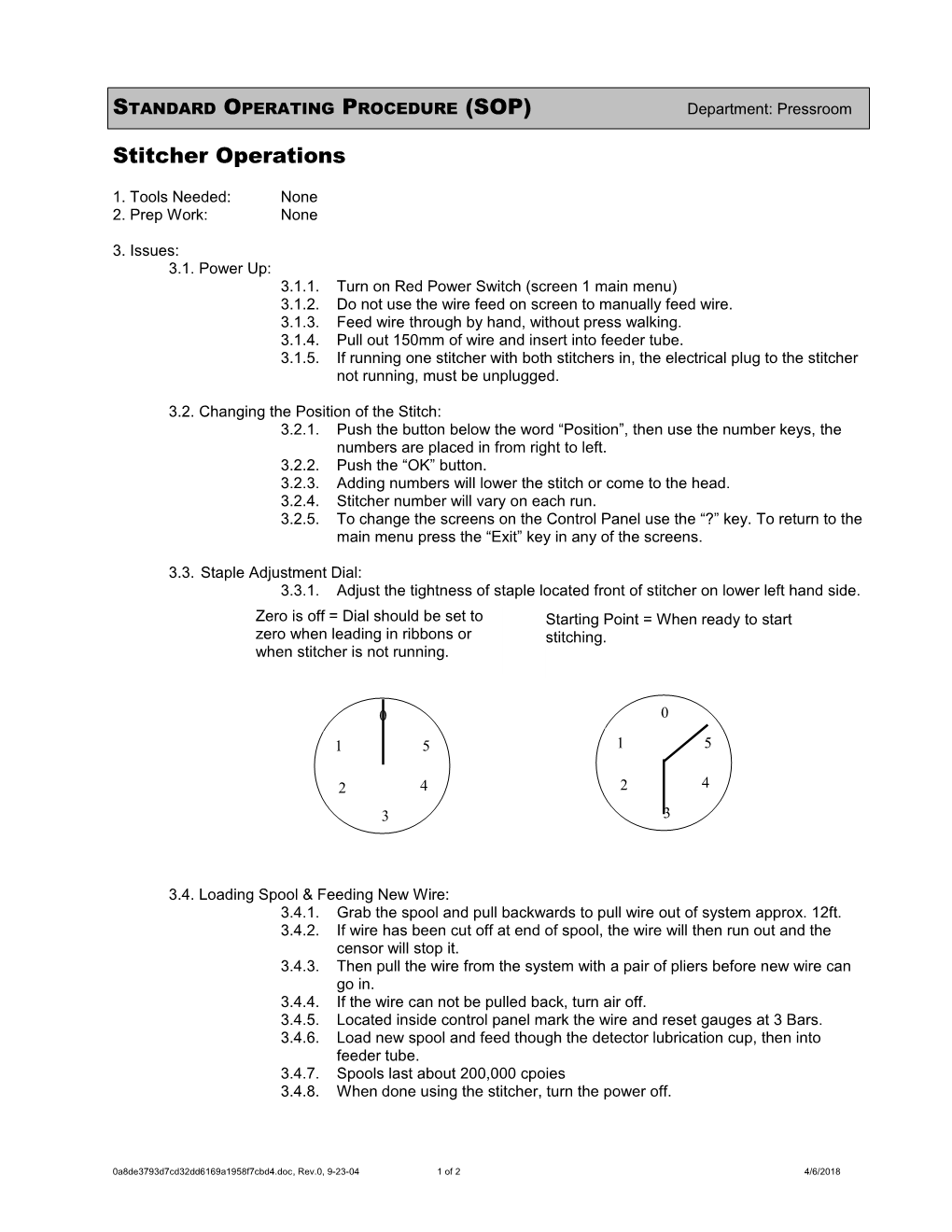

3.3. Staple Adjustment Dial: 3.3.1. Adjust the tightness of staple located front of stitcher on lower left hand side. Zero is off = Dial should be set to Starting Point = When ready to start zero when leading in ribbons or stitching. when stitcher is not running.

0 0 1 5 1 5

2 4 2 4 3 3

3.4. Loading Spool & Feeding New Wire: 3.4.1. Grab the spool and pull backwards to pull wire out of system approx. 12ft. 3.4.2. If wire has been cut off at end of spool, the wire will then run out and the censor will stop it. 3.4.3. Then pull the wire from the system with a pair of pliers before new wire can go in. 3.4.4. If the wire can not be pulled back, turn air off. 3.4.5. Located inside control panel mark the wire and reset gauges at 3 Bars. 3.4.6. Load new spool and feed though the detector lubrication cup, then into feeder tube. 3.4.7. Spools last about 200,000 cpoies 3.4.8. When done using the stitcher, turn the power off.

0a8de3793d7cd32dd6169a1958f7cbd4.doc, Rev.0, 9-23-04 1 of 2 4/6/2018 3.5. Maintenance: 3.5.1. Check to make sure there is WD-40 in the oilers located on the top of the control panel. Fill about half of an inch in the bottom. There are 4 oilers. 3.5.2. Need oil approx. every 30,000 copies 3.5.3. When done with stitcher, make sure control panel and wires are covered. 3.5.4. For more wire reels, they can be found in the Ink/Roller Room.

0a8de3793d7cd32dd6169a1958f7cbd4.doc, Rev.0, 9-23-04 2 of 2 4/6/2018