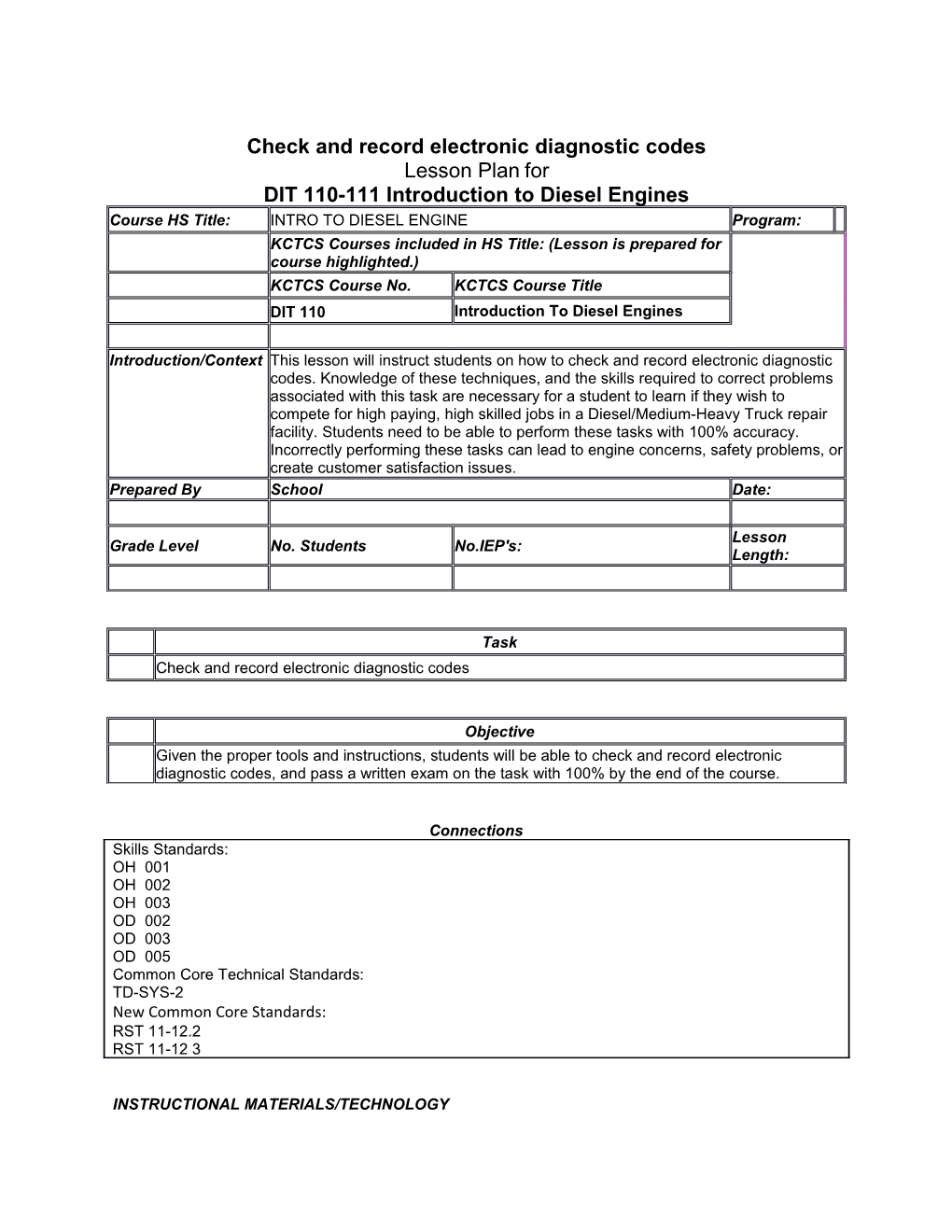

Check and record electronic diagnostic codes Lesson Plan for DIT 110-111 Introduction to Diesel Engines Course HS Title: INTRO TO DIESEL ENGINE Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title DIT 110 Introduction To Diesel Engines

Introduction/Context This lesson will instruct students on how to check and record electronic diagnostic codes. Knowledge of these techniques, and the skills required to correct problems associated with this task are necessary for a student to learn if they wish to compete for high paying, high skilled jobs in a Diesel/Medium-Heavy Truck repair facility. Students need to be able to perform these tasks with 100% accuracy. Incorrectly performing these tasks can lead to engine concerns, safety problems, or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Check and record electronic diagnostic codes

Objective Given the proper tools and instructions, students will be able to check and record electronic diagnostic codes, and pass a written exam on the task with 100% by the end of the course.

Connections Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-SYS-2 New Common Core Standards: RST 11-12.2 RST 11-12 3

INSTRUCTIONAL MATERIALS/TECHNOLOGY Teacher Designed Materials and Other Handouts Instructor may use the content section of this plan to create a handout for the students.

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Various Diesel Engines Test T2 Fourth Delmar 20-21 Kershaw/Bennett Medium/Heavy Duty Truck Diesel Engines 2001 Delmar 394

Equipment Quantity Item Source As Needed Scan Tool Various

Content/Presentation/Demonstration Outline Instruct students that current diesel engines use computerized engine control systems. Diagnostic codes are known as Diagnostic Trouble Codes, or DTCs. Explain that the DTC extraction method varies with the engine and truck manufacturer. Let them know that they will need to understand how to check, record, and clear DTCs. Tell them the typical process is to use a scan tool, diagnostic reader, or laptop computer to check for, record, and clear DTCs. Teach students that modern engines are controlled and monitored by electronic modules. These modules are capable of storing fault codes. While each manufacturer may use their own codes, tell students that the manufacturers must also design their software so that SAE (Society of Automotive Engineers)-sanctioned codes are displayed. Inform students that this means that one manufacturer’s diagnostic hardware and software is capable of at least reading any others. Explain that the term message identifier, or MID, is used to identify the chassis electronic system; the engine would be one of these systems, the transmission and antilock brakes others. Instruct students that within the electronic system or MID would be branches, components, and sub- circuits that are each divided into codes known as parameter identifiers (PIDs) and subsystem identifiers (SIDs). Tell students that within each PID or SID, faults are identified by common codes known as fault mode indicators, or FMIs. Explain that this makes it easy for a technician trained on one truck equipment brand troubleshooting one of its competitors. An example would be that FMI number 4 tells the technician that the component or circuit is voltage below normal or shorted low. This would be so on any PID or SID on any truck manufactured in North America. Instruct students that electronic service tools (ESTs) or Scan Tools connect to the truck electronic systems by means of a data connection, either a 6-pin Deutsch connector or a more recent nine-pin Deutsch connector. Inform them that these connectors are usually referred to as ATA (American Trucking Association) connectors and are the same on all trucks manufactured in North America. Let students know that most electronic systems will also blink codes out using dash-mounted diagnostic lights. Also, more frequently today, digital driver dash interface is designed to produce readouts that keep the driver (and the technician) fully informed as to the status of all the monitored equipment on the truck chassis. Teach students that OBD II Diagnostic Trouble Codes (DTC) The on-board diagnostic second generation (OBD II) code process comes from the Clean Air Act Amendment that required OEMs to meet more stringent standards for diesel applications by 1997. Explain that OBD II requires specific emission- related systems to be monitored for malfunction by the engine computer. Tell students that diesel engine systems must monitor exhaust gas recirculation (EGR), misfire, and glow plug malfunction. They must also further contain specific data organization, diagnostic trouble codes, and communication with the scan tool.

Instruct students that OBD II codes contain a letter and four digits. The letter indicates the function of the device at fault. Tell students that the following is a list of these letters: *P - Powertrain *C - Chassis *B - Body *U - Network or data link code. Explain that the first digit indicates if the DTC is generic or OEM (Original Manufacturer) specific (0 = generic and 1 specific). The second number indicates the specific vehicle system that has the fault. Tell students that the following chart details the second number: 1. Fuel and air metering 2.Fuel and air metering 3. Ignition system or misfire 4. Auxiliary emission system 5. Speed and Idle control 6. Computer output circuit 7. Transmission 8.Transmission Instruct students that the last two digits indicate the component or section of the system at fault. Finally, teach students that there are four types of DTCs indicated by the letters A, B, C, and D. Tell students that A and B codes are emission related and will light the malfunction indicator light (MIL), also known as a check engine light. Types C and D are non-emissions related and will not light the MIL. However, all four types will store an inactive or historical DTC.

Applications/Practice 1 Refer to Content.

Evaluation and feedback Prior to Testing or Lab Work Objective 1/ Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist should be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1/ Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required.

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)