OZOPURE

Owner’s Manual

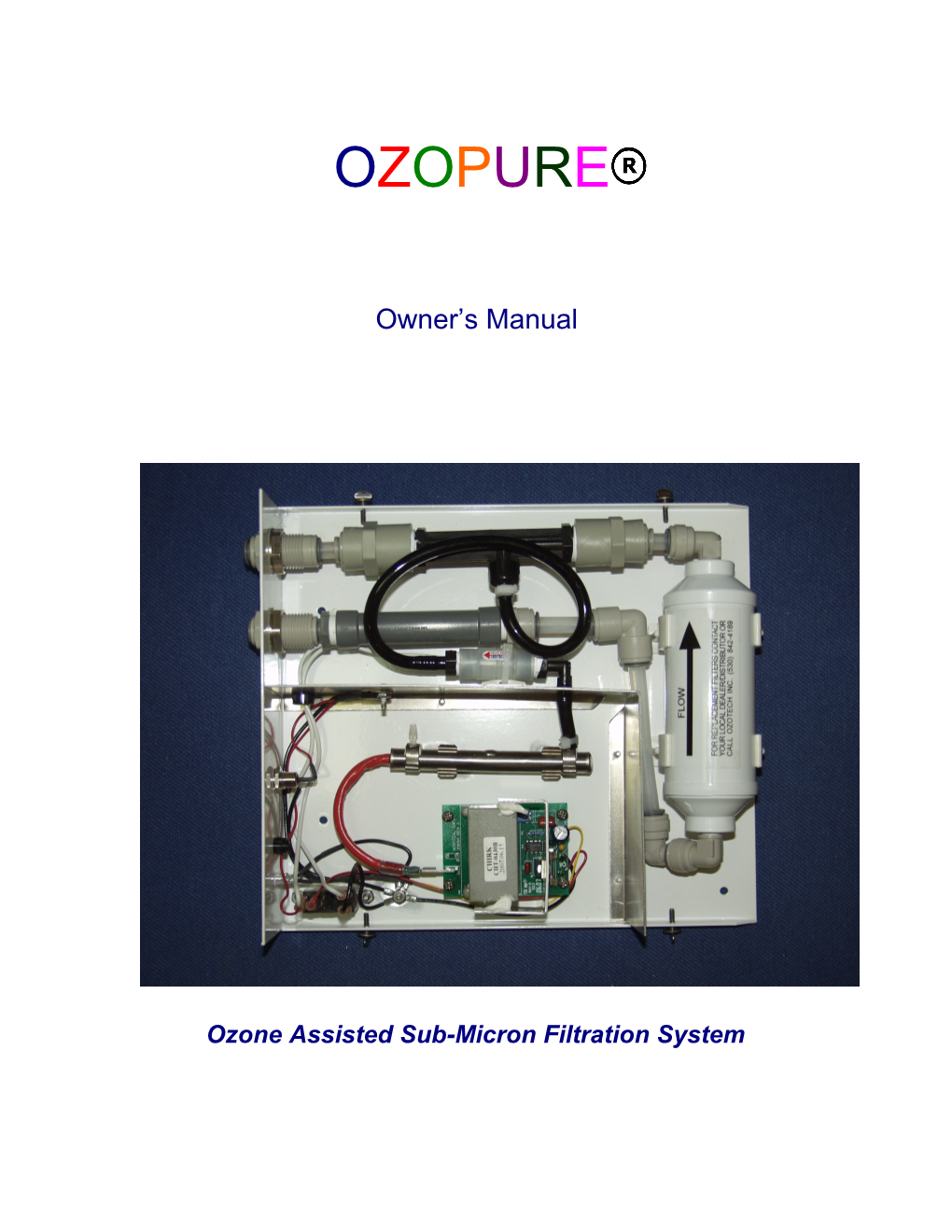

Ozone Assisted Sub-Micron Filtration System Table of Contents

Introduction…………………………………………………………………. 3

What is Ozone? …………………………………………………………… 3 - 4

General System Information ……………………………………………... 4 -5

Product Benefits, Features & Specifications …………………………… 5 – 6

System Installation ………………………………………………………… 7 - 8

Start-Up Instructions ………………………………………………………. 8

Maintenance ………………………………………………………………… 8 - 9

Filters and Check Valve Replacement

Basic Troubleshooting Guide

8.1 Typical Performance

9.0 Spare / Replacement Parts System Installation

10.0 Service Returns

11.0 Component Part Replacement

11.1 Venturi Assembly Replacement

11.1 Ozone Chamber Replacement

12.0 Warranty

2 3 Introduction

Thank you for purchasing your own Ozopure Advanced Food Sanitizer and Bottled Water Dispenser. This Point of Use (POU) device uses sub-micron carbon block filtration in conjunction with a unique ozone generator, which enables you, the user, to have superior quality water without the use of chemicals, Reverse Osmosis (RO) or Ultra Violet (UV).

The Ozopure was designed especially for use in Mexico. Due to the inconsistencies in our water quality, Ozopure selected a major ozone equipment manufacturer in the USA and the best filtering system we could find to bring you safe drinking water from your tap and ozone disinfection benefits for your health and your kitchen environment.

Through its multi-media design, the Ozopure system was designed to remove or reduce microscopic particulate matter, chlorine, bacteria, cysts, fungi, heavy metals (including arsenic and lead) and other inorganic compounds. It also removes musty, stale and metallic tastes and odors, and then adds activated oxygen (ozone) as the final step in the process.

The International Bottled Water Association and the FDA have determined that an ozone residual level of .1 to .4 milligrams per liter is ideal for the bottling process. Your Ozopure system is capable of providing ozone residual within the above range on most water supplies.

As a bonus application, the microbiological killing power of ozone will allow the user to minimize bacterial and viral counts on kitchen sponges, countertops, dishes, fruits, vegetables, chicken, fish, etc. Tests have shown that ozone can kill bacteria 3,125 times faster than chlorine!!

Using your Ozopure system in conjunction with safe sanitary practices in your kitchen will greatly decrease the risk of contact with all known pathogens, mold, fungus and other microorganisms.

What is Ozone?

Ozone is an unstable gas formed by an electrical reaction with oxygen molecules. A molecule of “normal” oxygen is comprised of two atoms of oxygen (O2) bonded together. Ozone or O3 is created by adding a third oxygen atom to the oxygen molecule. The Ozopure system takes oxygen found in the air we breathe and passes it through an ozone reaction chamber, where an electrical charge is created, converting the oxygen into ozone. As the newly formed ozone

4 molecule is used up, (either by “zapping” impurities or through normal degradation) it is changed back to normal oxygen, leaving no harmful by- products in your water.

Ozone has been used for treatment of drinking water in the bottled water industry for many years to effectively control bacteria growth in dispensed water, as well as help sanitize the container into which it is dispensed. Ozone has been shown to destroy E.coli bacteria with a kill ratio exceeding 99.9%.

It is normal to smell the off-gas, which is the ozone that was not dissolved during the process.

General System Information

The Ozopure is capable of treating up to 1,080 GPD. This will vary somewhat based on local water supply, your water pump and water turbidity levels. There is no wasted reject water with the Ozopure as there is with other types of treatment systems.

On water supplies with low water pressure (below 25 PSI), a booster pump may be required to elevate the pressure to sufficient levels for proper system operation.

Proper pre-treatment is recommended for installations where the water is from a source that is known to be microbiologically unsafe. It is always a good idea to test your water if you have any doubt as to its purity. The Ozopure system combines a NSF Matrikx Pb1 .5 micron pre-filter rated for lead, cysts and Class 1 turbidity removal, a secondary multi-barrier 6” inline filter and water ozonation to produce high quality drinking water.

For the most effective results, dispense the water into a water pitcher or gallon container and allow the ozone to contact the water for a minimum of 4 minutes prior to consumption.

Turbidity (solid particles) contained in raw water will vary from location to location, making it impossible to accurately predict when the filters must be changed. The Matrikx filter has a patented Waterminder valve that will automatically shut-off the water flow when it is time to change both of your filters.

5 Product Benefits, Features & Specifications

BENEFITS:

Modular design requires only a small amount of space under your sink Highly concentrated dissolved ozone levels for effective microbiological reduction on hands, sponges, wash cloths, countertops, dishes, fruits and vegetables Excellent for homes, restaurants or commercial kitchens No wasted water unlike reverse osmosis systems that waste 3-4 gallons for every gallon they make 99.9999% lead reduction (filter and ozone unit combined) Chemical free non-acidic healthy drinking water Does not remove beneficial minerals 12 VDC power source allows for optional use in RV’s and boats Removes the taste and odor of chlorine Removes musty, stale, metallic tastes and odors Ozone kills bacteria 3,125 times faster than chlorine Removes harmful lead that leaches from solder joints in your copper plumbing Washes off garlic and onion smell from your fingers Dispenses almost one gallon per minute of water containing an ozone residual within the FDA required range for bottled water No UV lamp to change every year

FEATURES:

High quality stainless steel “Corona Discharge” ozone generator Two stage pre-filtration system – includes a 5-micron washable, pleated sedimentation filter and a powerful, 1 micron absolute multi-functional lead/cyst reduction filter Solid state electronics Convenient and easy filter replacement with “filter change reminder”

6 REMOVAL CAPABILITIES:

Contaminant Raw Water Post Ozopure Chlorine* 75 ppm 0.01 ppm Arsenic* 5 ppm 0.01 ppm Hydrogen Sulfide* 10 ppm 0.01 ppm Lead* 2.05 ppm 0.1 ppm Mercury* 1.00 ppm 0.001 ppm Silver* 1.00 ppm 0.01 ppm Trichloromethane* 1.00 ppm 0.002 ppm Cysts/Turbidity N/A 99.96% Reduction

* Does not include Filter Unit

OZOPURE SPECIFICATIONS:

Ozone Unit

Weight……………………………………………. 5 lbs. Size……………………………………………….. 10”W x 11”H x 2.5”D Flow rate………………………………………… .6 to .8 gallons per min. at 50 PSI Daily capacity…………………………………… Up to 1008 gallons per day Current & voltage……………………………….. 350 milli-amps at 12 VDC Transformer……………………………………… 120 VAC to 12 VDC Max/Min water pressure……..….……………… 85 max / 25 min Ozone dosage…………………………………… Approximately 1.5 grams per cubic meter Ozone residual…………………………………… .1 to.4 mg/l at 50 PSI typical

Filter Unit

Weight………………………….………………….. 7 lbs. Filter size……………………………..…………… 9.75” x 2.5” Flow rate…………………………………………… .75 gallons per minute Maximum water pressure………………………… 250 psig Temperature range……………………………….. 40F – 140F Matrikx filter media………...……………………… Mixture of fine-mesh granular carbons and ultra- micronized ion-exchange filtration Filter life……………………………………………. 6,000 gallons at 1 GPM Lead removal……………………………………… >90% (Does not include ozone) Cyst removal………………………………………. 99.96% (Does not include ozone) NSF protocol………………………………………. Meets or exceeds standards

7 System Installation

Placement of the system is strictly a matter of individual choice. Since the system relies upon an electrical power supply to convert oxygen to ozone, it will also be necessary to locate it within reach of an AC (or 12 VDC regulated) outlet.

The following steps outline the under-the-sink installation. Please refer to the photos for location of parts called out in the text of this document.

New Faucet Installation

1. Choose a location for the faucet base and drill a ¾” diameter hole. (Granite countertops require a diamond drill bit.) It is recommended to drill a small pilot hole first.

Replacement Faucet Installation

1. Verify size of existing hole. If hole measures ¾”, your new faucet may be installed without changes.

Ozopure Installation

1. Remove the front cover of the Ozopure by loosening (it is not necessary to remove), the four wing screws. 2. Choose a location under the sink for placement of the Ozopure unit. The location must provide access for future filter maintenance, provide sufficient space to connect the input and output poly tubing and allow for accessibility to electric power. Four (4) self adhesive rubber feet have been provided with your hook-up kit should you want to put them on the back of the unit to prevent scratching the mounting surface. 3. Using a minimum of two (2) of the four (4) mounting screws provided, secure the Ozopure unit in the location of your choice. Note: Remember to allow for enough space to install the front cover. The two (2) additional screws are usually used on recreational vehicles or boats where vibration may be a problem. 4. Determine the length of poly tubing necessary to connect the water outlet (A-4) from the Ozopure to the inlet (A-5) of the faucet and cut off the

8 remaining tubing. Insert the open end of the tubing coming from the faucet into the water outlet port of the Ozopure. 5. Insert one end of the remaining tubing into the inlet port (A-7) of the Ozopure and connect the other end of the tubing to your cold water line. A standard tee connector with a dedicated shut-off valve is recommended for this installation. The dedicated valve will provide for easier service and maintenance during the life of the product. The size of the output fitting is 3/8” OD as is the tubing. 6. Connect the 12 VDC wall adaptor to the Ozopure power jack and plug the wall adaptor into an electrical 110 VAC source.

Start-Up Instructions

1. Make sure the spout of the faucet is pointed toward the sink basin and turn on the cold water. The LED (B-21) should now be illuminated. 2. If the faucet valve is open, water should now be dispensing into the sink. If the faucet valve is closed, turn it to the open position 3. Allow your water to run for a few minutes so that total flushing of the filter media is completed and the water becomes clear. 4. Close the faucet valve and inspect for any water leaks in the tubing and tubing connections.

Your system installation is now complete!

Maintenance

1. In order to enjoy many years of quality water and trouble free operation, it is strongly recommended that the following maintenance schedule be followed:

Your primary filter has a patented Waterminder that will turn off the water flow when it is time to change your filter When this happens, it is a good idea to replace check valve

Note: Replace filter immediately, regardless of elapsed time since last replacement, if any of the following occurs:

Waterminder shuts off water flow Decrease in water flow Water dispensed from the Ozopure while power is disconnected has an undesirable odor or contains visible particulate matter

9 Filter and check Valve Replacement

Use only factory replacement parts. Refer to Replacement Parts Section for replacement part information.

1. Disconnect unit from power supply. Make certain that the water supply is turned off. 2. Open the faucet to release the water pressure in the line.

Filter Assembly

1. Locate the filter assembly 2. Starting with the water inlet side of the filter, push the quick release ring (collet) towards the connector, hold the collet in place and then pull the poly tubing out of the connector 3. Lift the filter out of the retaining claps (B-3) with the tubing still connected to the filter output fitting (B-4) 4. Locate the opposite end of the filter. Push the collet towards filter output fitting (B-4), hold ring in place and then pull the entire filter assembly in a downward direction thus releasing the tubing from the fitting. 5. Install the new filter assembly noting direction of water flow (left to right) by reinserting the poly tubing on both ends.

Basic Troubleshooting Guide

A qualified individual, trained in electrical safety practices, must perform troubleshooting. Troubleshooting must be performed with the unit disconnected from power.

Symptom: NO OZONE IN THE WATER

Possible causes :

Faucet not in full open position The fuse (B-2) has blown Incoming water pressure is not per specification (water pressure must be a minimum of 25 PSI) Unit is not connected to proper input voltage Filter is restricting water flow due to clogging (filter must be replaced). Ozone delivery tubing, from ozone chamber assembly to venturi injector, is blocking flow of ozone gas. (Check tubing for free flow indirection of venturi injector, possible kinks in the tubing, check valve installed backwards or check valve in need of replacement).

10 Ozone is being injected into the water, but is being depleted during oxidation of materials from a contaminated filter (replace filter) Ozone chamber is not functioning (replace chamber). Defective relay (contact factory) High voltage power supply is not functioning (contact factory)

Spare/Replacement Parts

Part No. Description

43229……………………………..……………... Fuse 800 ma, IEC 127

33219……………………….…………………… Ozone Chamber Assembly

33220……………………………….…………… Filter Assembly

33221………………………….………………… Venturi Injector Assembly

33222………………………….………………… Check Valve Assembly

43146…………………………….……………… Relay, 12 VDC, SPST

40080-01……………………….……………….. Adaptor, 115 VAC to 12 VDC Regulated

Service Returns

If the need arises to return your equipment for service, the following procedure must be followed to ensure accurate and timely processing of repairs:

1. Obtain the serial number of the unit 2. Obtain a copy your original Factura 3. Contact Ozopure by phone or email 4. Describe what is the problem with the unit or write a description detailing the problem. Please be as specific as possible.

11 5. Depending on your location, you may bring the unit into our facility or you may ask for a RMA number and return the unit via a reputable and reliable shipping company.

The contents should be insured. Ozopure accepts no responsibility for damage or loss of equipment in transit.

ALL FREIGHT CHARGES INTO OZOPURE MUST BE PREPAID. If the repair is covered under warranty, the factory will pay return-shipping charges to the address listed on the package within Mexico. If the repair is not covered under warranty the returning party will be responsible for payment of return and handling charges, as well as labor and equipment costs associated with the repair.

Warranty

Ozopure products are warranted to be free from defects in parts and workmanship for twelve (12) months from date of invoice, under conditions of normal use.

Ozopure will refund the purchase price, perform repairs or replace equipment, at the option of Ozopure.

The warranty shall be null, void and non-binding upon Ozopure (or authorized service center) if it determines the cause of malfunction or defect to be the result of: 1] Failure to perform proper maintenance as defined and recommended in this manual, 2] Improper installation, 3] Use of replacement components not supplied by Ozopure, 4] use of improper power supply (voltage or amperage).

12 13