Background Statement for SEMI Draft Document 3846A Revision to SEMI E10-0304E, SPECIFICATION FOR DEFINITION AND MEASUREMENT OF EQUIPMENT RELIABILITY, AVAILABILITY, AND MAINTAINABILITY (RAM), with title change to: SPECIFICATION FOR DEFINITION AND MEASUREMENT OF EQUIPMENT RELIABILITY, AVAILABILITY, AND MAINTAINABILITY (RAM) AND UTILIZATION

NOTICE: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this Document. NOTICE: Recipients of this Document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, ‘patented technology’ is defined as technology for which a patent has been issued or has been applied for. In the latter case, only publicly available information on the contents of the patent application is to be provided.

Background The E10-0304E Standard is past the mandatory five-year review period and in need of a thorough review by the user community. At the same time, the E10 Revision Task Force has undergone their own review of the Document in order to clarify and expand the content based on user input and experiences. It is our belief that we have not changed the overall intent of SEMI E10 and have only made changes and additions to further its aim of defining the method to consistently measure equipment RAM and utilization. The major revisions include: multi-path cluster tool (MPCT) RAM metrics moved to the main body as official metrics clarification and addition of new definitions several new metrics added and some previous metrics updated or retired metrics have been standardized for all equipment types, including MPCTs This is a revised version of Document 3846 from that balloted in Cycle 4, 2011, which was failed by the NA Metrics Technical Committee at the NA SEMICON West 2011 Meetings and returned to the E10 Revision Task Force. This version directly addresses the concerns of a single reject voter. The first concern was distinguishing the productive time for one intended process set (IPS) from another. The logic for determining E10 states for IPSs has been altered for the tracking system to designate the Nonscheduled state for any IPS not in active use. This change required several supporting statements and Notes throughout the Document regarding the Nonscheduled state. The second concern was for the missing handling of division-by-zero errors, for which § 8.1.3 has been added explaining the general handling of such cases. Unrelated to the single reject vote, this version also includes a number of very useful clarifications. For example, the Document consolidates on the term ‘bound’ rather than ‘limit’ when describing the endpoints of confidence intervals, especially in § 9. Also, a top-to-bottom editorial pass has been made to bring the Document into compliance with the latest SEMI Standards Style Manual. Due to the extensive nature of the editing, no mark-up version of the changes is provided so the main body and Related Information 1 of the draft should be reviewed in their entirety. No other significant changes were made to Appendices 1 and 2, but these should also be reviewed in their entirety. The breakout of Total Time into the six SEMI E10 major states of Productive Time, Standby Time, Engineering Time, Scheduled Downtime, Unscheduled Downtime and Nonscheduled Time has not been fundamentally changed. As part of this revision, we have promoted the MPCT RAM metrics section from Related Information 1 in E10- 0304E to the main body of the revised Document, which will formalize this material and make it an official part of the E10 Standard. In addition, state priority reporting was added to the MPCT RAM metrics.

i A large number of defined terms and acronyms were either substantially revised or added; in many cases the added definitions are from other SEMI Standards. These are: component part, consumable material, consumable part, continuous downtime event, downtime event, engineering time, equipment, equipment module, equipment-related failure, equipment system, failure, host, intended function, intended process set (IPS), key group (K), mainframe equipment module, MPCT, noncluster tool, nonconsumable part, nonprocessing equipment module, nonscheduled time, nonsupplier, observation period, processing equipment, process path, productive time, module, recipe, scheduled downtime, single-path cluster tool (SPCT), standby time, state, supplier, training (off-line), and unscheduled downtime. Of these definition changes, the reviewer should especially focus on changes to differentiate consumable materials and consumable parts and the clause added to the failure definition to clarify that subsequent problems occurring during a continuous unscheduled downtime are not counted as additional failures. In addition, the term ‘Intended Process Flow’ was changed to ‘Intended Process Set (IPS)’ and added as a definition. This is more equipment- centric terminology and reduces confusion with other definitions for ‘process flow’. For consistency and ease of application, metrics have been standardized so one comprehensive set of metrics can be used for each IPS and the following equipment types: noncluster tool, SPCT, MPCT, and individual equipment modules that are part of an SPCT or MPCT. The reviewer should especially focus on this major change from the prior limited set of unique metrics for IPSs and MPCTs. To assist the reviewer in understanding these changes, please review the table below:

Status in Metric Motivation Letter Ballot MTBF No change p MFD New Mean failure duration for failures during productive time is a p companion metric to MTBF that supports calculation of ‘inherent p availability’ for a renewal cycle of strictly productive time and related time for failures. E-MTBF No change p

MTBFu New Added as alternatives to MTBF , etc. where engineering time and p MFDu New standby time are considered part of ‘normal’ equipment operation E-MTBF New u and not exempt from reliability measurement (e.g., equipment undergoing acceptance testing and qualification prior to production release or being used primarily for long-term process development). MCBF RETIRED Changed to specific uptime and productive time versions for E-MCBF RETIRED consistency with MTBF metrics.

MCBFu New

E-MCBFu New MCBF New p E-MCBF New p Total Uptime New Added for consistency and completeness with utilization metrics and to bridge to uptime definition in SEMI E79. Operational Uptime No change Equipment-Dependent Uptime UPDATE Metrics are redefined to more clearly and accurately reflect the Supplier-Dependent Uptime UPDATE original intention. Whereas the original denominator subtracts Equipment-Dependent UPDATE quantities from operations time to imply a conditional operations Scheduled Downtime time, the new denominator is defined as the sum of explicit Supplier-Dependent Scheduled UPDATE quantities with the same objective. Downtime Equipment-Dependent New Unscheduled downtime metrics are added for completeness and Unscheduled Downtime consistency to demonstrate that the conditional uptime, scheduled

ii Status in Metric Motivation Letter Ballot Supplier-Dependent New downtime, and unscheduled downtime add up to 100% of the Unscheduled Downtime conditional operations time. MTTPM New A new metric with a similar concept to MTTR, but to measure equipment system maintainability in terms of just PM time. MTTR No change E-MTTR No change MTOL No change TFR New Two fundamentally new metrics that measure against a 24x7 Impairment Time New timeline regardless of equipment system complexity. TFR measures the count of equipment module failure events and Impairment Time measures time when one or more equipment module failures is ongoing. These are simple, pragmatic measurements of maintainability, especially for MPCTs. Operational Utilization No change Total Utilization No change

A new Related Information 1 section “MTBF, Renewal Processes, and the Exponential Distribution” was added to explain the origins of MTBF and why it is significant in regards to predicting survival times. As this is Related Information, it is not an official part of the Standard. A completely revised Related Information 2 section (replacing prior Related Information 1) is also planned to give additional examples for calculating the new MPCT metrics, but will be completed for a subsequent revision. Once this technical content is completed in the main body, appropriate examples will be created. These following sections have not had any significant technical content changes from E10-0304E: Appendix 1: CONFIDENCE BOUND FACTORS Appendix 2: RELIABILITY GROWTH OR DEGRADATION MODELS

Note concerning SEMI E58 (Automated Reliability, Availability, and Maintainability Standard (ARAMS): Concepts, Behavior, and Services): Changes and additions to the substates of SEMI E10 states will result in the revised Document being temporarily out of synch with SEMI E58. The E58 ARAMS TF will need to come out of hiatus at a future date to make these changes or the E10 Revision TF may have to do so. In addition for consistency to E58, the revision now uses E58 state abbreviations (e.g., PRD, SBY) and references to time have been replaced by state or substate where appropriate.

Review and Adjudication Information Task Force Review Committee Adjudication Group: E10 Revision Task Force NA Metrics Technical Committee Date: October 24, 25, and 26, 2011 October 26, 2011 Time & Time zone: 0800-1200 PDT (Each day) 1330-1800 PDT Location: SEMI Headquarters SEMI Headquarters City, State/Country: San Jose, CA San Jose, CA Leader(s): Michael Werre (Intel) David Bouldin (Fab Consulting) David Busing (KLA-Tencor) Mark Frankfurth (Cymer) Standards Staff: Paul Trio (SEMI NA) Paul Trio (SEMI NA) 408.943. 7041 408.943.7041 [email protected] [email protected]

iii iv Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and eiig promne o Ps a ucin o qimn ouelvl promne hn dfnn MPCT defining 2.3 then performance, module-level equipment IPSs for of required MPCTs defined. is and handling special any function presented, metric each For a performance. IPS of function of as a as performance (IPSs) IPSs sets first of by process MPCTs for performance intended measurement RAM (MPCT), of defining treatment tool a defines cluster Document This multi-path MPCTs. and a modules, equipment within modules equipment (SPCTs), tools 2.2 of relationship the equipment on an concentrates for Document this state in usage. equipmentsystem to failures equipment system ‘failed’ reliability a system defines equipment of downtime measurement unscheduled The called system. state One fall. must system equipment 2.1 2 and availability, reliability, measuring for methodology standardized equipmentin manufacturingenvironment. (RAM) performance of a andmaintainability utilization a providing by equipment manufacturing 1.1 1 AND MAINTAINABILITY AVAILABILITY, (RAM) AND UTILIZATION AND MEASUREMENT EQUIPMENTRELIABILITY, DEFINITION OF (RAM), MAINTAINABILITY with FORchangeSPECIFICATION title to: AVAILABILITY,AND OFMEASUREMENT EQUIPMENT RELIABILITY, toSEMIE10-0304E, DEFINITIONRevision AND FOR SPECIFICATION Draft Document SEMI 3846A reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This and isbySEMI E79. productivity efficiency equipment systems.Equipment addressed 3.4 being as distinguished who the equipmentsystem,independentperforms the function. issues of of be may downtime of portions functional by determined are states equipment and the Otherwise, supplier. the on dependent or equipment events the to related downtime certain that except supplier, or user 3.3 type. equipment or user each for factors) human strategies, maintenance environment, recipes, processes, specifications, 3.2 E58and bySEMI SEMIE116. addressed 3.1 3 degradation. growthreliability and 2.4 Scope Purpose Limitations Limitations This Document defines metrics for: Document basic This cluster single-path tools, noncluster include that systems equipment to applicable are herein defined metrics All an for time of periods and conditions all which into states basic exclusive mutually six defines Document The semiconductor of suppliers and users between communication for basis common a establishes Document This The metrics defined herein do not address efficiency, productivity, diminished throughput, or capacity of capacity or throughput, diminished productivity, efficiency, address not do herein defined metrics The to failures system equipment for responsibility of assignment for guidance any provide not does Document This (e.g., conditions operational the on dependent are Document this in contained calculations the of results The is but Document, this of scope the within not is performance and states equipment of tracking Automated and uncertainty MTBF of measurement for concepts addresses Document this in included material Supporting 2.3.2 2.3.1 2.3.4 impairment total and offline, rate, rate. failure time 2.3.3 uptime. dependent Utilization Maintainability Availability Reliability — including mean time between failures and mean cycles betweenfailures. cycles and betweenfailures —includingmean time mean — including total utilization and operational utilization. —including operational utilization total and — including total uptime, operational uptime, equipment-dependent uptime, and supplier- and uptime, equipment-dependent uptime, operational uptime, total including — — including mean time to repair, mean time to (perform) preventive maintenance, mean maintenance, preventive (perform) to time mean repair, to time mean including — Page 5 jn l jn Document Number: 3846A Number: Document Doc. 3846A Doc. 3846A Date: 2011/08/29Date: DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 5.1 of Use and 5 Acquisition the for Documentation NOTICE: Supplier-Provided Equipment for Guide EquipmentManufacturing — E149 SEMI Equipment for Tracking Performance SEMI E116—Specification Equipment Definitionand for Measurement of Productivity SEMI E79—Specification Behavior, Concepts, (ARAMS): Services and Standard Maintainability and Availability, Reliability, Automated — E58 SEMI Semiconductor (COO) Ownership tofor CostManufacturing Equipment of Metrics SEMI E35—Guide Calculate 4.1 4 and practices, health and other ofprior thelimitations use. applicability regulatoryor to determine safety appropriate establish to Documents the of users the of responsibility the is It use. NOTICE: general. reliability in istreatment of theory a and equipment systems,asnot herein, comprehensive defined 3.5 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This Terminology StandardsReferenced Acronyms Acronyms Standards SEMI to importance of concepts reliability basic of treatment concise a provide to intended is Document This 5.1.6 5.1.5 5.1.4 5.1.3 5.1.2 5.1.1 5.1.22 5.1.21 5.1.20 5.1.19 5.1.18 5.1.17 5.1.16 5.1.15 5.1.14 5.1.13 5.1.12 5.1.11 5.1.10 5.1.9 5.1.8 5.1.7 Unless otherwise indicated, all Documents cited shall otherwisetheversions. Documentslatestpublished all cited be Unless indicated, its with associated issues safety address to purport not do Guidelines Safety and Standards SEMI This E-MTTR E-MTBF E-MTBF E-MCBF E-MCBF DT COO ARAMS AMSAA MPCT MFD MFD MCBF MCBF LN LCB K IPS HPP ENG MTBF MTBF —key group — downtime —downtime 2 —intended set process —liquid nitrogen — cost of ownership —cost of — lower confidence —lower bound —engineering u p — homogeneous Poisson process — mean failure duration for —meanduring uptime failures duration failure for time —meanduring productive failures duration failure u p — Army Materials Systems —Army Materials Analysis Activity —multi-path tool cluster u p — mean time between failures during uptime betweenfailures time —mean during productive betweenfailures time time —mean — Automated Reliability, Availability, and Maintainability Standard— Automatedand Reliability, Availability, Maintainability — mean time to repair during equipment-related to failures time repair —mean — mean cycles between failures during uptime betweenfailures cycles —mean time during productive betweenfailures cycles —mean u p u p — mean uptime time betweenequipment-related —meanfailures time uptime betweenequipment-related failures —meantime productive — mean cycles between equipment-related during uptime failures —mean cyclesbetween time equipment-related during productive failures —mean cyclesbetween

Page 6 jn l jn Document Number: 3846A Number: Document Doc. 3846A Doc. 3846A Date: 2011/08/29Date: DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 5.2 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This 2: NOTE be should it but system, distribution facility a by or equipment in treated a the manner.consistent for exchanger heat dedicated a by provided be may water cooling process example, For method. delivery the on based materials consumable distinguish not does definition this company, 1: NOTE Definitions wafers, die, assembly components), monitor/filler units (e.g., test wafers), and facility utilities (e.g., electricity, (e.g., utilities facility and wafers), test (e.g., units monitor/filler components), assembly die, wafers, mold equipment water, include (e.g.,not cooling substrates production cards), do probe carriers, (e.g., water, tools Examples support parts), consumable (e.g., parts ultrapure component frames). lead solvents, wire, acids, bonding sources, (e.g., implant (e.g., liquids solids air), compounds), Ar, (e.g., gases include Examples 5.2.4 Alsosometimes operation. called[SEMI capable of E149] just independent part. normally considered 5.2.3 the same come may not Thesupplier. from may equipmentmodules together. or linked mechanically modules 5.2.2 when required.function 5.2.1 5.1.34 5.1.33 5.1.32 5.1.31 5.1.30 5.1.29 5.1.28 5.1.27 5.1.26 5.1.25 5.1.24 5.1.23 vial, t efr t nedd fnto. Dwtm nlds shdld dwtm n unscheduled and downtime scheduled includes Downtime function. intended its downtime. perform to available, 5.2.8 process that systems equipment In processed. units processed. number batches the innumber ofunits of the cyclesequals batches, of number the equals cycles of number the individually, units process that systems equipment In subsystem. or system equipment an for steps testing or manufacturing, 5.2.7 vice a event. not downtime continuous versais or a is state downtime a to state state downtime unscheduled an to state downtime scheduled a from transition productive a but event, downtime continuous the from transition a example, For state. nondowntime a from state 5.2.6 intended function. perform its equipment to allow the to replacement requires periodic It year. one less than of expectancy life predictable a with equipment 5.2.5 exhaust).

Life Life expectancy comesconcept from E35. SEMI Since the source of these consumable materials may vary from equipment to equipment, site to site, and company to company and site, to site equipment, to equipment from vary may materials consumable these of source the Since yl — cycle — event downtime continuous part consumable material consumable — part component — tool cluster — availability onie(T — (DT) downtime UDT UCB TFR SPCT SDT SBY PRD PM OOS MTTR MTTPM MTOL — preventive maintenance —preventive —standby — total failure rate failure —total downtime —scheduled —productive — unscheduled downtime —unscheduled bound confidence —upper — out of— out specification — mean time to repair —mean to time — single-path cluster tool— single-path cluster — mean time off-line time —mean — mean time to [perform] preventive maintenance to time maintenance preventive [perform] —mean n opee oeainl sqec icuig ui od ad ula) o processing, of unload) and load unit (including sequence operational complete one the probability that the equipment system will be in a condition to perform its intended its perform to condition a in be will system equipment the that probability the an equipment system made up of multiple integrated equipment processing equipment processing equipment integrated multiple of up made system equipment an — component part of the equipment that is consumed by the process operation of the of operation process the by consumed is that equipment the of part component — the operations time when the equipment system is not in a condition, or is not is or condition, a in not is system equipment the when time operations the a constituent part, which can be separated from or attached to an assembly, not assembly, an to attached or from separated be can which part, constituent a

— h mtra ue b r nspot o teeupet ytm t ay time. any at system equipment the of support in or by used material the a downtime event when an equipment system transitions into a downtime a into transitions system equipment an when event downtime a Page 7 jn l jn Document Number: 3846A Number: Document Doc. 3846A Doc. 3846A Date: 2011/08/29Date: DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This operator to the equipment. [SEMI to E116] the equipment. operator a during occurring 5.2.16 problems subsequent failure; a is state downtime failures. additional counted arenot downtime as unscheduled continuous unscheduled the to initialevent the Only state. transition downtime unscheduled an into event downtime a is failure a states, E10 SEMI of terms In failure. system equipment an cause could errors human or malfunctions, supply utility or facility problems, recipe process or software failures, subsystem or component more or One function. intended its perform cannot and (MPCTs), tools 5.2.15 cluster multi-path in (IPSs) modules, sets equipment process tools, MPCTs. intended noncluster (SPCTs), includes tools This cluster desired. is single-path utilization and (RAM) maintainability and availability, reliability, of tracking independent the which for storage or transportation, metrology, inspection, 5.2.14 input). 5.2.13 equipmentmodule. processing aor equipmentmodule nonprocessing a either 5.2.12 (e.g., equipment peripheral or support auxiliary E149]. equipment). heat [SEMI pumps, effluent/exhaust treatment exchangers, vacuum direct all including storing), transporting, processing, (e.g., experiments, engineering conduct 5.2.11 to operated is but exist), problems the usagenotof the equipmentis normal production. where of indicative especially process or equipment (no function 5.2.10 scheduled a within transition substate a anstate. adowntime unscheduled substatewithin statedowntime transition nor neither is state downtime A versa. vice or state downtime scheduled an than other a from state state downtime unscheduled a an into transition from a be can state event downtime downtime A state. downtime unscheduled unscheduled an into (2) or state downtime scheduled a than other 5.2.9 function. Maintenance refers to function, not an organization; it includes adjustments, change of consumable of change material, adjustments, includes it organization; an not function, to refers Maintenance function. 5.2.22 of intendeda time. itfunction period specified perform its within can where 5.2.21 gas download, distribution. and and power recipe like services information resources, computing shared include Examples module. equipment individual an for than rather large at system equipment the of functionality represent to (MPCT) tool cluster multi-path a modeling in 5.2.20 key a hencethegroup MPCT.mainframeequipmentmodule. may A (K) include and IPSs all of failure a cause to sufficient is (K) group key the of failure the where (MPCT) tool cluster multi-path 5.2.19 more or one at modules equipment alternative include manypaths. containprocess the mayone process.Antherefore IPS or steps of may IPS An (IPSs). sets process intended such more or one have may (MPCT) tool cluster A multi-path equipment operation. foruser the byspecified isand process 5.2.18 is equipment time of period environmentalThe intended more function. equipmentmay have than Complex one temperature, (e.g., pressure). condition operating base reaching bonding. and initialization wire equipment includes and function intended deposition its performing vapor physical as as well such as equipment, functions metrology process for functions measurement and equipment transport for functions transport 5.2.17 downtime event — — event downtime ananblt — maintainability mainframe group(K) key (IPS) set process intended — function intended host — failure system equipment equipment-related failure module equipment equipment time engineering maintenance — — maintenance

software upgrades, — the factory computer system or an intermediate system that represents the factory and the and factory the represents that system intermediate an or system computer factory the — any unplanned or unscheduled event that changes an equipment system to a condition where it where condition a to system equipment an changes that event unscheduled or unplanned any

— the combination of hardware and software required to perform an operation or activity or operation an perform to required software and hardware of combination the — equipment module equipment — a subset of equipment modules that are common to all intended process sets (IPSs) in a in sets (IPSs) intended process all to common are that equipment modules of subset — a the act of sustaining equipment in or restoring it to a condition to perform its intended its perform to condition a to it restoring or in equipment sustaining of act the — a system of equipment capable of independently hosting material for processing, for material hosting independently of capable equipment of system a — an initial state transition event either (1) into a scheduled downtime state from a state a from state downtime scheduled a into (1) either event transition state initial an — the time when the equipment system is in a condition to perform its intended its perform to condition a in is system equipment the when time the — — — the probability that the equipment will be retained in, or restored to, a condition a to, restored or in, retained be will equipment the that probability the a manufacturing function that the equipment was built to perform. This includes This perform. to built was equipment the that function manufacturing a repair, preventive maintenance (PM), etc., no matter who performs the task. nomatter maintenance(PM), preventive who etc., performsthe repair, an indivisible entity within an equipment system. An equipment module may be may module equipment An system. equipment an within entity indivisible an — any failure solely caused by the equipment (e.g., not causedbytheout-of-specification solely equipment(e.g., failure an —any — a predetermined set of equipment modules that is used to achieve a achieve to used is that modules equipment of set predetermined a — — an individual abstract equipment module that may be used optionally used be may that module equipment abstract individual an — Page 8 jn l jn Document Number: 3846A Number: Document Doc. 3846A Doc. 3846A Date: 2011/08/29Date: DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This 5.2.35 and stations. processing processing of include chambers equipmentmodules 5.2.34 maintenancethe preventive SDT 5.2.33 panel. 5.2.32 5.2.31 1quarter,during pastwhich 90days) tracked. performancemonths, equipmentsystem is 5.2.30 third-party- independent and personnel, suppliers. maintenance third-party independent personnel, maintenance house in- as such system equipment an to resources other or information, materials, parts, provide that agents as as well host) or (operator user the include Examples delay. maintenance of source the classifying for used supplier 5.2.29 5.2.28 robotic include prealigners. load/unloadlocks, and handlers, modules equipment nonprocessing of Examples equipment. the through units of conditioning 5.2.27 to intended function. performits allow equipment to part component another with failure) a to due (e.g., replacement require may It equipment. the of operation 5.2.26 5.2.25 unit. fromto sequences vary in that unit modules 5.2.24 5.2.23 function due planned to events. downtime function 5.2.42 atime. period for specified conditions, of 5.2.41 betweenruns to or cycles. processing change subject units. the by seen environment processing the determines that agent processing a of control 5.2.40 downtime. unscheduled in and downtime included scheduled reboot system control recipes), routines, initialization periods, stabilization up, warm- down, pump includes It function. intended its perform can it where condition a to equipment the return 5.2.39 recipes), warm-up, cool-down, purging, includes It work. 5.2.38 5.2.37 5.2.36 modules. no alternative reliability recipe — ramp-up time productive product path process module equipment processing event (PM) maintenance preventive — operator timeoperations — — period observation — nonsupplier time — nonscheduled module equipment nonprocessing — part nonconsumable noncluster tool — (MPCT) tool cluster multi-path timemanufacturing — scheduled downtime scheduled etc. Ramp-down is only included in scheduled downtime and unscheduled in is etc.and downtime downtime. included scheduled Ramp-down only ramp-down — — ramp-down — — units produced during productive time producedduring productive (seeunit). —units the preplanned and reusable portion of the set of instructions, settings, and parameters under parameters and settings, instructions, of set the of portion reusable and preplanned the

— the portion of a maintenance procedure required, after the hands-on work is completed, to completed, is work hands-on the after required, procedure maintenance a of portion the control equipment’s the through equipment the with locally communicates who person any — a specific set of modules a unit passes through for which each module is unique and has and unique is module each which for through passes unit a modules of set specific a — h rbblt ta h qimn il prom is itne ucin ihn stated within function, intended its perform will equipment the that probability the — an acting agent of relevance to an equipment system other than the primary equipment primary the than other system equipment an to relevance of agent acting an — the time in which the equipment system function. which its performing in theis — theequipment time intended the portion of a maintenance procedure required to prepare the equipment for hands-on for equipment the prepare to required procedure maintenance a of portion the

an equipment system made upof one equipmentmodule.an only processing made equipmentsystem total time minus time time. nonscheduled total — the time when the equipment system is not available to perform its intended its perform to available not is system equipment the when time the — the time when theisproduction. equipmentsystem be in to when utilized scheduled the time not a specified continuous interval of calendar time (e.g., 72 hours, 6 weeks, 3 weeks, 6 hours, 72 (e.g., time calendar of interval continuous specified a the sum of productive time and time standby oftime. the sum productive component part of the equipment that is not normally consumed by the process the by consumed normally not is that equipment the of part component , etc. It does not include equipment or process test time. Ramp-up is only is Ramp-up time. test process or equipment include not does It etc. ,

substate occurs before the equipment exits the scheduled downtime state. thedowntime equipmentexitsthe scheduled substate before occurs — an indivisible production entity within an equipment system.Examples equipment an within entity indivisible production an

— a cluster tool in which the units visit a subset of the equipment the of subset a visit units the which in tool cluster a — a downtime event into a scheduled downtime (SDT) state where state (SDT) downtime scheduled a into event downtime a —

an indivisible equipment entity that supports the movement or movement the supports that entity equipment indivisible an Page software load, restoring dynamic values (e.g., parameters, (e.g., values dynamic restoring load, software software backup, storing dynamic values (e.g., parameters, (e.g., values dynamic storing backup, software 9 jn l jn Document Number: 3846A Number: Document Doc. 3846A Doc. 3846A Date: 2011/08/29Date:

Recipes DRAFT may be may SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This 5.3 Symbols done during the course of normal work functions. On-the-job training typically does not interrupt operation or operation interrupt not does typically training On-the-job functions. work normal of course the during done 5.2.53 only Off-linein trainingis time. oftime. outside included nonscheduled operations 5.2.52 tracked and for card, accounted be must probe states equipment basic carrier, six all accurately. time, total wafer of representation valid cassette, a have (e.g., operation 5.2.51 normal of course controller/monitor). the during it 5.2.50 (OEM). manufacturer orequipment vendor original 5.2.49 withinstate includes various (active).the aresponseto Behavior stimuli.[SEMI given E58] current 5.2.48 stabilization cool-down, warm-up, down, reboot,system pump includes It routines, initialization state. periods, nonscheduled a leaving when function, 5.2.47 operated.not is system equipment the but available, are facilities and materials consumable and function intended its perform 5.2.46 and uponbetweenuser supplier. as agreed equipmentoperation for in included 5.2.45 only is Shutdown condition. safe 5.2.44 a reach to necessary procedures any time. nonscheduled includes It state. 5.2.43 5.3.3 5.3.2 5.3.1 intendedspecifications. function its within performing 5.2.59 period. time specified 5.2.58 or downtime the equipment’sFrom viewpoint, of portion any include 5.2.57 not does and time, engineering time. nonscheduled and standby, productive, includes 5.2.56 intended function. may performits awhere restored to it equipment is condition 5.2.55 5.2.54 specialwithout categorization. nonscheduled) and standby (except state equipment any in included be therefore can and activities maintenance Ai M Li verification run — — run verification utilization — user — uptime downtime unscheduled — unit — (on-the-job) training — (off-line) training — time total — tool support — supplier — state — start-up standby operation) (equipment — specification single-path cluster tool — shutdown

— — — load lock i alternative equipmentmodule alternative equipment module etc. Start-up is etc.time. includednonscheduled Start-up only in any wafer, substrate, die, packaged die, or piece part thereof. part piece packagedthereof. substrate,die, or any wafer, die, a static set of conditions and associated behavior. While all of its conditions are met, the state is state the met, are conditions its of all While behavior. associated and conditions of set static a

any entity interacting with the equipment, either locally as an operator or remotely via the host. the via remotely or operator an as locally either equipment, the with interacting entity any time — — time

the time when the equipment system is in a condition to perform its intended function. It function. intended its perform to condition a in is system equipment the when time the — provider of equipment and related services to the user (e.g., unit manufacturer). Also called Also manufacturer). unit (e.g., user the to services related and equipment of provider the time required for equipment to achieve a condition where it can perform its intended its perform can it where condition a achieve to equipment for required time the all time (at the rate of 24 hours/day, 7 days/week) during the observation period. In order to In order period. the observation during 7 days/week) hours/day, 24 of rate the (at time all the percentage of time the equipment system is performing its intended function during a during function intended its performing is system equipment the time of percentage the the time required to put the equipment in a safe condition when entering a nonscheduled a entering when condition safe a in equipment the put to required time the a tool that, although not part of the equipment, is required by and becomes integral with integral becomes and by required is equipment, the of part not although that, tool a the time, other than nonscheduled time, when the equipment system is in a condition to condition a in is system equipment the when time, nonscheduled than other time, the a single cycle of the equipment (using (using equipment the of cycle single a the instruction of personnel in the operation and/or maintenance of equipment done equipment of maintenance and/or operation the in personnel of instruction the

— the time from when the equipment system has experienced a failure until failure a experienced has system equipment the when from time the — (SPCT) the instruction of personnel in the operation and/or maintenance of equipment of maintenance and/or operation the in personnel of instruction the software load, restoring dynamic values (e.g., parameters, recipes), control recipes), parameters, (e.g., values dynamic restoring load, software both the operator and the host the operatorboth and

— a cluster toola one follow only path. cluster whichprocess in units all the documented set of intended functions within set ofthe stated documented intended conditions functions Page 10

represent the user.represent the jn l jn units or no units no or units Document Number: 3846A Number: Document ) used to establish that it is it that establish to used ) Doc. 3846A Doc. 3846A Date: 2011/08/29Date: computerized DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This 5.3.8 5.3.7 5.3.6 5.3.5 5.3.4 T Si r — PMj P

— — —

number of failuresnumber transport equipmentmodule — mainframe equipment module mainframe equipment serial equipmentmoduleserial processing equipment module j equipmentmodule processing

Page 11 jn l jn Document Number: 3846A Number: Document Doc. 3846A Doc. 3846A Date: 2011/08/29Date: DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 6.1 6 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This Equipment States Tracking Equipment and Requirements Equipment StatesEquipment support certain metrics and other examples and guidance. other for support metrics certain operation manufacturing to required a are that some that give does but substates, possible resolution all list to tracking attempt no makes Document equipment This desires. the achieve to required are as substates many 6.1.3 production a operator, an a engineer). maintenancetechnician, process (e.g., a technician, it performs who matter no way same the classified is example, for procedure, 6.1.2 failure.that from arising or to contributing problems constituent underlying of number the of regardless time in point any at failure one most at to subject be must system equipment Any time. in point any at state E10 SEMI one only and one in be must system equipment Any fall. must time of periods and conditions equipment all which into states 6.1.1 h qimn tts ae dtrie y fnto, nt b raiain n ie maintenance given 1 Any organization. by not function, by determined are states equipment The equipment basic six defines Document this metrics), RAM (e.g., performance equipment measure To

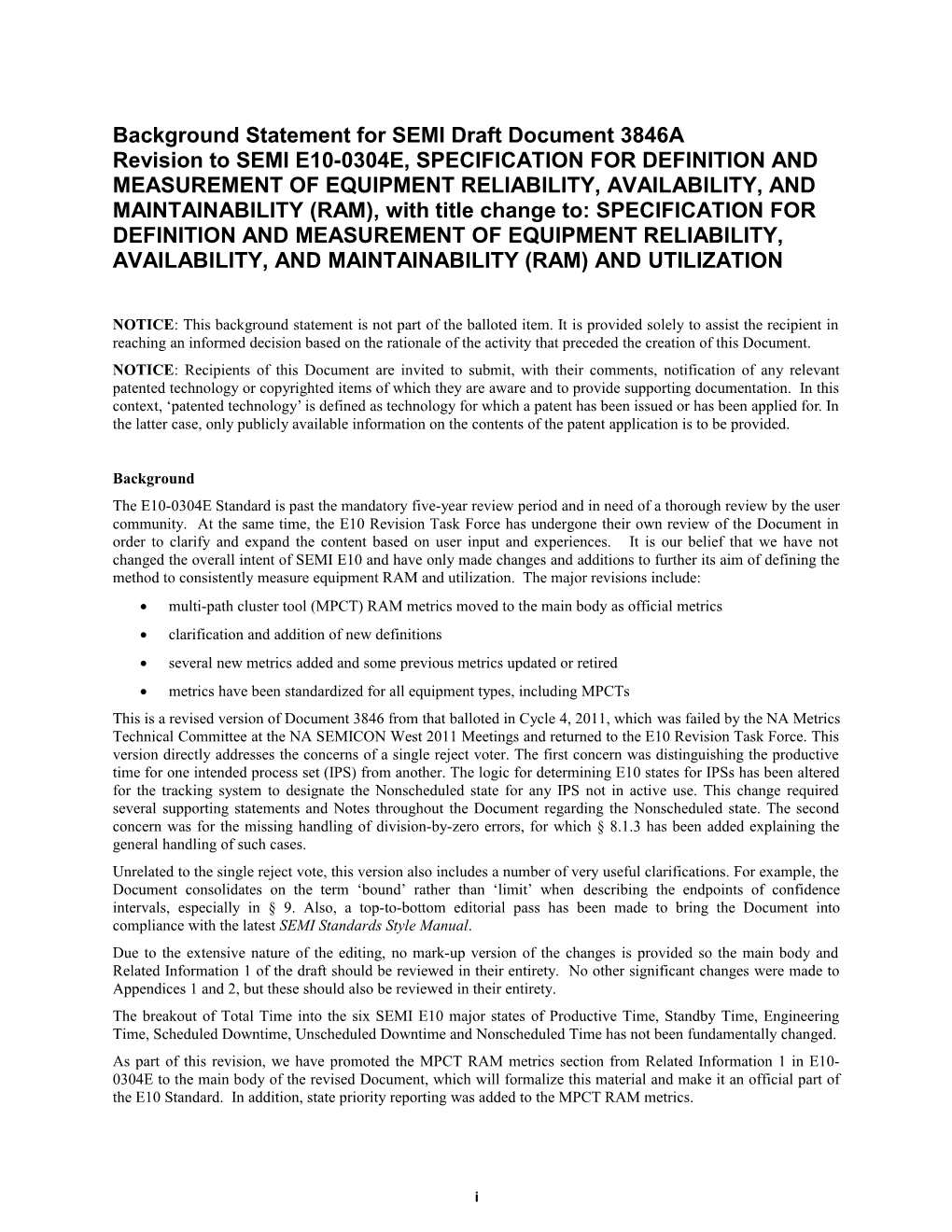

is a stack chart of the six basic equipment states. These basic equipment states can be divided into as into divided be can states equipment basic These states. equipment basic six the of chart stack a is

Equipment Uptime Manufacturing

Equipment Downtime Time

Equipment State StackChartEquipment State

NONSCHEDULED UNSCHEDULED ENGINEERING PRODUCTIVE SCHEDULED DOWNTIME DOWNTIME Figure 1 Figure Page STANDBY TIME TIME TIME TIME 12

jn l jn

Operations Time Total Time Total

Document Number: 3846A Number: Document

Doc. 3846A Doc. 3846A

Date: 2011/08/29Date: DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This either is “Support.”“Process” or type task E116 SEMI the and state ‘manufacturing’ a in be to known is system equipment the where events state BUSY module 3: NOTE of part as specified not are that times fromtime. be excluded recipesshall specifically productive production similar However, time. productive in included specifically be shall recipes 6.1.5.1

Shutdown/Start rebuild, Inst Off periods time Unworked used in the RAM equations given later in this Document. The blocks of time associated with the basic states basic the with substatesthesections. aredescribedfollowing in and associated time of blocks The Document. this in later given equations RAM the in used 6.1.4 Engineering runs done in conjunction withunits in split runs (e.g., production lotsEngineering done conjunction applications) ,new supportunits operations test or processing support otherequipment) (e.g., to Manufacturing processes Rework a party for third Work and to unitsrecipe download) production and (includingloading of internal the unloading equipment Regular theactivities: following function. state The includes productive intended 6.1.5 - allation, modification, modification, allation, Nonscheduled training line Software engineering engineering Equipment engineering Process Times for heating, cooling, purging, pump down, cleaning, etc., that are specified as part of production of part as specified are that etc., cleaning, down, pump purging, cooling, heating, for Times

or upgrade or Time Productive state events may be derived from SEMI E58 (ARAMS) state change data or SEMI E116 (EPT) equipment (EPT) E116 SEMI or data change state (ARAMS) E58 SEMI from derived be may events state Productive Productive (PRD) State — — State (PRD) Productive in given are substates and states basic the with associated time of blocks Key Engineering

Time - up

specified times specified recipe Production units production with runs Engineering operations support Manufacturing Rework party third for Work production Regular Uptime Productive

Time

Total Time Total

The time (productive time) in which the equipment system is performing its performing is system equipment the which in time) (productive time The Manufacturing

Time Equipment State Hierarchy

times Waiting/inactive system automation ext. from input No available results test production No down module tool cluster Associated too support No units No operator No

equipment Standby

Figure 2 Figure Time Page

13 l

Operations

Time

Unspecified related Facilities material C Out delay Maintenance Repair jn l jn hange of consumable of consumable hange

- Unscheduled of Downtime - spec input spec

Document Number: 3846A Number: Document Downtime 2 . These blocks of time are time of blocks These .

Unspecified related Facilities material consumable of Change testProduction Maintenance delay Setup maintenance Preventive

Doc. 3846A Doc. 3846A Date: 2011/08/29Date:

Downtime Scheduled

DRAFT

SEMI

LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This to supplier the expect they or that meet improve performance level. if program recommended the from deviation any identify to obligated are Users level. performance 5: NOTE 6.1.8.1 in metrics.used these §§ See not are substates SDT Other metrics. equipment-dependent and supplier-dependent accurate support to required are consumables 4: NOTE SDT maintenance delay, nonsupplier maintenance SDT delay, supplier maintenance SDT setupSDT maintenance preventive SDT mutually following the substates: exclusive into divided is downtime Scheduled conditions. equipment upon or based be usage, may equipment events time, These events. downtime planned to due function intended its perform to available 6.1.8 qualification) software Software engineering(e.g., equipmentevaluation) engineering(e.g., Equipment characterization) process engineering(e.g., Process state engineering The state. productive the from arise theactivities: following includes to considered be not should conditions extreme such under Failures production. normal of indicative not is equipment the of usage the where especially experiments, engineering conduct to operated is but exist), problems process or equipment (no function intended its perform 6.1.7 loadunload times,and for orwaiting Waiting times inactive including automation input host) from(e.g., systems No external production for results test available review No tool cluster down equipmentmodule Associated probe carrier, card) supporttool wafer cassette, (e.g., No metrologyequipment) unitsno ofsupport (e.g., equipment,such available available dueas No lack to lunches, (e.g., meetings) operator available breaks, No includes theactivities: following The not theis standby equipmentsystem state but operated. available, are facilities and materials consumable and function intended its perform to condition a in is system 6.1.6 is performing its intended function its within performing is intended specifications. run Verification power). specified reaches source ignites, plasma correct, is flow gas problem, without transfer units pressure, base reaches chamber (e.g., test Equipment basedor intervalsequipmentusage, conditions. may be upontime, Scheduled during operation. failure equipment of likelihood the reduce to designed replacement), part consumable (e.g., intervals scheduled action Preventive unspecifiedSDT facilitiesSDT related consumable changematerialSDT of productionSDT test SDT Preventive Maintenance Maintenance Preventive SDT

The substates SDT preventative maintenance; SDT setup; SDT maintenance delay, supplier; and SDT change of change SDT and supplier; delay, maintenance SDT setup; SDT maintenance; preventative SDT substates The Scheduled Downtime (SDT) State — — State (SDT) Downtime Scheduled — State (ENG) Engineering Standby Equipment suppliers are responsible for recommending a PM program to achieve a predetermined equipment predetermined a achieve to program PM a recommending for responsible are suppliers Equipment

SY tt — State (SBY)

— —

the operation of equipment after preventive action to demonstrate equipment functionality equipment demonstrate to action preventive after equipment of operation the — — the processing and evaluation of units after preventive action to establish that the equipment the that establish to action preventive after units of evaluation and processing the a predefined maintenance procedure (including equipment ramp-down and ramp-up), at ramp-up), and ramp-down equipment (including procedure maintenance predefined a 8.3.3 and 8.3.4 The time (standby time), other than nonscheduled time, when the equipment the when time, nonscheduled than other time), (standby time The — The time for the following procedures as specified bythe specified supplier: theprocedures following — Thefor as time . The time (engineering time) when the equipment system is in a condition to condition a in is system equipment the when time) (engineering time The The time (scheduled downtime) when the equipment system is not is system equipment the when downtime) (scheduled time The Page 14 jn l jn Document Number: 3846A Number: Document Doc. 3846A Doc. 3846A Date: 2011/08/29Date: DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and setup, or repair procedure. It also does not include the time results. Ittest also does repairincludewhile for procedure. waiting not the setup, or PM, a following done testing any include not does it and production, of running the to, transparent or with, in parallel the done be that can that confirm testing include to not does operation, It specifications. equipment within function for intended its specifications performing is user equipment the in defined as units, of evaluation for uptime 6.1.8.5 delay maintenance SDT An down and to postpone maintenance. due an the to equipment administrativedecision leave be also may substate results. delay maintenance nonsupplier-controlled SDT An test state. downtime scheduled parts, a as during point any at nonsupplier-controlled such occur may substate information personnel, nonsupplier-controlled nonsupplier or for materials, waiting consumable is it because function 6.1.8.4 consumable supplier-controlled state. downtime point scheduled any during a parts, at occur supplier-controlled may substate delay maintenance personnel, SDT An results. test as supplier such information supplier-controlled or for materials, waiting is it because function download Recipe time. 6.1.8.3 setup SDT under conversions as tracked be should thatactivities are regular, intervention automated of should trackedfunctions processing be under time. productive manual significant require that or 7: NOTE from recommendeddeviation the procedures. 6: NOTE 6.1.8.2 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This downtime. unscheduled than other state a to transition next the to downtime unscheduled than other state a from downtime unscheduled to 6.1.9.1 substates. 6.1.8.8 facilities- SDT the The facilities include: substate. related in included is function intended its perform can it where otherwise condition a if to equipment the example, return to For substate. facilities-related required time all repair, SDT or upgrade, change, facilities the scheduled a of result a in as needed are actions included PM unnecessary be shall below listed facilities the created by downtime Any facilities. out-of-specification scheduled of result a as solely function intended its perform 6.1.8.7 obtaining in consumableIt doesmaterial. include not delays the material. consumable change 6.1.8.6 performing its intendedspecifications. function its within performing run source Verification ignites, plasma correct, is flow gas problem, without power). specified reaches transfer units pressure, base reaches chamber production test Equipment normal of part as (e.g., parameter etc., include Examples configuration, adjustment. gasadjustment handler flow) current, temperature, and beam upgrades). package and type, rebuilds, modifications, unit permanent (excluding process, processing in change a accommodate Conversion failure until equipment is restored to a condition where it may perform its it equipmentisconditionintended mayfunction. perform until a where failure restored to 6.1.9 host other with Communications equipmentor links computers liquid nitrogen exhaust, [LN connections water,facility cooling gases, power, (e.g., Facility count) (e.g.,humidity, vibration,particle temperature, Environmental A continuous instance of unscheduled downtime is called a failure. A failure spans from the first transition first the from spans failure A failure. a called is downtime unscheduled of instance continuous A — Unspecified SDT — Facilities-Related SDT — Material Consumable of Change SDT — Test Production SDT — Nonsupplier Delay, Maintenance SDT — Supplier Delay, Maintenance SDT SetupSDT —

Equipment suppliers are responsible for recommending procedures for conversion. Users are obligated to identify any identify areto Users obligated proceduresconversion. recommending for for responsible are suppliers Equipment Recipe download activities that are unusual or infrequent, that have especially significant impact on equipment time, equipment on impact significant especially have that infrequent, or unusual are that activities download Recipe nceue onie(D)Sae—— State (UDT) Downtime Unscheduled

— the time required to complete an equipment alteration (hardware and/or software) necessary to necessary software) and/or (hardware alteration equipment an complete to required time the

—

The time for the following activities related to a setup as specified bythe specified supplier: a time to related setup theactivities as following The for — the operation of equipment after conversion to demonstrate equipment functionality (e.g., functionality equipment demonstrate to conversion after equipment of operation the the processing and evaluation of units after conversion to establish that equipment is equipment that establish to conversion after units of evaluation and processing the Any scheduled downtime that is not specifically tracked under one of the above the of one under tracked specifically not is that downtime scheduled Any The time (production test downtime) for the scheduled interruption of equipment of interruption scheduled the for downtime) test (production time The The time (scheduled facilities-related downtime) when the equipment cannot equipment the when downtime) facilities-related (scheduled time The The time during which the equipment cannot perform its intended its perform cannot equipment the which during time The The time during which the equipment cannot perform its intended its perform cannot equipment the which during time The The time for the scheduled interruption of equipment uptime to uptime equipment of interruption scheduled the for time The The time from when the equipment system has experienced a experienced has system equipment the when from time The Page 15 jn l jn Document Number: 3846A Number: Document 2 ]) Doc. 3846A Doc. 3846A Date: 2011/08/29Date: DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and actively repaired to bring it back to a productive state in response to a failure that is assigned to the supplier. the to assigned is that failure a to response in state productive a includes repairtheactivities: time following Complete to back it bring to repaired actively 6.1.9.5 these in used not are §§ metrics. See substates UDT Other metrics. equipment-dependent and supplier-dependent accurate support to required 8: NOTE 6.1.9.4 nonequipment-related failuresfailures. The remaining are the supplier. 6.1.9.3 additional as counted be not shall and events onset failure failures. not are downtime unscheduled of substates between Transitions failures. of count a requiring metrics all for used be shall event onset failure The downtime. unscheduled 6.1.9.2 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This the to assigned not is that failure a to response in state productive a following includes repairthe activities: supplier. time Complete to back it bring to repaired actively being 6.1.9.6 failure (e.g., component part replacement) and return the equipment to a condition where it can perform its perform can it where condition a to equipment function. intended the return and replacement) part component (e.g., failure restarting recycling, resetting, action Corrective Diagnosis unspecifiedUDT facilities-relatedUDT material changeof consumable UDT out-of-spec input UDT nonsupplier maintenancedelay, UDT supplier maintenancedelay, UDT repair, nonequipment-related UDT repair, equipment-related UDT is performing its intended function its within performing is intended specifications. run Verification power). specified reaches source ignites, plasma correct, is flow gas problem, without transfer units pressure, base reaches chamber (e.g., test Equipment its perform can it where condition a to function. equipment intended the return and replacement) part component (e.g., failure restarting recycling, resetting, action Corrective Diagnosis function itswithin performing is intended specifications. run Verification power). specified reaches source ignites, plasma correct, is flow gas problem, without transfer units pressure, base reaches chamber (e.g., test Equipment D ear oeupetRltd—— Nonequipment-Related Repair, UDT — Equipment-Related Repair, UDT statedivided downtime is unscheduled themutually following substates: The into exclusive to assigned are responsibilities and/or causes whose failures all of subset a are failures Equipment-related A

The substates UDT repair; equipment-related; UDT maintenance delay, supplier; and UDT change of consumables are consumables of change UDT and supplier; delay, maintenance UDT equipment-related; repair; UDT substates The failure onset event onset failure 8.3.3 — the procedure of identifying the source of an equipment problem or failure. failure. an of equipmentproblem —theidentifying or procedure sourceof failure. an of equipmentproblem —theidentifyingor procedure sourceof and — the operation of equipment after corrective action to demonstrate equipment functionality equipment demonstrate to action corrective after equipment of operation the — — the operation of equipment after corrective action to demonstrate equipment functionality equipment demonstrate to action corrective after equipment of operation the — — the processing and evaluation of units after corrective action to establish that the equipment the that establish to action corrective after units of evaluation and processing the — equipment the that establish to action corrective after units of evaluation and processing the — — the maintenance procedure (including equipment ramp-down and ramp-up, rebooting, ramp-up, and ramp-down equipment (including procedure maintenance the — — the maintenance procedure (including equipment ramp-down and ramp-up, rebooting, ramp-up, and ramp-down equipment (including procedure maintenance the — 8.3.4 . is the first transition to the unscheduled downtime state from a state other than other state a from state downtime unscheduled the to transition first the is , reverting to a previous software version, software previous a to reverting , version, software previous a to reverting , The unscheduled downtime substate in which the equipment is being is equipment the which in substate downtime unscheduled The The unscheduled downtime substate in which the equipment is equipment the which in substate downtime unscheduled The Page 16 jn l jn etc.) employed to address an equipment an address to employed etc.) equipment an address to employed etc.) Document Number: 3846A Number: Document Doc. 3846A Doc. 3846A Date: 2011/08/29Date: DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and intended function as the result of an unscheduled facilities failure. Any downtime created by the facilities listed facilities the by created downtime Any failure. facilities unscheduled an of result the as function intended 6.1.9.11 an by necessitated is that material consumable of material include the not delaysconsumable obtaining in It failure. does unrelated change a involve may it or material, consumable the to directly related failure a involve may This material. consumable change to uptime equipment of interruption unscheduled 6.1.9.10 to prior incurred downtime all short, card probe intermittent an of result a as OOSinputs input as UDT include The identifying thedowntime. problemrecategorized is repair for down put is system prober/tester a if, example, For downtime. input OOS UDT in included be shall below listed inputs the by postpone created and down downtime Any inputs. faulty or OOS by created problems of equipment result a as solely function intended its perform cannot the leave to decision 6.1.9.9 administrative an to due be maintenance. also may maintenance UDT substate A state. delay downtime unscheduled an during point any at occur may substate UDT delay An maintenance results. test as such information nonsupplier-controlled or materials, consumable nonsupplier-controlled parts, nonsupplier-controlled personnel, nonsupplier for waiting is it because function intended its perform cannot 6.1.9.8 delays downtime. atduring any unscheduled point may occur maintenance UDT results. test as such information supplier-controlled or materials, consumable controlled supplier- parts, supplier-controlled personnel, supplier for waiting is it because function intended its perform cannot 6.1.9.7 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This time equipmentshutdownand period for start-up. time unworked includes Each schedule. 6.1.10.1 substates. 6.1.9.12 facilities-related UDT the in included the is return function to intended required its time perform all can outage, facilities include: substate. The it power where 15-minute condition unscheduled a an to of equipment result a as needed is regeneration cryopump unnecessary otherwise an if example, For substate. facilities-related UDT the in included be shall below osmbe aeil eg, otmntd cd ek tre od dgae ht rss, erdd mold degraded resist, equipmentinputrecipe) or host wrong other Incorrect (e.g., photo degraded bond, target leaky compound) acid, contaminated (e.g., materials Consumable misread interpretation/entry) of erroneous metrologyequipmentout calibration, charts, data (e.g., Test data frames) contaminatedwarped lead warped wafers, wafers, upstream (e.g., problems, process Unit defective reticles) probe carriers, cassettes wafer cards, toolsfaulty Support warped or (e.g., NST IPS (IPSequipmentsystems IPS NST only) Modification Equipment InstallationEquipment Training Off-Line TimePeriods Unworked the activities: following Nonscheduledtime includes production. 6.1.10 host other with Communications equipmentor links LN2) exhaust, connections water,facility cooling gases, power, (e.g., Facility count, (e.g.,humidity,electromagnetic vibration,particle interference) temperature, Environmental D u-fSeiiain(O)Ipt—— Input (OOS) Out-of-Specification UDT — Nonsupplier Delay, Maintenance UDT — Supplier Delay, Maintenance UDT UDT Unspecified — — Unspecified UDT — Facilities-Related UDT — Material Consumable of Change UDT nokdTm eid Periods Time Unworked Nonscheduled (NST) State — — State (NST) Nonscheduled Any unscheduled downtime that is not specifically tracked under one of the above the of one under tracked specifically not is that downtime unscheduled Any — shifts, weekends, holidays, facilities shutdowns, etc. out of the production the of out etc. shutdowns, facilities holidays, weekends, shifts, — The unscheduled downtime substate in which equipment cannot perform its perform cannot equipment which in substate downtime unscheduled The The state in which the equipment system is not scheduled to be utilized in utilized be to scheduled not is system equipment the which in state The The unscheduled downtime substate during which the equipment the which during substate downtime unscheduled The The unscheduled downtime substate during which the equipment the which during substate downtime unscheduled The The unscheduled downtime substate in which the equipment the which in substate downtime unscheduled The Page The unscheduled downtime substate in which there is an is there which in substate downtime unscheduled The 17 jn l jn . Document Number: 3846A Number: Document Doc. 3846A Doc. 3846A Date: 2011/08/29Date: DRAFT SEMI LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900 Fax:408.943.6900 Phone: 408.943.7943 CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and od ad ula) o rcsig auatrn, o tsig ses fr a qimn ytm o usse. In subsystem. batches of or number processed. the equals system cycles of number the equipment batches, in units wafers) an process (e.g., that systems units equipment for of In number processed. the steps equals cycles of testing number the individually, or units process manufacturing, that systems equipment processing, of unload) and load unit (including sequence operational complete one is cycle A period. observation each for required also are cycles 6.2 for between idling productive should trackedof periods be in standby rathertime the state than nonscheduled the state. periods IPS moment-to-moment random general, nonscheduled In lot-to-lot. be from perhaps may IPS switch exception frequently that notable MPCTs agile only particularly The schedule. production long-term a in predetermined generally 10: NOTE state. or a ‘afteran productive either itselfoff trackedengineering hours’)mustin shut be 6.1.10.8 or downtime scheduled anstate. downtime unscheduled a either in tracked be must regeneration) cryopump programmed a as such routines maintenance automatic (including 6.1.10.7 activities. of intended itfunctionthese performits after one can where 6.1.10.6 to attributed be cannot time productive production, in utilized be to IPSs.This has directindividual attribution a effect the for on results all metrics productive IPS involving time. scheduled simultaneously are IPSs multiple that extent 9: NOTE § production. in See utilized 6.1.10.5 bytheschedule. regular not PM is or that software) accommodated upgrade (hardware 6.1.10.4 6.1.10.3 other output. productive any 6.1.10.2 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This in use E10metrics. for classified and be tracked must equipment system each for events substate, downtime and/or state SEMIE10 each 6.3 Tracking Requirements for Equipment Cycles — — Cycles Equipment for Requirements Tracking Tracking Requirements for Downtime Events for Tracking Requirements time off line (MTOL). line off time vice or state mean metric the in downtime used is events downtime continuous of unscheduled count The event. downtime continuous a an not is versa to state downtime scheduled a from transition continuous a a is but state event, downtime downtime a to state productive the from transition a example, For state. nondowntime a 6.3.2 an into transition a a be neither state. is can state downtime event A downtime versa. downtime vice unscheduled an within transition substate A a nor or state downtime scheduled a within transition substate state state. downtime scheduled downtime a unscheduled from state an downtime unscheduled than other state a state downtime from unscheduled an into (2) or state downtime scheduled a than other state a from state downtime 6.3.1 metric the in used is uptime during cycles equipment of MCBF count The time. standby during no cycles be should equipment there states, E10 SEMI of definition By time. engineering during cycles equipment of count the 6.2.2 used the is metric in time MCBF 6.2.1

By the same convention, any production or engineering work (including an unattended operation that may that operation unattended an (including work engineering or production any convention, same the By maintenance all since state, nonscheduled the in counted be cannot equipment to done maintenance Any condition a to equipment the bring to required time qualification any includes state nonscheduled The IPS NST Modification Equipment Installation Equipment Training Off-line